In various technical systems, it’s crucial to have a clear understanding of the individual elements that contribute to the overall functionality. Each part, no matter how small, plays a vital role in ensuring that the system operates smoothly and efficiently.

By examining the structure of the device, we can gain insight into how each section is designed to interact with the others. This knowledge can help in both troubleshooting and maintaining the equipment, ensuring longevity and optimal performance.

Familiarizing oneself with the detailed layout and functions of the components allows for easier identification of potential issues. This proactive approach helps prevent significant downtime and facilitates smoother operations.

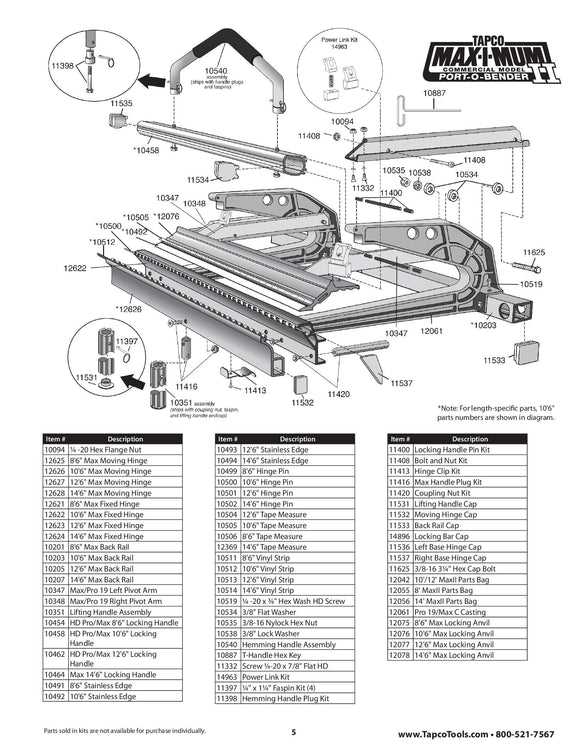

Tapco Pro 3 Components Overview

The system is designed with a variety of elements that work together to provide precise and reliable operation. Each section of the tool is engineered to ensure durability and efficiency, making it a versatile choice for users working with different materials.

Main Structural Elements

The main frame is crafted from robust materials, ensuring stability and strength. This structure is the backbone of the equipment, providing the necessary support during its operation. The framework includes specific features that enhance ease of use and adaptability.

Key Functional Sections

Several functional areas contribute to the overall performance. These include adjustable sections that allow users to customize settings for specific tasks. The layout of these sections is user-friendly, offering intuitive control over the system’s capabilities.

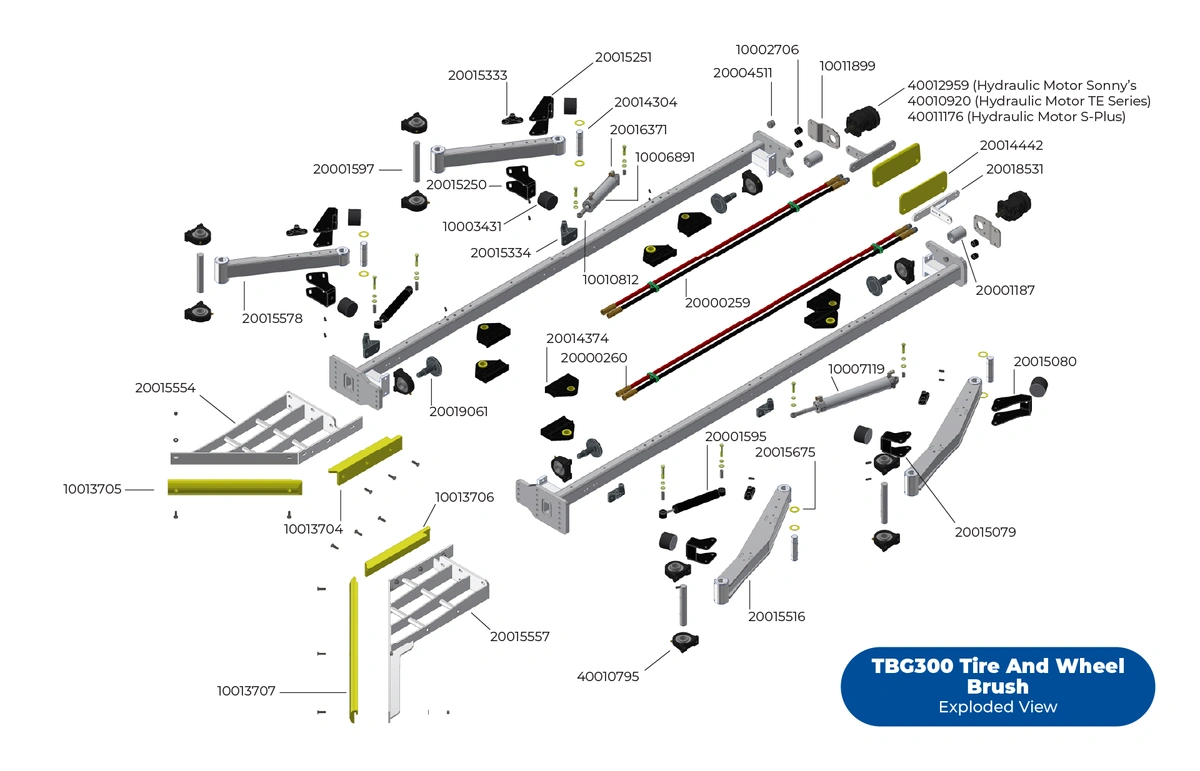

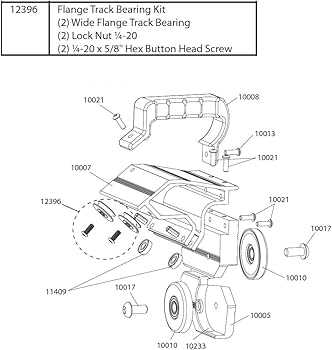

Main Structural Elements Breakdown

This section provides an overview of the essential components that contribute to the overall functionality and design of the system. Understanding these elements is crucial for effective maintenance and optimal performance.

Key Components Overview

The primary structural elements include various assemblies that play significant roles in ensuring stability and efficiency. Each assembly is designed to perform specific tasks while working cohesively with other components.

Functional Roles of Elements

Each part is meticulously engineered to fulfill its function, contributing to the overall reliability of the system. The interaction between these elements enhances performance and facilitates smooth operation, making it vital to comprehend their roles and configurations.

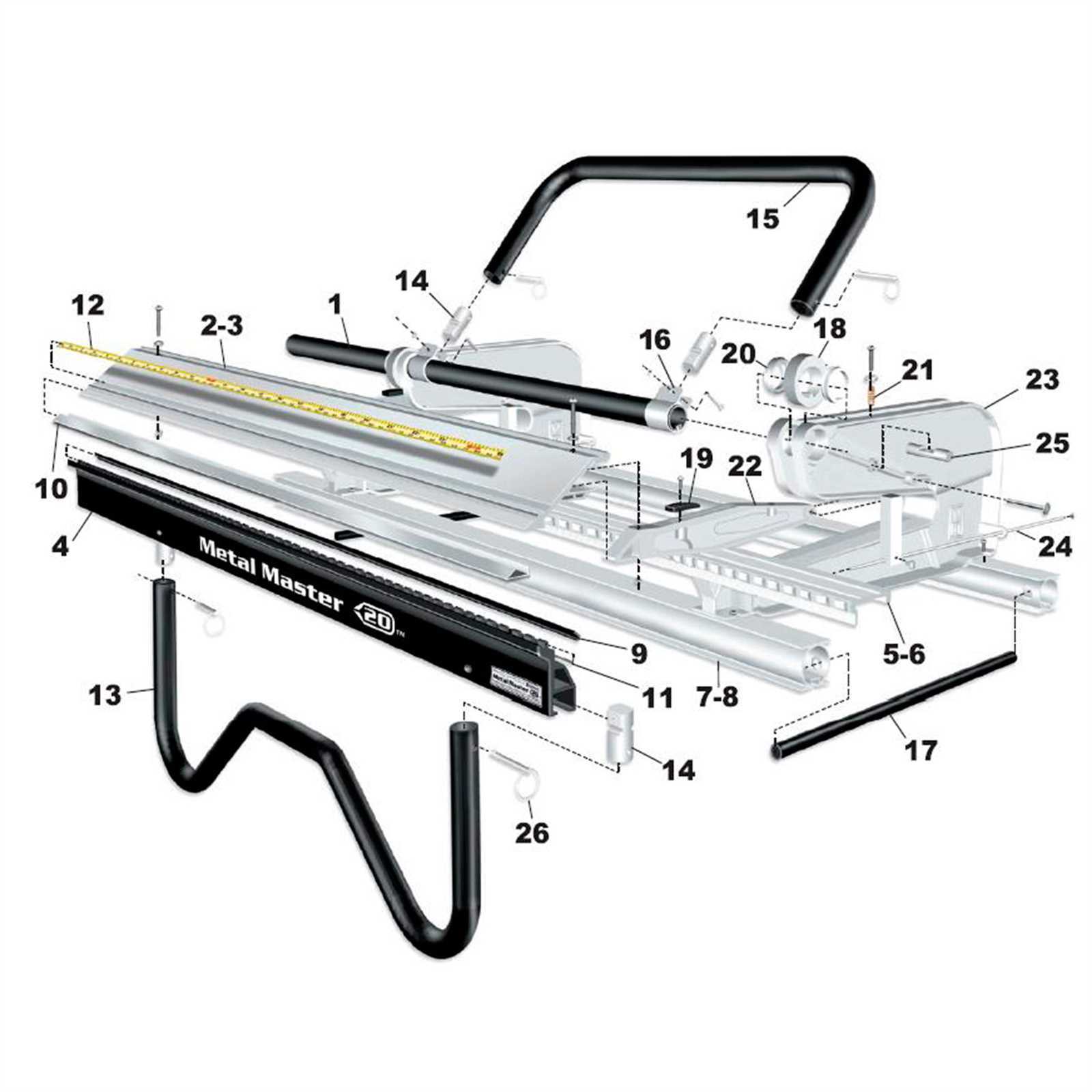

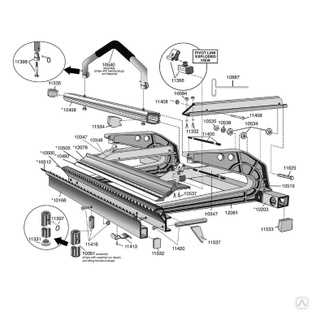

Key Functional Parts of the Pro 3

The essential components of this device play a crucial role in its overall efficiency and usability. Each element is designed to contribute to the seamless operation and enhance the user experience. Understanding these key features allows for better maintenance and optimal performance.

Main Components Overview

The primary elements include a robust framework, which provides stability and support, ensuring durability during use. The control mechanisms allow users to adjust settings easily, catering to various operational needs. Additionally, the integration of advanced technology enhances functionality and precision.

Importance of Each Element

Each component serves a specific purpose, working in harmony to achieve optimal results. Regular inspection and maintenance of these features are vital for longevity and efficiency. Knowledge of these functionalities can greatly assist users in troubleshooting and enhancing performance.

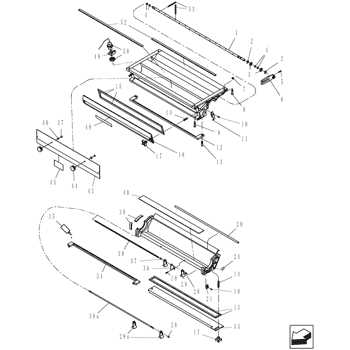

Detailed Look at Frame Components

This section provides an in-depth examination of the various elements that constitute the structural framework of the device. Understanding these components is essential for anyone seeking to enhance their familiarity with the unit’s functionality and maintenance.

The frame serves as the backbone, supporting other integral parts while ensuring durability and stability. Each element has a specific role that contributes to the overall performance and efficiency of the assembly.

| Component Name | Description | Function |

|---|---|---|

| Base | The foundation of the assembly. | Provides stability and support for the entire structure. |

| Side Panels | Vertical sections on either side. | Contribute to the overall rigidity and protect internal components. |

| Cross Members | Horizontal supports connecting the side panels. | Enhance structural integrity by distributing weight evenly. |

| Mounting Points | Locations for securing additional parts. | Facilitate attachment of various components for functionality. |

Guide to Essential Mechanical Sections

Understanding the fundamental mechanical components of machinery is crucial for efficient operation and maintenance. This guide provides an overview of key sections that play a vital role in the functionality of various equipment. By familiarizing oneself with these segments, users can enhance their comprehension of how systems work and address potential issues effectively.

Key Components Overview

Mechanical systems consist of several essential parts, each contributing to the overall performance. These sections typically include elements like drive mechanisms, control systems, and structural supports. Recognizing the purpose and function of these components allows for better troubleshooting and informed decision-making during repairs or upgrades.

Table of Essential Sections

| Component | Description | Function |

|---|---|---|

| Drive Mechanism | Transfers energy from the power source to other parts | Enables movement and operation of the system |

| Control System | Manages the operation of various components | Ensures precise functioning and safety |

| Structural Support | Provides stability and support to the machinery | Maintains the integrity of the system during operation |

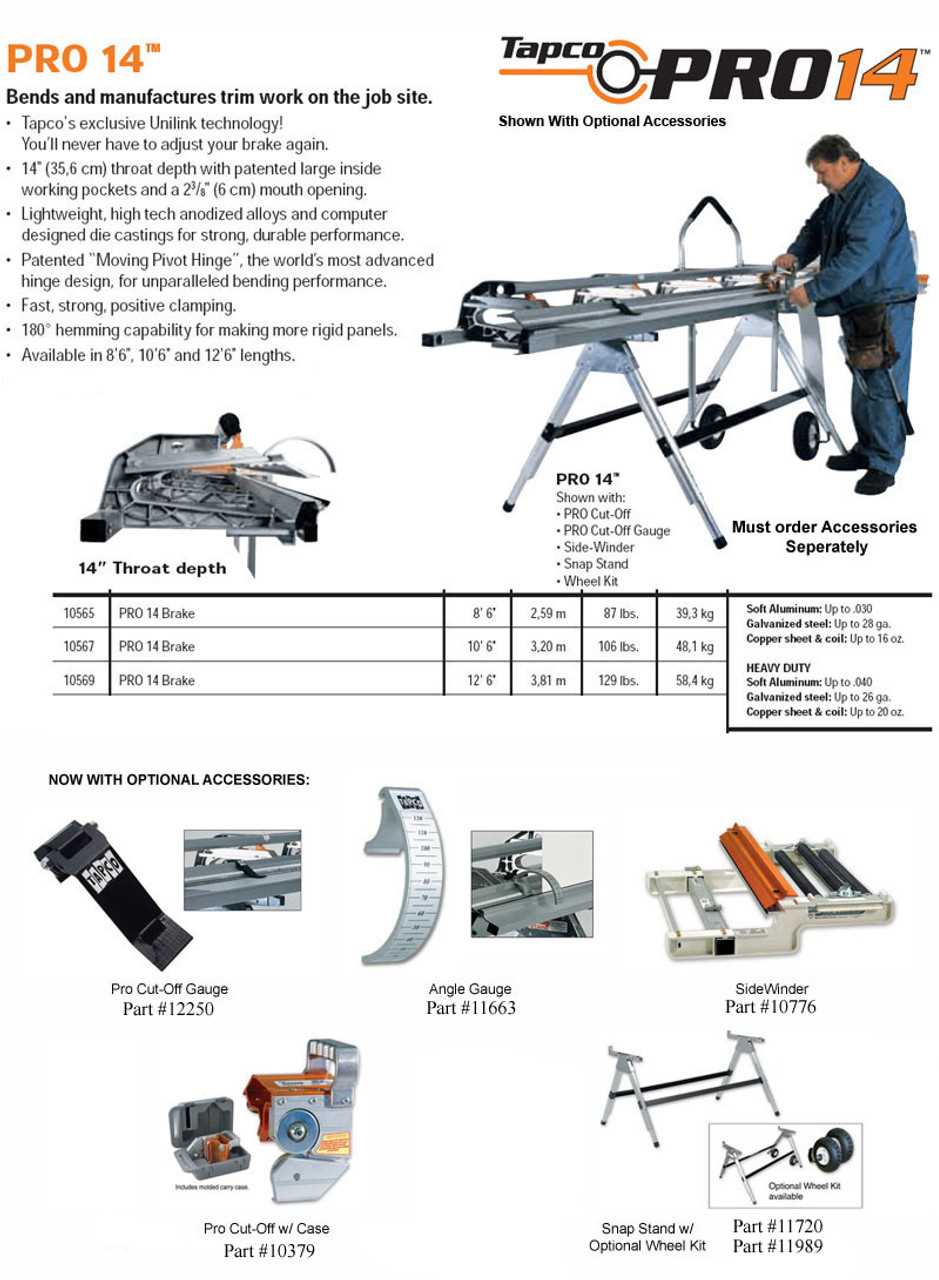

Exploring Pro 3 Accessories and Add-ons

When enhancing the functionality of a specific model, various supplementary components play a crucial role. These additional features can significantly improve user experience, enabling greater versatility and efficiency during operation. Understanding these accessories allows for more effective utilization of the device, catering to diverse needs.

Numerous enhancements are available, each designed to complement the core features of the device. Adapters are essential for ensuring compatibility with different systems, while carrying cases provide protection during transport. Additionally, customizable attachments allow users to tailor their setup according to personal preferences, enhancing usability.

Exploring these options can lead to a more tailored experience, transforming the basic functionality into something uniquely suited to individual requirements. By selecting the right accessories, users can unlock the full potential of their equipment and enjoy a more productive and enjoyable experience.

Material Specifications for Core Elements

This section outlines the essential characteristics and standards of the materials utilized in the primary components of the equipment. Understanding these specifications is crucial for ensuring optimal performance, durability, and safety in various operational environments.

Durability and Strength

The core materials are selected based on their ability to withstand significant wear and tear. High tensile strength and resilience are key factors, ensuring that the elements can endure mechanical stresses and environmental challenges without compromising functionality.

Environmental Resistance

In addition to strength, the materials must exhibit excellent resistance to corrosion and degradation. This includes properties that protect against moisture, chemicals, and temperature fluctuations, ensuring longevity and reliability in diverse settings.

Assembly Parts for Efficient Operation

In any mechanism designed for performance, the arrangement of individual components plays a crucial role in achieving optimal functionality. Understanding how these elements work together ensures that the system operates smoothly, minimizing the risk of malfunction and enhancing overall productivity.

Key Components for Performance

Each segment of the assembly contributes to the efficiency of the entire system. From drive mechanisms to support structures, selecting high-quality materials and ensuring precise fitting are essential. This attention to detail not only improves durability but also reduces wear and tear over time.

Maintenance for Longevity

Regular upkeep is vital to maintaining the effectiveness of the assembly. Routine inspections and timely replacements of worn elements can significantly extend the lifespan of the entire unit. Adopting a proactive approach to maintenance helps in identifying potential issues before they escalate, ensuring continued reliable operation.

Understanding Tapco Pro 3 Adjustment Mechanisms

The adjustment systems of specialized equipment play a crucial role in achieving optimal performance and precision. These mechanisms allow users to fine-tune the settings to meet specific operational requirements, enhancing the overall functionality of the device. Understanding these features is essential for maximizing efficiency and ensuring a smooth workflow.

In this section, we will explore the various adjustment components and their significance in achieving desired outcomes. The key mechanisms include:

- Height Adjustment: This feature allows users to modify the elevation of the working surface, accommodating different material thicknesses.

- Angle Settings: Adjusting the angle of the cutting blade or tool can lead to more accurate cuts, tailored to specific tasks.

- Speed Control: Variability in operational speed can enhance performance for various materials, contributing to better results.

- Locking Mechanisms: These are essential for maintaining stability during operation, preventing unwanted adjustments while in use.

By comprehensively understanding these mechanisms, users can ensure their equipment operates efficiently, ultimately leading to improved results and productivity.

Replacement Pieces for Long-term Maintenance

Ensuring the longevity and optimal performance of your equipment requires the timely replacement of certain components. Regularly updating these elements not only enhances functionality but also prevents unexpected failures that could disrupt operations. Understanding which components need periodic attention is essential for effective maintenance.

Key Components to Consider

- Filters: Regularly replacing air and fluid filters keeps systems clean and efficient.

- Belts and Hoses: Inspecting and replacing worn belts and hoses can prevent breakdowns.

- Seals and Gaskets: Maintaining these elements helps to avoid leaks and maintain pressure.

- Lubrication: Ensuring that moving parts are properly lubricated extends their lifespan.

Maintenance Schedule Recommendations

- Monthly: Check filters and lubricants for any signs of wear.

- Quarterly: Inspect belts, hoses, and seals for deterioration.

- Annually: Conduct a comprehensive review of all critical components to ensure readiness.

Durable Materials in Pro 3 Construction

The choice of robust materials is crucial for ensuring longevity and reliability in modern constructions. High-quality components not only enhance performance but also contribute to the overall efficiency and safety of the system. The use of advanced materials can significantly reduce wear and tear, ensuring that structures remain functional for extended periods.

Key Features of Durable Materials

- Resistance to Environmental Factors: Quality materials are designed to withstand various weather conditions, including moisture, UV exposure, and temperature fluctuations.

- Strength and Stability: Utilizing materials that offer high tensile strength ensures that the construction can endure heavy loads and resist deformation.

- Low Maintenance: Durable components require minimal upkeep, reducing long-term costs and enhancing user convenience.

Examples of Durable Materials

- High-Grade Plastics: Known for their lightweight and resistance to corrosion.

- Aluminum Alloys: Offer a great strength-to-weight ratio and excellent durability.

- Composite Materials: Combine the best properties of different substances for enhanced performance.