In the realm of modern cooling devices, comprehending the arrangement and functionality of various elements is essential for optimal performance and maintenance. Each unit consists of intricate systems working harmoniously to achieve efficient cooling, making it crucial to familiarize oneself with the overall structure and components.

Analyzing the configuration of these essential mechanisms provides valuable insights into troubleshooting and repairs. By understanding how each element interacts within the system, users can better address issues that may arise, ensuring the longevity and reliability of the appliance.

Furthermore, having access to a comprehensive representation of these components serves as a valuable resource for both enthusiasts and professionals alike. This knowledge empowers individuals to make informed decisions regarding repairs, upgrades, and maintenance, enhancing the overall user experience.

This section aims to provide a comprehensive understanding of the essential components of a cooling appliance, focusing on their functions and interconnections. By exploring these elements, readers can gain insights into how these systems operate efficiently to maintain desired temperatures.

Key Components

- Cooling Mechanism: This includes the primary method by which temperature control is achieved.

- Energy Source: Understanding the type of power supply that fuels the operation.

- Insulation: The materials that help maintain internal temperatures by reducing heat transfer.

- Control System: The interface that allows users to adjust settings and monitor performance.

Functions of Each Element

- Cooling Mechanism: Responsible for extracting heat from the interior.

- Energy Source: Can be powered by electricity, gas, or alternative energy sources.

- Insulation: Minimizes energy loss, ensuring optimal efficiency.

- Control System: Provides user interaction for setting desired temperatures and monitoring functionality.

Key Components Explained

Understanding the primary elements of cooling appliances is essential for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance and efficiency, contributing to the overall functionality of the unit.

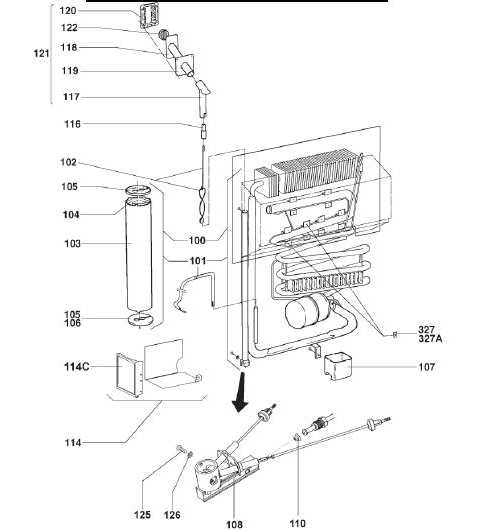

- Cooling Unit: This is the heart of the system, responsible for transferring heat and maintaining a low internal temperature.

- Thermostat: A critical device that regulates temperature by controlling the cooling cycle, ensuring that the desired environment is maintained.

- Compressor: This component compresses the refrigerant, raising its temperature and pressure, allowing it to circulate through the system effectively.

- Condenser Coils: These coils dissipate heat from the refrigerant as it transforms from gas to liquid, playing a crucial role in the cooling process.

- Evaporator Coils: Located inside the cooling chamber, these coils absorb heat from the interior, facilitating the cooling effect.

- Fans: Used to circulate air within the appliance, ensuring even temperature distribution and preventing hot spots.

- Insulation: Essential for minimizing heat exchange with the external environment, insulation helps maintain the desired internal temperature.

Each of these elements must work in harmony for the appliance to function efficiently. Regular maintenance and understanding of these components can enhance longevity and performance.

Understanding Cooling Systems

Efficient temperature management is essential for preserving perishable items and enhancing comfort in various environments. The core concept revolves around the transfer of heat from one area to another, utilizing various components designed to facilitate this process. These mechanisms play a vital role in ensuring that desired conditions are maintained, whether in a mobile unit or a stationary application.

The operation of cooling mechanisms typically involves the use of a refrigerant, a substance that circulates within the system to absorb and release heat. As the refrigerant transitions through different states, it effectively draws warmth from the interior space, expelling it to the external environment. This cycle is complemented by various elements such as compressors, evaporators, and condensers, each contributing to the overall efficiency and performance of the system.

Understanding the intricacies of these components and their interactions is crucial for troubleshooting, maintenance, and optimization. Recognizing how each part functions within the cooling cycle can aid in making informed decisions regarding repairs or enhancements, ultimately leading to improved functionality and longevity of the system.

Importance of Insulation

Effective thermal barriers play a crucial role in maintaining optimal temperatures within storage units designed for perishable goods. These barriers help to reduce energy consumption by minimizing heat transfer between the interior and exterior environments. As a result, they contribute to enhanced energy efficiency and prolonged freshness of the stored items.

Proper insulation not only aids in energy conservation but also helps in maintaining a stable internal climate. This stability is essential for ensuring that sensitive items remain in their ideal condition. Without adequate thermal protection, the efficiency of the cooling mechanism is compromised, leading to potential spoilage and waste.

In addition, well-designed insulation can significantly extend the lifespan of the equipment. By reducing the workload on the cooling components, it minimizes wear and tear, thereby enhancing the durability and reliability of the entire system. Investing in quality thermal barriers is a wise choice for anyone looking to improve performance and longevity.

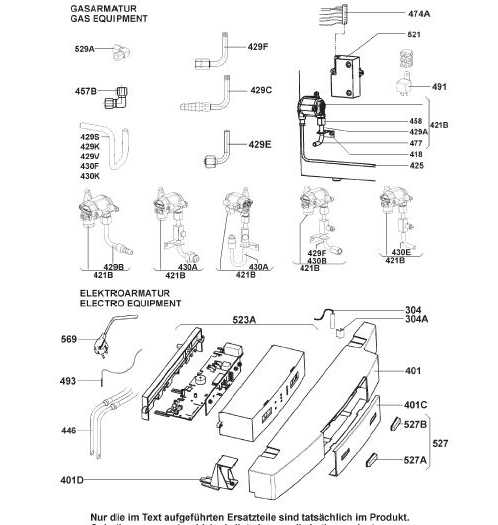

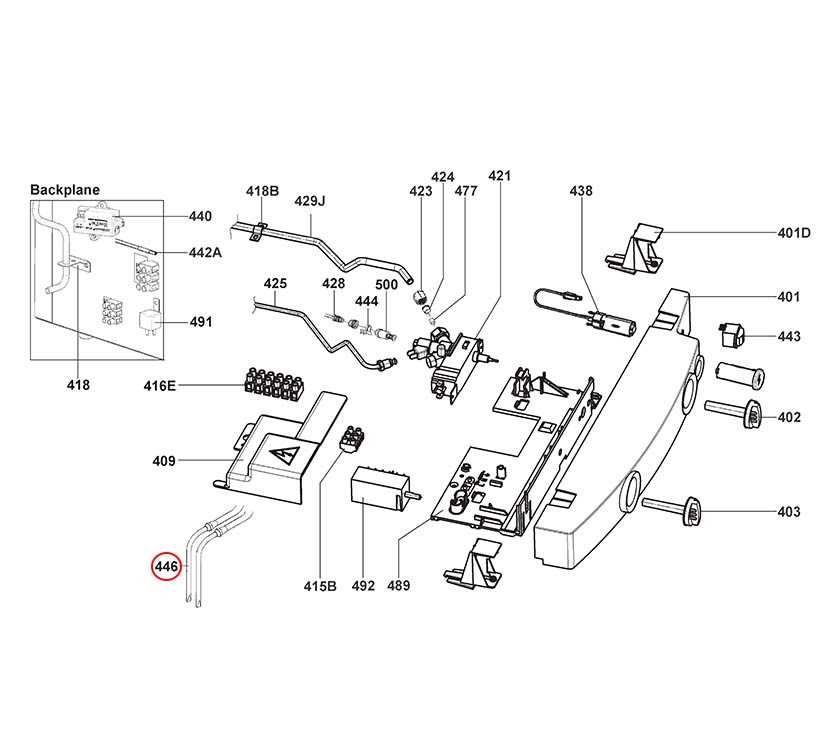

Identifying Electrical Parts

Understanding the components of an electrical cooling system is crucial for effective maintenance and troubleshooting. Each element plays a vital role in the overall functionality, ensuring that the system operates efficiently. Familiarity with these components can help in diagnosing issues and performing repairs when necessary.

Key Components to Recognize

- Power Supply: The source that provides the necessary voltage for operation.

- Compressor: A vital element responsible for circulating refrigerant throughout the system.

- Thermostat: The device that regulates temperature by controlling the cooling cycle.

- Fan Motor: Ensures proper airflow, aiding in heat exchange and cooling efficiency.

- Condenser Coils: Help in dissipating heat from the refrigerant, essential for maintaining optimal performance.

Helpful Tips for Identification

- Refer to the manufacturer’s documentation for specific component layouts and functions.

- Utilize a multimeter to check for electrical continuity and performance of each part.

- Observe wiring diagrams to understand connections and troubleshoot effectively.

- Label components during disassembly to facilitate easier reassembly and maintenance.

Common Refrigerant Types

Refrigerants are essential substances used in cooling systems to transfer heat efficiently. Various types of these fluids exist, each designed to meet specific performance requirements and environmental regulations. Understanding the common varieties can aid in selecting the right one for different applications.

Hydrochlorofluorocarbons (HCFCs)

HCFCs have been widely used in the refrigeration industry due to their favorable thermodynamic properties. However, their ozone-depleting potential has led to a phasedown in many countries. Despite this, they still serve as transitional refrigerants as industries move towards more sustainable options.

Hydrofluorocarbons (HFCs)

HFCs emerged as alternatives to HCFCs, providing efficient cooling while minimizing ozone depletion. However, concerns about their global warming potential have prompted ongoing research into newer, more environmentally friendly options. These substances are currently prevalent in various cooling applications, balancing performance and environmental impact.

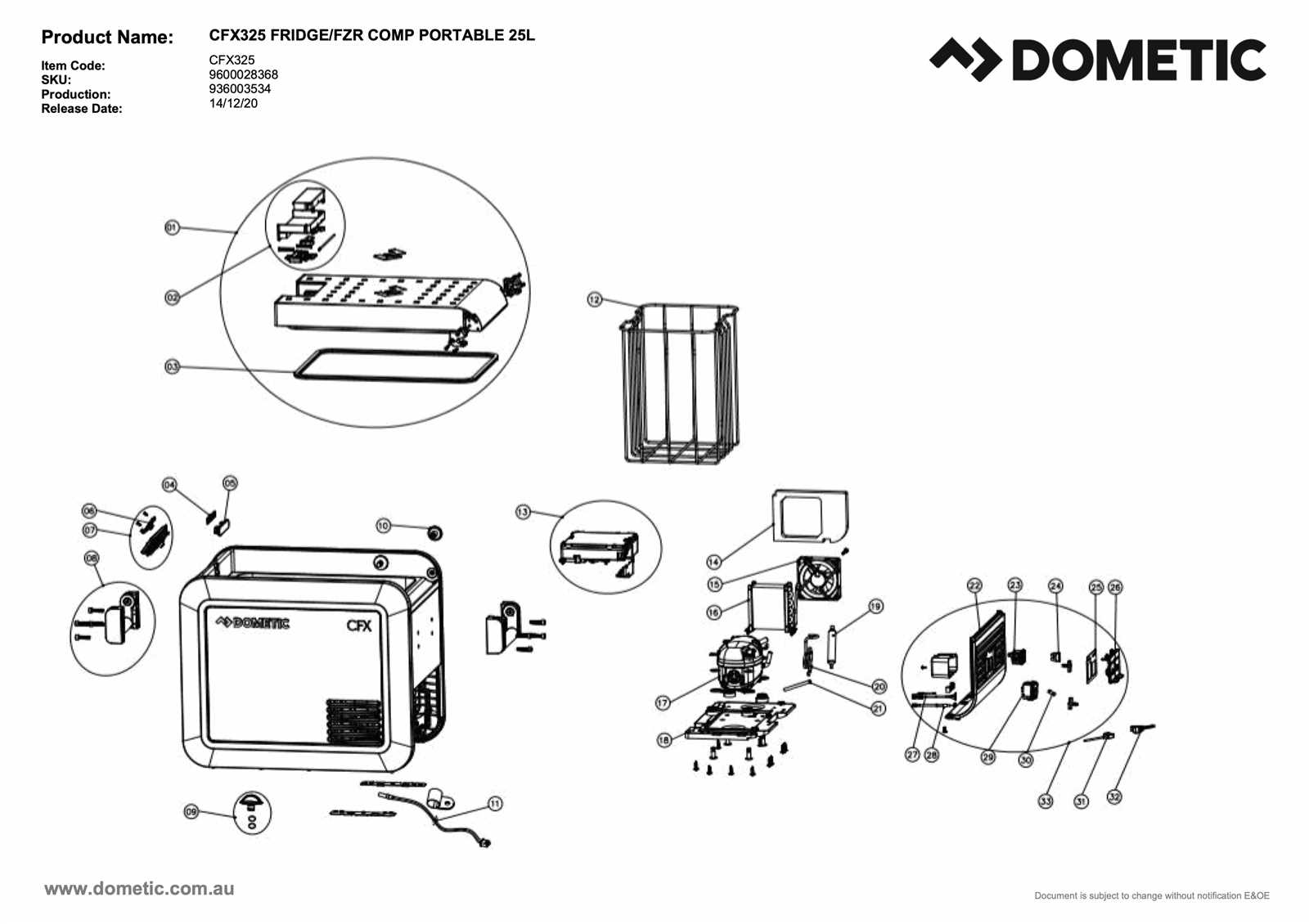

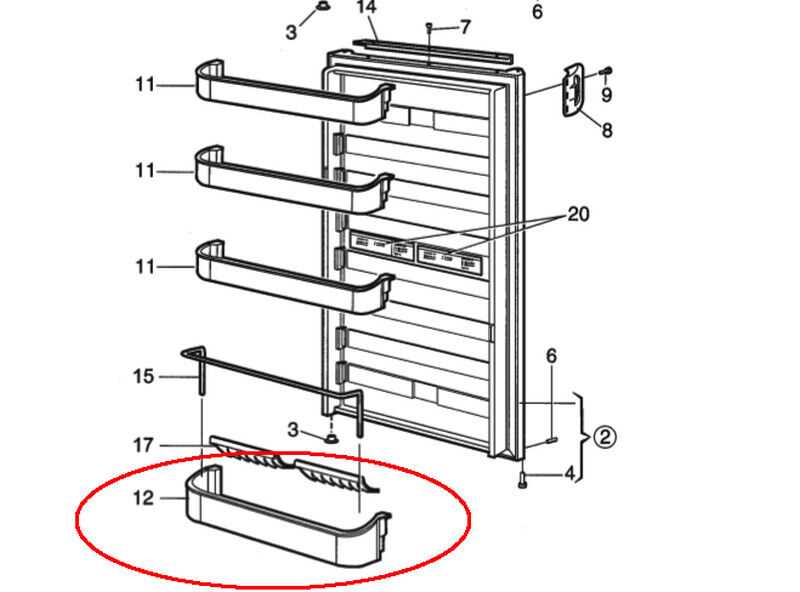

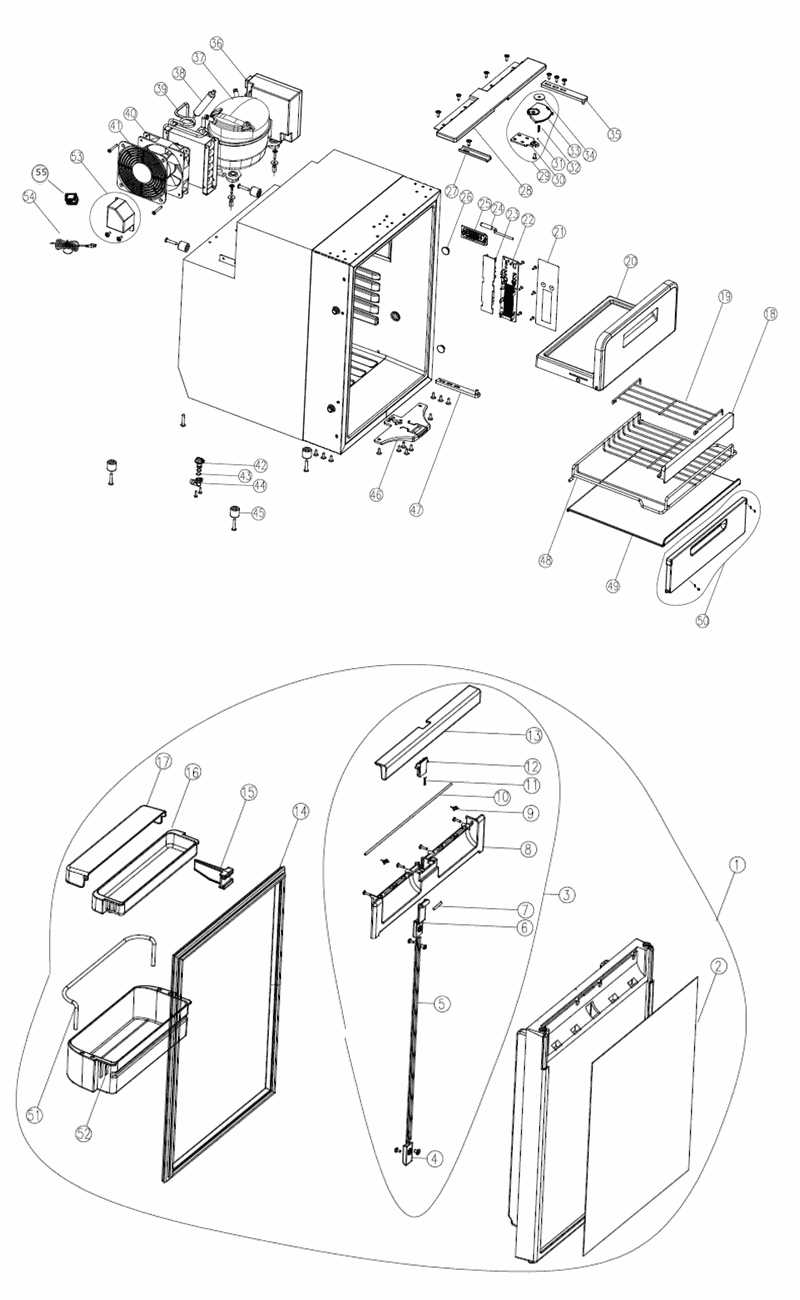

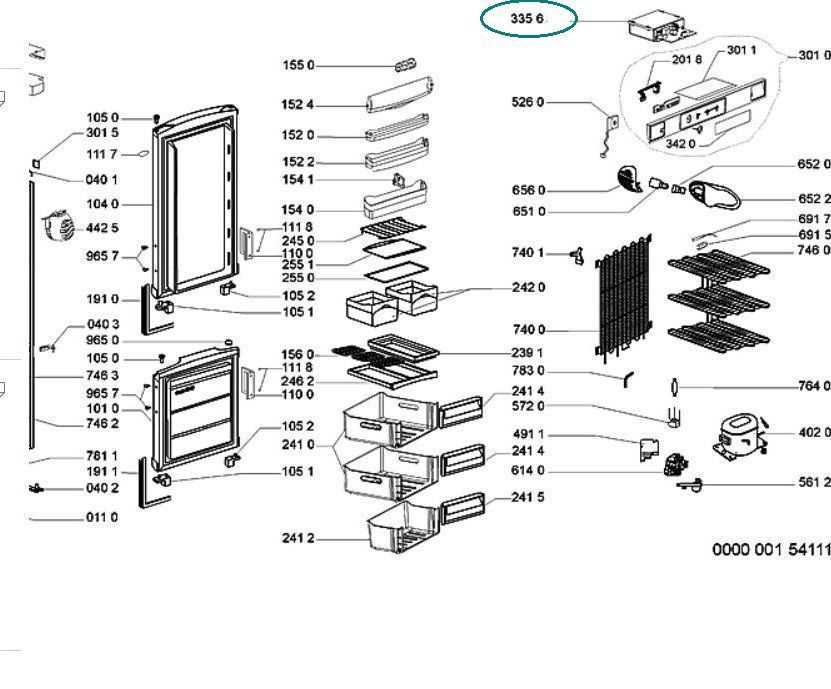

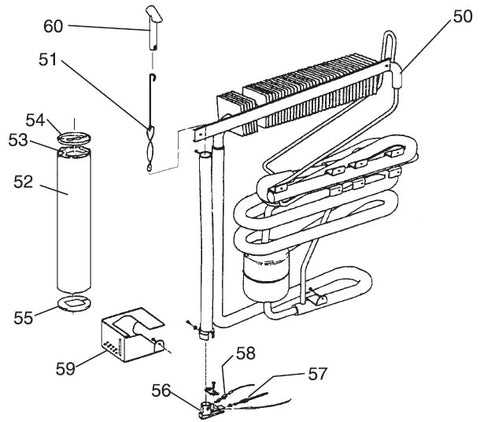

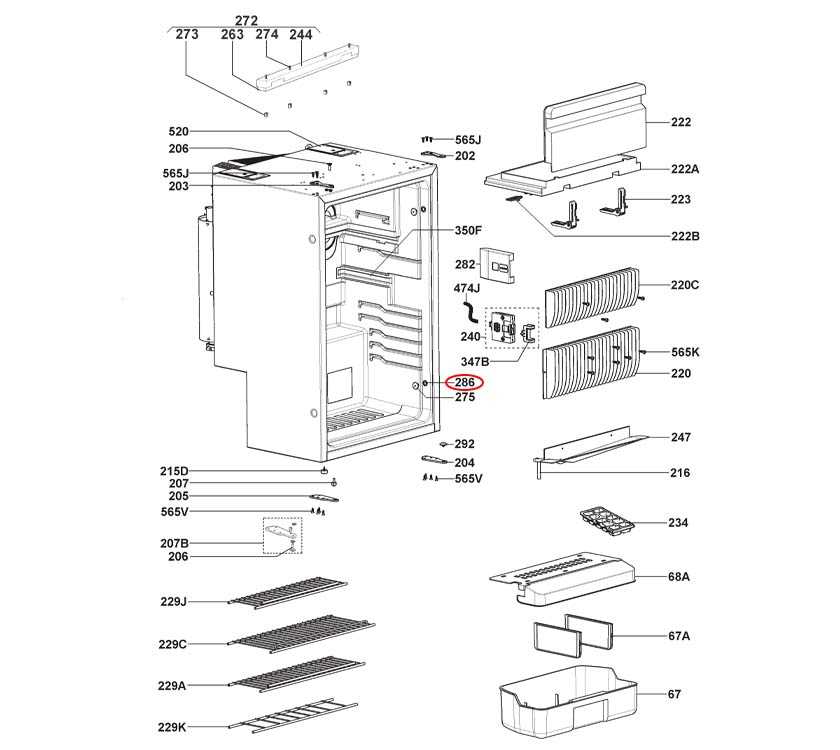

How to Read Diagrams

Understanding visual representations is crucial for effective troubleshooting and maintenance. These graphical layouts serve as guides, illustrating the components and their interconnections within a system. By mastering the art of interpretation, you can easily navigate complex arrangements and identify key elements.

Essential Elements of Visual Representations

- Symbols: Recognize the various icons used to depict different components. Each symbol has a specific meaning that conveys the function of the item it represents.

- Lines and Connections: Pay attention to the lines connecting symbols, as they indicate relationships and pathways for energy or information flow.

- Labels: Look for annotations or labels that provide additional details, such as specifications or part numbers, which are vital for proper identification.

Steps for Effective Interpretation

- Familiarize yourself with the standard symbols and conventions used in the representation.

- Begin by identifying the main components and their locations within the layout.

- Trace the connections to understand how each part interacts with others.

- Refer to the accompanying documentation for clarifications on specific elements.

- Practice reading various layouts to improve your skills over time.

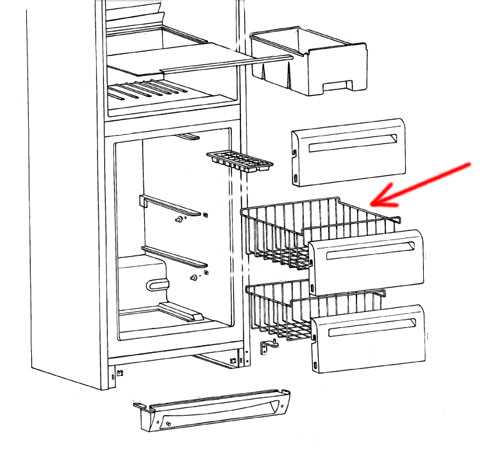

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended functionality of any cooling unit. By following a few straightforward guidelines, users can significantly enhance the performance and lifespan of their appliances.

Here are some key practices to consider:

- Regular Cleaning: Ensure the exterior and interior surfaces are clean. Dust and debris can accumulate and hinder efficiency.

- Check Seals: Inspect the gaskets around doors for any signs of wear or damage. A tight seal is crucial for maintaining optimal temperatures.

- Monitor Temperature: Regularly check and adjust the internal temperature settings to ensure the appliance operates within the ideal range.

- Defrosting: If frost builds up, perform defrosting periodically to improve efficiency and prevent ice buildup.

- Avoid Overloading: Do not overcrowd storage compartments, as this can obstruct airflow and affect cooling performance.

- Professional Servicing: Schedule routine inspections and servicing with qualified technicians to address any potential issues before they become significant problems.

By implementing these practices, users can enjoy the benefits of their cooling equipment for years to come.

Troubleshooting Common Issues

Identifying and resolving frequent complications can significantly enhance the performance of your cooling unit. Understanding typical symptoms and their potential causes allows for efficient maintenance and reduces the need for professional repairs.

Here are some prevalent problems you might encounter:

- Inadequate Cooling:

This issue may arise from various factors, including:

- Blocked air vents or insufficient airflow.

- Incorrect temperature settings.

- Defective thermostat or cooling elements.

- Unusual Noises:

Uncommon sounds can indicate:

- Loose components or damaged insulation.

- Malfunctioning fan or compressor.

- Foreign objects obstructing moving parts.

- Power Issues:

If the appliance fails to operate, consider:

- Checking the power source and outlet connections.

- Inspecting fuses or circuit breakers for damage.

- Evaluating the appliance’s power cord for wear or fraying.

- Odors:

Unpleasant smells might be attributed to:

- Improper food storage or expired items.

- Dirty filters or vents.

- Leaking fluids or other contamination.

For each of these issues, performing routine checks and maintenance can help mitigate problems. If complications persist, consulting a professional technician is advisable for thorough diagnostics and repairs.

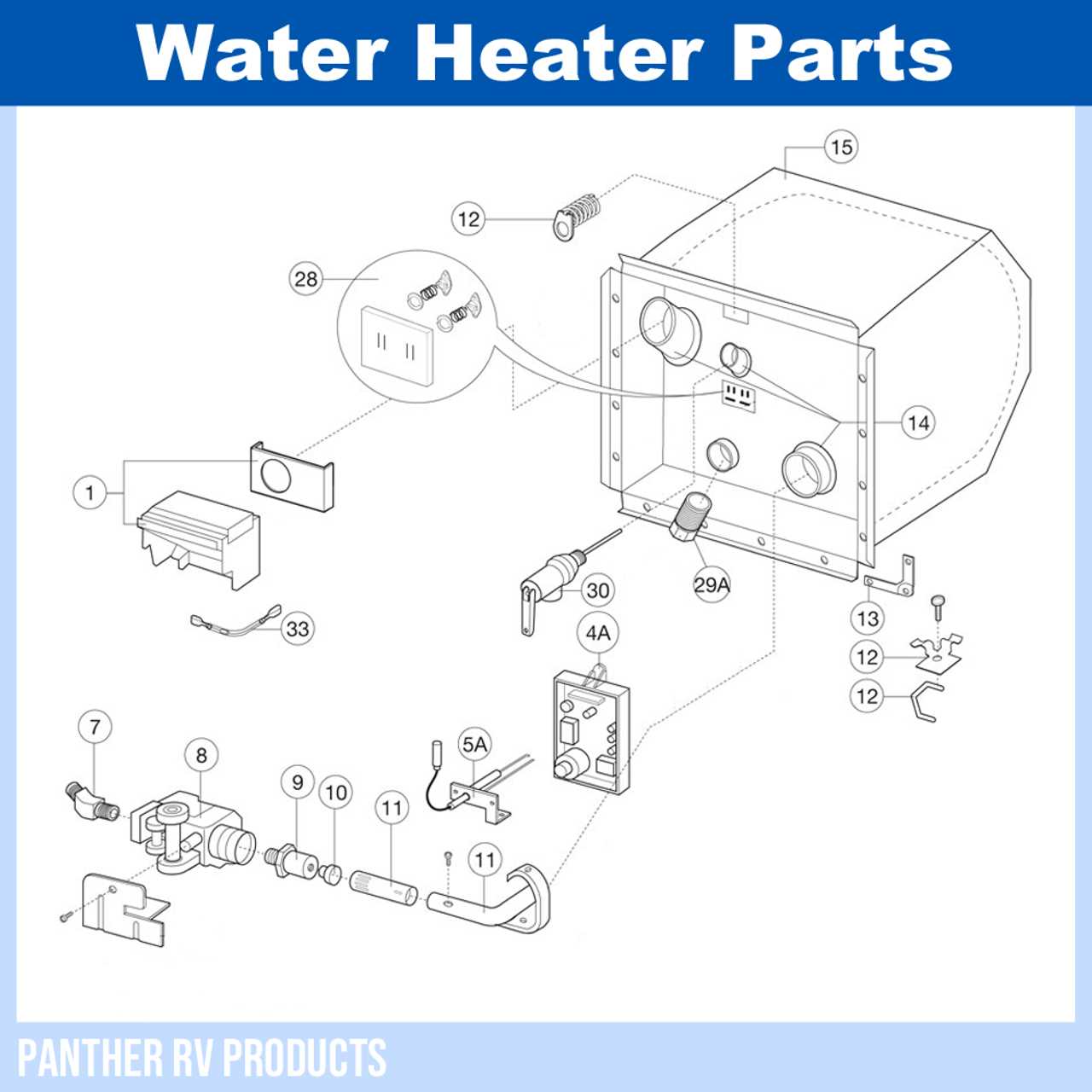

Replacement Parts Availability

When it comes to maintaining and repairing cooling appliances, understanding the availability of components is crucial. Numerous suppliers and manufacturers offer a wide range of essential elements, ensuring that users can easily find what they need to keep their devices functioning optimally. Access to reliable resources helps facilitate the timely acquisition of necessary items, minimizing downtime and enhancing overall satisfaction.

Several online and physical retailers specialize in these components, providing options for various models. These vendors often feature extensive catalogs that allow customers to search for specific items or browse through categories. Here is a summary of the typical components that can be sourced:

| Component Type | Description | Availability |

|---|---|---|

| Cooling Unit | Essential for temperature regulation within the appliance. | Commonly available at specialized retailers. |

| Thermostat | Regulates the internal temperature settings. | Widely found in both online and brick-and-mortar stores. |

| Seal Gasket | Ensures proper insulation and prevents air leakage. | Available through various home appliance suppliers. |

| Compressor | Critical for the refrigeration cycle, maintaining cold temperatures. | Accessible via specialized component distributors. |

By exploring multiple options and understanding what is typically offered, users can confidently seek out the necessary elements to ensure their cooling systems remain in excellent working order.

DIY Repair Considerations

When attempting to restore a cooling appliance, several factors warrant careful attention. Understanding the mechanisms involved can significantly impact the effectiveness of the repair. Ensuring proper techniques and safety measures is essential for a successful outcome.

Before starting any repair, consider the following key points:

- Safety First: Always disconnect the unit from the power source to avoid electrical hazards.

- Assessment: Examine the malfunction to determine whether it’s a minor issue or requires professional intervention.

- Tools Required: Gather all necessary tools and components before commencing work to streamline the process.

- Manufacturer’s Guidelines: Refer to the manufacturer’s recommendations for troubleshooting and repairs to avoid voiding warranties.

- Replacement Components: Ensure that any replacement parts are compatible and of high quality to prevent future issues.

Taking these considerations into account can lead to a more effective and safer repair experience, prolonging the life of the unit.

Safety Precautions to Follow

Ensuring a secure environment while operating or maintaining cooling appliances is crucial for preventing accidents and ensuring longevity. Following specific guidelines can help mitigate risks associated with handling these devices.

General Guidelines

- Always disconnect the appliance from the power source before performing any maintenance or repairs.

- Use personal protective equipment, such as gloves and goggles, to prevent injuries while working.

- Keep the surrounding area clean and free from any flammable materials.

Handling Procedures

- Refer to the manufacturer’s instructions before attempting any repairs or adjustments.

- Ensure that the appliance is level and stable to avoid tipping or falling.

- Check for any signs of wear or damage to components before use.

Manufacturer Support Resources

Accessing reliable assistance from the manufacturer is essential for effective maintenance and troubleshooting of your appliance. Support resources can provide invaluable guidance, from installation instructions to detailed repair manuals. Utilizing these resources can enhance the user experience and ensure optimal performance over time.

Documentation and Manuals

Comprehensive documentation is often available on the manufacturer’s official website. This includes user manuals, installation guides, and maintenance checklists that can assist in understanding the functionality and care required for your unit. Reviewing these documents can significantly reduce the time needed to address issues or perform routine upkeep.

Customer Service and Technical Support

For more specific inquiries, reaching out to customer service or technical support is advisable. Trained professionals can provide tailored solutions based on the issue at hand. Engaging with support representatives ensures that you receive accurate information and assistance tailored to your specific model.