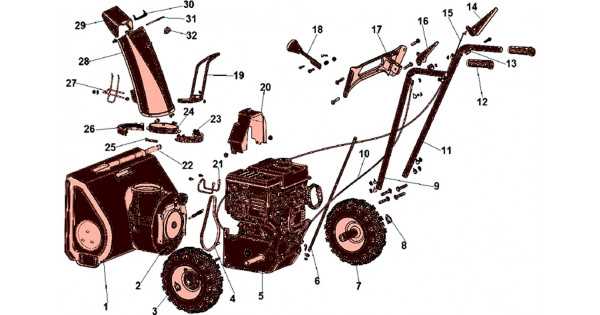

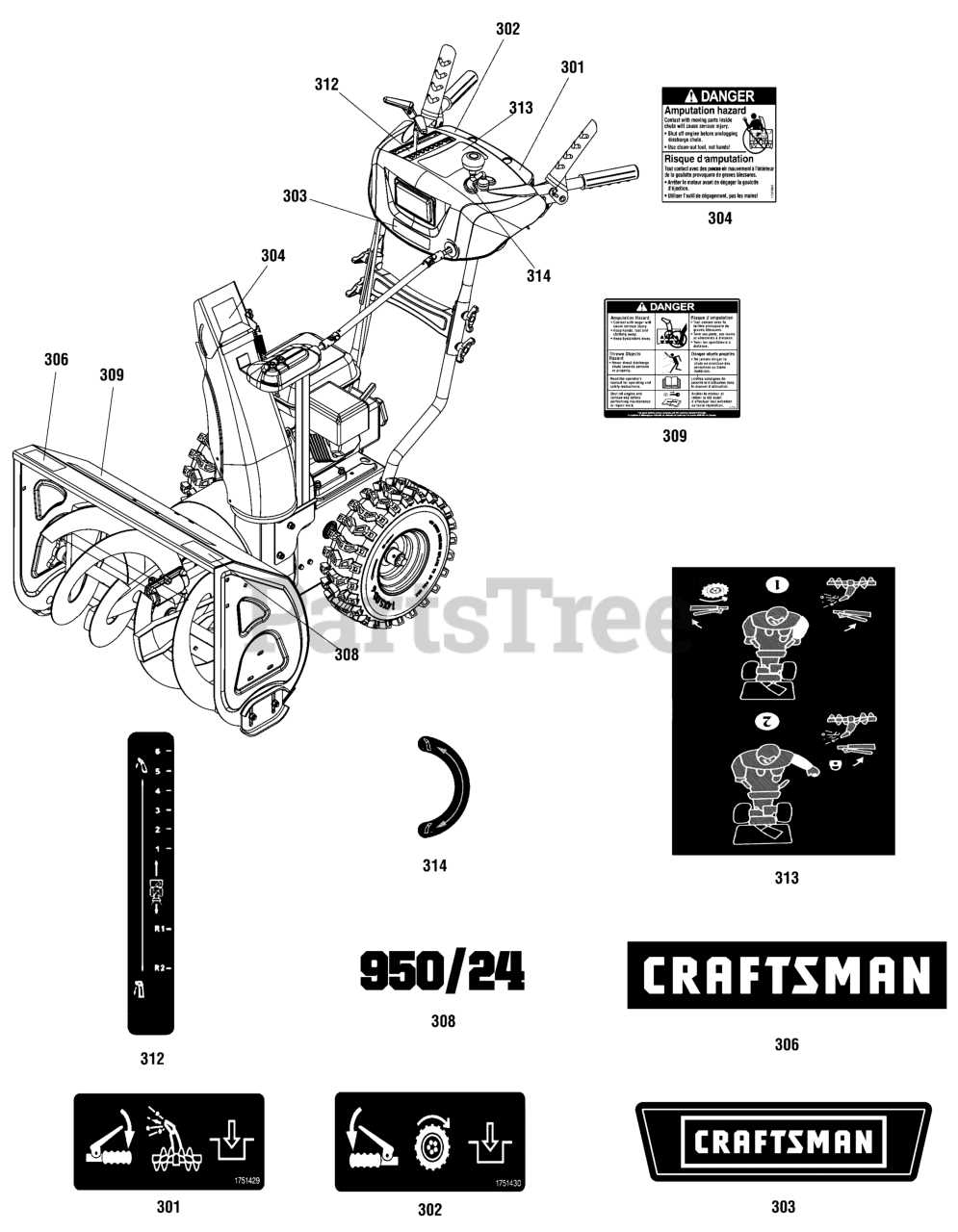

When it comes to maintaining your snow removal device, having a clear visual representation of its components can be invaluable. This guide offers insights into the various elements that make up your equipment, allowing you to identify, replace, and troubleshoot effectively. Understanding the arrangement and function of each part ensures a smoother operation during those heavy winter months.

Each segment of your clearing machine plays a crucial role in its overall performance. Familiarizing yourself with the layout not only aids in repairs but also enhances your ability to optimize the machine’s capabilities. Whether you’re a seasoned user or a newcomer, having this knowledge at your fingertips can lead to improved efficiency and longevity of the equipment.

In addition to identifying the structure, knowing how to access and maintain these components will contribute significantly to the reliability of your snow removal system. Regular checks and timely replacements will ensure that your equipment remains in top condition, ready to tackle the harshest winter weather.

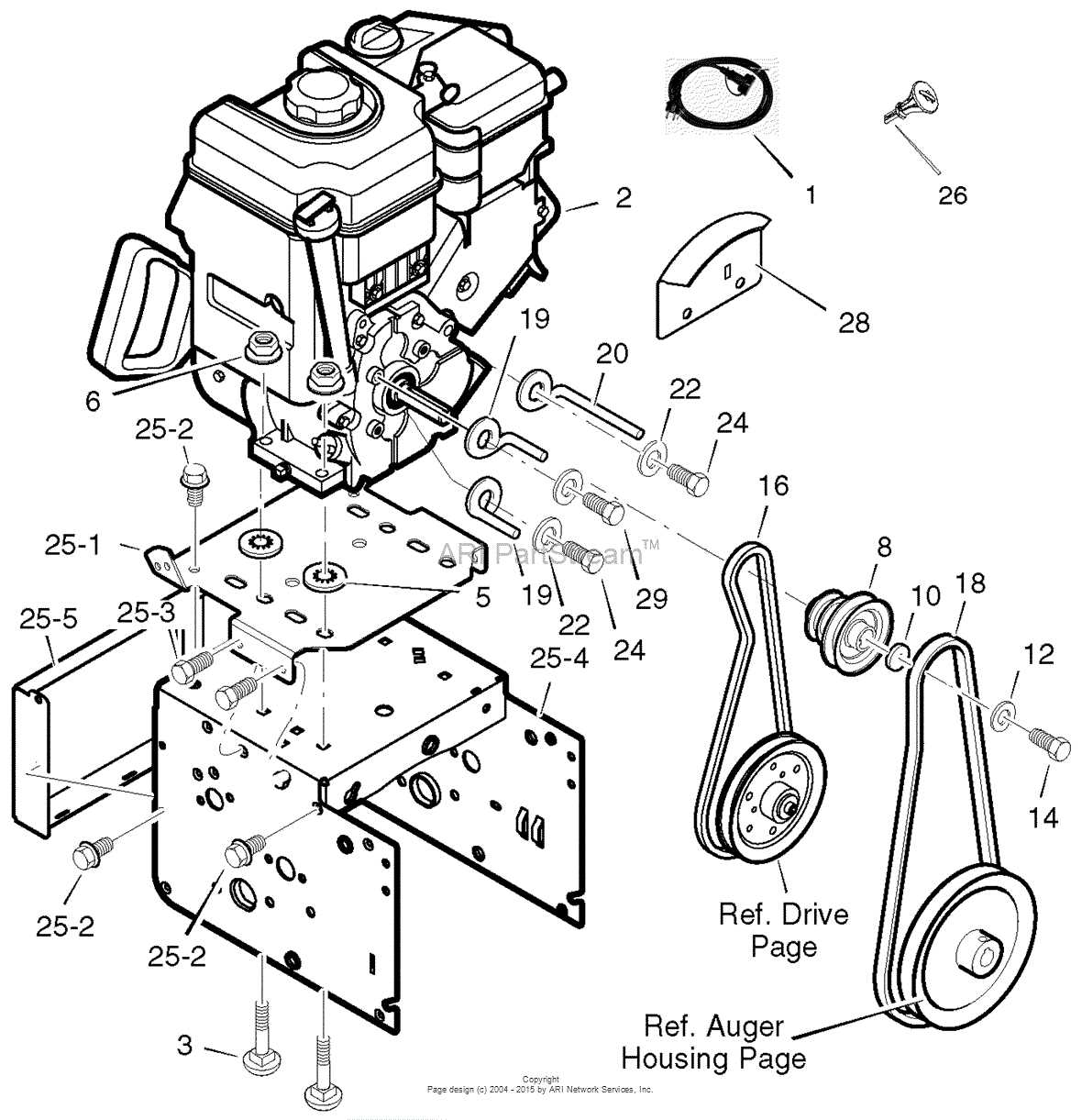

To ensure the best performance of your winter equipment, it is crucial to recognize and understand its fundamental components. These elements work harmoniously to provide efficiency and reliability during operation. A thorough knowledge of each component can help in troubleshooting and maintenance.

Key components that contribute to optimal functionality include:

- Engine: The powerhouse that drives all operations.

- Auger: Designed to gather and propel snow away from the pathway.

- Chassis: The sturdy frame that supports all parts and ensures stability.

- Drive System: Enables movement and control of the machine.

- Control Panel: The interface that allows the operator to manage settings and functions.

- Wheels or Tracks: Provide traction and maneuverability on various surfaces.

Regular inspection and maintenance of these critical components can significantly extend the lifespan of your equipment and enhance its performance during heavy snowfall. Prioritizing these aspects is essential for anyone looking to maintain their machinery in peak condition.

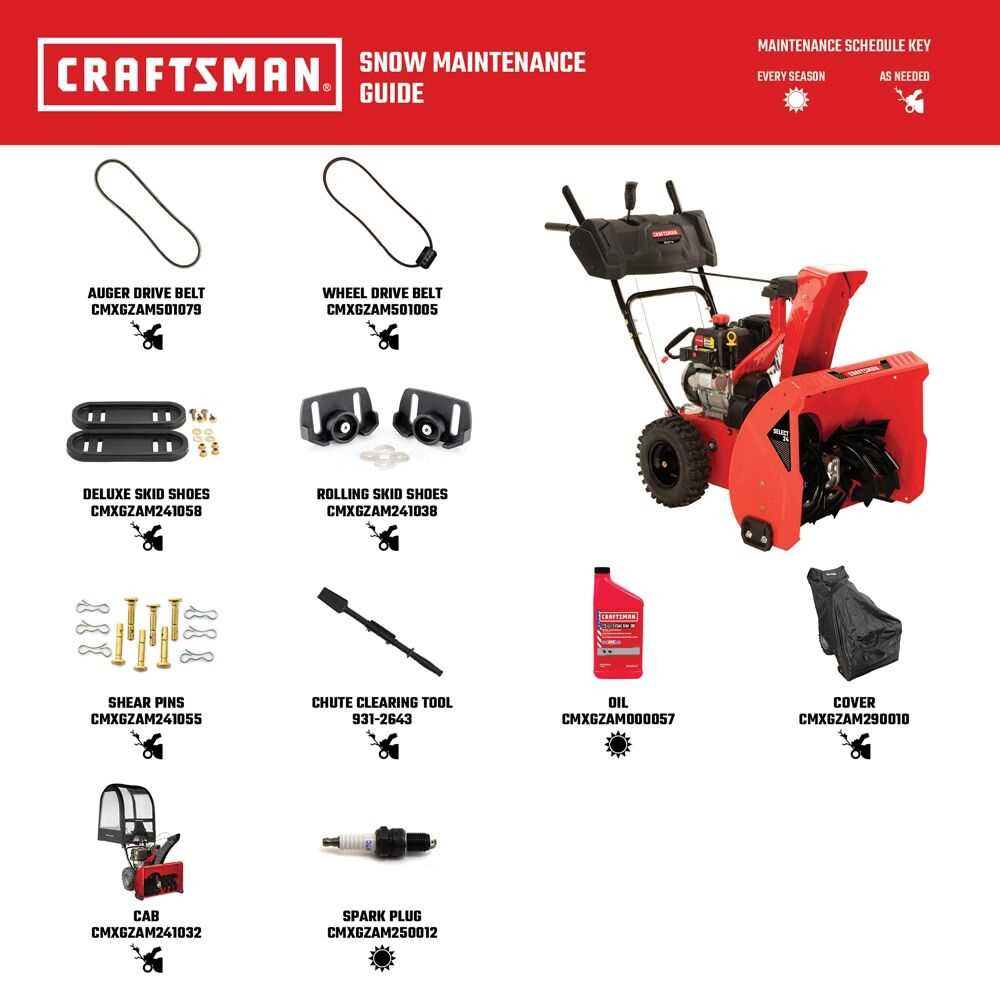

Common Repair and Replacement Items

Maintaining a reliable outdoor equipment unit requires attention to various components that may wear out over time. Identifying the essential elements for repair or replacement can enhance performance and prolong the life of the machine. Understanding these common items helps users make informed decisions when servicing their units.

| Component | Description | Signs of Wear |

|---|---|---|

| Drive Belt | Transfers power from the engine to the wheels, facilitating movement. | Slipping, fraying, or unusual noises during operation. |

| Auger Blade | Used for breaking up and clearing snow efficiently. | Dull edges, visible cracks, or difficulty in snow removal. |

| Shear Pins | Designed to protect the auger from damage by breaking under excessive stress. | Frequent breaking or missing pins after use. |

| Fuel Filter | Prevents dirt and debris from entering the engine. | Engine stalling or poor performance. |

| Spark Plug | Ignites the air-fuel mixture for combustion. | Hard starting or misfiring engine. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life and optimal performance of your outdoor equipment. By following a few straightforward practices, you can significantly enhance the durability and reliability of your machinery. Consistent maintenance not only helps prevent breakdowns but also improves efficiency, allowing you to tackle seasonal tasks with ease.

Routine Inspection

Conducting frequent checks on your equipment can help identify potential issues before they escalate. Examine critical components such as the engine, belts, and cables for any signs of wear or damage. Cleaning debris from the machine after each use will also promote better airflow and prevent overheating.

Lubrication and Storage

Proper lubrication of moving parts is vital for smooth operation. Use suitable oils and greases as recommended by the manufacturer. Additionally, when the season ends, ensure that your machinery is stored in a dry, sheltered location to protect it from environmental factors that could cause rust or degradation.

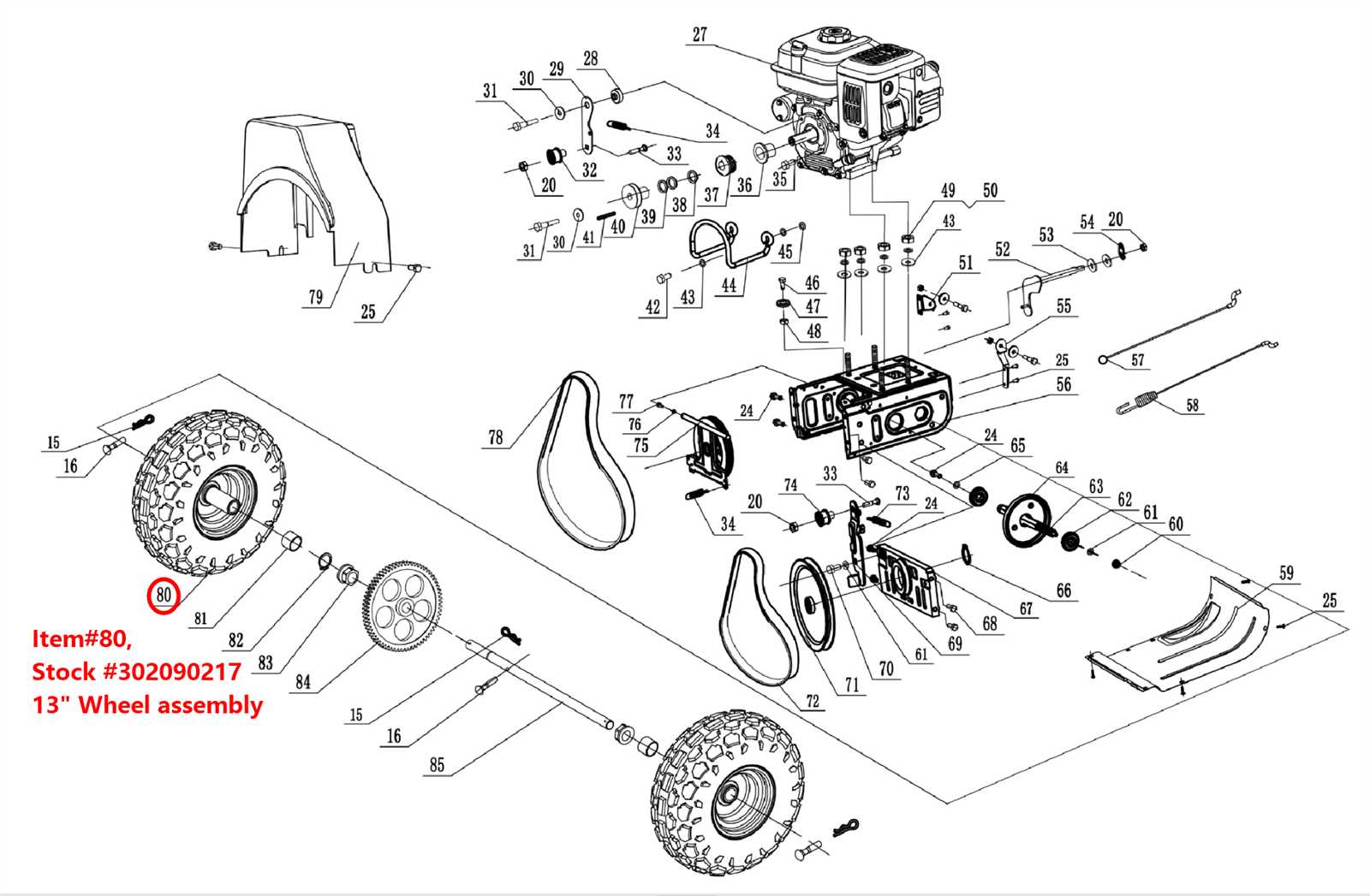

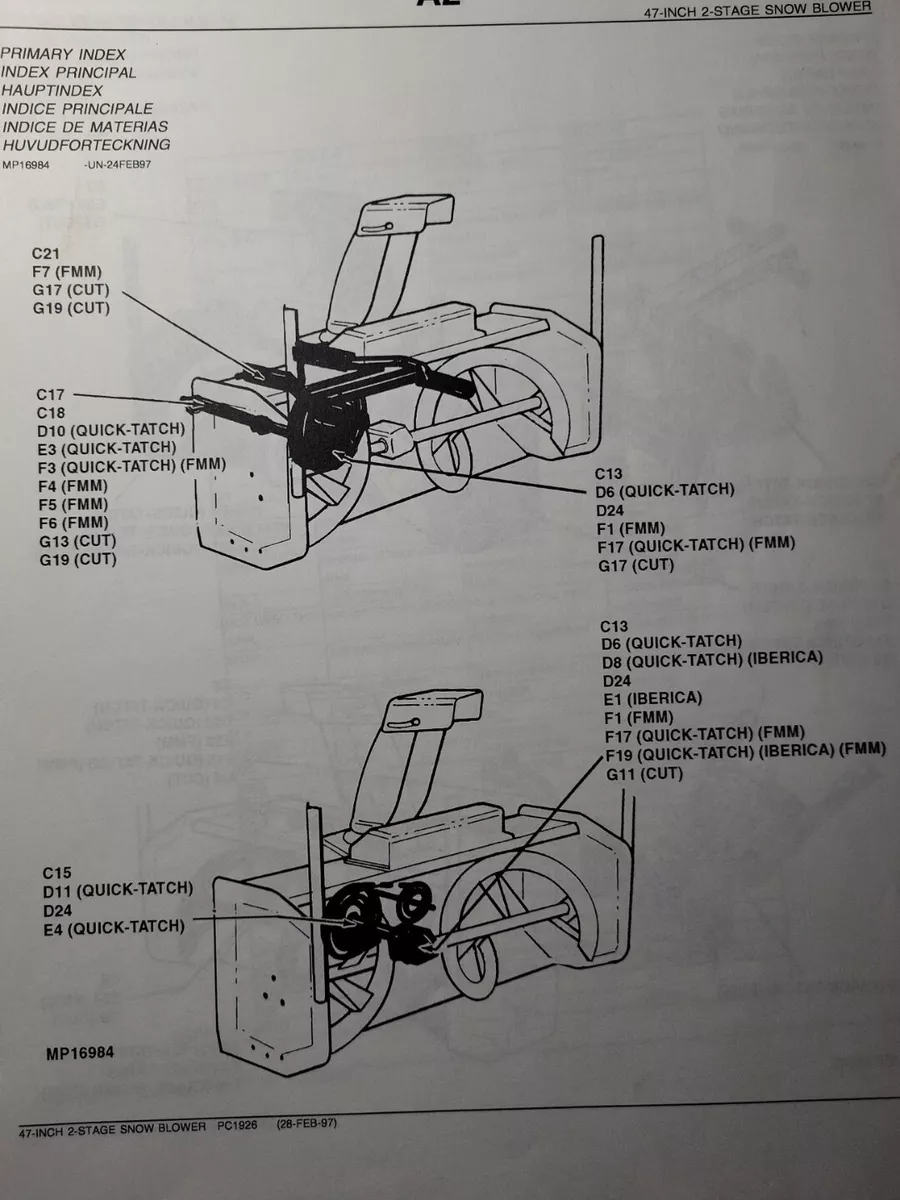

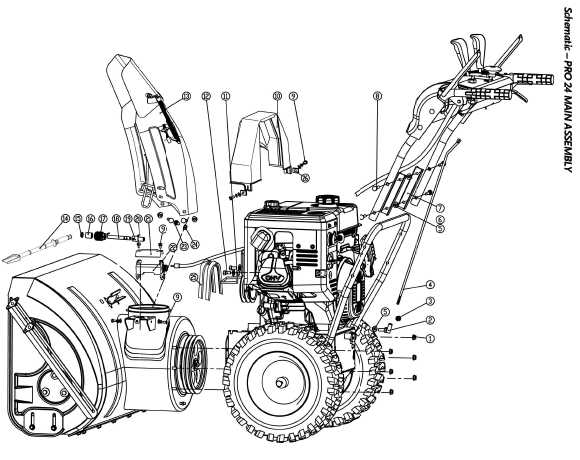

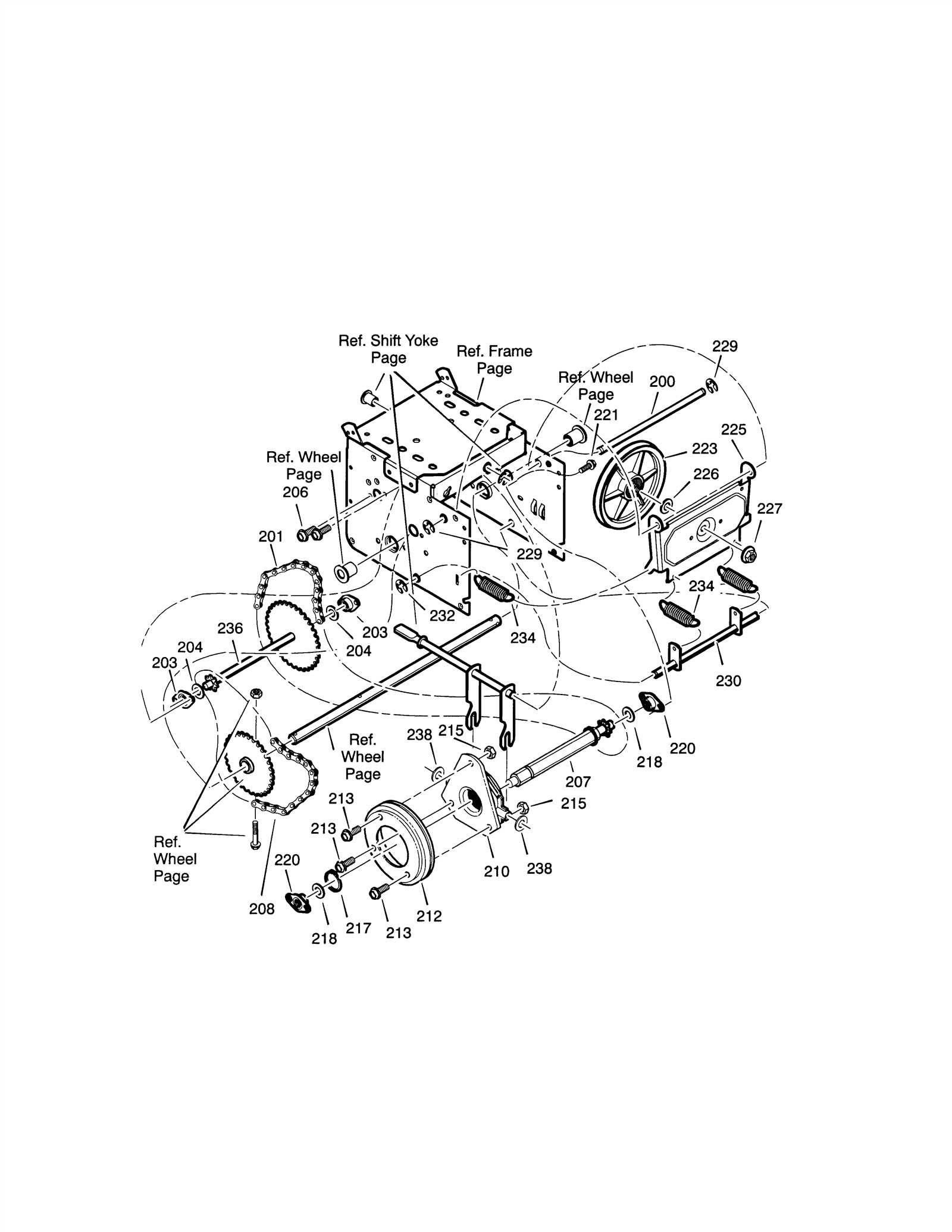

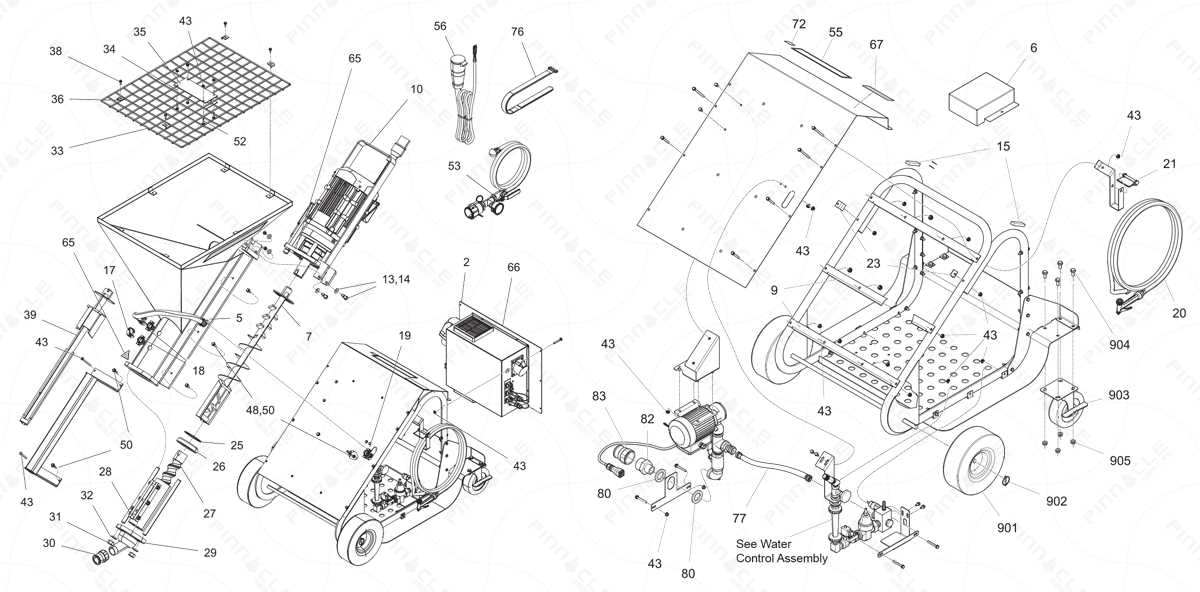

Understanding the Parts List

Having a clear grasp of the components involved in any machinery is essential for efficient maintenance and troubleshooting. A comprehensive inventory of these elements allows users to identify replacements easily and understand the overall functionality of their equipment.

Key Components

Each mechanism consists of various vital units that work in harmony. These essential sections can include engines, belts, and control levers, among others. Familiarity with these critical parts not only enhances operational efficiency but also extends the lifespan of the machine.

Benefits of Knowing the Components

Being knowledgeable about the specific elements of your equipment can significantly reduce downtime during repairs. Identifying the correct replacements swiftly minimizes disruptions, allowing you to return to your tasks more quickly. Additionally, a thorough understanding helps in preventive maintenance, ultimately saving time and resources.

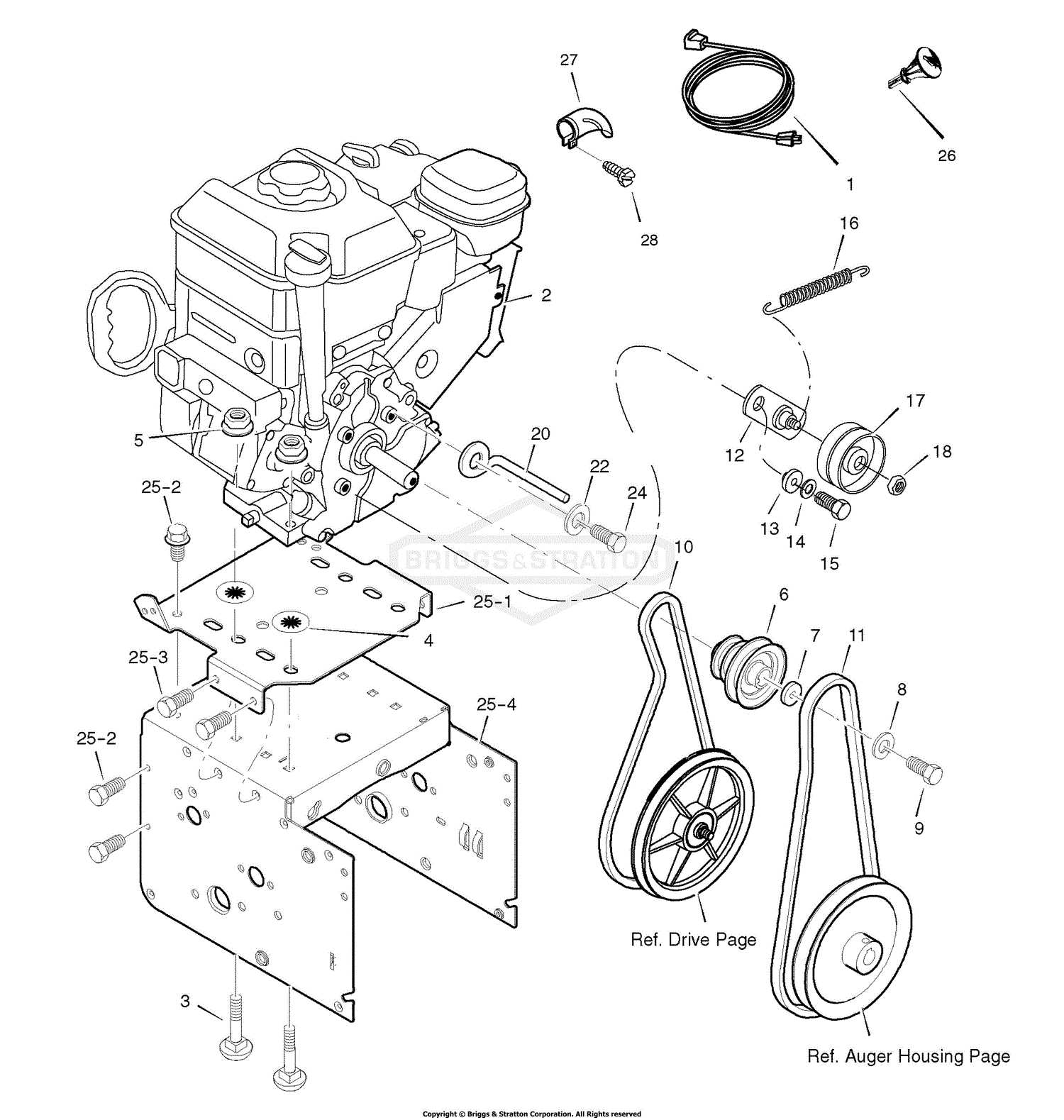

Diagram Analysis for Efficiency

Understanding the layout of components in machinery can significantly enhance operational effectiveness. By examining the arrangement and interaction of elements, one can identify potential improvements and ensure optimal performance. This section focuses on dissecting the structural representation of equipment to promote better maintenance and functionality.

When analyzing the layout, several key factors contribute to overall efficiency:

- Component Placement: The positioning of each element affects accessibility and ease of maintenance.

- Functional Relationships: Identifying how components interact can reveal areas for enhancement or adjustment.

- Streamlined Design: A well-organized structure can reduce the risk of mechanical failure and improve reliability.

To facilitate a comprehensive evaluation, consider the following steps:

- Review the configuration of elements thoroughly.

- Assess the accessibility of each component for maintenance purposes.

- Identify any redundancies that may be eliminated to optimize performance.

- Implement necessary changes based on the analysis to enhance overall operation.

In conclusion, a thorough examination of the component layout can lead to increased efficiency, reduced downtime, and prolonged equipment lifespan.

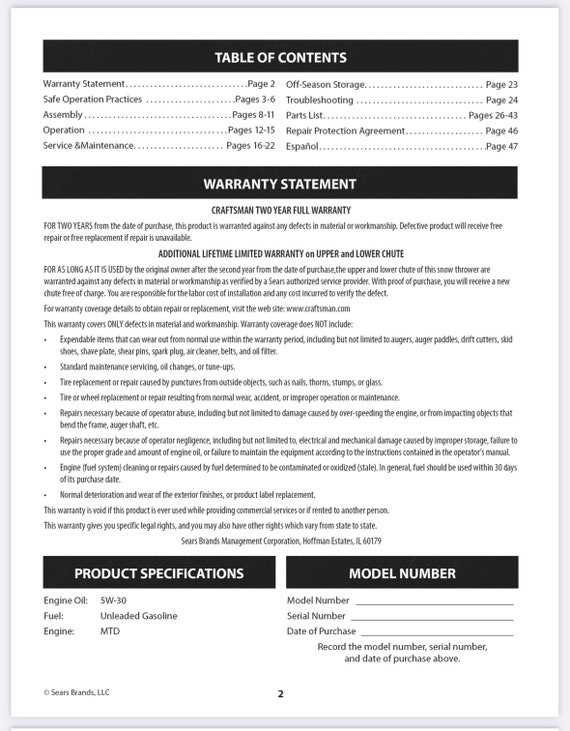

Comparing Different Model Specifications

When selecting a snow-clearing machine, it’s essential to evaluate the specifications of various models to determine which best suits your needs. Each variant may come equipped with distinct features, power capacities, and operational efficiencies that significantly influence performance in different conditions. Understanding these aspects helps users make informed decisions tailored to their specific requirements.

Key Features

The following table outlines the primary specifications of popular models, highlighting their differences and advantages.

| Model | Engine Power | Clearing Width | Weight |

|---|---|---|---|

| Model A | 208cc | 24 inches | 150 lbs |

| Model B | 250cc | 26 inches | 160 lbs |

| Model C | 196cc | 22 inches | 140 lbs |

Performance Considerations

When comparing specifications, consider how each model’s characteristics impact performance. Higher engine power often correlates with improved capability in challenging conditions, while weight can influence maneuverability. Selecting the right model entails balancing these factors based on the typical weather conditions and terrain where the equipment will be used.

Where to Purchase Replacement Parts

Finding the right components for your outdoor equipment can be a straightforward task if you know where to look. Various sources are available, each offering a range of options to ensure your machine runs smoothly. Whether you’re seeking OEM items or aftermarket alternatives, understanding your purchasing options is essential.

Local Retailers

Many hardware stores and garden centers stock a selection of components for outdoor machinery. Visiting these establishments can provide immediate access to what you need. It’s advisable to call ahead to check availability or ask about specific items.

Online Suppliers

The internet offers a vast array of websites that specialize in equipment components. Shopping online can provide the convenience of home delivery and often a wider selection than local shops. Be sure to compare prices and read reviews before making a purchase.

| Source Type | Advantages | Considerations |

|---|---|---|

| Local Retailers | Immediate availability, personal assistance | Limited selection, potentially higher prices |

| Online Suppliers | Wider selection, home delivery | Shipping times, potential for return issues |

| Manufacturer’s Website | Authentic items, warranty options | Higher costs, limited to original components |

Tools Required for Disassembly

To effectively take apart your equipment, having the right tools is essential. Proper tools ensure a smooth process and help avoid any potential damage to the components. It’s important to be prepared with a suitable selection of instruments that can handle various fasteners and parts.

Begin by gathering basic hand tools, including screwdrivers with various head types and sizes, as well as a set of wrenches or socket sets for bolts and nuts. Additionally, pliers can be useful for gripping and twisting, while a torque wrench may be necessary for reassembling parts to specified tightness. A utility knife is also handy for cutting any securing materials or seals.

Lastly, keep a work surface clear and organized to lay out the tools and parts as you disassemble. This will not only aid in the efficiency of the process but also facilitate easier reassembly later on.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is vital for both efficiency and personal safety. Proper precautions can prevent accidents and injuries, making the repair process smoother and more effective.

- Wear Appropriate Gear: Always use safety glasses, gloves, and sturdy footwear to protect against injuries.

- Disconnect Power Sources: Before beginning any repair, ensure that the equipment is unplugged or the battery is removed to avoid accidental activation.

- Work in a Well-Ventilated Area: Proper airflow is essential, especially when working with tools that may produce fumes or require chemicals.

- Follow Manufacturer Instructions: Always refer to the guidelines provided in the user manual for specific safety recommendations related to your equipment.

- Keep the Workspace Organized: A clutter-free area minimizes the risk of tripping hazards and allows for efficient movement.

- Use the Right Tools: Ensure you have the appropriate tools for the job to avoid using makeshift alternatives that could lead to accidents.

By adhering to these safety measures, you can significantly reduce risks and ensure a more effective repair process.

Frequently Asked Questions

This section addresses common inquiries regarding a specific type of outdoor equipment designed for handling snow. Understanding the various components and their functions can help users maintain and troubleshoot their machines effectively.

What should I do if my equipment won’t start?

If your machinery fails to start, first ensure that the fuel tank is filled and that the battery is charged. Additionally, check the connections and look for any blockages in the fuel line. Regular maintenance can also prevent such issues.

How can I improve the performance of my device?

To enhance the efficiency of your unit, consider regularly sharpening the blades and inspecting the belts for wear and tear. Keeping the equipment clean and storing it properly during the off-season also contributes to optimal performance.

Finding Professional Repair Services

When it comes to maintaining your equipment, seeking expert assistance can be crucial. Professionals in the field can provide comprehensive support, ensuring that your machinery operates efficiently and safely. Utilizing specialized services can extend the life of your device and enhance its performance, ultimately saving you time and money in the long run.

Benefits of Hiring Experts

Engaging skilled technicians for repairs offers numerous advantages. These professionals possess in-depth knowledge and experience, enabling them to diagnose issues accurately and perform repairs effectively. Additionally, they often have access to high-quality tools and replacement components, ensuring that your equipment is serviced correctly.

Choosing the Right Service Provider

Finding the right repair service involves careful consideration. Look for companies with a solid reputation and positive customer feedback. It’s also beneficial to inquire about warranties on repairs and the availability of emergency services. By doing your research, you can find a provider that meets your specific needs.

| Criteria | Importance |

|---|---|

| Experience | High |

| Customer Reviews | Medium |

| Warranty on Services | High |

| Emergency Availability | Medium |