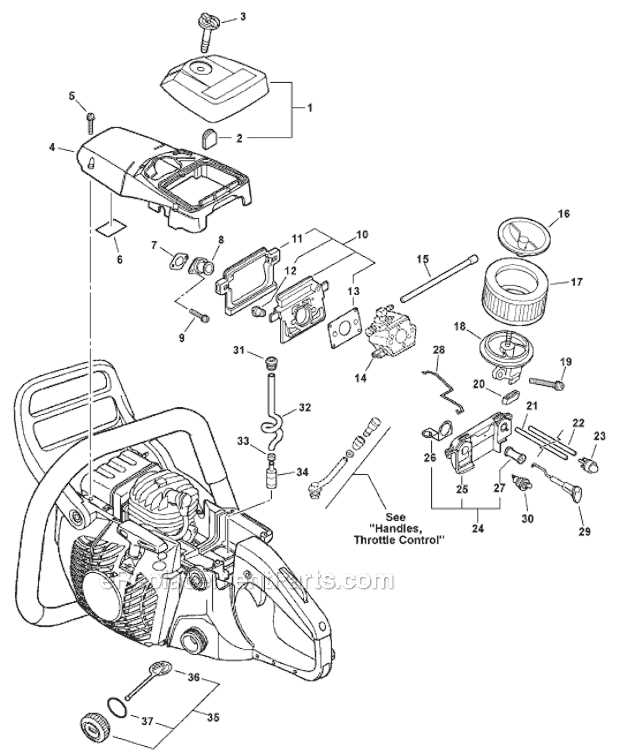

When working with a trusted outdoor tool, understanding its internal layout is essential for smooth operation and easy maintenance. Each individual element plays a significant role in ensuring the machine functions efficiently and safely. Whether it’s regular upkeep or addressing specific performance issues, having a clear visual representation of the internal structure can greatly simplify the task.

In this section, we’ll explore the various mechanical elements that contribute to the overall performance. By reviewing the arrangement of different components, you’ll gain a deeper insight into the functioning of the tool and how to approach repairs or adjustments effectively. This knowledge will empower you to maintain and extend the life of your equipment.

Identifying the correct components and understanding their interactions will make troubleshooting and replacement processes more straightforward. A detailed map of the machine’s internal elements ensures that you can quickly locate and address any potential issues, reducing downtime and improving the overall experience.

Essential Components for the Husqvarna 450 Rancher

Understanding the key elements that contribute to the optimal performance of your equipment is crucial for efficient operation. These primary components work together to ensure durability, power, and reliability in demanding conditions. Regular maintenance and proper care of these core elements will help extend the life of your tool and improve its overall functionality.

Engine System

The heart of the tool is the engine, which delivers the necessary force for cutting and other tasks. Regularly checking and maintaining the motor ensures smooth operation. Components such as the carburetor, spark plug, and air filter are vital for consistent performance. Ensuring that these parts are clean and in good condition helps prevent malfunctions and improves fuel efficiency.

Cutting Mechanism

The cutting mechanism is responsible for the primary function of the equipment. It includes the chain,

Understanding the Chain Mechanism

The chain mechanism plays a crucial role in the operation of any cutting tool, transferring power efficiently to ensure smooth and effective performance. It involves a series of components working together to rotate the cutting chain at high speeds, enabling the tool to cut through materials with precision.

To grasp how this system functions, it’s important to break it down into its main elements. Each part must work in harmony to ensure reliability and safety during use. Below are the key components involved in the chain mechanism:

- Drive System: This part generates the power that moves the chain. It includes elements like the motor and drive sprocket, which ensures that the chain moves consistently.

- Clutch Assembly: This component engages and disengages the power transmission, allowing the operator to control the tool’s operation efficiently.

- Drive Shaft: A vital link that transmits rotational force from the engine to the cutting attachment.

- Gears and Pulleys: These components facilitate speed adjustments and torque modifications, adapting to various tasks.

- Bearings: Essential for reducing friction and ensuring smooth movement of the drive system parts.

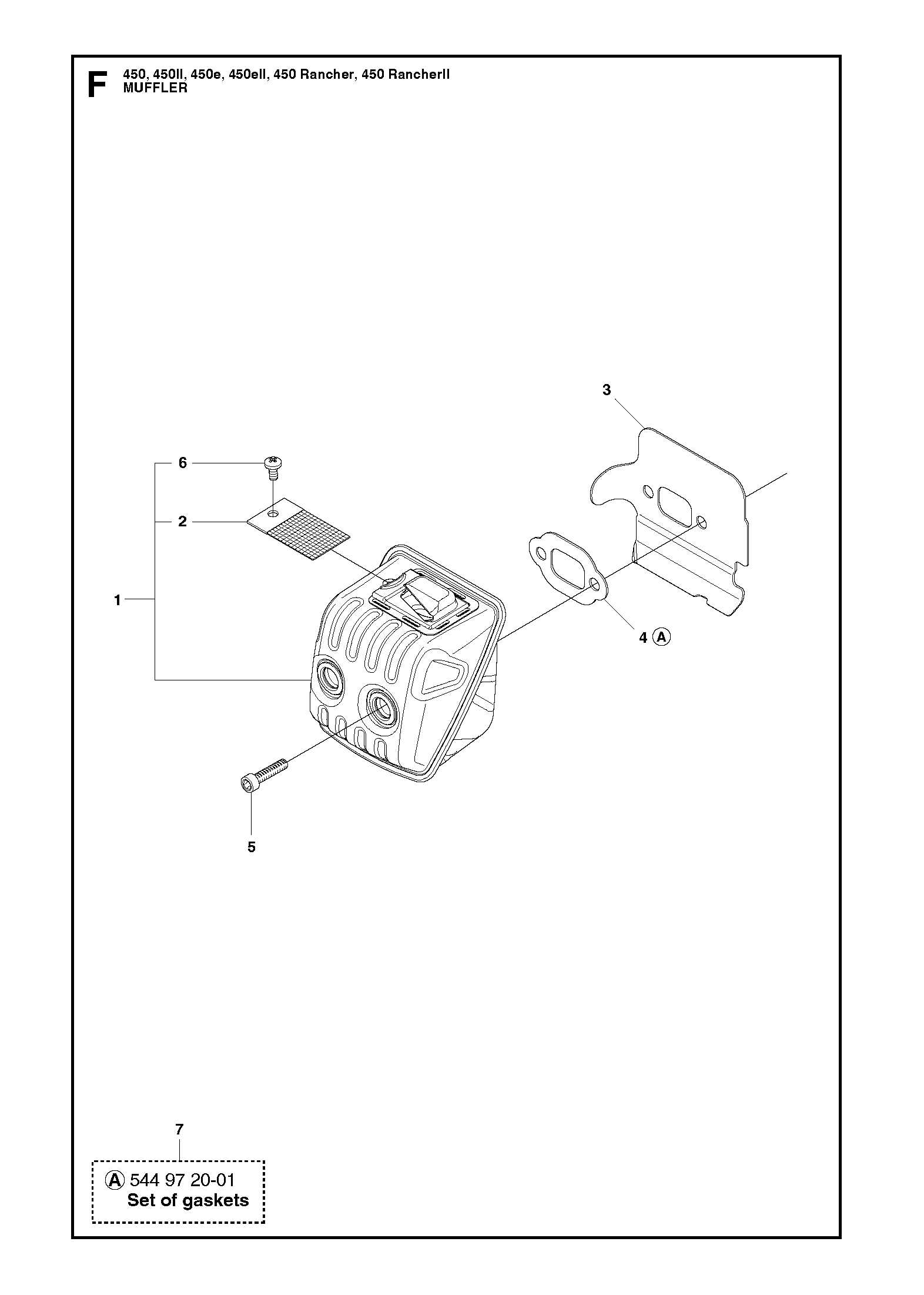

- Muffler: Designed to reduce engine noise, the muffler is an essential part of the exhaust system. It helps in silencing the sound produced during operation while allowing exhaust gases to exit smoothly.

- Exhaust Pipe: This component connects the engine to the muffler, facilitating the flow of gases. It is crucial for maintaining proper pressure and ensuring that emissions are directed away from the operator.

- Exhaust Gasket: The gasket serves as a seal between the engine and the exhaust components, preventing leaks and ensuring efficient gas flow.

- Heat Shield: Protecting surrounding components from heat damage, the heat shield provides a barrier between the exhaust system and other sensitive parts.

Guide Bar Assembly Breakdown

The guide bar assembly plays a crucial role in ensuring smooth and efficient operation. Understanding the individual elements within this component helps users maintain it properly and extend the overall lifespan of the machine. Below is a detailed overview of the key parts and their functions in this essential component.

Core Elements of the Assembly

The guide bar itself is the foundation that supports the cutting mechanism. It provides stability and precision during use, ensuring that the chain moves smoothly along its length. Additional elements include tensioning systems, which help in maintaining the correct tightness of the chain, allowing for consistent performance.

Maintenance and Care

Proper maintenance of the guide bar assembly involves regular cleaning and inspection. Ensuring that the bar is free from debris and that the chain tension remains correct will prevent unnecessary wear and tear. Periodic lubrication also plays a vital role in reducing friction, which enhances efficiency and prolongs the working life of the assembly.

Fuel System and Tank Layout

The structure of the fuel system is designed to ensure efficient and reliable operation. It includes several interconnected components that work together to deliver fuel from the tank to the engine. This setup plays a key role in maintaining the overall performance, ensuring smooth operation under different conditions.

The layout of the tank and fuel lines is carefully arranged to optimize space and facilitate easy access for maintenance. With strategically placed elements, the system allows for effective fuel flow, minimizing the risk of blockages or disruptions. The design also prioritizes safety, reducing potential hazards related to fuel handling and storage.

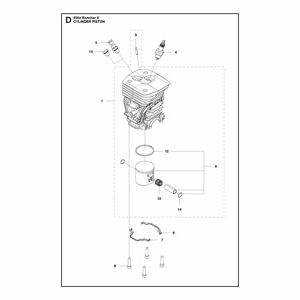

Exploring the Engine Parts

The internal components of a chainsaw’s engine play a crucial role in ensuring optimal performance and efficiency. Understanding how these elements work together allows users to maintain and troubleshoot their equipment more effectively. From the combustion chamber to the connecting mechanisms, each element has a specific function that contributes to the overall operation.

Key mechanical features, such as the piston and crankshaft, are designed to convert energy into motion. These pieces, along with various seals and bearings, form the heart of the engine, transforming fuel into the power needed to drive the machine. Proper maintenance of these components is essential for smooth operation and extended service life.

Carburetor and Air Filter Overview

The carburetor and air filter are crucial components in the fuel delivery system of small engines. Their proper functioning ensures optimal performance and efficiency of the machinery. This section provides an insight into their roles, maintenance, and key features, allowing users to better understand their significance in engine operation.

The carburetor serves as the mechanism that mixes air and fuel in the correct proportions for combustion. It regulates the mixture based on engine demand, which varies during operation. A well-maintained carburetor can significantly enhance engine responsiveness and power.

The air filter plays a vital role in protecting the engine by trapping dirt and debris from the incoming air. A clean air filter allows for better airflow, which is essential for proper combustion. Regular inspection and replacement of the air filter are necessary to prevent engine wear and maintain efficiency.

| Component | Function | Maintenance Tips |

|---|---|---|

| Carburetor | Mixes air and fuel for combustion | Clean regularly and adjust settings as needed |

| Air Filter | Filters dirt and debris from incoming air | Inspect frequently and replace when dirty |

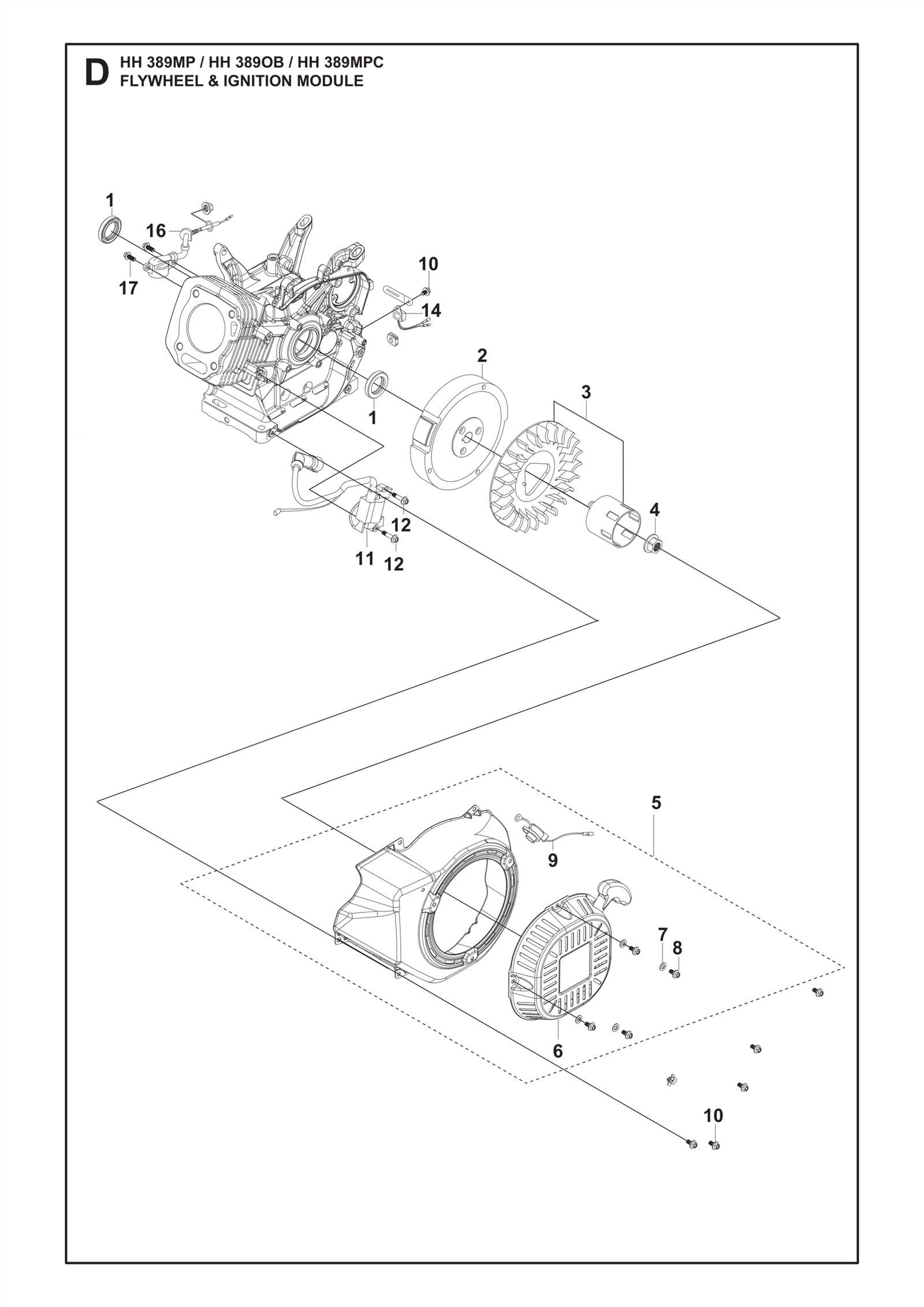

Ignition System Components

The ignition system is a vital element in the operation of a two-stroke engine, playing a crucial role in the process of combustion. It is responsible for creating the spark necessary to ignite the air-fuel mixture within the combustion chamber, ensuring optimal engine performance and efficiency.

This system consists of several key elements, each contributing to the overall functionality. The spark plug generates the electric spark that ignites the fuel mixture, while the ignition coil transforms low voltage into high voltage, facilitating this spark. Additionally, the flywheel, equipped with magnets, produces the electrical current needed to charge the coil. The ignition module regulates the timing and delivery of the spark, ensuring precise ignition in accordance with the engine’s operating conditions.

Regular inspection and maintenance of these components are essential to ensure reliable engine start-up and operation. Faulty ignition elements can lead to performance issues, including misfires, reduced power output, and increased fuel consumption.

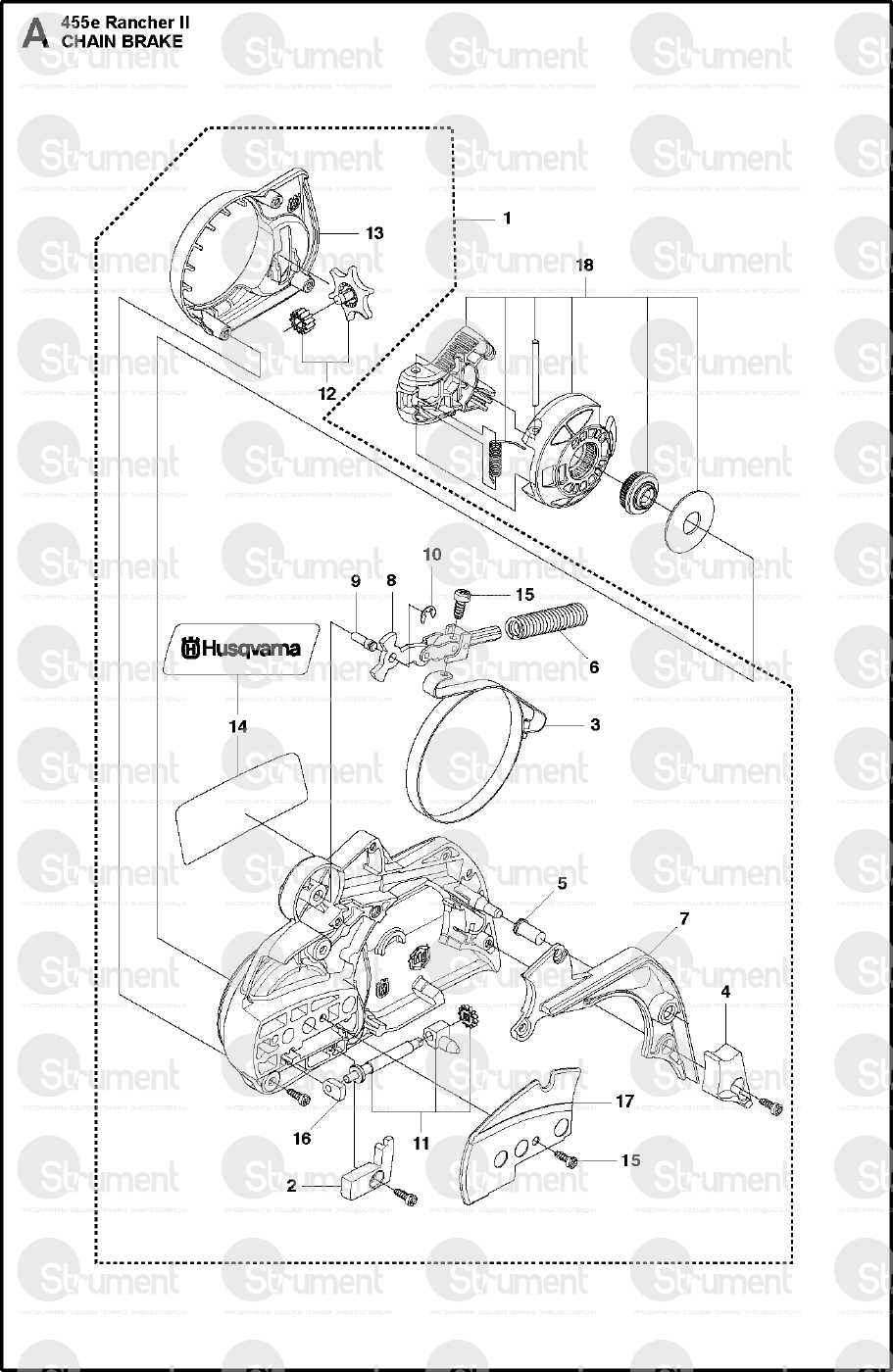

Handle and Safety Mechanisms

The handle and safety features of a chainsaw are critical components that ensure both ease of use and user protection during operation. These elements work in unison to provide a secure grip while minimizing the risk of accidents. A well-designed handle allows for better maneuverability and control, which is essential when working in various environments.

Ergonomic Design

One of the key aspects of a chainsaw’s handle is its ergonomic design. This feature is crafted to fit comfortably in the user’s hand, reducing fatigue during prolonged use. An ergonomically shaped handle provides an optimal grip, enabling better handling and precision when cutting through different materials.

Safety Features

In addition to comfort, safety mechanisms play a vital role in protecting the user. A prominent feature is the chain brake, which automatically halts the chain’s movement in case of kickback, a common hazard. Furthermore, the presence of a safety throttle lock prevents accidental activation of the engine, ensuring that the tool remains under the user’s control at all times.

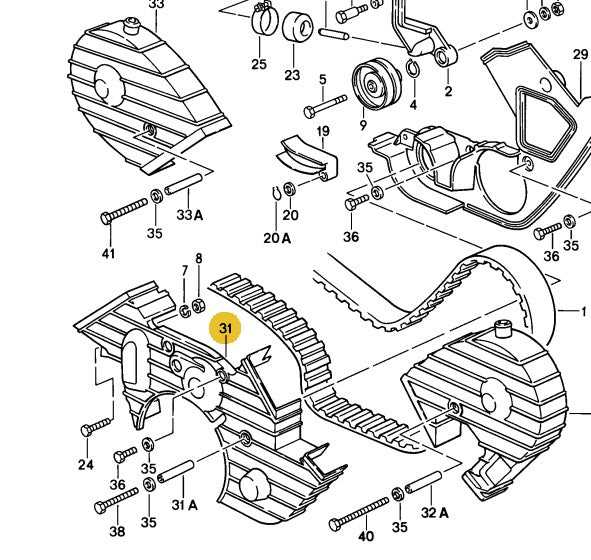

Clutch and Drive System Structure

The clutch and drive mechanism is a crucial aspect of any outdoor power equipment, providing the necessary power transfer from the engine to the cutting tool. Understanding its components and functionality can enhance performance and longevity.

Typically, the drive system comprises several key elements:

Maintaining the integrity of the clutch and drive assembly is essential for optimal operation. Regular inspections and timely replacements of worn-out parts can significantly enhance the efficiency and effectiveness of the equipment.

In summary, a well-functioning clutch and drive system not only improves performance but also contributes to the overall reliability of outdoor power tools. Proper understanding and maintenance of these components can lead to better user experience and extended service life.

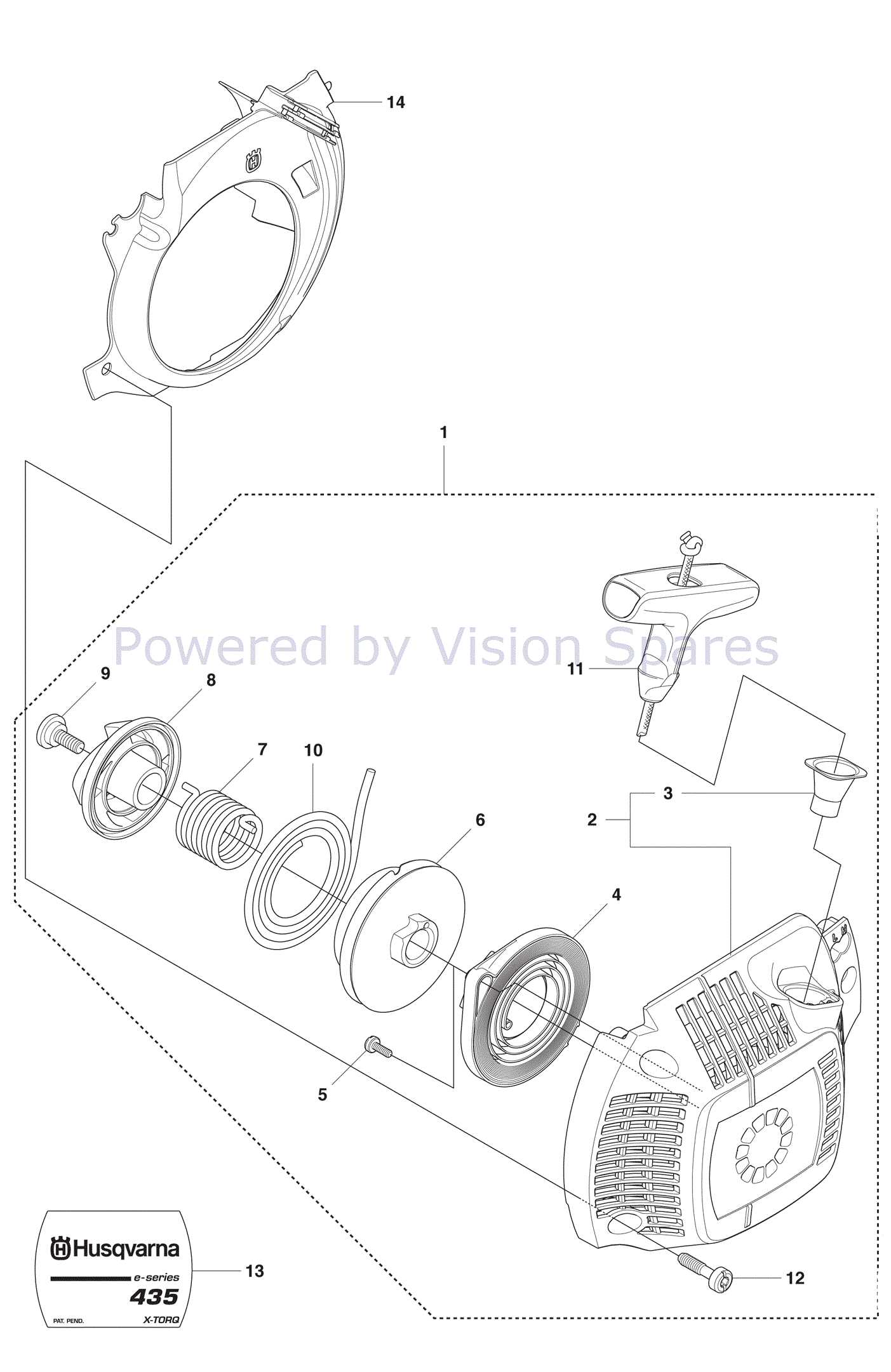

Starter Mechanism and Recoil Housing

The starter system is a crucial component in any outdoor power equipment, responsible for initiating the engine’s operation. It typically consists of several interconnected elements that work together to create the necessary force to start the engine. Understanding the function and structure of the recoil housing and its associated components can enhance maintenance and troubleshooting efforts.

Key Components of the Starter Mechanism

The starter mechanism generally includes various parts, such as the recoil spring, pulley, and handle. Each of these components plays a vital role in the overall functionality:

| Component | Function |

|---|---|

| Recoil Spring | Stores energy and assists in retracting the starter rope after use. |

| Pulley | Transmits the pulling force from the handle to the engine crankshaft. |

| Starter Handle | Provides the user with a grip to pull the rope and activate the mechanism. |

Importance of Proper Maintenance

Regular inspection and maintenance of the recoil housing and starter components are essential for optimal performance. Ensuring that all parts are free from damage and debris will prolong the lifespan of the starter system and improve reliability during operation. Proper lubrication and timely replacement of worn-out components are also key to preventing potential issues.

Oil Pump and Lubrication Setup

The oil pump and lubrication system are crucial components in maintaining the efficiency and longevity of any chainsaw. Proper lubrication ensures that the chain and bar operate smoothly, reducing friction and wear during use. An efficient setup not only enhances performance but also minimizes the risk of damage to essential parts.

To achieve optimal functionality, it is vital to ensure that the oil pump is correctly calibrated. This involves adjusting the flow rate of the oil, allowing for an adequate supply to the chain while preventing excessive waste. Regular maintenance, including cleaning and inspecting the oil reservoir and lines, is essential to avoid clogs and ensure consistent oil delivery.

Additionally, choosing the right type of lubricant is critical. Different environments and cutting conditions may require specific oil formulations to provide the best protection and performance. Users should refer to the manufacturer’s recommendations to select an appropriate oil that meets the operational demands of their equipment.

Exhaust System and Muffler Parts

The exhaust system is a vital component of any power tool, ensuring efficient operation and reducing harmful emissions. It plays a crucial role in directing exhaust gases away from the engine while minimizing noise. This section provides an overview of the key elements that make up this system, highlighting their functions and importance for optimal performance.

Key Components

Maintenance Tips

- Regularly inspect the muffler and exhaust pipe for signs of damage or corrosion.

- Check the exhaust gasket for wear and replace it as needed to prevent leaks.

- Ensure that the heat shield is securely in place and free from debris.

- Consult the user manual for specific maintenance recommendations and intervals.

Proper upkeep of the exhaust system not only enhances the performance of the equipment but also contributes to a safer working environment by reducing harmful emissions and noise levels.

Maintenance Tips for Optimal Performance

Ensuring your equipment runs smoothly and efficiently requires regular upkeep and attention. By following a few essential guidelines, you can enhance the lifespan and functionality of your device. Consistent maintenance not only prevents unexpected breakdowns but also guarantees peak performance during operation.

Here are some effective practices to maintain your machinery:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 25 hours | Replace the oil to ensure optimal lubrication of internal components. |

| Filter Inspection | Every 10 hours | Check and clean or replace air and fuel filters to prevent clogging. |

| Chain Tensioning | After each use | Adjust the chain tension to prevent slippage and ensure safe operation. |

| Blade Sharpening | As needed | Keep the cutting edge sharp for efficient cutting and to reduce strain. |

| Visual Inspection | Before each use | Inspect the overall condition for any signs of wear or damage. |

By adhering to these maintenance recommendations, you will not only prolong the life of your equipment but also improve its efficiency and safety. Regular care will lead to better performance, allowing you to tackle tasks with confidence.