When maintaining outdoor machinery, comprehending the individual elements that contribute to its functionality is essential. A clear representation of these components can greatly enhance your ability to troubleshoot and perform necessary repairs. This resource aims to provide an insightful overview of the essential features of your device, ensuring that you are well-equipped for any maintenance tasks.

In the realm of outdoor tools, familiarity with each segment’s role can lead to more efficient operations and prolong the lifespan of the equipment. By visualizing how each piece interacts, you can better appreciate the overall design and engineering involved. This knowledge not only empowers you as an operator but also instills confidence in your ability to address any issues that may arise.

Whether you’re a seasoned professional or a casual user, having access to a comprehensive guide of the various elements can streamline your repair process. By understanding the layout and function of each component, you can make informed decisions, ensuring your machinery continues to perform at its best. Dive into this exploration to discover how each part contributes to optimal performance.

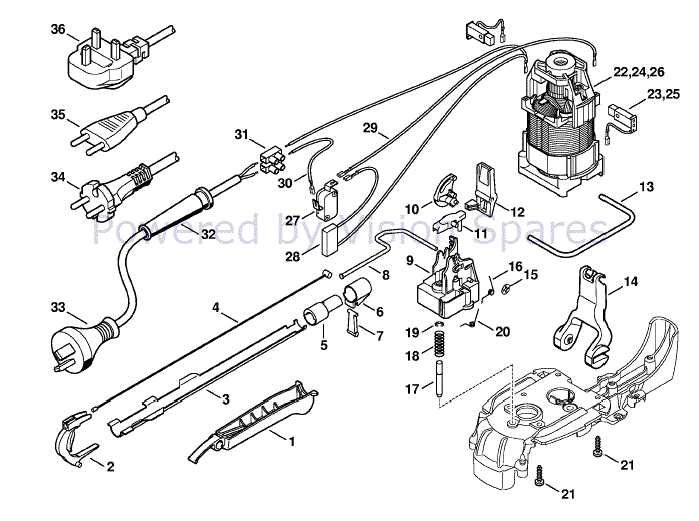

Understanding a schematic representation is essential for effective maintenance and repairs. This visual guide simplifies the complexity of components and their interactions, enabling users to navigate efficiently through the assembly.

To grasp the information presented, follow these steps:

- Familiarize Yourself: Start by identifying the overall layout and organization of the image.

- Component Identification: Look for labels and symbols that represent different elements.

- Connection Lines: Observe how parts are interconnected, noting any directional indicators.

- Reference Numbers: Utilize any numerical annotations to find detailed descriptions in accompanying documents.

By applying these strategies, you can confidently navigate the representation and perform necessary tasks with ease.

Identifying Key Components

Understanding the essential elements of your equipment is crucial for its optimal performance and maintenance. By recognizing these vital parts, users can ensure longevity and efficiency, leading to a more effective operation overall.

Main Assembly

The core structure houses various mechanisms that work in unison. This assembly not only provides stability but also supports the internal functions necessary for smooth operation. Identifying this central unit allows for better troubleshooting and repairs.

Operational Mechanisms

Key operational features play a significant role in the functionality of the machine. Elements such as the propulsion system and power delivery components must be understood for effective use. Regular inspection of these parts ensures that any wear or malfunction is addressed promptly, maintaining peak performance.

Replacement Parts and Availability

When it comes to maintaining equipment, having access to high-quality components is crucial for optimal performance. Ensuring that the right elements are readily available allows users to efficiently repair and restore their machinery, extending its lifespan and enhancing functionality. This section explores various options for sourcing these essential elements and the factors that influence their availability.

Many retailers and online platforms offer a wide range of replacements, catering to different needs and budgets. It is important to consider authorized dealers, as they provide genuine components that meet the manufacturer’s specifications. Additionally, local hardware stores might carry compatible alternatives that can serve as cost-effective solutions for certain repairs.

Availability may vary based on geographic location, demand, and the specific requirements of the equipment. Users should stay informed about local supply chains and seasonal trends that may impact access to necessary components. Building relationships with suppliers can also facilitate timely procurement, ensuring that maintenance activities proceed without delays.

Maintenance Tips for SG 71

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few key practices, you can prevent common issues and enhance the reliability of your machine. Here are some effective strategies to consider.

Routine Inspections

Conduct frequent checks on all components to identify any wear or damage. This proactive approach allows for timely replacements, reducing the risk of breakdowns during operation.

Cleaning and Lubrication

Keep the equipment clean and well-lubricated. Removing debris and applying appropriate oils will help maintain efficiency and prevent rust, contributing to a smoother operation.

Common Issues and Solutions

Addressing common challenges can enhance the efficiency and longevity of your equipment. Understanding these issues allows for timely interventions and effective resolutions.

-

Performance Problems:

- Check fuel quality and ensure proper mixing ratios.

- Inspect the air filter for clogs and clean or replace as needed.

-

Starting Difficulties:

- Examine the spark plug for wear; replace if necessary.

- Ensure the choke is functioning correctly and adjust as required.

-

Leakage Issues:

- Inspect hoses and connections for cracks or damage.

- Tighten fittings and replace any defective components.

-

Noise and Vibration:

- Check for loose screws or bolts and tighten them.

- Inspect the blades or nozzles for damage that could cause imbalance.

By staying proactive and addressing these common issues, users can achieve optimal performance and extend the life of their equipment.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right tools is essential for efficiency and effectiveness. A well-equipped toolkit not only streamlines the repair process but also ensures that tasks are completed safely and accurately. Understanding which instruments are necessary can make all the difference in achieving successful outcomes.

Essential Instruments

Below is a list of vital instruments that will facilitate the repair process:

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers is crucial for handling different types of screws, ensuring compatibility with your equipment. |

| Wrench Set | Both adjustable and fixed wrenches are needed for loosening or tightening bolts and nuts. |

| Socket Set | Socket wrenches allow for quick and efficient turning of fasteners, making repairs much easier. |

| Pliers | These are essential for gripping, twisting, and cutting wire or small components. |

| Safety Gear | Protective gloves and eyewear are necessary to ensure safety while working on machinery. |

Additional Helpful Tools

In addition to the basic instruments, having some specialized tools can further enhance your repair capabilities:

| Tool | Description |

|---|---|

| Torque Wrench | This tool helps ensure that fasteners are tightened to the manufacturer’s specifications. |

| Multimeter | Useful for diagnosing electrical issues, a multimeter measures voltage, current, and resistance. |

| Cleaning Supplies | Brushes, rags, and solvents are important for maintaining cleanliness during repairs. |

| Replacement Parts | Having spare components on hand can expedite repairs and minimize downtime. |

Step-by-Step Repair Guide

This guide provides a clear approach to repairing your equipment effectively. Following a structured method ensures that you can address issues systematically, minimizing the risk of further complications.

- Gather Your Tools: Collect all necessary tools before starting. This may include screwdrivers, wrenches, and replacement components.

- Safety First: Always wear protective gear, such as gloves and goggles, to prevent injuries.

- Consult the Manual: Refer to the user manual for specific instructions and troubleshooting tips relevant to your model.

- Disassemble Carefully: Begin disassembly by removing the outer casing or cover, taking note of the order and location of each screw.

- Inspect Components: Check all parts for wear and damage. Make a list of items that need replacement.

- Replace Faulty Parts: Install new components where necessary, ensuring a snug fit.

- Reassemble the Equipment: Carefully put everything back together, following the reverse order of disassembly.

- Test the Equipment: Once reassembled, run a test to ensure everything functions as intended.

By adhering to these steps, you can effectively tackle repairs and enhance the longevity of your machine.

Where to Find Parts

Locating components for your equipment can significantly enhance its performance and longevity. Understanding where to source these items is essential for effective maintenance and repairs. Various avenues exist to ensure you acquire the necessary items efficiently.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers offer genuine items, ensuring compatibility and quality. |

| Online Retailers | Numerous e-commerce platforms provide a vast selection, often at competitive prices. |

| Local Repair Shops | These establishments may stock essential items and provide valuable advice on replacements. |

| Manufacturer’s Website | The official site often features an extensive catalog and direct purchasing options. |

Safety Precautions During Repairs

When performing maintenance or troubleshooting on any equipment, prioritizing safety is essential. Proper precautions not only protect the individual conducting the work but also ensure the longevity and functionality of the machinery. Understanding the potential hazards involved is crucial for a successful and secure repair process.

Before starting any repair work, it is vital to wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear. These items safeguard against physical injuries, such as cuts or impacts, and help protect against exposure to harmful substances. Ensuring that the workspace is well-lit and organized further minimizes the risk of accidents.

Always disconnect the power source or remove the fuel supply before attempting any maintenance tasks. This simple yet crucial step prevents accidental starts, which could lead to severe injuries. Additionally, familiarizing oneself with the specific equipment’s manual can provide valuable insights into safe handling procedures and potential hazards.

It is also advisable to work with a partner when tackling more complex repairs. Having someone nearby can provide assistance in case of emergencies and can also offer a second set of eyes to help identify any overlooked risks. Finally, always keep a first aid kit within reach, as prompt access to medical supplies can make a significant difference in case of an injury.