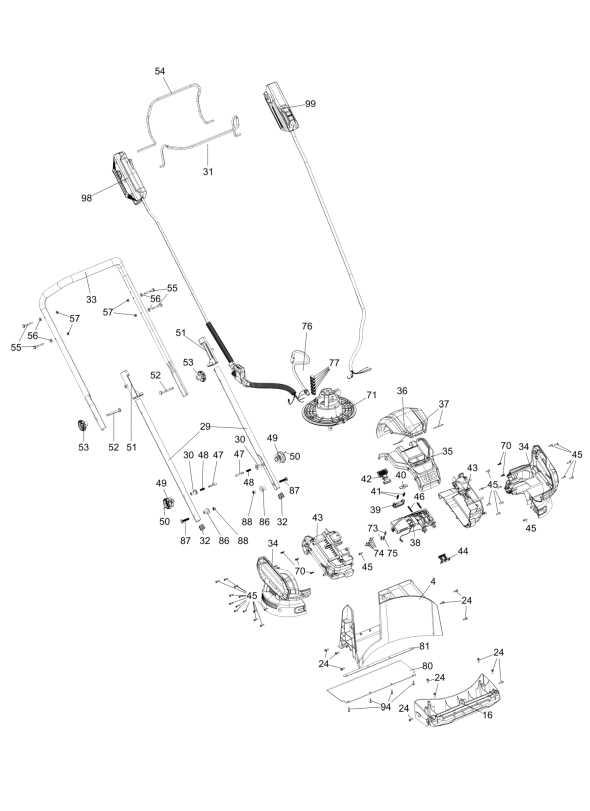

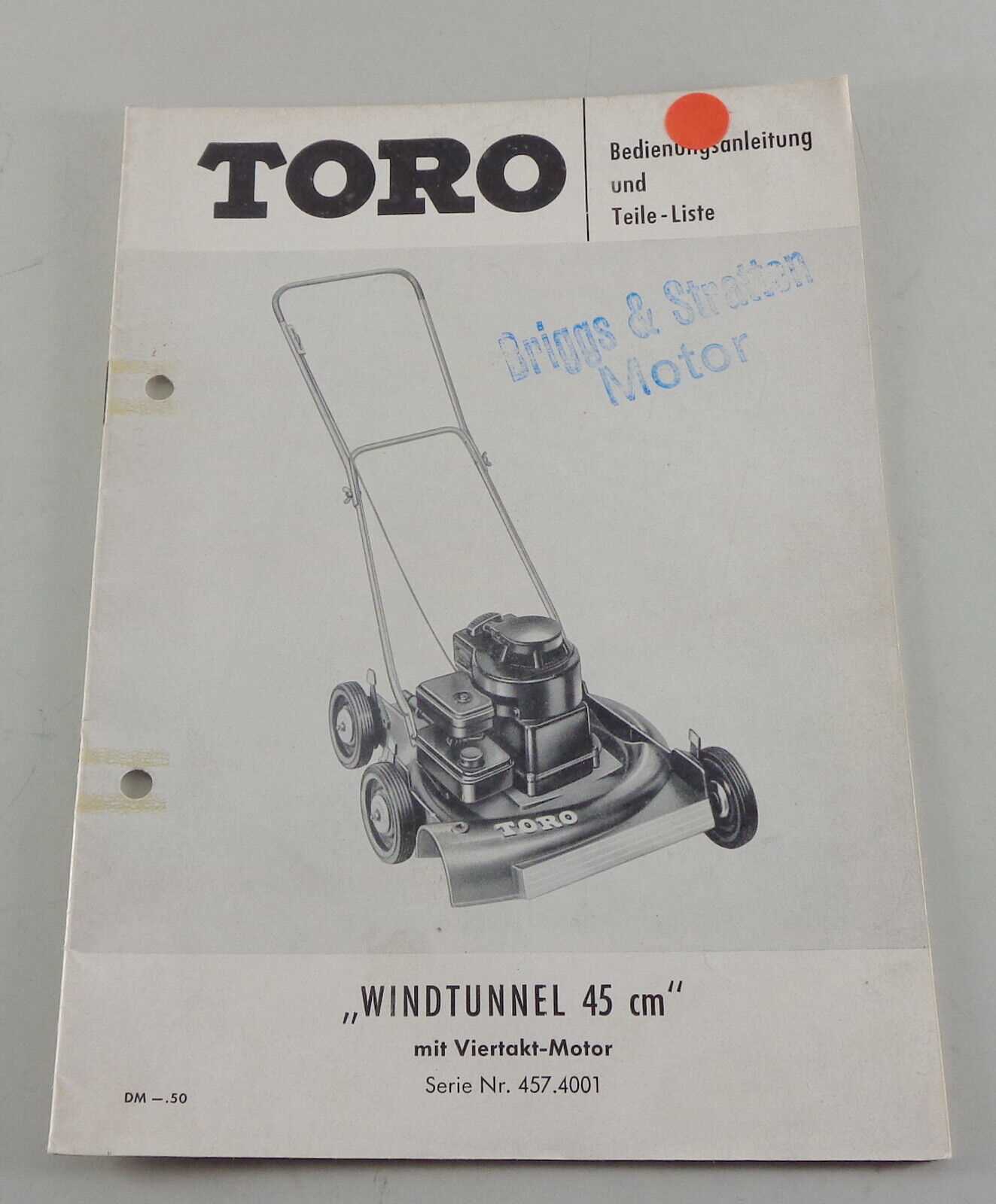

The proper functioning of garden equipment is essential for maintaining outdoor spaces efficiently. To keep these devices operating smoothly, it’s crucial to become familiar with the internal components and how they interact. In this section, we will explore the intricate design and the key elements that make up such machinery, ensuring optimal performance.

By having access to a detailed breakdown of these mechanical elements, you can enhance your ability to troubleshoot and maintain your equipment. This resource provides a clear view of the connections between various elements, helping users stay informed and prepared for any maintenance needs.

Whether you’re addressing specific issues or simply learning how to care for your garden tool, this comprehensive guide offers the insights needed to extend its longevity and functionality.

Drive System Overview

The mechanism responsible for forward movement in this type of outdoor equipment is a critical component that enhances ease of use. This system allows the user to control speed and direction with minimal effort, ensuring efficient operation on various terrains. Understanding the functionality of this mechanism is essential for both maintenance and troubleshooting.

Main Components

The primary system consists of several interconnected elements that work together to transmit power from the engine to the wheels. The key parts include the transmission, drive belt, and wheels, all synchronized to provide smooth and responsive operation. The transmission converts engine power into wheel movement, while the belt transfers this energy efficiently. These components must be maintained to ensure optimal performance.

Common Issues and Maintenance

Over time, wear and tear may lead to reduced efficiency or failure of the drive system. Common problems include loose belts, worn-out wheels, or faulty transmission. Regular inspection and timely replacement of these components can prevent issues and extend the life of the equipment. Maintaining proper tension on the belt and ensuring the transmission is functioning correctly are crucial steps in upkeep.

Understanding Toro Self Propelled Mechanism

The advanced drive system of this machine allows for effortless maneuvering, enhancing the user’s experience. It simplifies the process of moving the device, ensuring that less physical effort is required while still maintaining excellent control. This section will provide insights into how the internal components collaborate to achieve smooth movement across various terrains.

Drive Transmission: The heart of the system is the transmission, which transfers power from the engine to the wheels. By adjusting speed and torque, it allows for a more adaptable response to changing conditions, ensuring consistent motion.

Engagement Mechanism: The activation process is controlled by a lever or handle, which connects to a cable system. When engaged, the cable tightens, initiating the movement of the wheels. This feature ensures quick activation and deactivation, giving the operator control over the system.

Wheel Assembly: Specially designed wheels enhance grip and stability, particularly on uneven surfaces. The wheels are connected to the drivetrain, which ensures that they rotate smoothly and consistently, adapting to the user’s pace.

Regular maintenance and occa

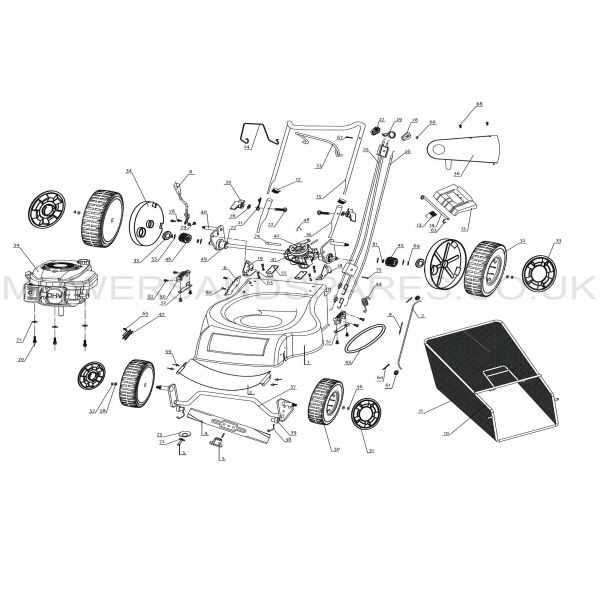

Main Components of Toro Lawn Mower

The machine designed for grass trimming consists of several key mechanisms that ensure efficient and smooth operation. These mechanisms work together to deliver a precise and even cut while providing easy maneuverability for the user. Understanding the basic elements of the device is crucial for maintaining optimal performance.

Engine: The motor serves as the powerhouse, providing the energy needed to drive the cutting and motion functions. Its reliability and power output significantly affect the machine’s overall performance.

Blade System: At the heart of the cutting process is the sharp blade or set of blades. These rotate at high speeds, slicing through the grass cleanly and evenly. Regular maintenance of the blade system is essential for efficient operation.

Wheel Mechanism: The wheels ensure mobility and play a key role in navigating various terrains. They also support the weight of the machine, allowing smooth movement over different surfaces.

Deck: The protective casing around the blades is designed to shield both the operator and the surroundings from debris. It also helps in directing the cut material into the collection system.

Handle

Identifying Key Parts of the Mower

Understanding the essential components of your machine is crucial for maintaining its efficiency and ensuring smooth operation. By recognizing and becoming familiar with the primary elements, you can ensure your device functions optimally and troubleshoot any issues that arise during use.

The engine is the heart of the system, driving all the mechanical processes. Additionally, the cutting mechanism, which includes the blades and their housing, plays a vital role in achieving precise results. Other important elements include the wheels, responsible for smooth movement, and the handle assembly, designed for easy maneuverability and control.

By identifying and understanding these crucial components, you can extend the lifespan of your equipment and maintain its performance at a high level.

Toro Mower Blade Assembly Breakdown

The blade setup plays a crucial role in ensuring efficient grass cutting and overall machine performance. Understanding the components involved in this mechanism is key to maintaining and replacing worn-out elements. Below is a detailed breakdown of the essential elements involved in the blade attachment and how they work together.

Main Components

- Cutting Blade – This is the sharp-edged component responsible for trimming the grass, designed for durability and precision.

- Blade Mounting Bolt – A fastener that secures the blade to the rotating deck, ensuring stability during operation.

- Blade Adapter – This connects the blade to the machine’s spindle, ensuring smooth motion and correct alignment.

Assembly Process

- First, position the blade on the adapter, ensuring proper alignment with the notches.

- Insert the bolt through the center of the blade and tighten it using the

Functions of the Cutting Blade System

The cutting mechanism is a crucial component in ensuring efficient grass trimming. Its design is crafted to deliver precise and consistent performance, shaping the ground surface to the desired height. The system works by rotating at high speeds to achieve an even and uniform result, minimizing the need for repeated passes.

Precision in Trimming

One of the key features of this system is its ability to provide accurate cutting results. The sharp edges are designed to slice through vegetation cleanly, reducing tearing or damage to the surface. This not only enhances the look of the terrain but also promotes healthier growth over time.

Durability and Maintenance

The blades are engineered for long-lasting use, requiring minimal upkeep while maintaining their sharpness. Regular inspection and occasional sharpening ensure that they continue to perform optimally, cutting through dense and wet conditions without losing efficiency.

Drive Belt Replacement and Maintenance Tips

The drive mechanism in many machines requires regular care to ensure smooth operation. One of the critical components responsible for movement is the belt, which may wear down over time due to constant use. Keeping it in optimal condition can prevent unexpected breakdowns and maintain overall performance.

Inspecting the belt: Regular checks are essential to catch signs of damage early. Look for cracks, fraying, or excessive slack, which could indicate the need for a replacement. A damaged belt not only reduces efficiency but may also lead to more significant issues.

Replacing the belt: When replacing the worn component, make sure the new one matches the original in size and material. Incorrect fittings can lead to poor functionality or premature wear. Follow the machine’s manual for specific instructions on how to safely remove and install the new belt.

Maintenance tips: Keeping the belt free from debris and dirt will extend its lifespan. Periodically check the tension to ensure it is neither too tight nor too loose. Proper tension helps in avoiding unnecessary strain on the drive system.

How to Maintain the Drive Belt

Regular upkeep of the drive mechanism is essential to ensure smooth and efficient operation. By paying attention to the condition of the belt, you can avoid unnecessary wear and prolong the life of your machine. Below, we will walk through the key steps involved in inspecting, cleaning, and adjusting the drive belt to maintain optimal performance.

Step 1: Inspect the Belt

Begin by examining the belt for signs of wear, such as cracks, fraying, or stretching. A worn belt can lead to reduced power transmission, which negatively impacts the machine’s efficiency. If you notice any damage, it’s crucial to replace the belt as soon as possible.

Step 2: Clean the Area

Before making any adjustments or replacements, clear any debris that may have accumulated around the belt and pulleys. Dirt and grass can build up over time, affecting the belt’s grip and leading

Common Problems with Toro Lawn Mowers

Owners of these types of machines often encounter a range of issues that can affect performance and usability. Understanding these common challenges can help in troubleshooting and maintaining your equipment effectively.

- Engine Starting Issues:

Difficulty in starting the engine is a frequent concern. This can stem from various factors such as fuel problems, electrical issues, or insufficient maintenance.

- Unusual Noises:

Unexpected sounds during operation can indicate mechanical problems. Common causes include loose components or worn-out parts that need replacement.

- Inconsistent Cutting:

A machine that fails to provide a uniform cut may have dull blades or misalignment in the cutting deck. Regular sharpening and adjustments can help resolve this issue.

- Vibrations:

Excessive vibrations may suggest an imbalance in the cutting components or a need for lubrication. Checking for debris and ensuring all parts are secure can mitigate this problem.

- Clogging:

Debris build-up can obstruct the cutting mechanism, leading to reduced efficiency. Regular cleaning is essential to maintain optimal performance.

Addressing these common concerns promptly can enhance the longevity and functionality of your machine, ensuring it operates at its best.

Frequent Mechanical Issues and Solutions

In the realm of garden maintenance equipment, users often encounter a variety of mechanical challenges that can hinder performance and efficiency. Understanding common issues and their corresponding remedies can greatly enhance the longevity and functionality of these machines. Below are some frequently experienced problems and practical solutions to address them.

1. Engine Does Not Start: One of the most prevalent issues is an engine that fails to ignite. This may result from several factors, including an empty fuel tank, stale fuel, or a faulty spark plug. Ensure the tank is filled with fresh fuel and check the spark plug for wear and cleanliness. If necessary, replace the spark plug to restore functionality.

2. Uneven Cutting: If the equipment is leaving uneven patches on the grass, it may indicate that the cutting blade is dull or damaged. Regularly inspect the blade for sharpness and nicks. Sharpen or replace the blade as needed to achieve a uniform cut.

3. Excessive Vibration: Vibrations during operation can be a sign of loose components or an unbalanced blade. Check all screws and bolts to ensure they are tightly secured. Additionally, verify that the blade is properly balanced to reduce vibrations and improve overall performance.

4. Stalling or Loss of Power: Machines may stall or experience power loss due to a clogged air filter or fuel system issues. Regularly clean or replace the air filter to maintain optimal airflow. Inspect the fuel lines for blockages and ensure that fuel is reaching the engine effectively.

5. Leaking Oil: Oil leaks can lead to reduced lubrication and potential engine damage. Check for loose seals or gaskets and replace any worn components. Regular maintenance, including oil changes, can help prevent leaks and ensure efficient operation.

By proactively addressing these common mechanical issues, users can ensure their equipment remains in excellent working condition, providing reliable service for all gardening tasks.

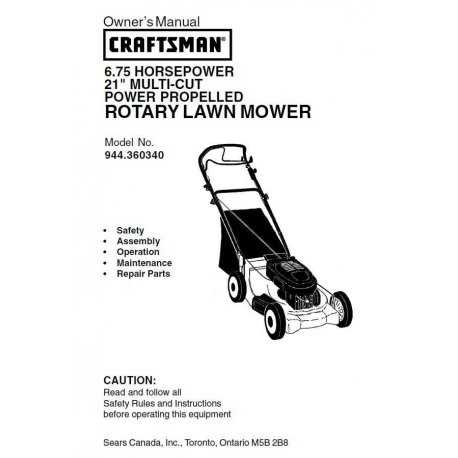

How to Download Toro Parts Diagram PDF

Accessing a detailed visual representation of your equipment’s components is crucial for maintenance and repairs. This guide will provide step-by-step instructions on obtaining these resources efficiently, ensuring you have the right information at your fingertips.

Steps to Obtain the Visual Resource

Follow these straightforward steps to successfully download the required illustration:

- Visit the official website or a trusted supplier’s platform.

- Navigate to the section dedicated to resources or support.

- Utilize the search function to locate the specific model.

- Look for the relevant document type among the available resources.

- Click on the download link to save the file to your device.

Helpful Tips for a Smooth Download

Ensure a seamless experience by following these additional tips:

Tip Description Check Compatibility Ensure that your device can open the downloaded file type. Stable Internet Connection A reliable connection can prevent download interruptions. Storage Space Verify that you have sufficient space on your device before downloading. Steps for Accessing Diagrams Online

Finding visual representations of mechanical components online can greatly enhance your understanding and ability to perform maintenance or repairs. This section outlines a straightforward approach to locating these resources effectively.

Utilize Search Engines

Start by using a search engine to input relevant keywords that describe the equipment in question. Be specific about the model and the type of visual aid you are looking for. Adding terms like “schematic” or “illustration” may help refine your results.

Visit Manufacturer Websites

Once you have gathered a list of potential sources, navigate to the official websites of manufacturers or authorized dealers. They often provide resources and documentation that include the visual guides you need. Check their support or resources section for downloadable content.

Importance of Regular Lawn Mower Maintenance

Routine upkeep of gardening equipment is essential for ensuring optimal performance and longevity. Regular inspections and maintenance can prevent minor issues from escalating into major problems, thus saving time and money in the long run.

Keeping the equipment in top condition not only enhances its efficiency but also promotes a healthier environment. Well-maintained tools operate more effectively, resulting in a cleaner and more uniform appearance for your outdoor space.

Additionally, routine care reduces the likelihood of unexpected breakdowns. By identifying wear and tear early on, users can replace components before they fail, avoiding inconvenient downtime during critical periods of use.

Moreover, investing time in maintenance can also improve safety. Properly functioning machinery minimizes the risk of accidents caused by faulty parts or improper operation, providing peace of mind while working outdoors.

In summary, prioritizing the regular maintenance of gardening tools is a crucial practice that enhances performance, promotes safety, and contributes to the overall aesthetics of the yard.

- Engine Starting Issues: