The intricate design of power tools showcases the essential components that work in harmony to achieve optimal performance. Grasping the layout and functionality of these elements is crucial for both maintenance and effective use. Each section of the tool serves a specific purpose, contributing to its overall efficiency and reliability.

Familiarizing oneself with the configuration of these tools not only aids in troubleshooting but also enhances the user’s ability to perform repairs. A comprehensive overview of the various segments will provide insights into their respective roles and how they interact within the assembly.

Whether you are an experienced technician or a hobbyist, diving deep into the details of these components can empower you to make informed decisions. Understanding the ultimate interplay between each part can lead to better care and longevity of your equipment.

Understanding Milwaukee M18 Sawzall

This section explores a powerful tool renowned for its versatility and efficiency in cutting tasks. It operates with precision, making it ideal for various materials, and is highly regarded among professionals and DIY enthusiasts alike.

Key Features

Among its standout characteristics are its lightweight design and exceptional battery life, allowing for prolonged use without frequent recharging. The quick blade change mechanism enhances user convenience, while the adjustable speed settings provide greater control over different cutting applications.

Maintenance Tips

To ensure optimal performance, regular inspection and cleaning are essential. Users should check for wear on the blades and other components, replacing them as necessary to maintain cutting efficiency and extend the tool’s lifespan.

Key Features of the M18 Sawzall

This powerful cutting tool is designed to deliver exceptional performance and versatility for various applications. Its innovative technology enhances user experience, making it a preferred choice among professionals and DIY enthusiasts alike.

One standout characteristic is the impressive battery life, allowing for prolonged use without frequent recharging. Additionally, the ergonomic design ensures comfort during operation, reducing fatigue even during extended tasks.

The variable speed settings provide adaptability for different materials, from wood to metal, enabling precise cuts. Furthermore, the quick-change blade system facilitates seamless blade swaps, enhancing efficiency on the job.

Durability is another crucial aspect, with robust construction that withstands demanding conditions. Overall, this cutting tool combines power, convenience, and reliability, making it an ultimate asset for any toolkit.

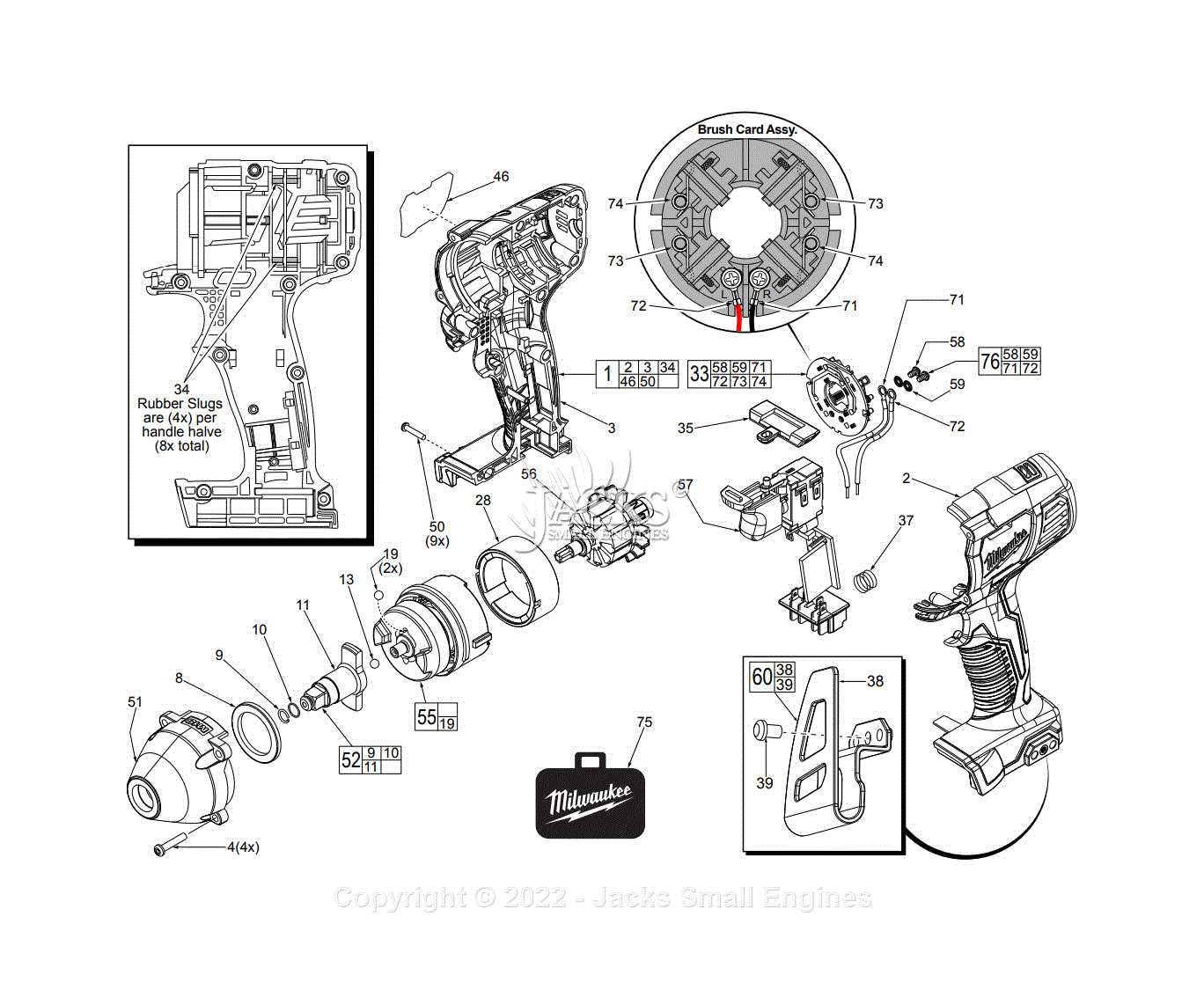

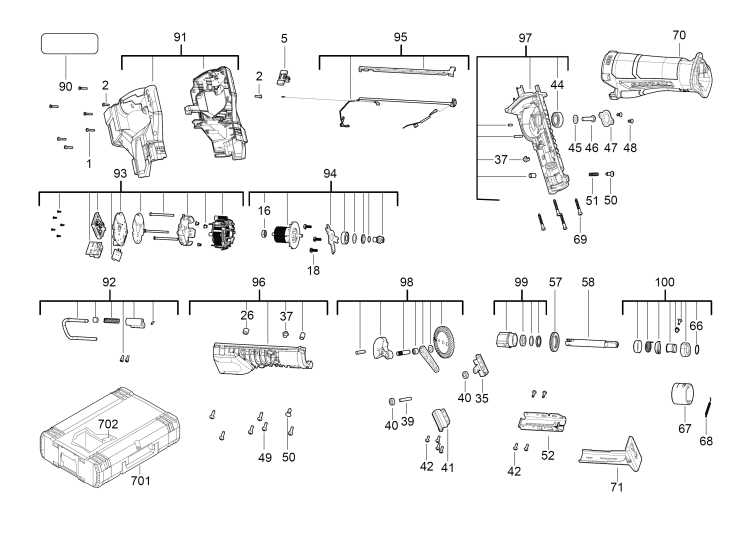

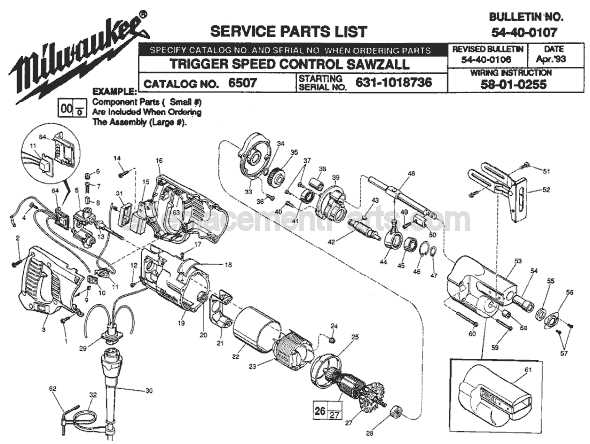

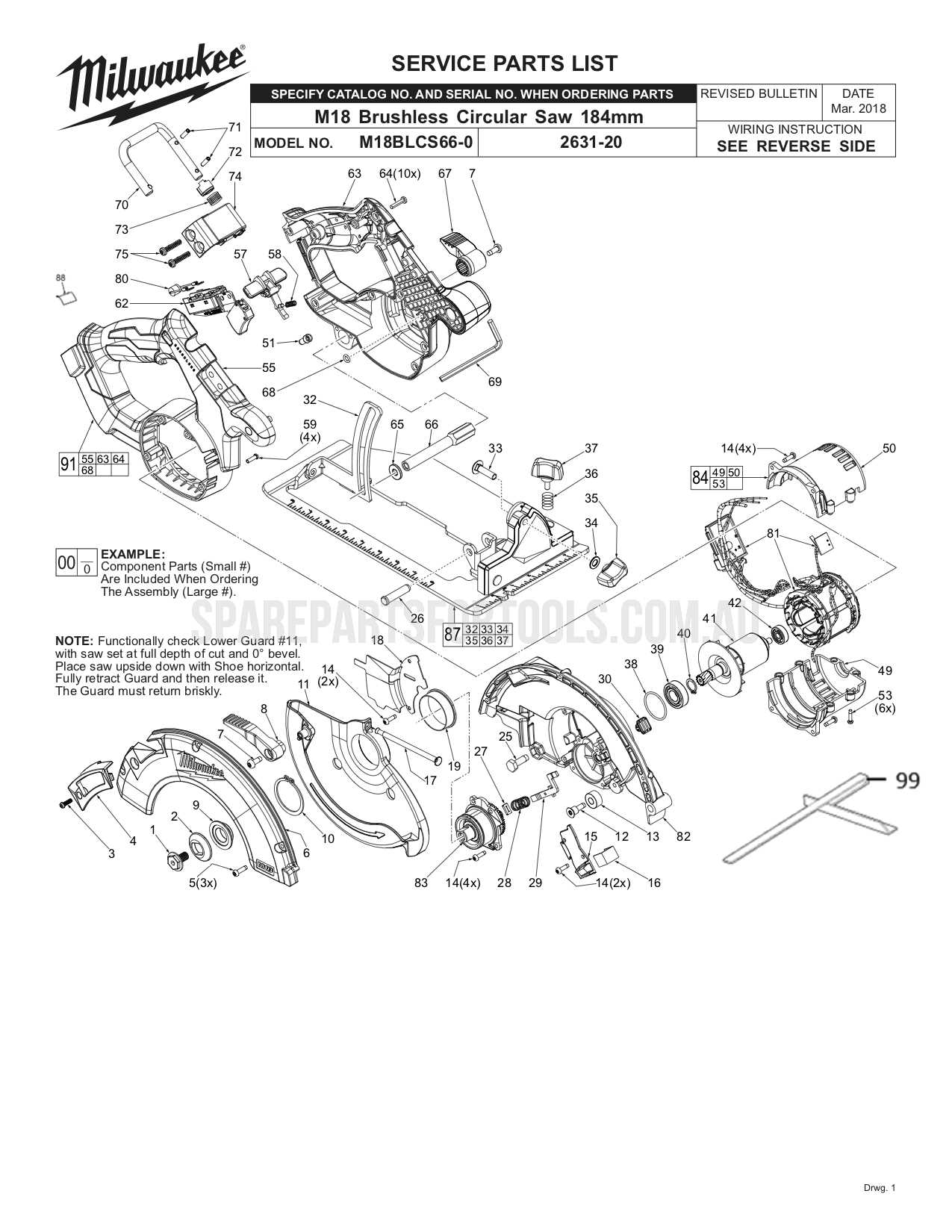

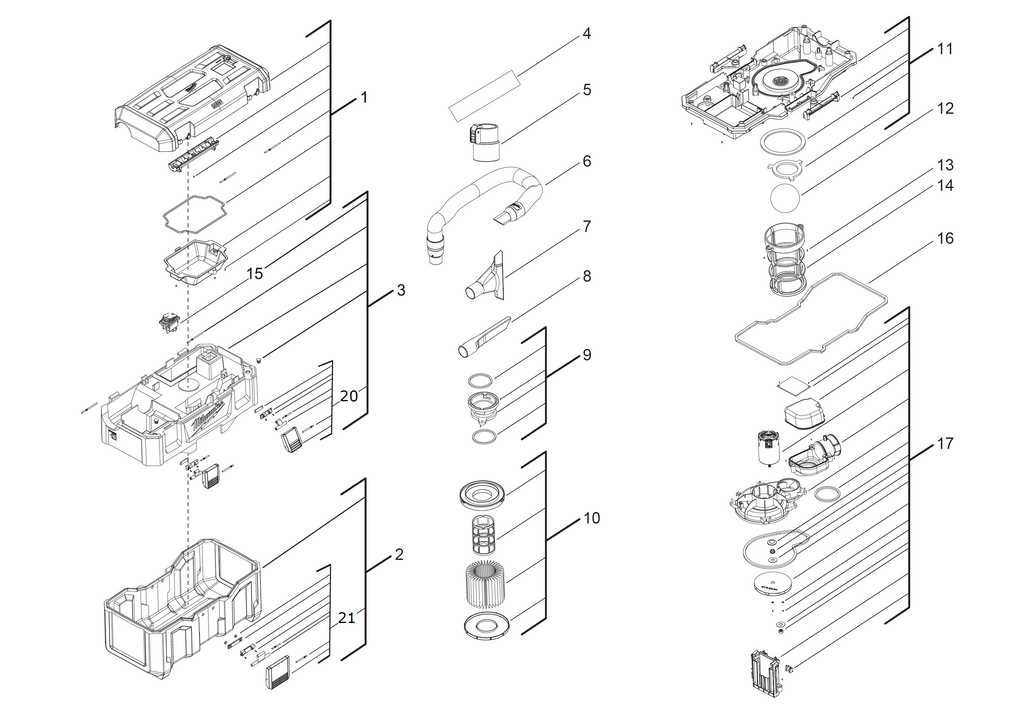

Importance of Parts Diagrams

Understanding the components of a tool is crucial for effective maintenance and repair. A visual representation of these elements not only enhances comprehension but also streamlines the process of identifying issues and sourcing replacements. Such illustrations serve as a valuable resource for both novice and experienced users alike.

Here are some key reasons why these visual guides are essential:

- Enhanced Clarity: Diagrams provide a clear view of each component, making it easier to understand their function and relationship within the assembly.

- Efficient Troubleshooting: When problems arise, these visuals enable users to quickly locate the source of the issue, reducing downtime and frustration.

- Accurate Replacements: Knowing the exact part number and its placement helps in sourcing the correct replacement without unnecessary errors.

- Improved Assembly: For those looking to rebuild or modify, a detailed illustration serves as a helpful guide, ensuring all parts fit together seamlessly.

- Educational Resource: These representations are not just for repairs; they also serve as an educational tool for those looking to deepen their understanding of tool mechanics.

In summary, visual representations of tool components are indispensable for anyone involved in maintenance or repairs, providing clarity, efficiency, and educational value that enhance overall user experience.

Common Parts of the Sawzall

Understanding the fundamental components of a reciprocating tool is essential for effective operation and maintenance. Each element plays a critical role in ensuring that the device performs optimally, providing the necessary power and precision for various cutting tasks.

- Motor: The powerhouse of the device, responsible for generating the required force to drive the blade.

- Blade Holder: This part securely grips the cutting blade, allowing for easy installation and removal.

- Trigger: The control mechanism that allows users to start and stop the tool, often featuring variable speed settings.

- Handle: Designed for ergonomic grip, this part enhances user comfort and control during operation.

- Foot Plate: Provides stability and balance while cutting, ensuring precise movements.

By familiarizing yourself with these components, you can better understand the tool’s functionality and address any maintenance or replacement needs effectively.

How to Interpret the Diagram

Understanding the visual representation of components can significantly enhance your ability to repair or maintain tools effectively. By familiarizing yourself with the layout and symbols used, you can identify each element’s function and relation to others within the assembly. This knowledge streamlines troubleshooting processes and aids in efficient reassembly.

Start by examining the overall layout, noting how parts are arranged and labeled. Look for any numbers or letters that correspond to specific pieces; these annotations are crucial for accurate identification. Typically, diagrams will use a clear numbering system, guiding you through the assembly order and relationship of various components.

Pay close attention to the legends or keys, which explain the symbols used in the illustration. Understanding these can clarify what each part represents, making it easier to locate replacement items or perform necessary repairs. Additionally, recognize any exploded views, as they provide a detailed perspective on how individual elements fit together.

Finally, consider the context in which this visual guide is presented. Knowing the manufacturer’s guidelines or recommendations will ensure you interpret the information correctly, leading to successful maintenance or upgrades. Taking the time to study this representation can ultimately save you both time and effort in your repair endeavors.

Maintenance Tips for Longevity

Ensuring the durability of your cutting tool requires consistent care and attention. By implementing a few key practices, you can enhance its performance and extend its lifespan significantly.

Regularly inspect the equipment for any signs of wear or damage. Clean the surfaces and moving parts to prevent debris buildup, which can hinder functionality. Lubricate necessary components to reduce friction and promote smooth operation.

Store the tool in a dry, secure location to protect it from environmental factors. Avoid overworking the device; give it time to cool down during extended use. Lastly, refer to the manufacturer’s guidelines for specific maintenance recommendations tailored to your model.

Replacing Worn Out Components

Over time, tools can experience wear and tear, affecting their performance and efficiency. Identifying and replacing these degraded elements is crucial to maintaining optimal functionality and ensuring safety during use.

Common Symptoms

Signs of deterioration may include unusual noises, reduced cutting power, or visible damage to certain components. Recognizing these indicators early can prevent further issues and enhance the tool’s longevity.

Essential Steps

Begin by consulting the user manual for guidance on disassembly. Carefully remove the affected parts, taking note of their arrangement. Once replaced, reassemble the tool meticulously, ensuring all connections are secure.

Quality Considerations

Always opt for high-quality replacements to guarantee compatibility and durability. Investing in superior components can significantly improve the overall performance of your equipment.

Regular maintenance and timely replacements will ultimately keep your tool operating at its best, enabling you to tackle projects efficiently.

Identifying Compatible Parts

When it comes to ensuring optimal performance of your cutting tool, recognizing suitable components is essential. Compatibility not only enhances efficiency but also extends the lifespan of your equipment. Understanding the specific characteristics of each element will aid in making informed choices that align with your needs.

Key Factors to Consider

Several critical aspects must be taken into account when selecting compatible components. These include the model specifications, operational requirements, and material quality. Ensuring these factors align with your equipment guarantees a seamless integration.

Comparison Table of Components

| Component Type | Recommended Specifications | Compatible Models |

|---|---|---|

| Blade | Length: 12″, Thickness: 0.5mm | Model A, Model B |

| Battery | Voltage: 18V, Capacity: 5Ah | Model A, Model C |

| Housing | Material: High-Impact Plastic | Model B, Model C |

By utilizing this information, you can confidently select components that will work harmoniously with your tool, ensuring sustained performance and durability.

Common Issues and Solutions

In the realm of power tools, users often encounter various challenges that can hinder performance. Understanding these common problems and their respective solutions can significantly enhance the user experience and extend the lifespan of the equipment.

-

Battery Problems:

Insufficient power or failure to charge can lead to frustration. Ensure the battery connections are clean and secure. If issues persist, consider replacing the battery or checking the charger for faults.

-

Blade Wear:

Over time, blades may dull or become damaged. Regularly inspect blades for wear and replace them as needed to maintain cutting efficiency.

-

Vibration Issues:

Excessive vibration can affect precision and comfort during use. Check for loose components or misalignment and tighten any loose screws or bolts.

-

Motor Overheating:

Overheating may occur due to prolonged use or heavy loads. Allow the tool to cool down, and avoid continuous operation without breaks to prevent damage.

-

Operational Noise:

Unusual sounds may indicate underlying issues. Listen for grinding or rattling noises, which can signal the need for maintenance or part replacement.

Addressing these common challenges with timely solutions can ensure optimal functionality and reliability, making your power tool experience more efficient and enjoyable.

Upgrades for Enhanced Performance

Enhancing the efficiency of your cutting tool can significantly impact your work quality and speed. By exploring various modifications and accessories, users can elevate their equipment’s capabilities, resulting in smoother operation and improved durability. These upgrades often focus on optimizing power delivery, enhancing blade stability, and increasing user comfort.

One effective upgrade is the use of high-performance blades designed for specific materials, which can lead to cleaner cuts and reduced wear. Additionally, incorporating vibration-dampening features or ergonomic handles can enhance user control, making prolonged use more comfortable. Power options, such as improved battery systems, also play a crucial role in extending run time and maintaining consistent performance.

Investing in these enhancements not only boosts productivity but also prolongs the life of the tool. By carefully selecting upgrades tailored to individual needs, users can achieve the ultimate cutting experience, making each project more efficient and enjoyable.

Safety Precautions While Repairing

When engaging in maintenance or repair tasks on power tools, ensuring personal safety and preventing accidents is of utmost importance. Proper precautions not only protect the individual performing the repair but also enhance the longevity and functionality of the equipment. Adhering to safety guidelines can significantly reduce the risk of injury and ensure a smooth repair process.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) before beginning any repair work. This includes safety goggles to protect your eyes from flying debris, gloves to shield your hands from sharp edges, and sturdy footwear to guard against falling objects. Additionally, consider using ear protection if your repairs involve loud machinery.

Work Environment

Maintain a clean and organized work area to minimize hazards. Ensure that the workspace is well-lit and free from clutter, as this can help prevent trips and falls. Keep all necessary tools within reach to avoid unnecessary movements that could lead to accidents. Lastly, make sure that all tools are in good working condition and appropriate for the task at hand.

Where to Find Replacement Parts

When it comes to maintaining and repairing your equipment, locating the right components is essential for optimal performance. Various resources are available to help you find the necessary items, ensuring your tools remain in excellent working condition.

| Source | Description |

|---|---|

| Manufacturer Website | The official site often has a comprehensive catalog of available components, allowing you to search by model or type. |

| Authorized Retailers | Many authorized dealers carry a selection of original components, ensuring compatibility and quality. |

| Online Marketplaces | Platforms like Amazon or eBay offer a wide range of options, including both new and refurbished items at varying price points. |

| Local Hardware Stores | Your nearby store may stock some essential components, making it convenient for quick repairs without waiting for shipping. |

| Repair Shops | Local technicians often have access to various components and may offer repair services, saving you time and effort. |

By exploring these options, you can efficiently find the components you need to keep your tools functioning effectively.