The intricate design and functionality of various mechanical assemblies play a crucial role in optimizing overall efficiency. A well-organized representation of these configurations allows for better understanding and streamlined maintenance, ensuring that each component performs at its peak. By examining how different elements interact, users can enhance their experience and extend the lifespan of their systems.

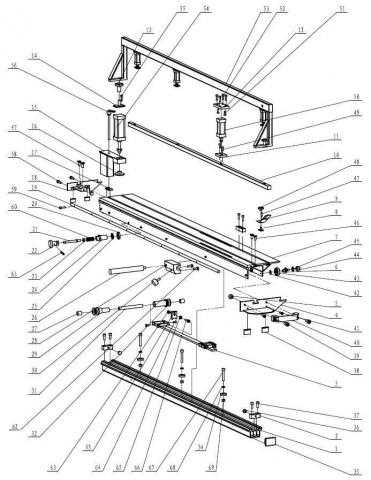

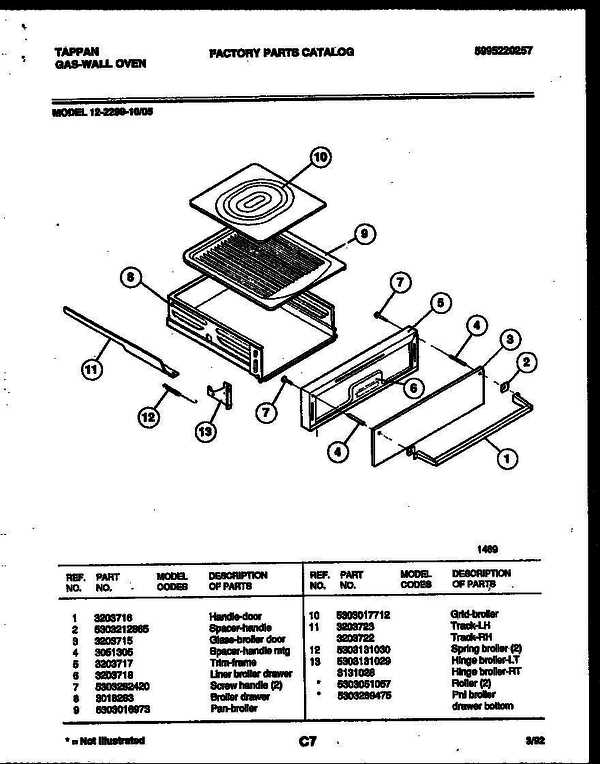

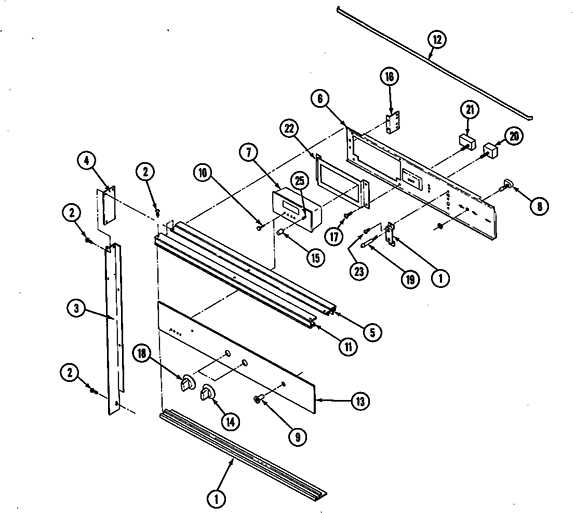

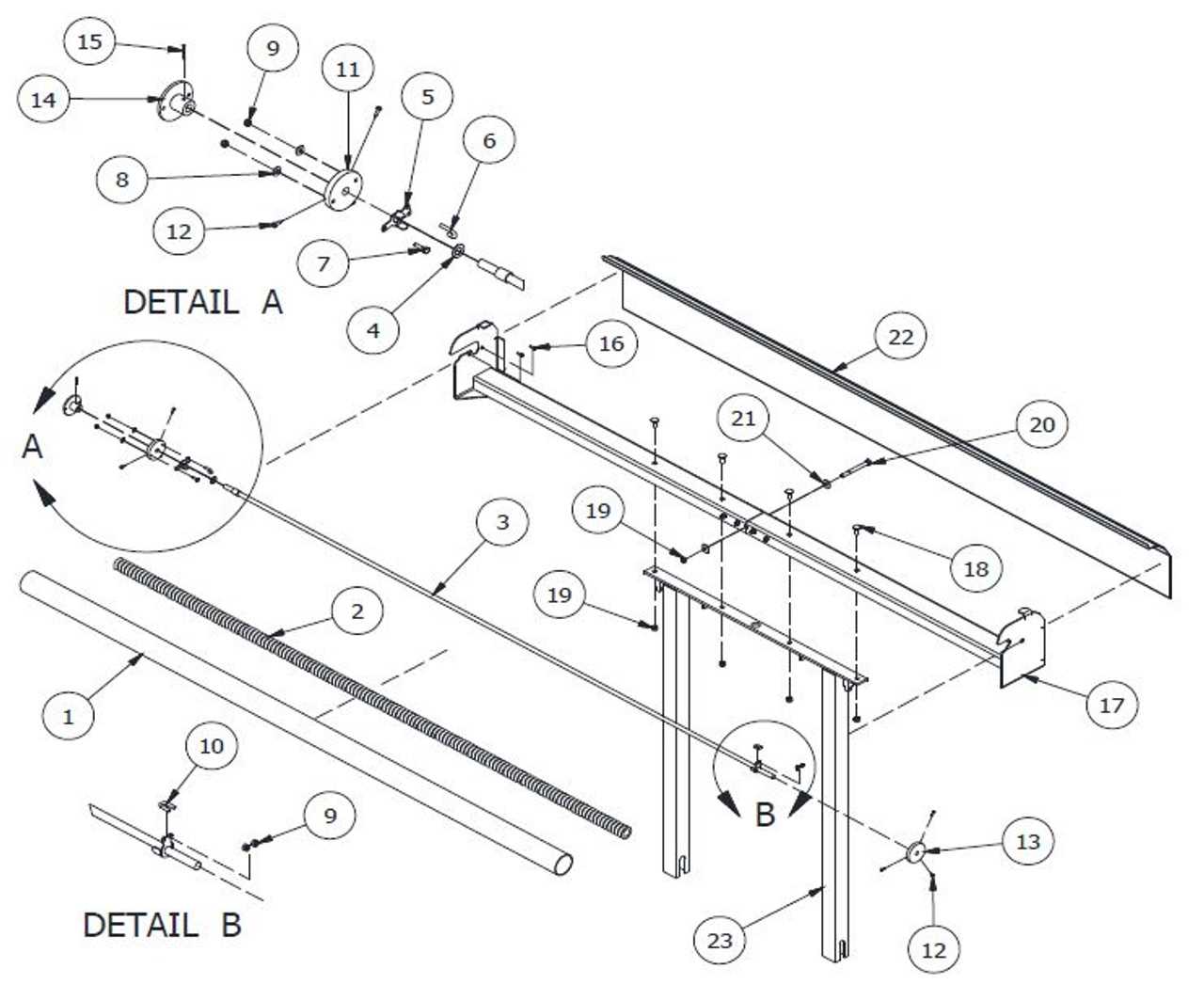

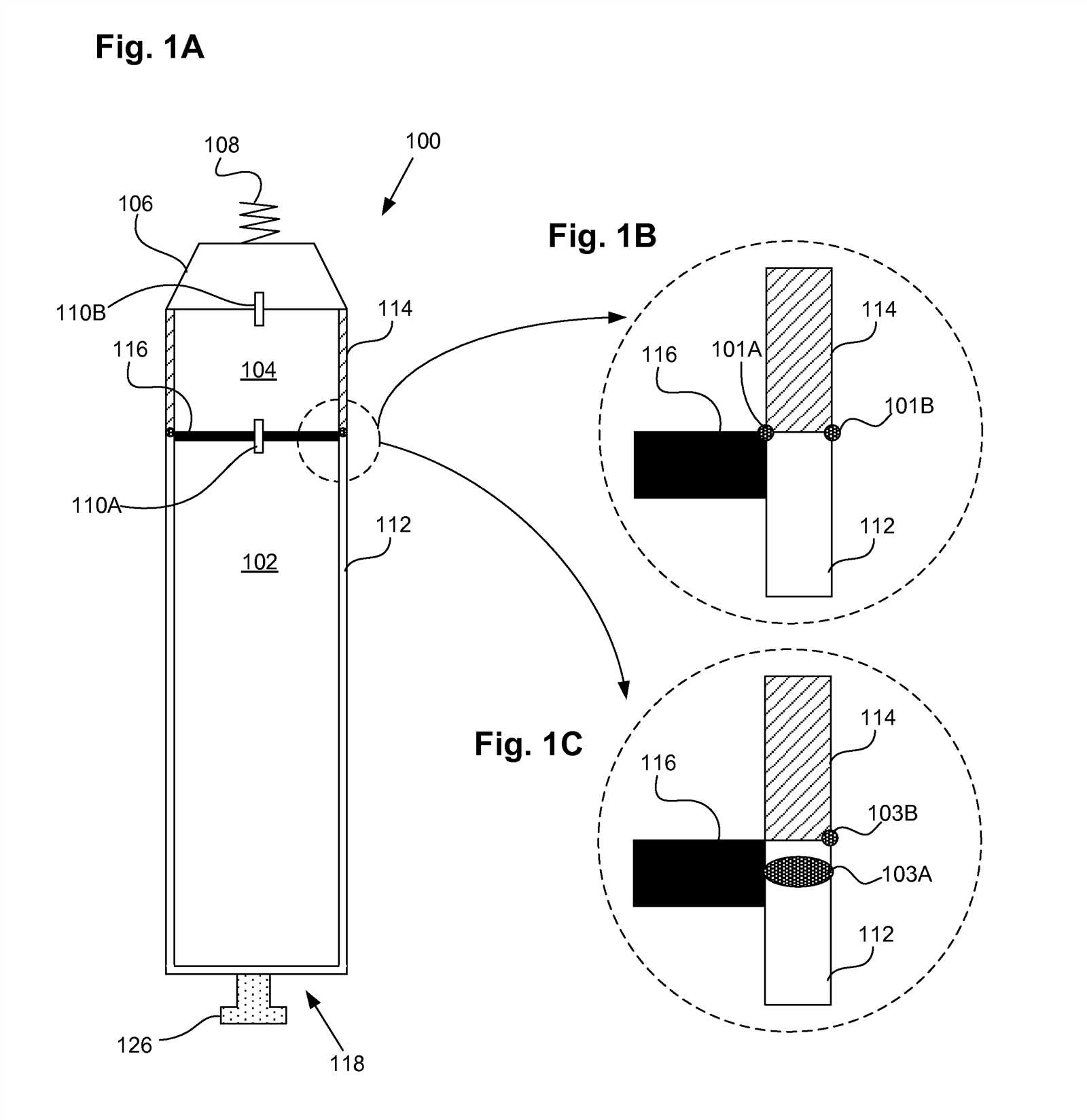

Detailed visual aids serve as essential references for anyone seeking to navigate the complexities of assembly structures. These illustrations not only clarify the positioning of individual elements but also highlight their interrelationships and operational roles. This understanding empowers users to troubleshoot issues effectively and execute modifications with confidence.

Additionally, engaging with these visual representations fosters a deeper appreciation for the craftsmanship involved in design and engineering. By exploring the layout of each section, users can identify potential upgrades or replacements, ultimately enhancing the reliability and functionality of their systems.

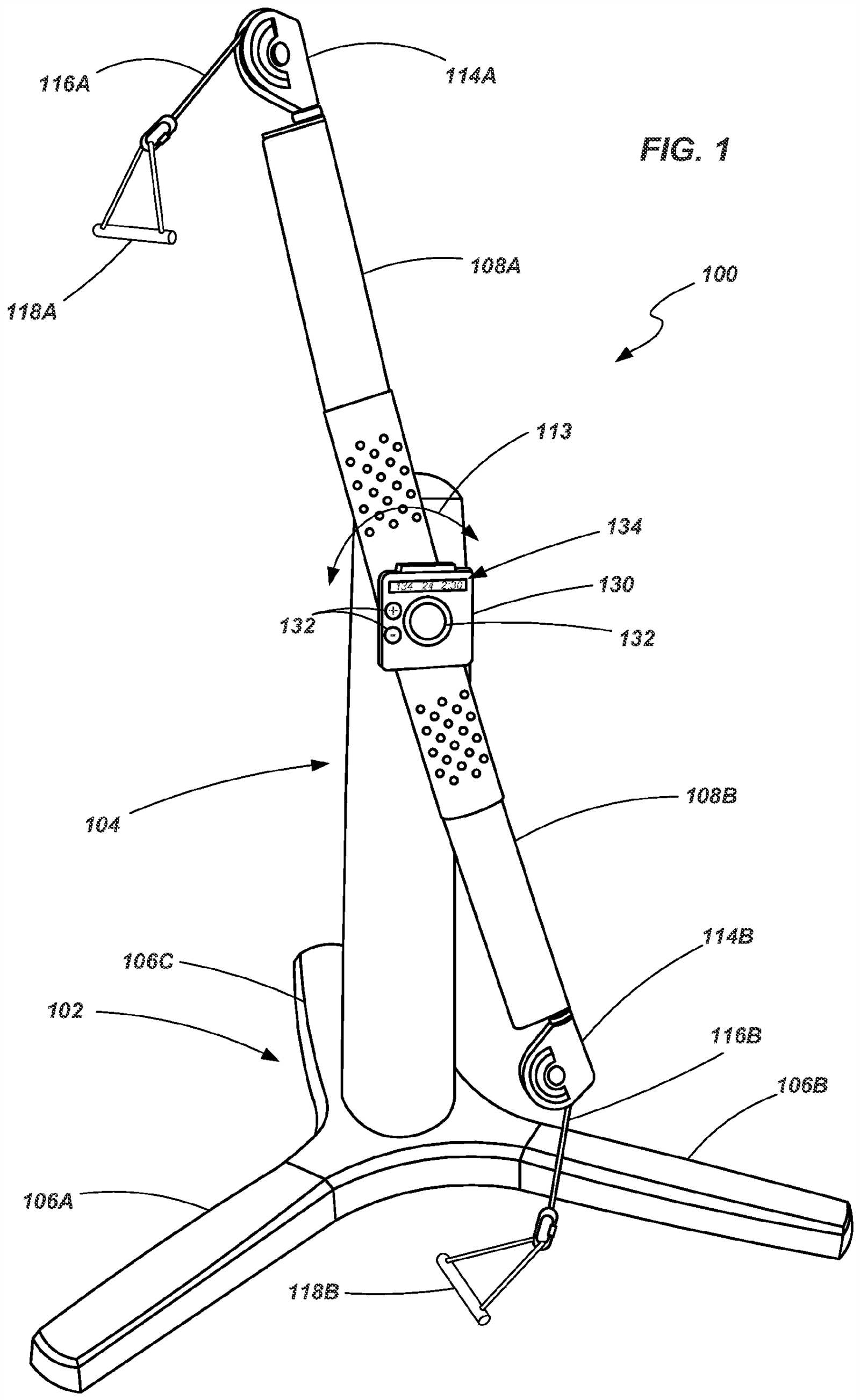

Understanding Wilson Pacesetter Components

This section provides an overview of the various elements that contribute to the functionality and performance of specific mechanical systems. Each component plays a vital role in ensuring that the entire mechanism operates smoothly and efficiently, highlighting the importance of understanding how these elements interact with one another.

Familiarity with the individual parts enhances troubleshooting and maintenance efforts, enabling users to identify potential issues before they escalate. The following table outlines key components, their functions, and relevance to overall operation.

| Component | Function | Importance |

|---|---|---|

| Base Assembly | Supports and stabilizes other parts | Essential for structural integrity |

| Control Mechanism | Regulates system operations | Crucial for performance optimization |

| Connector Pins | Facilitates electrical connections | Vital for functionality |

| Power Supply Unit | Provides necessary energy | Critical for system operation |

| Sensor Array | Monitors system parameters | Important for data accuracy |

Key Features of the Pacesetter Model

This model stands out for its remarkable blend of functionality and innovation, making it a top choice among enthusiasts. Its design focuses on enhancing performance while ensuring ease of use, catering to a wide range of users. Key attributes contribute to its reputation as a reliable option in its category.

Enhanced Performance

One of the standout characteristics is its ability to deliver superior efficiency. The configuration allows for optimal output, which translates into improved overall operation. Users can expect a seamless experience, whether for daily tasks or more demanding applications.

Durability and Reliability

The construction of this model emphasizes resilience. Built with high-quality materials, it withstands various conditions, ensuring longevity. This reliability is crucial for users who require dependable performance over extended periods.

In conclusion, this model’s combination of advanced features and robust design positions it as a leading choice for individuals seeking quality and performance in their equipment.

Importance of Quality Parts Selection

Choosing high-grade components is essential for ensuring the optimal performance and longevity of any mechanical system. Quality influences not only the efficiency but also the reliability of operations. When inferior materials are utilized, the risk of failure escalates, leading to increased downtime and repair costs.

Benefits of Selecting Superior Components

- Enhanced Durability: Premium materials are engineered to withstand wear and tear, extending the lifespan of the equipment.

- Improved Performance: Well-manufactured components operate more efficiently, contributing to better overall functionality.

- Cost-Effectiveness: Although the initial investment may be higher, the reduced need for replacements and maintenance makes quality choices financially prudent in the long run.

- Safety Assurance: High-quality materials minimize the risk of accidents caused by component failures, safeguarding both operators and equipment.

Considerations for Optimal Selection

- Supplier Reputation: Always opt for suppliers known for their commitment to quality and reliability.

- Material Specifications: Ensure that components meet industry standards and specifications relevant to your application.

- Compatibility: Verify that selected items are compatible with existing systems to prevent any operational issues.

- Warranty and Support: Choose manufacturers that offer warranties and technical support, ensuring assistance in case of issues.

Common Issues with Pacesetter Equipment

Users of this type of machinery often encounter several challenges that can impact performance and efficiency. Understanding these common problems is crucial for maintaining optimal functionality and prolonging the lifespan of the equipment.

One frequent issue involves malfunctions that arise from inadequate maintenance practices. Over time, components may wear out or become obstructed, leading to decreased efficiency. Regular inspections and timely servicing can mitigate these risks.

Another prevalent concern is electrical failures. These can occur due to faulty connections or damaged wiring, resulting in interruptions in operation. It is essential to regularly check the electrical system for any signs of wear or damage.

Furthermore, users may experience performance inconsistencies related to calibration. If the machinery is not properly calibrated, it can result in inaccurate readings and diminished effectiveness. Routine calibration checks are vital to ensure that all functions are performing as intended.

Lastly, environmental factors such as dust and moisture can adversely affect the machinery’s performance. Keeping the equipment clean and stored in a controlled environment can help reduce these issues significantly.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. By following a few straightforward practices, you can ensure that your device remains in optimal working condition for many years. Regular attention not only enhances performance but also minimizes the risk of unexpected failures.

Routine Inspection

Regular checks can help identify potential issues before they escalate. Consider the following:

- Inspect all components for signs of wear or damage.

- Check for loose connections and tighten them as necessary.

- Monitor any unusual noises or vibrations during operation.

Cleaning Procedures

Keeping your device clean is vital for maintaining its functionality. Follow these cleaning tips:

- Dust the exterior regularly to prevent buildup.

- Use a damp cloth to wipe surfaces, avoiding harsh chemicals.

- Ensure that ventilation areas are clear to promote airflow.

Identifying Genuine Replacement Parts

Ensuring the authenticity of components is crucial for maintaining the performance and longevity of your equipment. Distinguishing between original and counterfeit items can significantly impact the functionality of your system. By understanding key characteristics, you can make informed decisions when sourcing new elements.

Key Features of Authentic Components

When evaluating the quality of a component, several factors can help you identify genuine items. Look for indicators such as packaging, labels, and build quality, as these aspects often provide insight into the component’s origin.

| Indicator | Description |

|---|---|

| Packaging Quality | Authentic items typically come in high-quality packaging, featuring clear branding and no signs of damage. |

| Labeling | Check for consistent logos, part numbers, and barcodes that match the manufacturer’s specifications. |

| Build Quality | Genuine components usually exhibit superior craftsmanship, with precise dimensions and materials that feel sturdy. |

Where to Source Authentic Items

To ensure you are purchasing original components, consider acquiring them from authorized distributors or the manufacturer’s official channels. Online marketplaces can be convenient, but it’s essential to verify the seller’s credibility to avoid counterfeit products.

Assembly Instructions for New Parts

When integrating new components into your system, following a systematic approach is essential for ensuring a smooth and efficient assembly process. Each element should be installed with precision to maintain optimal functionality and safety. Understanding the sequence and method of assembly will contribute significantly to the overall performance of your device.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Ensure that the work area is clean and organized, allowing easy access to everything required. Refer to any available manuals or guidelines for specific instructions related to the elements being utilized. Taking the time to prepare thoroughly will help prevent errors and streamline the assembly process.

Installation Process

Start by positioning each component according to the provided guidelines, making sure they align correctly with their designated spaces. Secure each piece using the appropriate fasteners, ensuring a snug fit without over-tightening, which could lead to damage. Once all components are in place, double-check connections and settings to confirm that everything is properly installed and ready for operation.

Upgrades for Enhanced Performance

Improving the efficiency and capabilities of your vehicle can significantly enhance its overall driving experience. Various modifications are available that not only boost power output but also contribute to better handling and responsiveness. By selecting the right enhancements, enthusiasts can enjoy a more dynamic and enjoyable ride.

One of the most effective ways to increase horsepower is through an improved intake system. A high-performance air intake allows for better airflow into the engine, resulting in enhanced combustion and power generation. Coupled with a performance exhaust system, this upgrade can create a more aggressive sound while optimizing exhaust flow, further improving engine performance.

Another avenue for enhancement lies in the suspension system. Upgrading to adjustable shocks and struts can greatly improve handling by allowing drivers to fine-tune their ride height and stiffness. This customization leads to better traction and stability, particularly during cornering and off-road situations.

In addition, upgrading the braking system with high-performance rotors and pads ensures that your vehicle can handle increased speeds safely. Enhanced stopping power is essential for maintaining control, especially when modifications increase overall performance.

Finally, consider implementing electronic tuning solutions. These software upgrades can optimize engine parameters for maximum efficiency, delivering noticeable improvements in throttle response and fuel economy. When combined with other modifications, such tuning can transform the driving experience into one that is not only powerful but also refined.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and ensure a smooth process. Taking the necessary precautions can significantly reduce the risk of injury and damage to the equipment. Awareness of potential hazards and adherence to safety guidelines are crucial for both novice and experienced individuals.

Understanding the Environment

Before starting any repair work, assess the workspace for potential dangers. Ensure that the area is well-lit and free from clutter, as obstructions can lead to accidents. Additionally, check for proper ventilation if working with chemicals or materials that may produce harmful fumes. Always have a first aid kit accessible in case of emergencies.

Utilizing Proper Equipment

Wearing appropriate protective gear is vital for safeguarding oneself against injuries. This includes gloves to protect hands from sharp edges, goggles to shield eyes from debris, and masks if there is a risk of inhaling harmful particles. Furthermore, using the right tools for each task not only enhances efficiency but also minimizes the likelihood of accidents. Always follow the manufacturer’s guidelines for tool usage.

Recommended Tools for Installation

When undertaking an installation project, having the right equipment is crucial for ensuring a smooth and efficient process. Selecting appropriate tools not only enhances productivity but also minimizes the risk of errors. Below is a list of essential instruments that can aid in the successful execution of your task.

1. Wrenches and Sockets: A variety of wrenches, including adjustable and socket types, will provide the necessary leverage for loosening and tightening fasteners. Consider a comprehensive set to accommodate different sizes.

2. Screwdrivers: Both flathead and Phillips screwdrivers are indispensable. Having multiple sizes will allow you to tackle various screws you may encounter.

3. Torque Wrench: This tool ensures that all connections are tightened to the manufacturer’s specifications, preventing potential damage from over-tightening.

4. Pliers: A good pair of pliers is essential for gripping, twisting, and cutting wires or other materials, making them versatile for many tasks.

5. Utility Knife: For cutting through packaging or materials, a sharp utility knife is invaluable. Make sure to have extra blades on hand for continued use.

6. Measuring Tape: Accurate measurements are vital, so a reliable measuring tape will help you ensure everything fits perfectly.

7. Safety Gear: Don’t forget personal protective equipment such as gloves, goggles, and a dust mask to ensure your safety while working.

Equipping yourself with these tools will significantly contribute to the overall success of your installation endeavor. Each item plays a specific role in making the process efficient and safe.

Differences Between Pacesetter Versions

When examining variations within a specific product line, several key aspects emerge that differentiate each model. These distinctions can impact functionality, compatibility, and overall performance. Understanding these differences is crucial for consumers and enthusiasts alike, as it allows for informed decisions regarding selection and application.

Performance Characteristics

Each iteration of the product is designed with varying performance specifications that cater to different user needs. Some models prioritize efficiency and fuel economy, while others emphasize power output and speed. It is essential to evaluate these features based on the intended use to maximize the benefits.

Compatibility and Fitment

The fitment of each version can vary significantly, affecting how well they integrate with different systems. Certain models may offer enhanced compatibility with specific setups, making them more desirable for particular applications. Users should carefully assess these factors to ensure optimal integration and functionality.

Resources for Further Information

Exploring additional resources can significantly enhance your understanding and provide deeper insights into related topics. Various platforms offer valuable information, technical specifications, and community support that can aid in troubleshooting and enhancing your knowledge.

Online Forums and Communities

Participating in online forums and communities allows you to connect with others who share similar interests. Websites such as Reddit and dedicated forums provide a space for users to discuss their experiences, ask questions, and share solutions. Engaging with these platforms can lead to discovering practical advice and innovative approaches to common challenges.

Official Documentation and Manuals

Consulting official documentation and user manuals is crucial for accurate information. Many manufacturers provide downloadable resources that detail technical specifications, setup instructions, and maintenance tips. Utilizing these documents can help you gain a thorough understanding of the system’s functionalities and ensure proper usage.

In summary, leveraging diverse resources can empower you to navigate challenges effectively and foster continuous learning in your projects.