The efficient maintenance of outdoor spaces often hinges on the functionality of specialized machinery designed for land management. This section aims to explore the essential elements that contribute to the optimal performance of these tools. By examining the intricate relationships between various components, users can enhance their understanding and proficiency in lawn care.

In the pursuit of achieving the perfect turf, a comprehensive grasp of equipment features is paramount. Knowledge of each segment’s role and interconnectivity not only streamlines operation but also aids in troubleshooting potential issues. Such insights can significantly improve overall results and ensure a healthy landscape.

Ultimately, familiarizing oneself with the mechanical aspects can empower users to make informed decisions regarding maintenance and repairs. With a detailed overview of crucial features at hand, operators will be better equipped to tackle their landscaping endeavors effectively.

Understanding Bluebird Sod Cutter Components

This section aims to provide a comprehensive overview of the essential elements that make up a specific type of turf removal machinery. Understanding these components is crucial for effective operation and maintenance, ensuring optimal performance and longevity of the equipment.

Key Elements of the Machine

The machinery comprises various components, each serving a distinct function that contributes to the overall efficiency. Recognizing these elements can enhance the user experience and simplify troubleshooting processes.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to operate the device, allowing it to perform its tasks effectively. |

| Blade | Designed to slice through the ground material, facilitating clean and precise removal. |

| Frame | The structural backbone of the machine, ensuring stability and support during operation. |

| Wheels | Assist in mobility, allowing the operator to maneuver the unit with ease across various terrains. |

Maintenance and Care

Proper upkeep of these components is vital to maintaining functionality. Regular inspections and timely replacements can prevent operational failures and enhance the durability of the machinery.

Importance of Quality Parts in Maintenance

Maintaining equipment in optimal condition is crucial for ensuring efficiency and longevity. High-quality components play a significant role in this process, directly influencing performance and reliability. Using superior materials and precision-engineered items not only enhances functionality but also reduces the likelihood of unexpected failures.

When machinery operates with reliable elements, it minimizes downtime and maximizes productivity. Investing in quality is not merely about the immediate benefits; it also contributes to the long-term sustainability of the equipment. Durable components withstand wear and tear, leading to lower overall maintenance costs and fewer replacements over time.

Furthermore, quality items often come with better warranties and customer support, providing peace of mind for users. This assurance allows for more confident operation and planning, ultimately fostering a more efficient working environment. Therefore, prioritizing quality in maintenance should be a fundamental consideration for anyone looking to achieve consistent and effective results.

Step-by-Step Parts Replacement Guide

Replacing components in your equipment can seem daunting, but with a clear plan, it becomes manageable. This guide provides a systematic approach to ensure that every necessary element is correctly addressed, enhancing performance and extending the lifespan of your machine.

1. Gather Necessary Tools: Before starting, collect all tools required for the task. This may include wrenches, screwdrivers, and replacement components.

2. Safety First: Always prioritize safety by wearing protective gear such as gloves and goggles. Ensure the equipment is powered down and disconnected from any power source.

3. Identify Components: Refer to your equipment’s manual to locate the specific components needing replacement. Familiarize yourself with their positions and functions.

4. Remove Old Components: Carefully detach the old parts, taking note of how they are connected. Keep track of screws and fasteners to avoid losing them.

5. Install New Components: Position the new elements as indicated in the manual. Secure them firmly, ensuring they are correctly aligned and functioning as intended.

6. Test Your Equipment: Once everything is reassembled, conduct a thorough check to confirm that the new components are working correctly. Run the machine briefly to ensure optimal performance.

7. Regular Maintenance: After replacing parts, establish a routine maintenance schedule to keep your equipment in top condition. This proactive approach can prevent future issues.

Common Issues with Sod Cutter Parts

Understanding frequent challenges with essential components can enhance the longevity and efficiency of your equipment. Many users encounter similar problems that can hinder performance, leading to frustration and potential repairs.

Wear and Tear

Excessive use can lead to significant deterioration of crucial elements. Components may experience wear over time, necessitating regular checks to ensure optimal functionality.

Improper Maintenance

Neglecting routine upkeep often results in malfunctioning mechanisms. Regular cleaning and lubrication are vital to prevent blockages and ensure smooth operation, ultimately prolonging the lifespan of your equipment.

Benefits of Using Genuine Bluebird Parts

Opting for authentic components ensures superior performance and longevity of your equipment. These original elements are designed to meet specific standards, enhancing the overall functionality and reliability of your machine.

Using genuine items provides a perfect fit, minimizing the risk of malfunctions and reducing wear and tear. This precise compatibility leads to optimal efficiency, enabling the machinery to operate at its best.

Additionally, authentic components often come with warranties and manufacturer support, giving you peace of mind. This protection can save you time and money in the long run, as you can avoid frequent replacements and repairs.

Moreover, investing in original elements contributes to the resale value of your equipment. Potential buyers are more likely to trust machinery that has been maintained with genuine parts, knowing that it has been cared for with the best materials available.

In conclusion, choosing original components is a wise decision that pays off through enhanced performance, reliability, and long-term savings.

Tools Needed for Sod Cutter Repairs

Effective maintenance of turf removal equipment requires a specific set of instruments to ensure optimal functionality. Having the right tools not only facilitates repairs but also enhances overall performance and longevity of the machinery.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are indispensable for disassembly and assembly tasks. These items enable the user to access various components easily, making troubleshooting more efficient.

Power Tools for Efficient Repairs

Incorporating power tools like drills and impact drivers can significantly expedite the repair process. These tools allow for quick fastening and removal of screws and bolts, ensuring a smoother workflow during maintenance tasks.

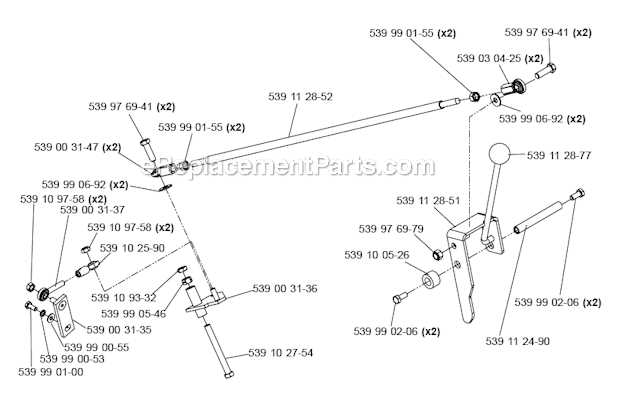

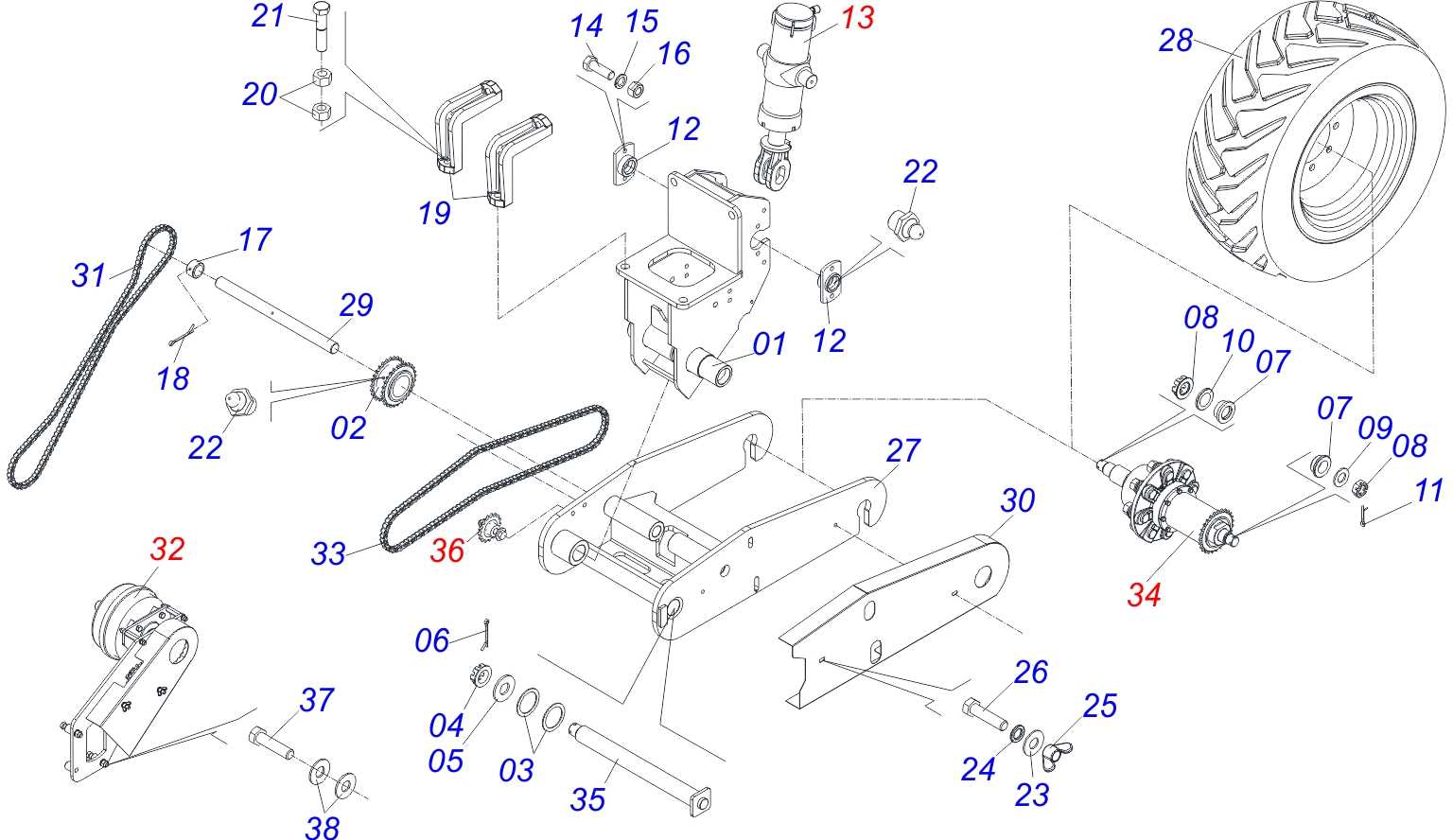

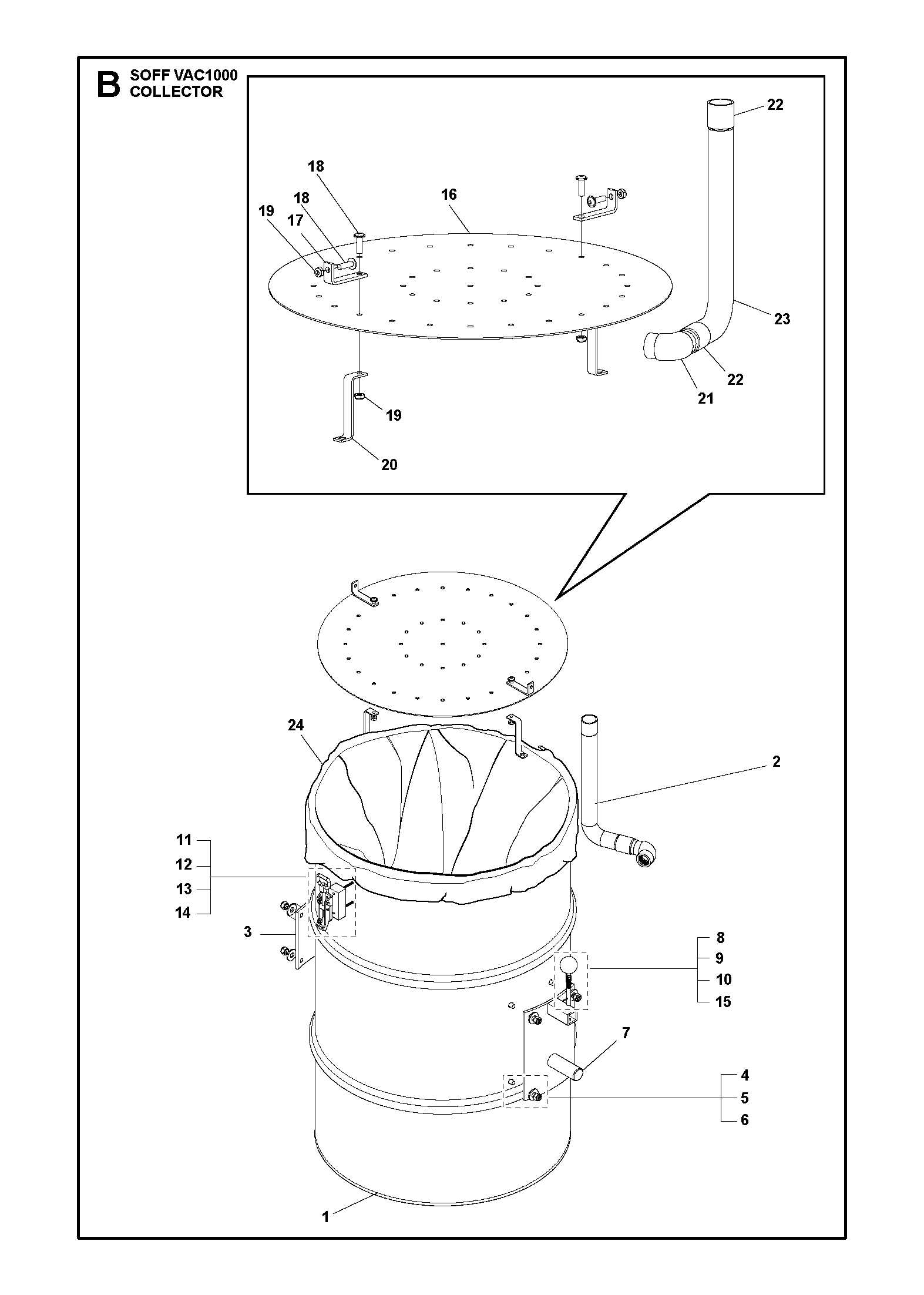

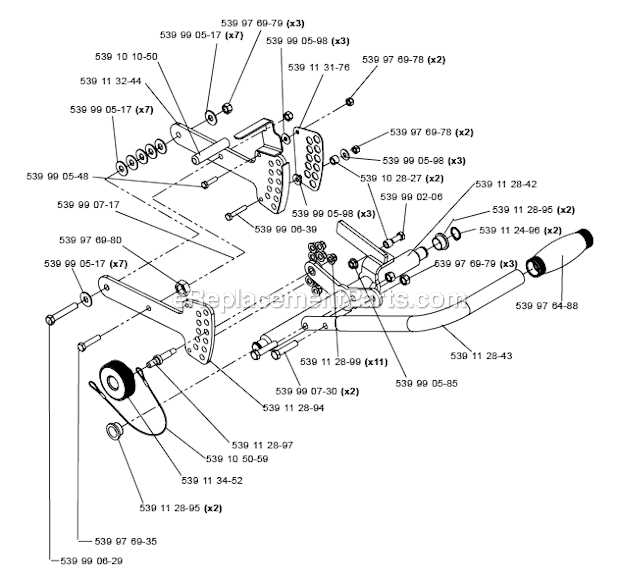

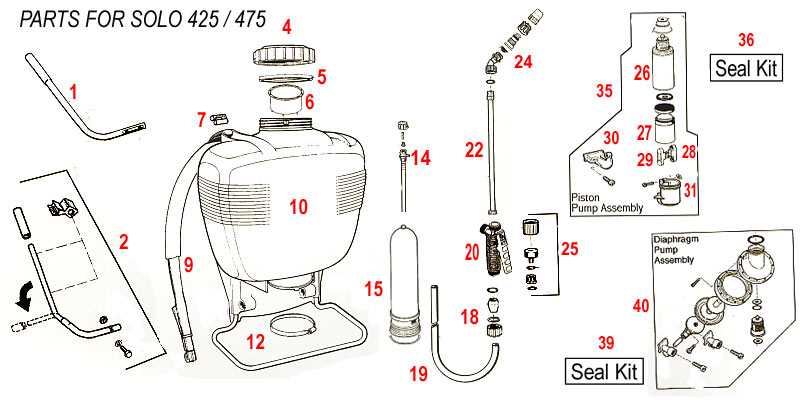

How to Read the Parts Diagram

Understanding a technical illustration can greatly enhance your ability to maintain and repair equipment. This section will guide you through the essential elements of interpreting such visual aids effectively. Familiarizing yourself with the layout and symbols will make the process smoother and more efficient.

Key Elements to Identify

- Labels: Look for clearly marked sections that identify various components.

- Legend: Many illustrations include a legend or key, explaining the symbols and color codes used.

- Numbering: Items are often numbered sequentially, allowing for easy reference to specific components.

Steps to Follow

- Begin by locating the legend to understand the symbols used.

- Identify the major assemblies to get a sense of the overall structure.

- Cross-reference numbers or labels with a parts list if available.

- Take note of any special instructions or notes included in the illustration.

By following these guidelines, you’ll gain confidence in navigating technical illustrations, enabling you to perform repairs and maintenance tasks more effectively.

Frequently Asked Questions About Components

This section aims to address common inquiries regarding the various elements involved in landscape preparation machinery. Understanding these components is essential for effective maintenance and operation, ensuring optimal performance and longevity of your equipment.

Common Queries

| Question | Answer |

|---|---|

| What are the primary components of this machinery? | The main parts typically include the blade assembly, drive system, and control handles, each serving a unique function in the operation process. |

| How can I identify worn-out components? | Look for signs of damage such as cracks, rust, or excessive wear on the surfaces. Regular inspections will help in timely identification. |

| Where can I purchase replacement parts? | Replacement components can usually be obtained from authorized dealers or online retailers specializing in landscaping equipment. |

| Are there maintenance tips for extending component life? | Regular cleaning, proper lubrication, and timely replacements of worn parts can significantly enhance the lifespan of your machinery. |

Additional Resources

For further assistance, consult your user manual or reach out to professionals for expert advice tailored to your specific equipment needs.

Where to Purchase Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Knowing where to look is essential for obtaining high-quality replacements that fit perfectly and function effectively. This section outlines the best avenues for sourcing necessary items.

Authorized Dealers

One of the most reliable options for acquiring replacements is through authorized dealers. These vendors typically offer a wide range of original equipment manufacturer (OEM) items, ensuring compatibility and quality. Checking the official website of your equipment’s manufacturer can help you locate nearby authorized sellers.

Online Retailers

The internet is a treasure trove for purchasing components. Numerous online platforms specialize in selling various items, often at competitive prices. Be sure to read customer reviews and verify seller ratings to ensure you receive authentic products. Many online retailers also provide detailed specifications and diagrams, making it easier to identify the correct items for your needs.

Ultimately, whether opting for local dealers or online options, ensuring that you choose reputable sources is crucial for maintaining the efficiency of your machinery.

Maintenance Tips for Longevity

Proper upkeep is essential to extend the lifespan of your equipment. Regular attention not only ensures optimal performance but also helps prevent costly repairs down the line. Here are some key strategies to keep your machinery in top condition.

- Regular Cleaning: After each use, clean the exterior and moving parts to remove debris and dirt that can cause wear and tear.

- Lubrication: Apply appropriate lubricants to moving components to reduce friction and prevent rusting. Check the manufacturer’s recommendations for the right type of oil.

- Inspect for Wear: Periodically examine blades, belts, and other critical components for signs of wear. Replace any parts that show significant damage.

Following these practices will not only enhance the efficiency of your equipment but also contribute to its durability, ensuring that it serves you well for years to come.

- Store Properly: When not in use, store the machinery in a dry, sheltered location to protect it from the elements.

- Check Fluid Levels: Regularly monitor and maintain the appropriate levels of fuel, oil, and other fluids to ensure smooth operation.

- Follow the Manual: Always refer to the user manual for specific maintenance guidelines and schedules tailored to your model.

Implementing these maintenance tips will maximize your equipment’s efficiency and lifespan, ultimately saving you time and money in the long run.

Comparing Bluebird to Other Brands

This section explores the distinctions between a prominent manufacturer and its competitors in the market for turf management equipment. Understanding these differences can help consumers make informed decisions based on performance, durability, and overall value.

Quality and Performance: The leading brand is known for its exceptional build quality and reliability, often outpacing rivals in user satisfaction. Customers frequently highlight the efficiency of its machines, which deliver superior results in less time.

Innovation: While many brands offer traditional models, the featured manufacturer continuously integrates cutting-edge technology. This commitment to innovation provides users with advanced features that enhance ease of use and efficiency.

Customer Support: A critical aspect of any brand is the level of service provided. The discussed company typically receives high marks for its responsive customer service and comprehensive support, setting a standard that competitors strive to match.

Price Point: Pricing strategies vary among manufacturers. While the highlighted brand may command a premium, many users find the investment worthwhile due to the longevity and performance of their equipment.

In conclusion, evaluating these factors allows potential buyers to delve deeper into their options, ensuring they choose the ultimate solution for their needs.