In the realm of heavy machinery, comprehending the intricate layout and functionality of each element is crucial for effective maintenance and repair. This knowledge not only enhances the performance of the machine but also extends its lifespan, ensuring that it operates at peak efficiency.

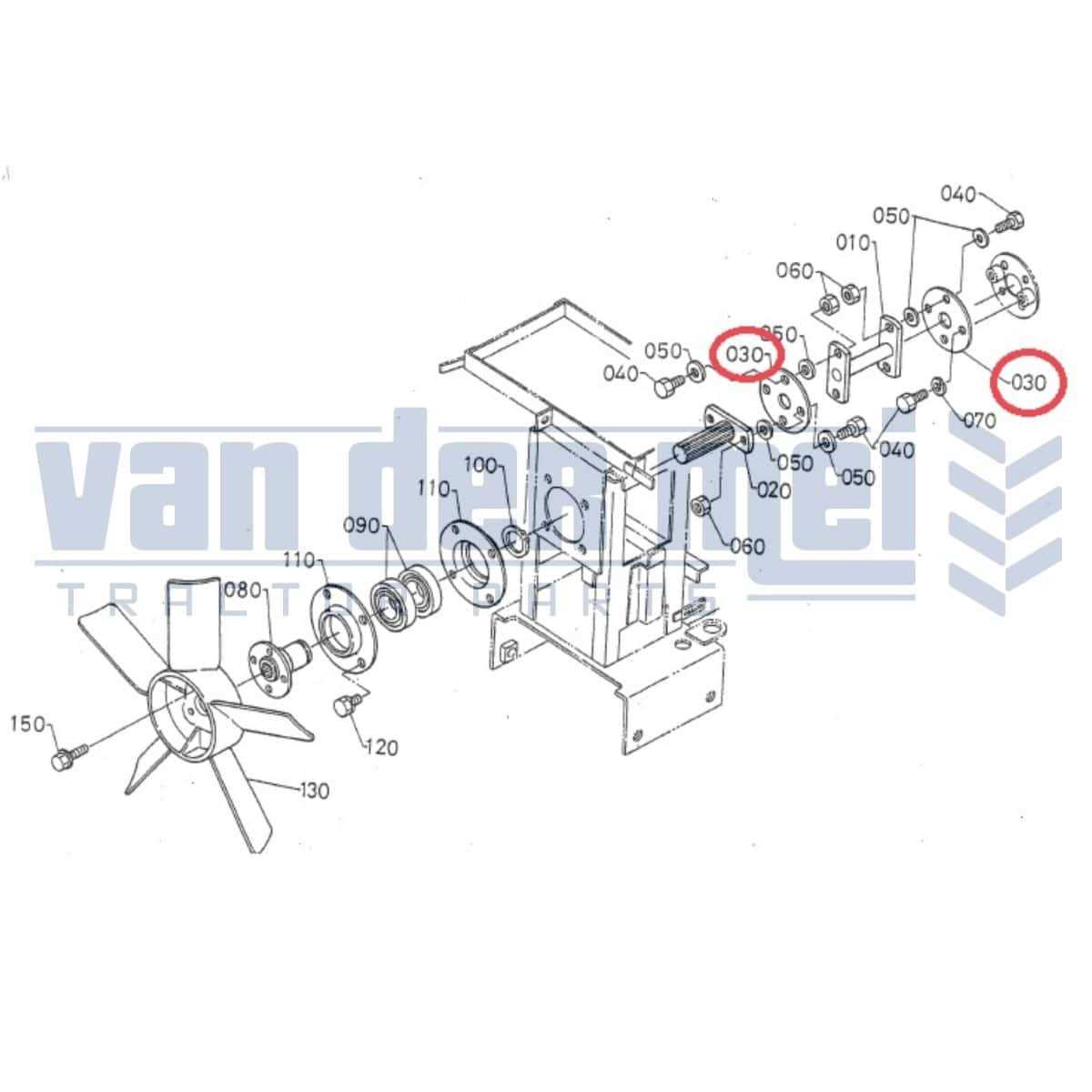

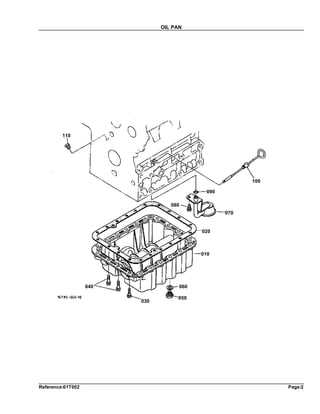

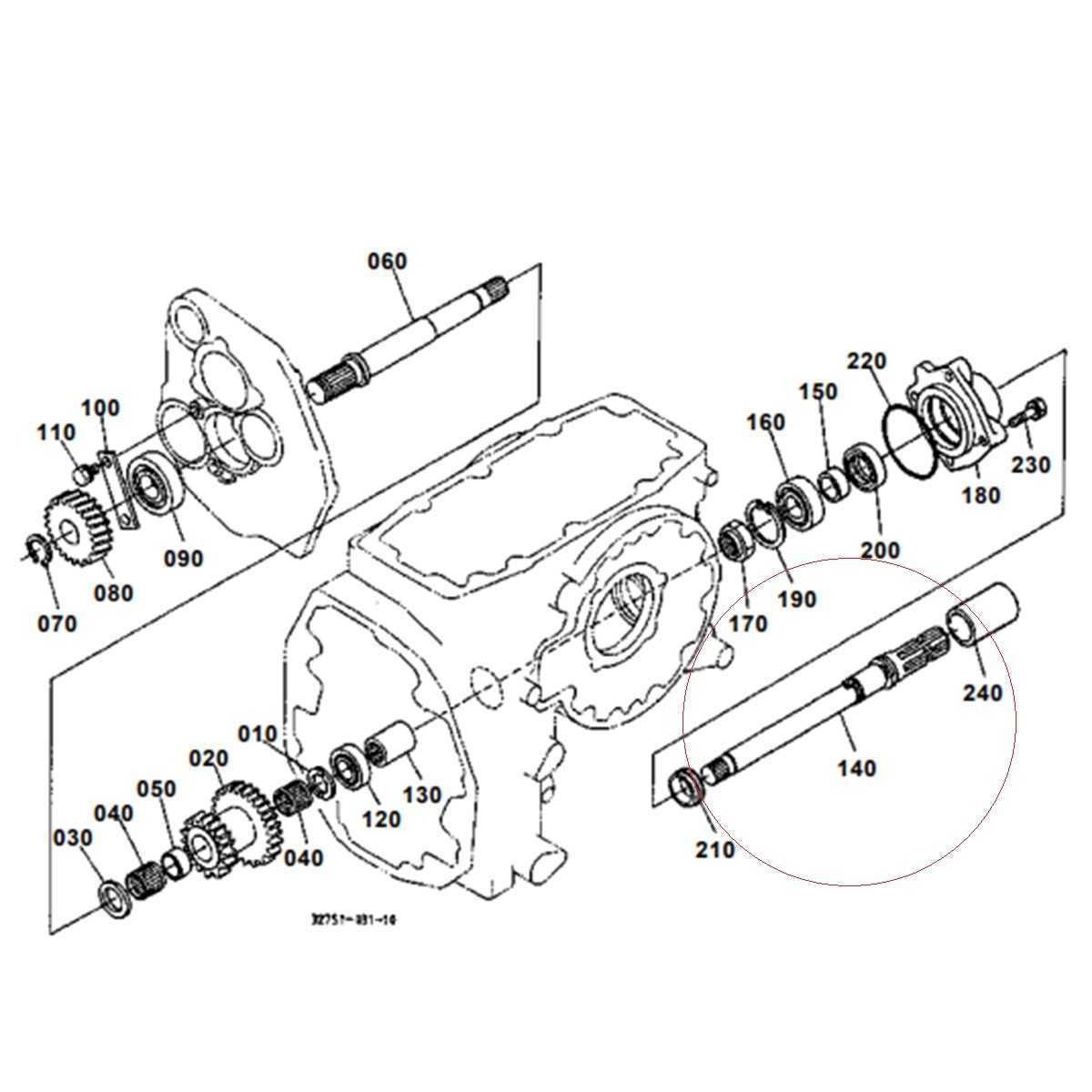

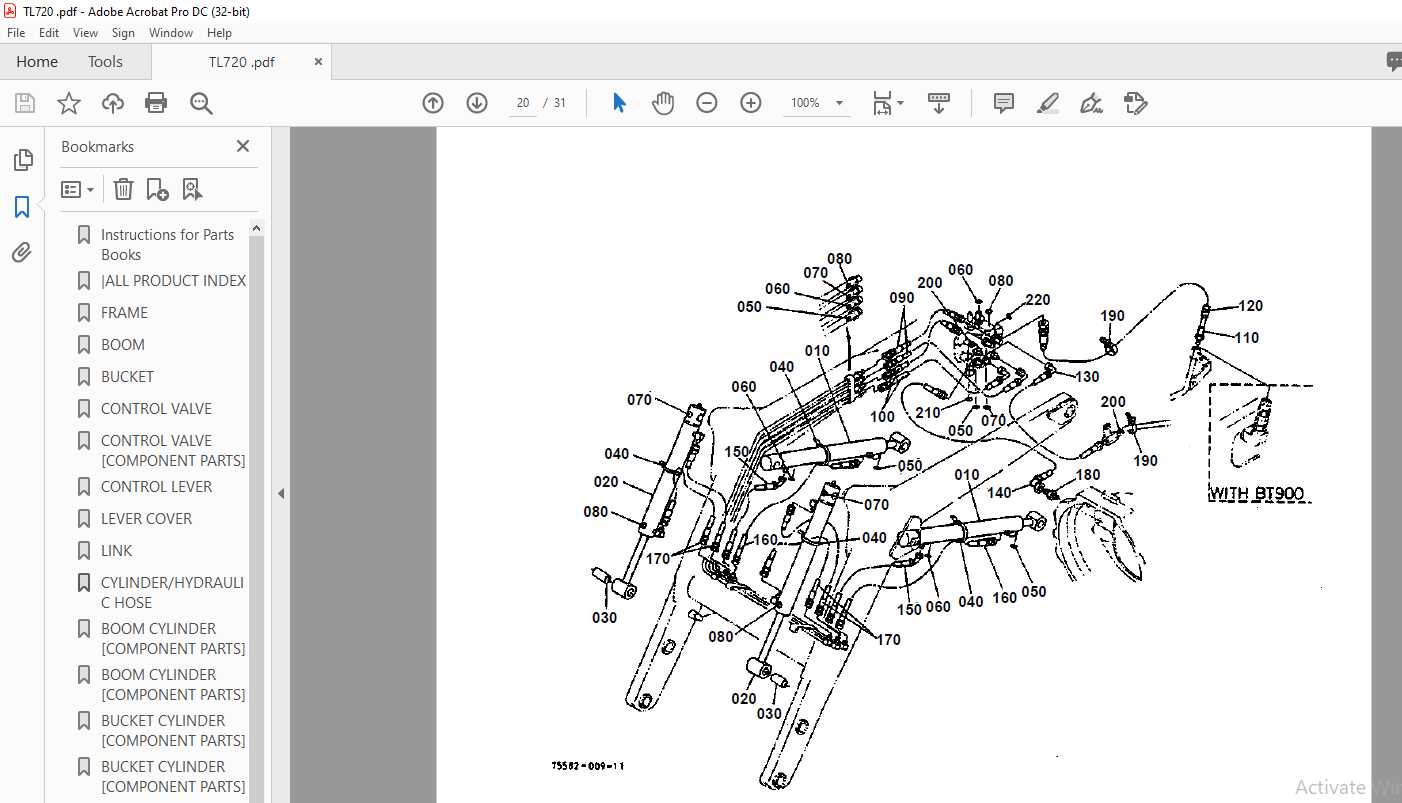

Detailed visual representations serve as valuable tools for technicians and enthusiasts alike. These illustrations provide clarity on the relationships between various components, simplifying the process of identifying and replacing parts when necessary. Understanding the specific arrangement of each piece empowers users to troubleshoot issues with confidence.

As we delve into the specifics of these mechanical systems, we will explore the unique characteristics of different elements, highlighting their roles and importance. With this information, operators can make informed decisions regarding maintenance and enhancements, ultimately optimizing the functionality of their equipment.

Parts Overview

This section provides a comprehensive look at the essential components of a popular machinery model, highlighting their functions and significance in overall performance. Understanding these elements is crucial for maintenance and efficient operation.

Key Components

The primary elements include the engine, hydraulic system, and transmission, each playing a vital role in ensuring optimal functionality. Engine efficiency directly impacts power output, while the hydraulic system is essential for operation versatility. The transmission facilitates smooth movement and power transfer.

Maintenance Considerations

Regular inspection and replacement of worn components are critical for longevity and reliability. Staying informed about compatible replacements ensures that users can maintain their equipment in top condition, thus enhancing productivity.

Importance of Parts Diagrams

Understanding the intricate layout of machinery components is essential for effective maintenance and repair. Visual representations serve as vital tools, enabling operators and technicians to identify each element’s function and relationship within the overall system.

Efficiency in troubleshooting significantly increases when users have access to clear illustrations. These resources help in pinpointing specific issues quickly, reducing downtime and associated costs. Furthermore, they facilitate informed decision-making regarding repairs or replacements.

Training new personnel becomes more straightforward with detailed visuals. Learners can better grasp complex systems when they can reference accurate illustrations, fostering a deeper comprehension of machinery operations.

Additionally, having a comprehensive visual guide can enhance communication among team members. When everyone references the same resource, misunderstandings diminish, leading to more cohesive and effective teamwork.

In summary, the value of well-constructed visual aids cannot be overstated. They serve as essential references that streamline operations, improve education, and promote collaboration in the maintenance of mechanical systems.

Key Components of Kubota L35

The essential elements of this compact machinery play a vital role in its performance and functionality. Understanding these core components is crucial for effective maintenance and operation, ensuring the equipment runs smoothly and efficiently over time.

Engine: The heart of the machine, the engine provides the necessary power to drive various functions. Its design focuses on reliability and fuel efficiency, making it suitable for a range of tasks.

Hydraulic System: This system enables precise control of attachments and implements, allowing for enhanced versatility. By utilizing hydraulic fluid under pressure, it facilitates smooth operation and quick response times.

Transmission: A robust transmission system is responsible for transferring power from the engine to the wheels. Its design ensures optimal performance in different terrain conditions, making it adaptable to various environments.

Chassis: The sturdy framework supports all components and provides stability during operation. Its design considers load distribution, ensuring safety and durability while working on uneven surfaces.

Operator Controls: Intuitive controls enhance the user experience, allowing for easy operation. Ergonomically designed, they ensure comfort and efficiency, enabling operators to focus on the task at hand.

Understanding these key elements not only aids in effective operation but also extends the lifespan of the machinery, ensuring it remains a valuable asset for years to come.

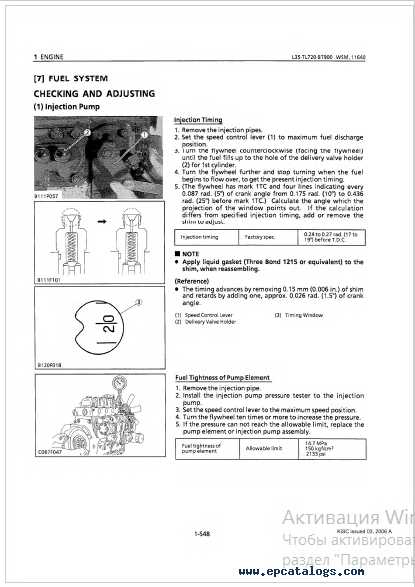

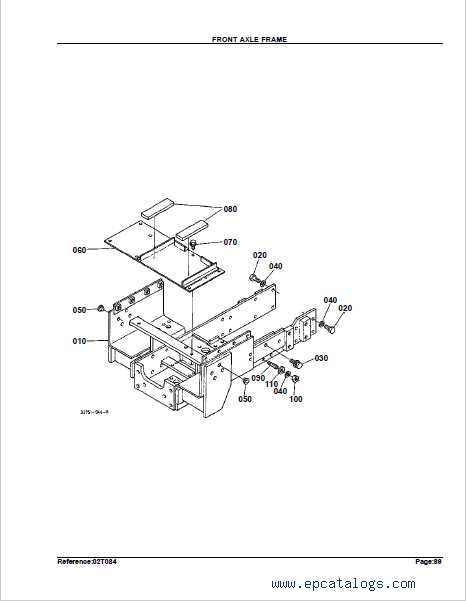

How to Read Parts Diagrams

Understanding illustrations that depict various components of machinery can significantly enhance maintenance and repair efficiency. These visual representations offer a clear layout of elements, making it easier to identify specific items and their interrelationships.

First, familiarize yourself with the legend or key that accompanies the illustration. This will provide essential information on symbols and numbering used throughout the representation. Each symbol typically corresponds to a specific component, allowing for quick reference.

Next, take note of the orientation and layout of the components. Understanding the spatial arrangement helps in visualizing how parts fit together and interact. Pay attention to any groupings, as they may indicate assemblies or systems within the machinery.

Finally, refer to any supplementary notes or specifications that might accompany the illustration. These often include crucial details regarding dimensions, material types, or maintenance tips, providing a comprehensive understanding of the components in question.

Common Replacement Parts for L35

Regular maintenance and timely replacement of components are essential for ensuring optimal performance and longevity of heavy machinery. Understanding which elements are frequently worn out can help operators prepare and minimize downtime. This section highlights the most commonly replaced components for efficient operation.

One of the crucial elements that often require attention is the hydraulic filter. A clean filter ensures proper fluid flow and protects the system from contaminants, ultimately enhancing the machine’s efficiency.

Another frequently replaced item is the oil filter. Regular changes of this component are vital to maintaining engine health and preventing damage caused by impurities in the lubrication system.

Additionally, the drive belts should be monitored regularly. Worn or frayed belts can lead to significant power loss and potential system failure, making timely replacement imperative.

Moreover, the battery is a key part that may need replacement due to age or usage patterns. Ensuring a reliable power source is critical for starting and operating various electrical components.

Finally, keeping an eye on the tires is essential for maintaining traction and stability. Worn tires can affect overall performance and safety, thus requiring periodic replacement to ensure optimal functionality.

Benefits of Genuine Kubota Parts

Using authentic components for machinery maintenance ensures optimal performance and longevity. These quality elements are designed to fit seamlessly, enhancing the overall efficiency of equipment. By investing in original items, operators can avoid complications and ensure their machines run smoothly.

Reliability and Durability

Authentic items are manufactured to meet stringent standards, offering superior reliability. Their durability reduces the need for frequent replacements, leading to lower operational costs in the long run.

Enhanced Performance

Original components are engineered for specific models, providing enhanced functionality. This precision leads to improved output and efficiency, ensuring that machines perform at their ultimate best.

Where to Find L35 Parts Diagrams

Locating detailed schematics for machinery components can be essential for maintenance and repairs. Understanding where to access these visual aids helps ensure that tasks are performed efficiently and correctly. Various resources are available, each offering unique benefits for users seeking to enhance their knowledge of equipment layouts.

Manufacturer Websites: The official websites often provide a wealth of information, including downloadable resources that illustrate the structure of various models. These platforms usually feature user manuals and maintenance guides that include comprehensive visuals.

Online Forums and Communities: Engaging with fellow enthusiasts and professionals on specialized forums can be incredibly valuable. Members frequently share links and resources, making it easier to obtain the necessary schematics for specific machinery.

Retailers and Dealers: Authorized dealers often have access to extensive parts catalogs. Visiting these locations or their online portals can yield high-quality illustrations that assist in identifying components and understanding assembly.

Aftermarket Resource Providers: Several companies specialize in aftermarket materials that cater to various machinery. These resources often include detailed visual aids that can serve as alternatives to original schematics.

Service Centers: Local repair shops and service centers often have reference materials that detail machinery layouts. Building a relationship with these professionals can provide access to crucial information and expert advice.

Understanding Part Numbers

In the world of machinery, identifying components can often seem daunting due to the complex systems in place. Each item is assigned a unique identifier that serves as a key to understanding its specifications, compatibility, and purpose within the larger assembly. This section delves into the significance of these identifiers and how they facilitate efficient repairs and maintenance.

Importance of Identifiers

Unique identifiers are crucial for ensuring that the correct elements are sourced and installed. They help prevent confusion that may arise from similar-looking items and ensure that every component fits seamlessly into the machine. By referencing these numbers, operators and technicians can quickly access relevant documentation, including specifications and installation guides.

Decoding the Structure

The format of these unique identifiers often reveals important information about the item. For example, certain sections of the number might indicate the type of component, while others may specify the model or the manufacturing date. Understanding this structure not only aids in identifying the right part but also enhances the overall efficiency of machinery management.

In summary, familiarizing oneself with these unique identifiers is essential for anyone involved in the upkeep and operation of machinery. It simplifies the process of finding and ordering the necessary components, ensuring that everything runs smoothly.

Maintenance Tips for Kubota L35

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. By following a few key practices, you can enhance performance and minimize the risk of unexpected breakdowns. Implementing a routine check and addressing minor issues promptly can save time and resources in the long run.

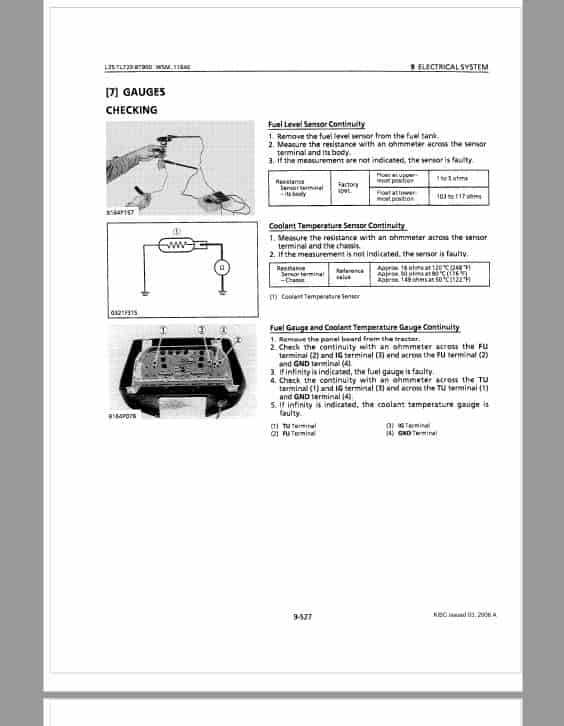

Fluid Checks and Changes

Consistently monitor all fluid levels, including engine oil, coolant, and hydraulic fluids. Regularly replacing these fluids based on the manufacturer’s recommendations will prevent wear and tear, ensuring that the equipment runs smoothly and efficiently.

Inspection of Wear Parts

Periodically inspect components that experience significant wear, such as filters, belts, and hoses. Replacing these items before they fail can avert costly repairs and keep the machinery operating at peak performance. Staying proactive is key to successful maintenance.

Identifying Wear and Tear

Recognizing signs of degradation is crucial for maintaining machinery efficiency and longevity. By understanding common indicators of wear, operators can address issues before they escalate, ensuring optimal performance and reducing the risk of costly repairs.

Common Indicators of Degradation

Operators should be vigilant for various symptoms that may signal wear. These include unusual noises, vibrations, leaks, and changes in performance. Regular inspections can help pinpoint these issues early on.

Inspection Checklist

| Indicator | Description | Action |

|---|---|---|

| Unusual Noises | Grinding, rattling, or squeaking sounds | Investigate and service affected components |

| Vibrations | Excessive shaking during operation | Check for loose or damaged parts |

| Fluid Leaks | Any visible leakage of oils or fluids | Identify source and replace seals or gaskets |

| Performance Changes | Decreased power or responsiveness | Assess and tune engine or system components |

Using Diagrams for Repairs

Utilizing visual representations can significantly enhance the repair process for machinery. These illustrations provide clarity, helping technicians understand the assembly and function of various components. By referencing these guides, one can streamline troubleshooting and ensure accurate reassembly.

Benefits of Visual Aids

Visual aids allow for quick identification of parts, reducing the time spent searching for specific components. They also help in comprehending complex systems, making repairs more efficient and less prone to error.

How to Effectively Use Illustrations

To make the most of these resources, follow a systematic approach. Begin by locating the appropriate visual aid, then carefully analyze the layout to understand how parts interact. This method can lead to successful repairs and maintenance.

| Step | Description |

|---|---|

| 1 | Identify the issue with the equipment. |

| 2 | Find the corresponding visual representation. |

| 3 | Analyze the parts and their connections. |

| 4 | Proceed with the necessary repairs. |

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionalities. Understanding these elements can enhance your overall experience and efficiency when maintaining or repairing machinery.

Common Queries

| Question | Answer |

|---|---|

| How do I identify the right component for my machinery? | Consult your user manual or online resources for specific model numbers and descriptions. |

| What should I consider when purchasing replacements? | Quality, compatibility, and warranty are essential factors to ensure longevity and performance. |

Maintenance Tips

Regular checks and timely replacements can significantly prolong the lifespan of your equipment. Stay proactive to avoid costly repairs.

Resources for Kubota Owners

For enthusiasts and operators of compact machinery, having access to reliable information and quality resources is essential for maintaining and enhancing performance. This section provides a variety of tools and references to ensure optimal operation and care for your equipment.

Here are some valuable resources to consider:

- Official Manuals: Always start with the manufacturer’s manuals. They provide detailed information on operation, maintenance, and troubleshooting.

- Online Forums: Join community forums where fellow users share experiences, tips, and solutions to common challenges.

- Parts Suppliers: Identify trusted suppliers that offer a wide range of components and accessories, ensuring you find what you need easily.

- Instructional Videos: Platforms like YouTube feature numerous tutorials, demonstrating repairs and maintenance procedures.

- Local Dealerships: Establish a relationship with your nearest dealership for expert advice and assistance with parts and service.

- Maintenance Checklists: Utilize checklists for routine maintenance tasks to keep your machinery in top shape.

- Trade Magazines: Subscribe to industry publications that cover the latest news, innovations, and best practices in equipment management.

Leveraging these resources can enhance your understanding and efficiency, ensuring your machinery serves you well for years to come.