In the world of machinery maintenance, having a clear visualization of various elements is essential for effective operation and repair. A comprehensive overview of these components can significantly enhance one’s ability to troubleshoot and perform necessary upgrades.

Identifying individual pieces within your machine enables users to delve deeper into the mechanics involved, fostering a greater appreciation for the intricate designs and functionalities. This knowledge ultimately leads to improved performance and longevity.

Whether you’re a seasoned technician or a novice enthusiast, familiarizing yourself with the layout of your equipment can empower you to take charge of its upkeep. Understanding how each part fits into the larger framework is crucial for achieving optimal results and ensuring smooth functionality.

Kubota Z122R Overview

This section provides a comprehensive look at a compact mowing machine designed for efficiency and versatility. Ideal for both residential and commercial use, it combines power with user-friendly features, making it an excellent choice for maintaining lawns and landscapes.

Key Features

Equipped with a robust engine, this model ensures reliable performance across various terrains. Its innovative design includes easy maneuverability, allowing users to navigate tight spaces effortlessly. Additionally, the cutting system is engineered for precision, delivering a clean finish while minimizing maintenance needs.

Benefits of Usage

One of the main advantages of this mowing unit is its ability to enhance productivity. With a comfortable operator seat and intuitive controls, users can work for extended periods without fatigue. The machine’s durability also guarantees long-term service, making it a valuable investment for those who prioritize quality and efficiency.

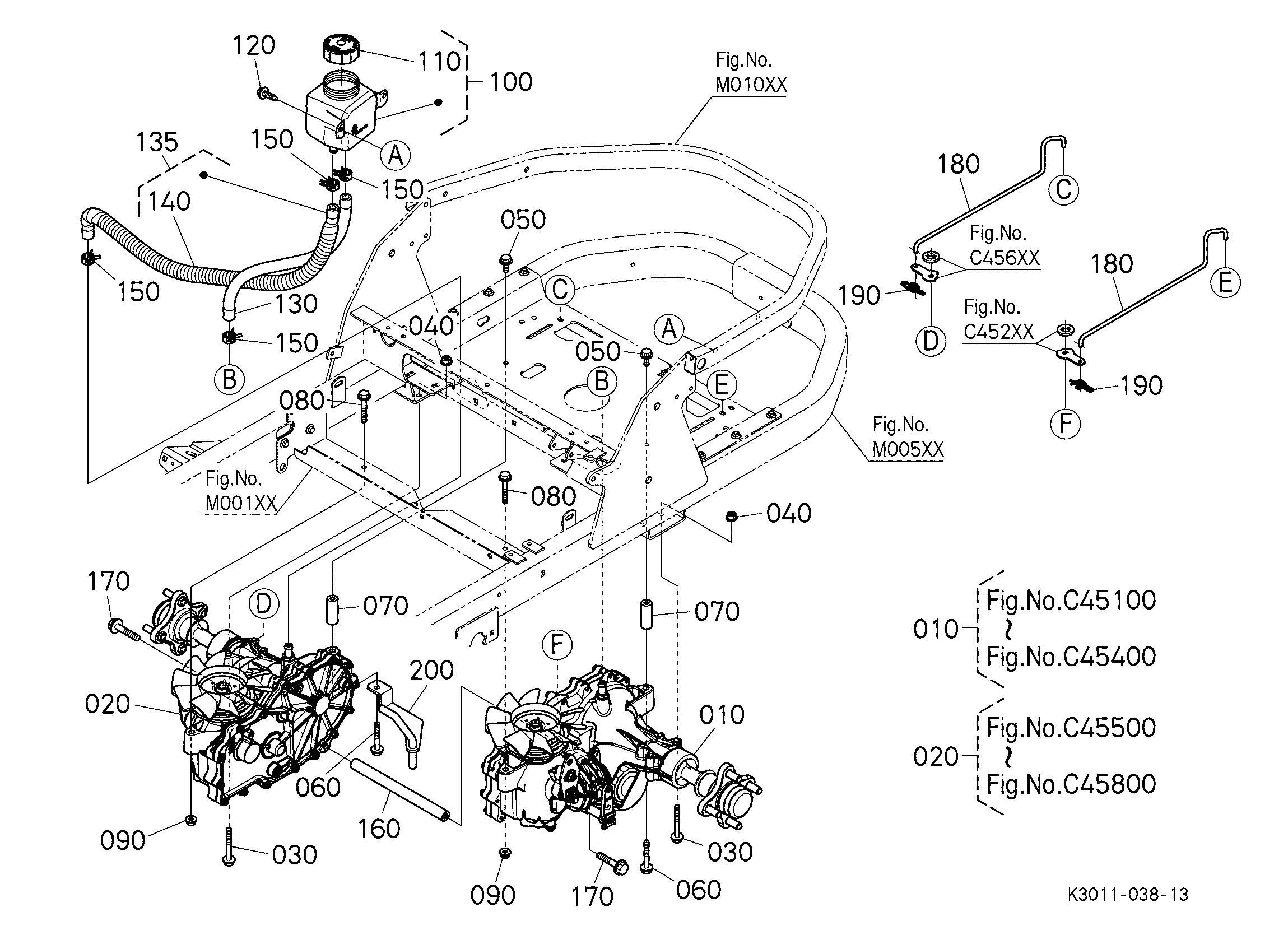

Importance of Parts Diagrams

Visual representations of components are crucial for understanding the intricate assembly of machinery. They provide clarity on how different elements interact, ensuring efficient maintenance and repairs. Without these illustrations, identifying and sourcing the correct pieces can become a daunting task.

Enhancing Maintenance Efficiency

Accurate illustrations significantly streamline the upkeep process. Technicians can quickly locate specific sections, facilitating faster repairs and minimizing downtime. This efficiency not only saves time but also reduces costs associated with prolonged machinery inactivity.

Facilitating Proper Installation

Well-structured visuals guide users in correctly positioning various components, ensuring optimal functionality. This is essential for maintaining the longevity and performance of equipment. Moreover, it minimizes the risk of errors that could lead to severe malfunctions.

| Benefit | Description |

|---|---|

| Clarity | Provides a clear understanding of component relationships. |

| Time-saving | Speeds up maintenance and repair tasks. |

| Accuracy | Reduces errors in installation and assembly. |

| Cost-effectiveness | Minimizes equipment downtime and repair costs. |

Key Components of the Z122R

This section highlights the essential elements that contribute to the efficient operation of the mower. Understanding these components can enhance maintenance practices and improve overall performance.

- Engine: The heart of the machine, responsible for providing the necessary power to operate various functions.

- Transmission: Facilitates smooth movement and speed control, allowing for efficient maneuverability across different terrains.

- Deck: The cutting area that houses the blades, designed to ensure optimal grass cutting and discharge.

- Wheels: Provide stability and support, crucial for handling diverse ground conditions while maintaining traction.

- Control System: Includes levers and pedals that allow the operator to manage speed, direction, and cutting height effectively.

Each of these components plays a significant role in the functionality and reliability of the mower, making regular inspections and maintenance vital for longevity.

Understanding the Engine Assembly

The engine assembly is a complex unit that plays a crucial role in the overall functionality of machinery. Comprising various interconnected components, it is essential for converting fuel into mechanical energy. Understanding each part’s role can significantly enhance maintenance and troubleshooting efforts.

The main elements of the engine assembly include the block, cylinder heads, and the fuel delivery system. Each component contributes to the engine’s performance, efficiency, and longevity. Below is a summary of these key parts and their functions:

| Component | Function |

|---|---|

| Engine Block | Houses the cylinders and provides a base for other components. |

| Cylinder Head | Seals the top of the cylinder and contains valves for air and fuel intake. |

| Pistons | Move up and down within the cylinders, creating the power stroke. |

| Crankshaft | Transforms linear motion from the pistons into rotational motion. |

| Fuel System | Delivers fuel to the combustion chamber for ignition. |

By familiarizing oneself with these components, operators can better appreciate the intricacies of the engine assembly and ensure optimal performance through proper care and maintenance.

Transmission System Details

The transmission system plays a crucial role in the efficiency and performance of machinery, facilitating the transfer of power from the engine to the wheels. Understanding its components and functionality is essential for maintaining optimal operation and ensuring longevity.

| Component | Description |

|---|---|

| Gearbox | Translates engine power into rotational force, allowing for speed variations. |

| Clutch | Engages and disengages the transmission from the engine, providing control during operation. |

| Drive Shaft | Transfers torque from the gearbox to the wheels, ensuring effective propulsion. |

| Final Drive | Adjusts the rotational speed and torque before reaching the wheels, enhancing performance. |

Each of these elements contributes to the overall functionality of the system, enabling seamless operation and adaptability in various conditions.

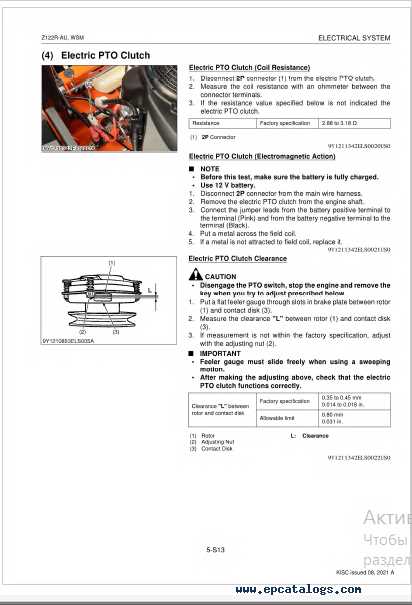

Electrical System Breakdown

The functionality of any machinery heavily relies on its electrical components, which serve as the backbone for operational efficiency. This section will explore the intricate network of circuits and devices that facilitate power distribution, control mechanisms, and safety features.

Power Distribution is fundamental to ensuring that every component receives the necessary voltage and current. This involves various connectors, wires, and fuses that must be properly configured to avoid disruptions.

Control Mechanisms play a crucial role in regulating the performance of the equipment. Switches, relays, and sensors work in unison to manage the operation, providing real-time feedback to the user and optimizing functionality.

Safety Features are essential to prevent electrical failures that could lead to serious malfunctions. Incorporating circuit breakers and overload protection systems helps safeguard the machinery and its operator from potential hazards.

Maintenance Parts and Their Roles

Ensuring the longevity and optimal performance of machinery relies heavily on understanding the various components that contribute to its functionality. Each element plays a critical role, providing support, protection, and efficiency during operation.

Filters are essential for maintaining cleanliness within the system, preventing contaminants from causing damage. Regular replacement ensures uninterrupted performance.

Belts transmit power efficiently, facilitating movement and operation of various parts. Over time, wear and tear can lead to slippage or breakage, making timely inspection crucial.

Blades are vital for achieving the desired cutting quality. Dull or damaged edges not only reduce effectiveness but can also strain the engine, highlighting the importance of regular sharpening or replacement.

Fluids are necessary for lubrication and cooling, preventing overheating and reducing friction. Monitoring fluid levels and quality is key to maintaining overall system health.

By delving into the specifics of each component, operators can enhance maintenance strategies and ensure their machinery operates at its ultimate efficiency.

How to Use the Diagram Effectively

Understanding the visual representation of components can significantly enhance your ability to maintain and repair equipment. By utilizing these illustrations, you can identify parts more easily, streamline your workflow, and ensure that each task is completed with precision. Effective use of these resources can save you time and reduce frustration during maintenance or assembly processes.

Familiarize Yourself with Symbols and Labels

Before diving into the details, take some time to familiarize yourself with the various symbols and labels present in the illustration. Each element is typically accompanied by a designation that corresponds to specific components. Knowing what each symbol represents will allow you to navigate the layout quickly and locate necessary items without confusion.

Cross-Reference with the Manual

Once you have a good understanding of the visual guide, it’s beneficial to cross-reference it with the equipment manual. This can provide additional context and detailed instructions that may not be immediately obvious from the visual alone. By doing this, you can enhance your comprehension and ensure that you are following the correct procedures for maintenance or repairs.

Common Issues and Solutions

When operating outdoor machinery, users often encounter a variety of challenges that can affect performance and efficiency. Understanding these common issues and their solutions can enhance the longevity of the equipment and improve overall functionality.

Engine Performance Problems

One frequent concern is related to engine performance. Issues such as difficulty starting or stalling can arise due to fuel quality, air filter clogs, or battery malfunctions. Regularly checking the fuel system and ensuring that the air filter is clean can mitigate these problems. Additionally, keeping the battery charged is essential for smooth operation.

Hydraulic System Failures

Hydraulic system issues can lead to significant downtime. Common signs include slow response or complete failure of hydraulic functions. This may be caused by low fluid levels, leaks, or contaminated fluid. Regular inspections of the hydraulic fluid levels and checking for any leaks can help identify and resolve these issues promptly.

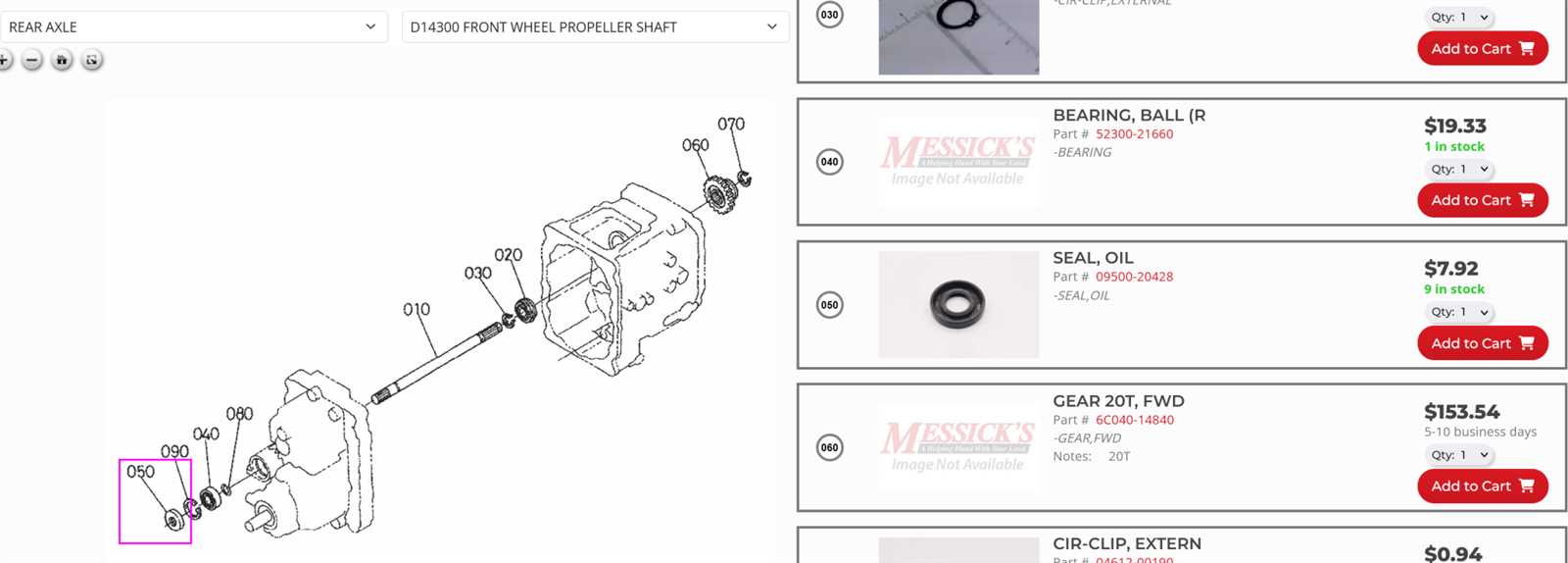

Where to Find Replacement Parts

Locating suitable components for your machinery is essential for maintaining optimal performance and longevity. Various sources can provide reliable options, ensuring that you can restore your equipment effectively.

Authorized Dealers

Visiting certified distributors is a reliable approach. They offer genuine components, ensuring compatibility and quality, along with knowledgeable staff who can assist you in selecting the right items.

Online Marketplaces

Many e-commerce platforms feature a wide range of components. These sites often include customer reviews and ratings, allowing you to assess quality and reliability before making a purchase.

Cost Considerations for Repairs

When it comes to maintenance and restoration of machinery, understanding the financial aspects is crucial. Various factors influence the overall expenses, impacting both short-term budgets and long-term investments.

Factors Affecting Repair Costs

- Type of Damage: Minor issues often require less funding compared to significant failures.

- Labor Costs: The expertise of technicians can vary, affecting overall service charges.

- Parts Availability: Sourcing components may incur additional expenses if they are rare or discontinued.

- Warranty Status: Equipment still under warranty may reduce out-of-pocket expenses.

Budgeting for Maintenance

- Conduct Regular Inspections: Early detection can prevent costly repairs.

- Research Repair Options: Compare different service providers for competitive pricing.

- Set Aside a Contingency Fund: Allocating extra resources can help manage unexpected expenses.

Tips for DIY Maintenance

Regular upkeep of your equipment is essential for ensuring its longevity and optimal performance. Engaging in hands-on maintenance can save you time and money while providing a sense of accomplishment. By following some practical advice, you can keep your machinery running smoothly and efficiently.

1. Familiarize Yourself with the Manual: Start by reading the manufacturer’s guidelines. Understanding the recommended maintenance schedule and procedures will give you a solid foundation for your tasks.

2. Invest in Quality Tools: Having the right tools is crucial. Quality equipment not only makes the job easier but also helps prevent damage during repairs. Ensure you have the necessary wrenches, screwdrivers, and safety gear.

3. Keep a Maintenance Log: Documenting your maintenance activities helps you track what has been done and what needs attention. This can be invaluable for identifying patterns or recurring issues.

4. Clean Regularly: Dirt and debris can hinder performance. Regularly cleaning your equipment prevents build-up and allows for easier inspections. Pay special attention to air filters and cooling systems.

5. Use Genuine Components: When replacement parts are necessary, opt for genuine or high-quality alternatives. This ensures compatibility and reliability, reducing the risk of future problems.

6. Stay Safe: Always prioritize safety. Wear appropriate protective gear and follow safety protocols. Disconnect power sources before beginning any work to prevent accidents.

7. Seek Guidance: Don’t hesitate to reach out to online forums or local professionals if you’re unsure about a procedure. Learning from others’ experiences can be incredibly beneficial.

By adhering to these tips, you can enhance the performance and durability of your machinery, ensuring it serves you well for years to come.