In this section, we delve into the intricate arrangement of elements that comprise the detailed setup of the ZD-DNBB-7MDC-24PX system. Our focus lies on understanding the internal structure and organization of the various components that form an integral part of this sophisticated assembly.

Examining the Construction: Our exploration entails a meticulous examination of how each unit is strategically positioned within the framework, highlighting their interconnectivity and functional roles. This detailed scrutiny aims to provide a comprehensive insight into the operational synergy among the system’s constituent parts.

Unveiling Interdependencies: Beyond mere physical arrangement, we uncover the interdependencies that govern the functionality and efficiency of the configuration. This involves discerning the crucial relationships that ensure seamless operation and optimal performance of the apparatus in diverse applications.

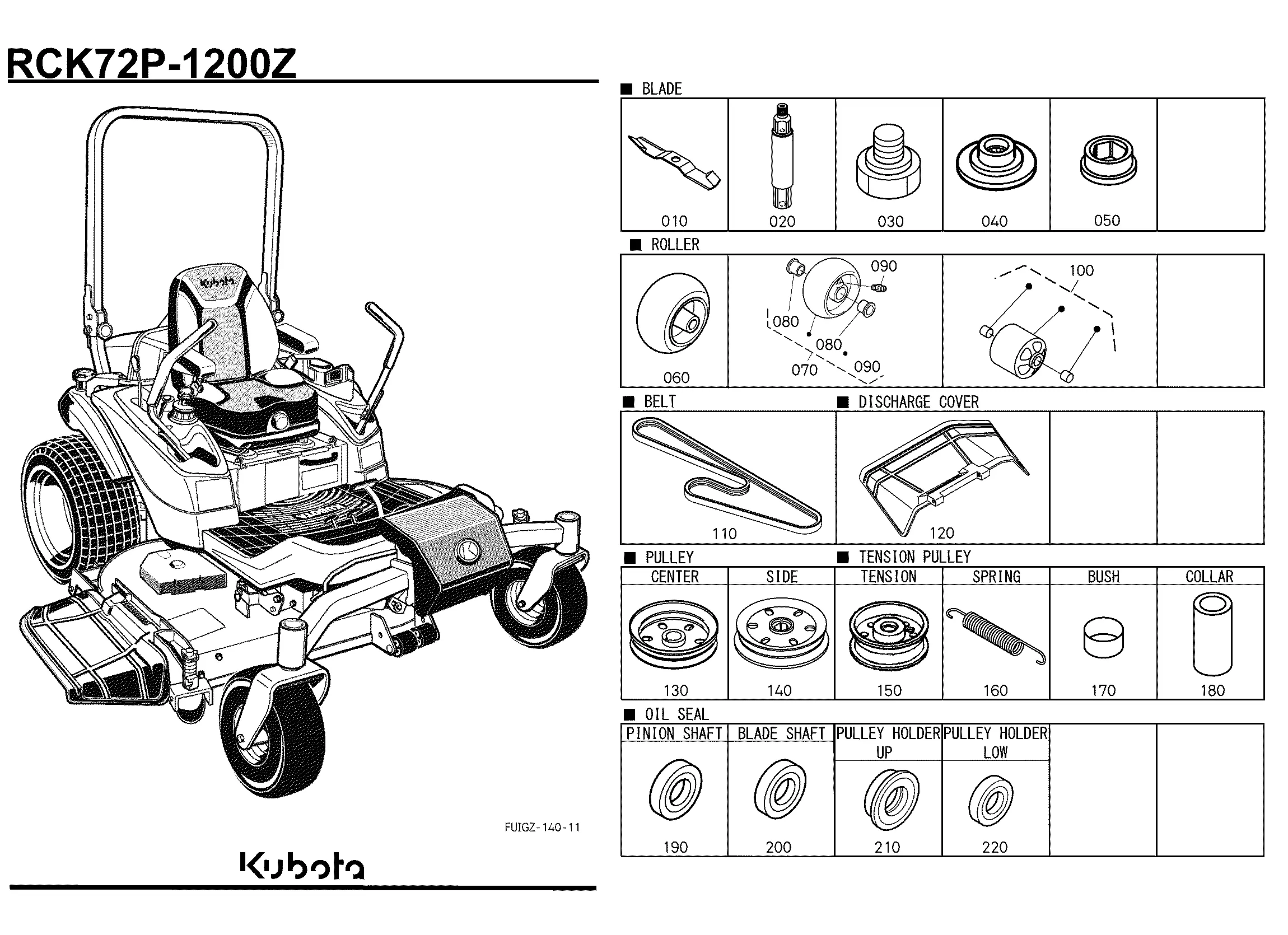

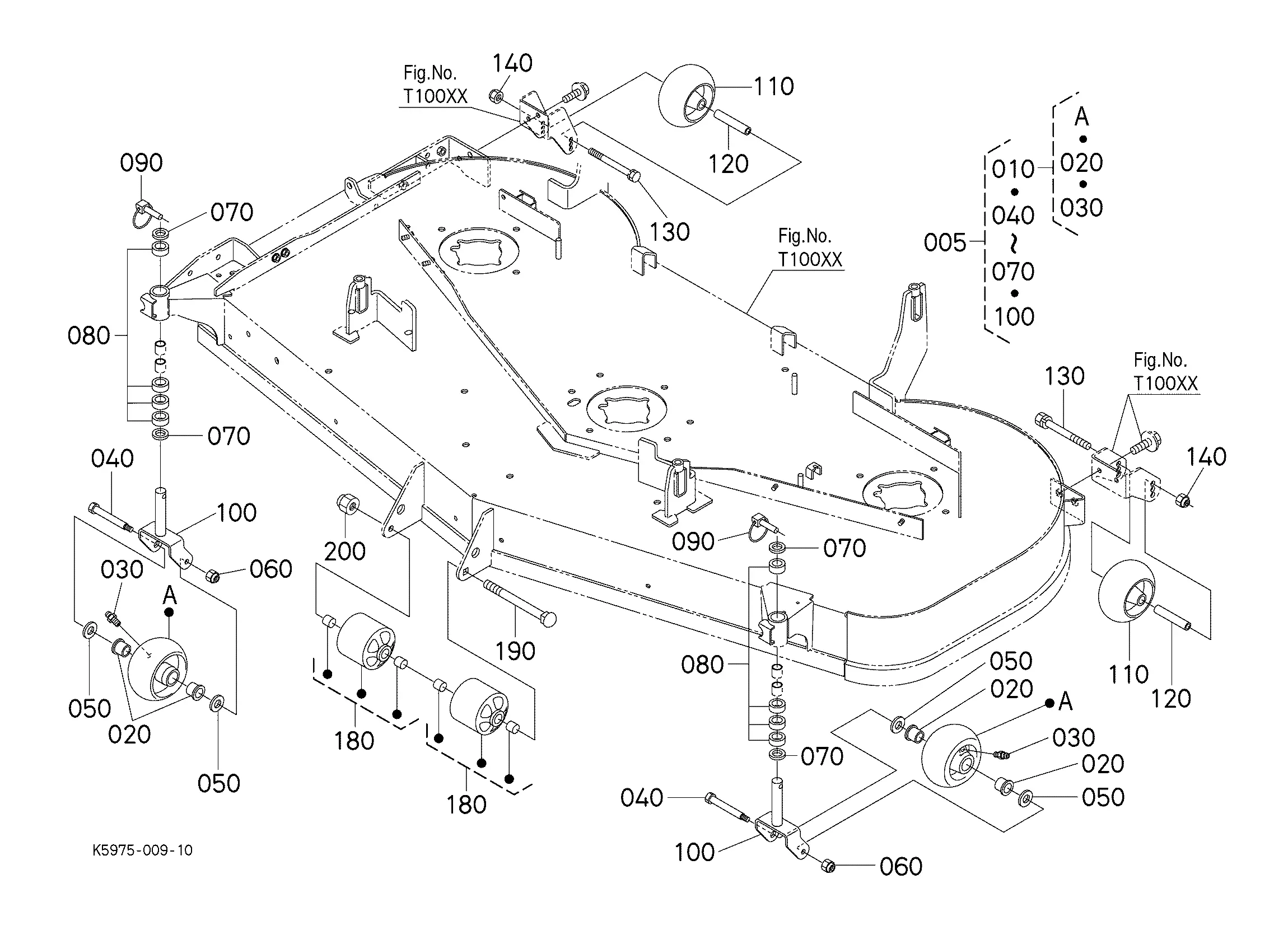

Overview of the Zd-dnbb-7mdc-24px Model

This section presents a comprehensive look at one of the key systems designed for efficient and reliable operation. Its engineering emphasizes durability, precision, and versatility, making it suitable for a variety of technical applications. By exploring its core features and assembly, users can better understand how each component contributes to the overall performance.

- Durability: Constructed from high-quality materials, ensuring long-term use even in demanding environments.

- Precision: Engineered for accuracy in both control and execution, enhancing the effectiveness of its functionality.

- Modularity: Designed to allow for easy adjustments and upgrades, making it adaptable to different requirements.

Each part

Key Components and Their Functions

The system is composed of several critical elements, each of which plays a vital role in ensuring smooth operation and overall efficiency. Understanding how these elements interact is crucial for maintaining optimal performance and troubleshooting potential issues.

One essential part is the control unit, which governs the overall functionality by managing input signals and directing processes. It ensures that every function is executed in accordance with predefined instructions, making it the core of the system.

Another significant element is the power module, responsible for distributing energy efficiently to various sections. Its role is to provide stable power levels, ensuring uninterrupted operation and protecting sensitive components from surges or disruptions.

The communication interface connects different segments, allowing for seamless data exchange between them. This ensures that all signals are accurately transmitted, enhancing coordination and synchronization across the entire system.

Lastly, the safety mechanisms safeguard the structure by monitoring conditions and activating preventive measures if needed. This

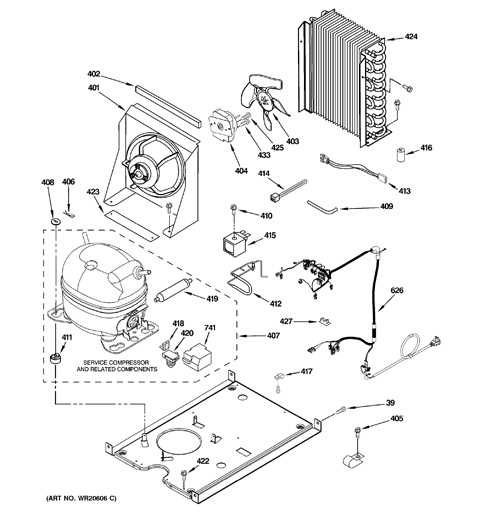

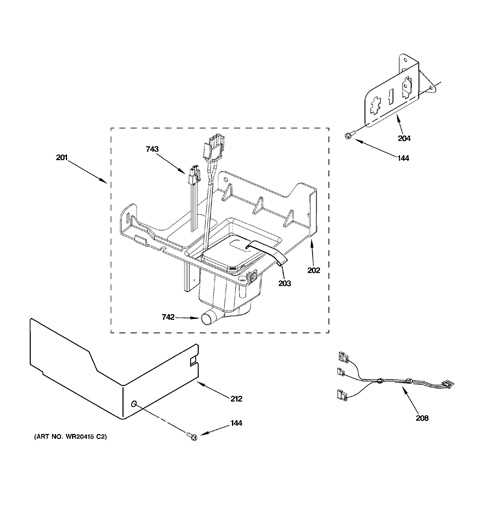

Internal Structure and Assembly

The design is built around a carefully arranged system of components that work in unison to ensure functionality and reliability. Each section plays a crucial role in the overall operation, connecting seamlessly to form a cohesive unit. Understanding the internal configuration helps in identifying how each element interacts with the others during assembly.

- Main Framework: This core section provides structural integrity and houses the essential mechanical parts, ensuring that all internal elements remain securely in place.

- Connection Points: Multiple junctions within the system allow for the smooth transfer of energy and signals between different sections, enabling efficient communication between elements.

- Fastening Mechanisms: Various screws, clips, and locking mechanisms are used to secure each segment, ensuring stability and ease of maintenance during disassembly or repair.

- Support Components:

Materials Used in Construction

In the assembly of the device under consideration, a variety of high-quality components are meticulously selected to ensure durability and performance. These components include metals, polymers, and specialized alloys, each chosen for their specific properties that contribute to the functionality and longevity of the product.

Metal Alloys Selected for their robustness and conductivity, these alloys form the structural backbone of critical components, offering both strength and reliability. Polymers Utilized in parts requiring lightweight construction and flexibility, polymers provide resilience against impact and environmental factors. Specialized Composites Engineered composites integrate multiple materials to enhance specific properties such as heat resistance, insulation, and dimensional stability. Elastomers Contributing to sealing and vibration absorption, elastomers ensure operational integrity by maintaining tight seals and minimizing mechanical stress. Each material is strategically applied to optimize performance and endurance, reflecting a commitment to precision engineering and superior manufacturing standards without compromising on quality or reliability.

Identifying Essential Replacement Parts

Maintaining the proper function of equipment often requires recognizing which components may need to be swapped out over time. Understanding the core elements that contribute to the system’s efficiency helps in selecting the appropriate substitutes during upkeep or repair.

Below are the critical elements that typically require attention when addressing mechanical or electrical issues:

- Control modules that ensure smooth operation and command over the system.

- Connectors and wiring that facilitate communication and power distribution across the unit.

- Power sources or batteries that fuel the entire setup,

Wiring and Electrical System Layout

The organization of the electrical connections is crucial to ensure the smooth functioning of the entire system. Understanding the flow of current and how different components interconnect can help with troubleshooting and future modifications. The electrical pathways are designed to efficiently manage power distribution while keeping the system safe and reliable.

Each circuit plays a specific role in delivering energy or control signals to various units. By following the layout, one can trace the flow from the power source to each destination, ensuring that every link is properly secured. Whether managing sensors, switches, or other elements, the structure of the wiring supports seamless operation across the system.

Step-by-Step Breakdown of the Mechanism

The internal workings of this system are intricate, with various components interacting to ensure smooth functionality. Understanding how each element interacts with the others provides insight into its overall operation. In this section, we will explore the key stages involved, focusing on the sequence of actions that drive the mechanism.

Initial Activation Process

The system begins its operation through an initial triggering event. This sets off a series of coordinated movements that activate different elements. As the trigger engages, a primary component moves, causing other connected parts to respond in a predefined order. This sequence is crucial for the subsequent stages to unfold correctly.

Sequential Movements and Final Output

Once the initial stage is completed, the system enters the core phase where multiple components work in sync. Each piece moves according to a precise pattern, ensuring a balanced interaction between all elements. The result of this synchronized action is the desired outcome, achieved through efficient motion and minimal resistance.

Common Issues and Troubleshooting Tips

Understanding how various components of a system interact is crucial for identifying potential problems. When specific elements fail to perform as expected, it can disrupt overall functionality. Recognizing common problems early on helps in maintaining smooth operation and avoiding larger complications.

One of the most frequent concerns arises from connectivity issues, which can be caused by improper connections or worn-out interfaces. Ensuring all links are securely fastened can prevent such failures. Another area to watch out for is electrical irregularities, often leading to unexpected malfunctions. Regular checks of power sources and conductors can mitigate such risks.

If performance degradation occurs, this could indicate overheating or mechanical wear. Proper ventilation and periodic maintenance of physical components can extend operational life and reduce the likelihood of damage. When dealing with intermittent faults, inspecting signal flow or checking for potential corrosion in the system may uncover hidden weaknesses.

Lastly, always refer to the manufacturer’s recommendations for calibration and reset procedures when troubleshooting persistent issues. Timely updates or replacements of individual modules can prevent future disruptions.

Maintaining Optimal Performance Over Time

Ensuring long-term efficiency requires a proactive approach to upkeep. Over time, components can experience wear and tear, making it essential to follow specific guidelines to preserve functionality. By adhering to routine checkups and addressing potential issues early, you can extend the life of your equipment and prevent unexpected breakdowns.

Regular Inspection and Cleaning

One of the key aspects of maintaining smooth operation is regular inspection. This includes checking for any visible signs of wear, loose connections, or dirt buildup. Accumulated debris can impact the system’s efficiency, so periodic cleaning is critical.

- Examine critical areas for wear and tear.

- Clean surfaces to avoid performance degradation.

- Inspect connectors and fasteners for proper fit.

Timely Replacement of Worn Components

As certain elements degrade over time, replacing

Upgrading and Modifying the System

Enhancing and customizing your equipment can significantly improve its performance and adaptability. By implementing strategic upgrades and modifications, users can tailor the system to better meet their specific needs, whether for efficiency, functionality, or overall capability. This section explores various approaches to elevating the existing setup, ensuring a seamless integration of new features and components.

Identifying Areas for Improvement

Before initiating any enhancements, it is essential to assess the current configuration thoroughly. Focus on identifying components that may benefit from upgrades, such as processing units, connectivity modules, or storage solutions. Evaluating the system’s performance metrics can also reveal potential bottlenecks, guiding you towards targeted enhancements that can yield substantial benefits.

Implementing Upgrades

When considering modifications, selecting high-quality replacements or additional parts is crucial. Investing in superior components can lead to noticeable improvements in reliability and performance. Additionally, ensuring compatibility with existing elements is vital to maintain stability and functionality. Careful planning and execution during the upgrade process will enhance the overall system and extend its lifespan.

Safety Features and Precautions

Ensuring the safe operation of any mechanical system is paramount. This section discusses various protective measures and considerations that contribute to the effective and secure functioning of such equipment. By adhering to recommended guidelines, users can minimize risks and enhance overall performance.

- Emergency Shutoff: A critical feature that allows for immediate disconnection of power or operation in case of unforeseen circumstances.

- Overload Protection: Systems designed to prevent damage by automatically halting operation when exceeding specified limits.

- Safety Guards: Physical barriers that shield users from moving parts, reducing the likelihood of accidents.

- Regular Maintenance: Routine inspections and servicing are essential to ensure all safety mechanisms function correctly.

In addition to these features, users should always be aware of the operational environment and follow recommended usage protocols to further enhance safety.

- Always read the manufacturer’s guidelines before operating the equipment.

- Wear appropriate personal protective equipment (PPE) during use.

- Keep the workspace clear of obstructions to facilitate safe operation.

- Ensure all emergency procedures are well understood by all personnel involved.

Implementing these safety features and adhering to precautions not only protects users but also extends the lifespan of the equipment.

Compatibility with Other Devices

Understanding how components interact with various systems is crucial for ensuring optimal performance and functionality. This section delves into the interoperability of specific units with a range of devices, highlighting key aspects that users should consider.

When assessing compatibility, it is important to take into account several factors:

- Connectors and Interfaces: Ensure that the connection types match the requirements of the target devices.

- Voltage and Power Ratings: Check that the power specifications align to avoid potential damage or operational issues.

- Signal Types: Consider whether the signals transmitted are compatible to facilitate proper communication.

- Size and Mounting Options: Verify physical dimensions and installation methods to ensure proper fit.

Moreover, it is advisable to refer to manufacturer specifications and guidelines to confirm compatibility with additional units. This approach not only maximizes efficiency but also extends the lifespan of the devices involved.

In summary, thorough evaluation of compatibility is essential for seamless integration, enabling users to make informed decisions and enhance their overall experience.