When it comes to operating machinery effectively, having a clear understanding of the internal structure is essential. The layout of various elements within a device plays a crucial role in ensuring optimal functionality and performance. By examining these configurations, users can identify key components, facilitating maintenance and repair tasks.

Thorough knowledge of the specific arrangements of parts enhances the user experience and promotes safe operation. Each element within the assembly serves a distinct purpose, contributing to the overall efficiency of the tool. Therefore, having a reference for these arrangements can empower users to troubleshoot issues confidently.

In this section, we will delve into the intricacies of the component configurations, providing insights that will assist both novice and experienced users. By familiarizing oneself with these layouts, one can better appreciate the engineering behind the equipment and its operational effectiveness.

This section provides a comprehensive overview of a particular model of a cutting machine, highlighting its key components and functionalities. By understanding the layout and interaction of these elements, users can optimize their usage and maintenance practices. This foundational knowledge is essential for both novice and experienced users seeking to enhance their efficiency and troubleshooting skills.

Key Components and Their Functions

The cutting device comprises several crucial elements that contribute to its overall performance. Each part plays a specific role, ensuring the machine operates smoothly and effectively. Here are the primary components to consider:

| Component Name | Function |

|---|---|

| Motor | Powers the blade for cutting tasks. |

| Blade | Responsible for performing the actual cutting action. |

| Base Plate | Provides stability and support during operation. |

| Handle | Facilitates user control and maneuverability. |

Maintenance and Care

Proper upkeep of this equipment is vital for ensuring longevity and optimal performance. Regular inspections and timely replacements of worn-out parts will help in maintaining the machine’s efficiency. Users are encouraged to consult the maintenance guide for specific instructions on caring for individual components.

Key Features of the Tool

This section highlights the essential attributes and functionalities of the tool designed for precise cutting and shaping tasks. It emphasizes the advanced technology incorporated within the device, ensuring efficiency and user-friendliness. The features outlined below reflect its capability to meet both professional and DIY project needs.

Advanced Cutting Mechanism

The cutting mechanism is engineered to deliver high performance, allowing for smooth and accurate cuts in various materials. This ensures that users can achieve their desired results without compromising on quality.

User-Friendly Design

The tool’s ergonomic design provides optimal comfort during operation, minimizing fatigue during extended use. Additionally, its lightweight structure enhances portability, making it convenient for both in-shop and on-site applications.

| Feature | Description |

|---|---|

| Powerful Motor | Delivers consistent power for tough cutting tasks, improving efficiency. |

| Adjustable Cutting Depth | Allows users to customize the cutting depth based on project requirements. |

| Dust Collection System | Helps maintain a clean workspace by effectively minimizing debris during operation. |

| Safety Features | Equipped with mechanisms to enhance user safety, including blade guards and automatic shut-off. |

Understanding Component Functions

In any complex assembly, each individual piece plays a crucial role in ensuring the overall system operates efficiently. By comprehending the specific roles and interactions of these elements, users can better appreciate the functionality and maintenance of the entire mechanism. This understanding aids in troubleshooting and enhances the user experience, making it vital for operators and technicians alike.

Key Functions of Various Elements

Every component within a system serves a distinct purpose, contributing to its operational effectiveness. Identifying these functions helps in recognizing how they work together to achieve desired outcomes. Below is a table summarizing some essential elements and their respective roles:

| Component | Function |

|---|---|

| Motor | Drives the mechanism, providing necessary power for operation. |

| Switch | Controls the flow of electricity, allowing for the activation or deactivation of components. |

| Gear | Transmits motion and alters speed and torque as required by the operation. |

| Blade | Performs the primary cutting action, critical for the effectiveness of the device. |

Importance of Understanding Component Roles

Grasping the roles of individual parts empowers users to make informed decisions regarding maintenance and troubleshooting. Knowledge of how each piece functions and interacts with others not only enhances operational efficiency but also extends the lifespan of the entire system. Being well-versed in component functions fosters a proactive approach to care and management.

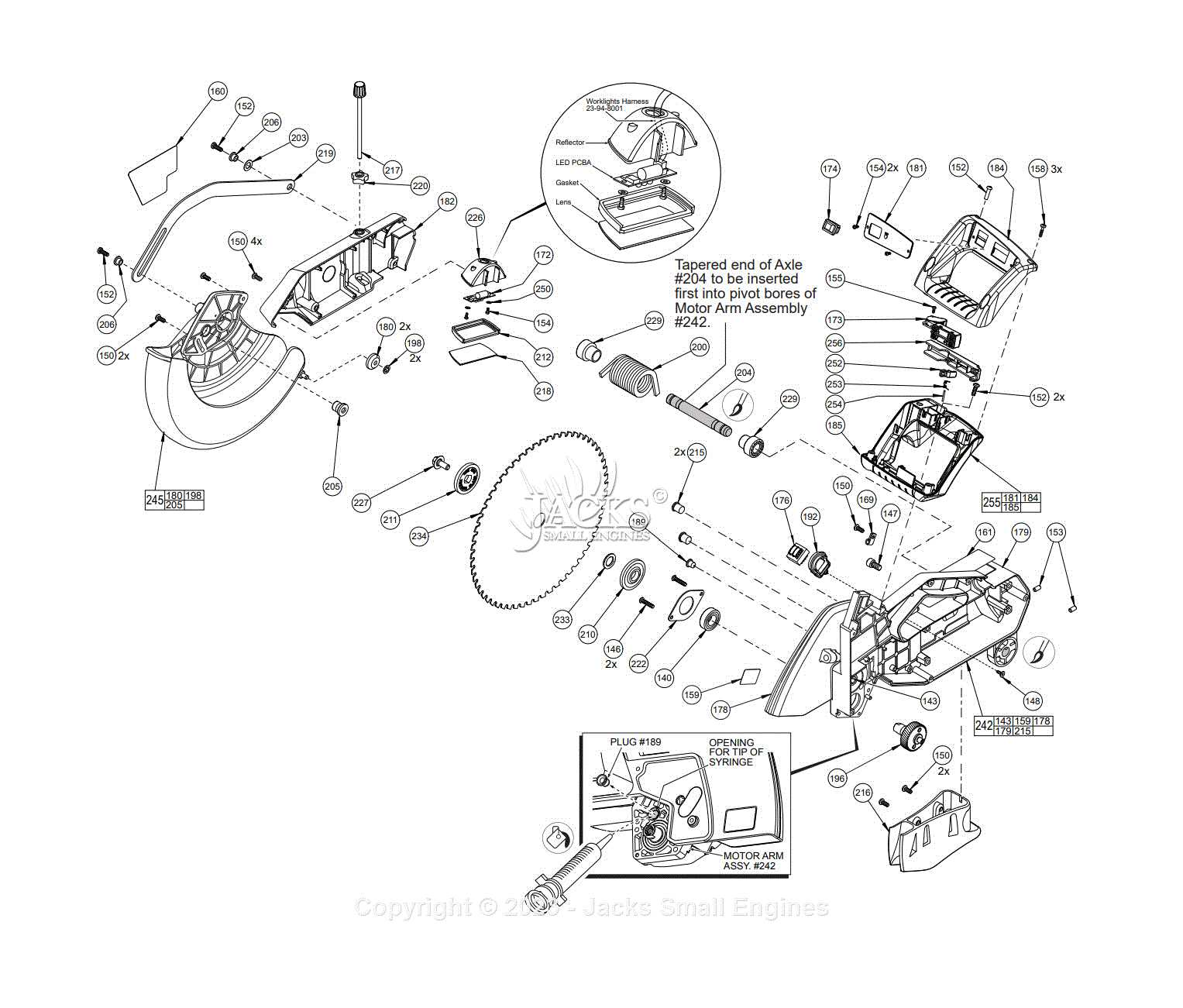

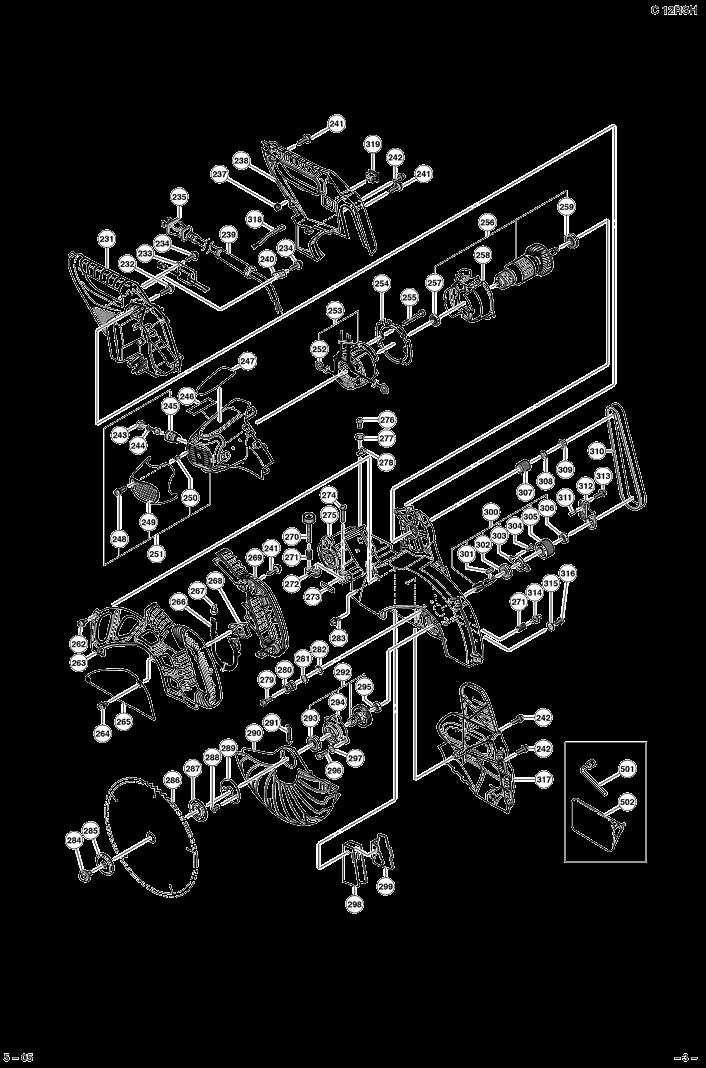

Parts Diagram Explanation

The visual representation of component arrangement serves as a vital tool for understanding the assembly and functionality of a specific device. By illustrating how various elements interact, this resource enables users to identify and locate each piece efficiently, facilitating maintenance and repairs. A comprehensive overview enhances clarity, ensuring that individuals can effectively navigate the complexities of the unit in question.

Key Features of the Visual Representation

- Identification: Each section clearly labels individual components, allowing for easy recognition.

- Organization: The layout typically arranges parts logically, reflecting their physical arrangement within the machinery.

- Functionality Insights: It provides insights into how different elements work together to achieve desired outcomes.

Benefits of Utilizing the Visual Resource

- Streamlined troubleshooting by pinpointing problematic areas.

- Efficient ordering of replacements by understanding which components are necessary.

- Enhanced comprehension of assembly processes for DIY repairs.

Identifying Main Components

Understanding the primary elements of a specific tool is crucial for effective operation and maintenance. By recognizing each part’s function, users can ensure optimal performance and longevity of the equipment. This section will outline the key components that make up this particular device.

Each element plays a vital role in the overall functionality. The following list highlights some of the main components to be familiar with:

- Motor Assembly: The heart of the machinery, responsible for driving the main operations.

- Blade Holder: A critical part that secures the cutting instrument in place, ensuring stability during use.

- Base Plate: Provides a sturdy foundation and helps maintain balance while in operation.

- Adjustment Mechanism: Allows users to modify the depth and angle of the cut for various applications.

- Power Switch: Enables control over the device’s operation, ensuring safety during use.

Familiarity with these components not only enhances user confidence but also aids in troubleshooting and repair processes, ensuring that the equipment remains in peak condition.

Replacement Parts Availability

When it comes to maintaining and repairing machinery, ensuring access to suitable components is crucial for optimal performance and longevity. The market offers a variety of options for acquiring these essential items, ranging from authorized dealers to independent suppliers. This variety ensures that users can find the necessary replacements without excessive delays, contributing to smoother operational continuity.

In many instances, authorized retailers provide high-quality replacements that adhere to the manufacturer’s specifications, thereby ensuring compatibility and reliability. Additionally, many online platforms now offer an extensive inventory of compatible alternatives, allowing users to compare prices and quality. This accessibility fosters a more efficient approach to sourcing components, ultimately aiding in timely repairs.

Moreover, understanding the common components that may require replacement can help users anticipate needs and stock up in advance. By staying informed about availability and options, individuals can effectively manage their maintenance schedules, minimizing downtime and enhancing productivity.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any machinery. By implementing a consistent maintenance routine, users can ensure optimal performance and prevent premature wear and tear. This section provides practical advice to help achieve long-lasting functionality.

Regular Cleaning

- Dust and debris can accumulate, leading to potential damage. Ensure that all components are regularly cleaned.

- Use appropriate cleaning agents that do not harm the surfaces of the equipment.

- Pay special attention to areas prone to buildup, such as air vents and moving parts.

Periodic Inspections

- Conduct routine checks to identify any signs of wear or malfunction.

- Look for loose connections and fasteners that may need tightening.

- Inspect belts, blades, and other critical components for signs of degradation.

Implementing these maintenance strategies will significantly enhance the reliability and durability of the equipment, ensuring it remains efficient over time.

Common Issues and Solutions

This section addresses frequent challenges encountered during the operation of specific machinery, along with practical remedies. Understanding these common pitfalls can significantly enhance performance and prolong the lifespan of the equipment.

Frequent Malfunctions

Users may experience various issues, often linked to wear and tear, improper maintenance, or environmental factors. Recognizing these symptoms early can lead to timely interventions.

| Issue | Symptoms | Recommended Solution |

|---|---|---|

| Overheating | Excessive heat buildup, unusual noise | Ensure proper ventilation; check for blockages. |

| Inconsistent Performance | Irregular cuts, vibration | Inspect blades for damage; adjust settings as needed. |

| Electrical Issues | Frequent power interruptions, failure to start | Check electrical connections; replace faulty components. |

Preventive Measures

Regular maintenance is essential to avoid many of the problems mentioned above. Implementing a routine check-up can help identify potential issues before they escalate into significant failures.

Assembly Instructions and Guidelines

This section provides essential guidance for the assembly process of your equipment, ensuring that all components are put together correctly and efficiently. Following the outlined steps will help achieve optimal functionality and longevity of the device.

Before starting the assembly, ensure you have all necessary components at hand and familiarize yourself with each part’s function. Carefully review the assembly sequence to avoid common pitfalls that may arise from incorrect assembly. It’s advisable to work in a clean, organized space to facilitate the process.

Begin by connecting the foundational elements, ensuring a stable structure. Pay attention to any alignment marks or indicators that assist in positioning the parts accurately. Tighten any fasteners securely but avoid over-tightening, which can lead to damage.

As you progress, periodically check that each section is aligned properly. If any issues arise, disassemble the affected parts and recheck the fitting before continuing. Once the assembly is complete, conduct a thorough inspection to ensure all components are securely fastened and functioning as intended.

Finally, consult the operational guidelines to familiarize yourself with the device’s functions. This preparation will ensure you can operate the equipment safely and effectively, maximizing its performance and lifespan.

Safety Precautions While Operating

Ensuring safety during the use of machinery is paramount to prevent accidents and injuries. Proper adherence to safety measures not only protects the operator but also extends the life of the equipment. Familiarizing oneself with essential guidelines is crucial for a secure working environment.

Before engaging with any equipment, operators should take the following precautions to minimize risks:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as safety glasses, gloves, and ear protection to safeguard against potential hazards. |

| Work Area Inspection | Inspect the workspace for clutter, obstacles, and proper ventilation. A clean environment reduces the risk of accidents. |

| Read the Manual | Familiarize yourself with the operation manual before use. Understanding the equipment’s functions and safety features is essential. |

| Emergency Procedures | Know the emergency shutdown process and have a plan in place in case of an unexpected situation. |

| Tool Maintenance | Regularly check and maintain tools for optimal performance. Worn or damaged equipment should be repaired or replaced immediately. |

By following these essential guidelines, operators can significantly reduce the likelihood of accidents and ensure a safer working environment while utilizing machinery.

Comparison with Similar Models

This section explores how this particular model stacks up against comparable alternatives in the market. By analyzing various attributes such as functionality, build quality, and user feedback, potential buyers can make informed decisions about which machine best meets their needs.

Key Features Overview

When evaluating alternatives, it’s essential to consider several key features that contribute to overall performance. The following table highlights the differences and similarities among leading contenders in this category.

| Model | Power (Watts) | Cutting Capacity (Inches) | Weight (Pounds) | Price ($) |

|---|---|---|---|---|

| Model A | 15 | 12 | 40 | 199 |

| Model B | 14 | 10 | 35 | 179 |

| Model C | 16 | 14 | 45 | 229 |

User Experiences

Customer reviews and experiences offer invaluable insights into the practicality of each option. Feedback often highlights aspects such as ease of use, durability, and customer support, which can significantly influence purchasing decisions.

Customer Reviews and Feedback

This section highlights the insights and experiences shared by users regarding their recent purchases. Feedback from customers serves as a valuable resource for potential buyers, providing an understanding of product performance, reliability, and overall satisfaction.

Common Themes in Reviews

- Performance: Many users have noted the efficiency and effectiveness of the tools in various applications.

- Durability: A significant number of reviews emphasize the long-lasting nature of the equipment, often mentioning its resilience under heavy use.

- User-Friendliness: Customers frequently praise the ease of operation, highlighting intuitive features that enhance usability.

Positive Feedback

- Users have expressed appreciation for the robust construction, stating it exceeds their expectations.

- Several reviews commend the lightweight design, making it easy to handle and maneuver during tasks.

- Many customers report satisfaction with the quality of results achieved, emphasizing precision and reliability.

Overall, the reviews reflect a consensus on the high standards of quality and performance, making it a recommended choice for both professionals and enthusiasts.

Where to Buy Authentic Parts

Finding reliable sources for genuine components is essential for maintaining the longevity and performance of your equipment. Whether you are looking to replace a worn-out piece or upgrade your machinery, ensuring that you purchase from reputable suppliers can make a significant difference in the quality and durability of the items you acquire.

Authorized Dealers

One of the best places to start your search is through authorized dealers. These vendors are officially recognized by manufacturers and typically offer a wide range of genuine components. Here are some advantages of purchasing from them:

- Guaranteed authenticity of products

- Access to comprehensive warranties and customer support

- Up-to-date inventory reflecting the latest offerings

Online Marketplaces

Another option is exploring well-known online marketplaces. However, caution is advised when navigating these platforms. To ensure you receive genuine items, consider the following tips:

- Check seller ratings and reviews for feedback from previous buyers.

- Look for listings that explicitly mention authenticity and warranty information.

- Be wary of deals that seem too good to be true; they often are.

By following these guidelines and sourcing components from trusted suppliers, you can ensure that your equipment remains in peak condition, minimizing the risk of issues related to inferior replacements.