For those who manage or maintain a swimming pool, comprehending the intricacies of its operational equipment is crucial. Each element plays a vital role in ensuring the system functions efficiently. Familiarity with these components can simplify troubleshooting and enhance overall maintenance practices.

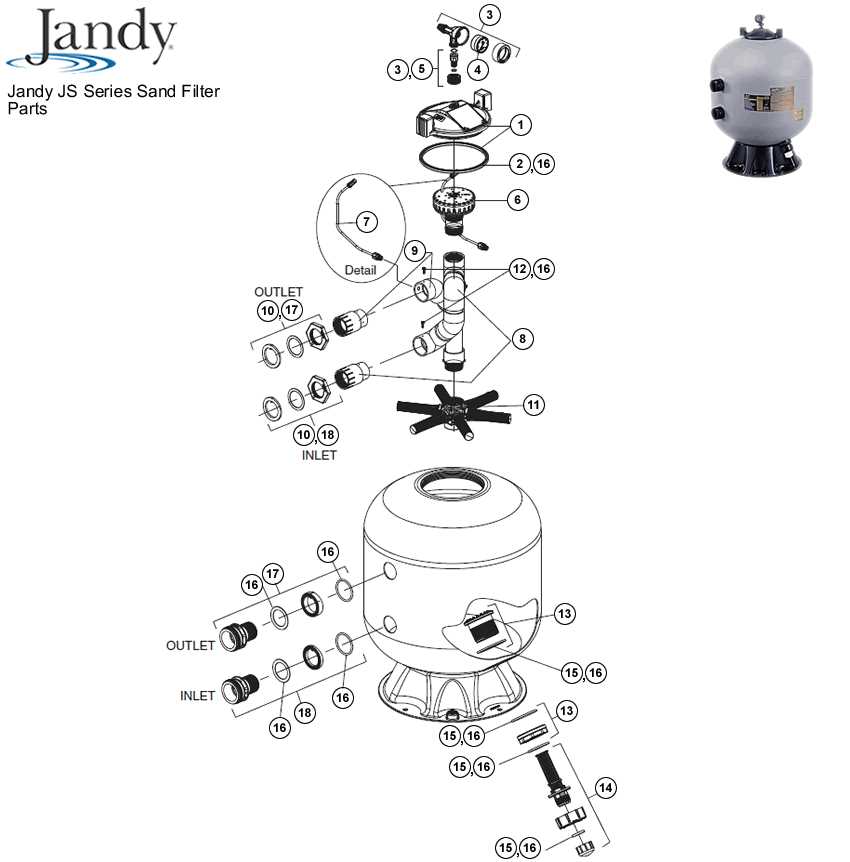

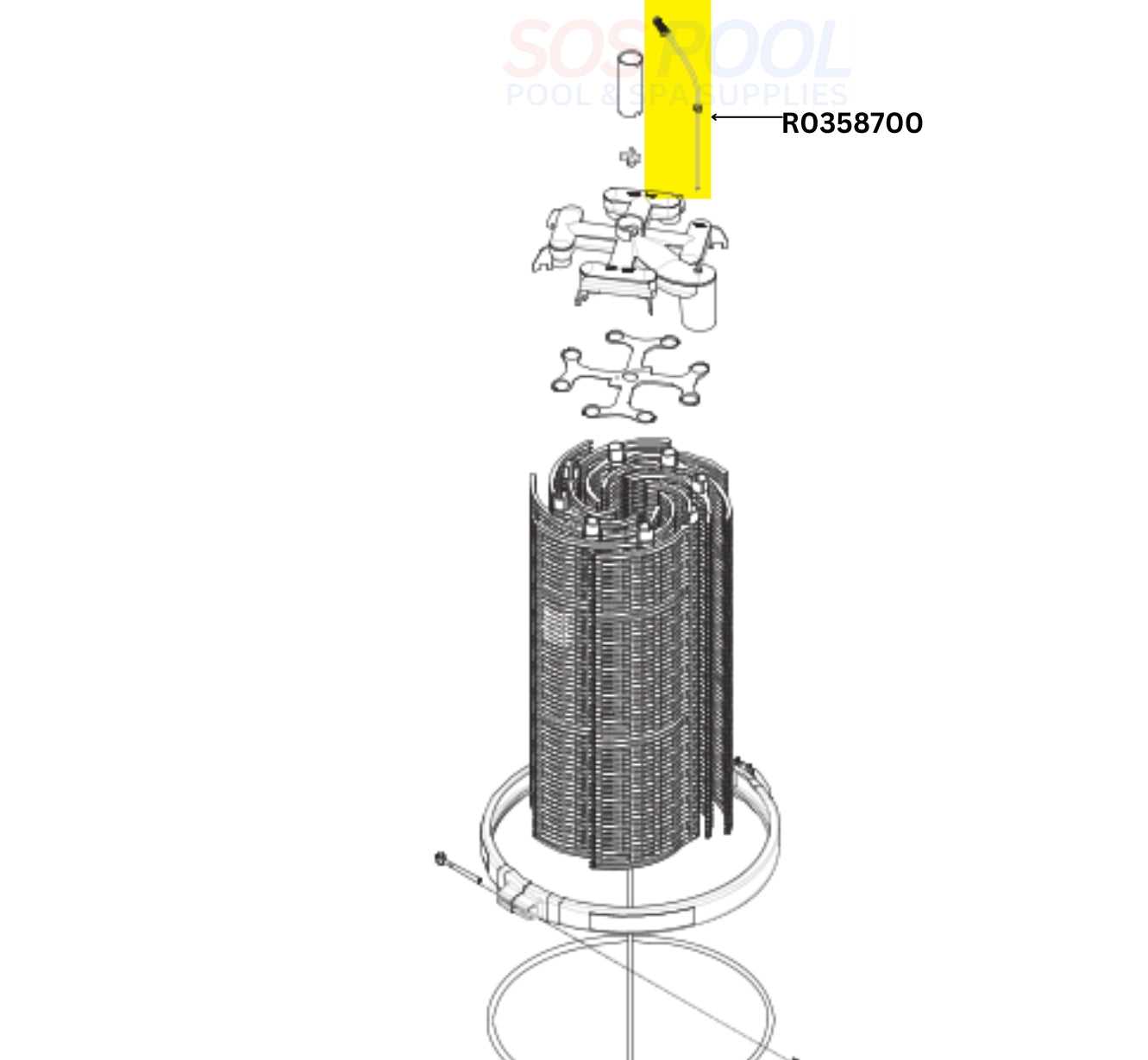

Visual representations of the individual units involved are essential for effective understanding. These illustrations not only clarify the interconnections between the various parts but also highlight their specific functions. By utilizing detailed visual guides, users can quickly identify and replace components as needed, leading to improved performance and longevity of the system.

Moreover, knowing the structure and layout of the equipment aids in planning upgrades or modifications. A well-organized overview facilitates better decision-making when it comes to purchasing replacements or additional features. Ultimately, this knowledge empowers pool owners to take proactive measures in maintaining their recreational spaces.

Understanding Jandy CV460 Components

In any system, a thorough comprehension of its elements is essential for optimal performance and maintenance. Each component plays a critical role, contributing to the overall efficiency and functionality of the equipment. By grasping how these individual pieces interact, users can ensure longevity and reliability in their operations.

First and foremost, the primary unit serves as the heart of the assembly, facilitating essential processes that allow the entire system to function seamlessly. This core component is complemented by various attachments, each designed to enhance specific operations, ranging from filtration to control mechanisms.

Moreover, understanding the significance of supporting elements cannot be overlooked. These auxiliary parts contribute to the stability and efficiency of the main unit, ensuring that every operation runs smoothly. Regular checks and maintenance of these elements can prevent potential issues and enhance the overall lifespan of the entire system.

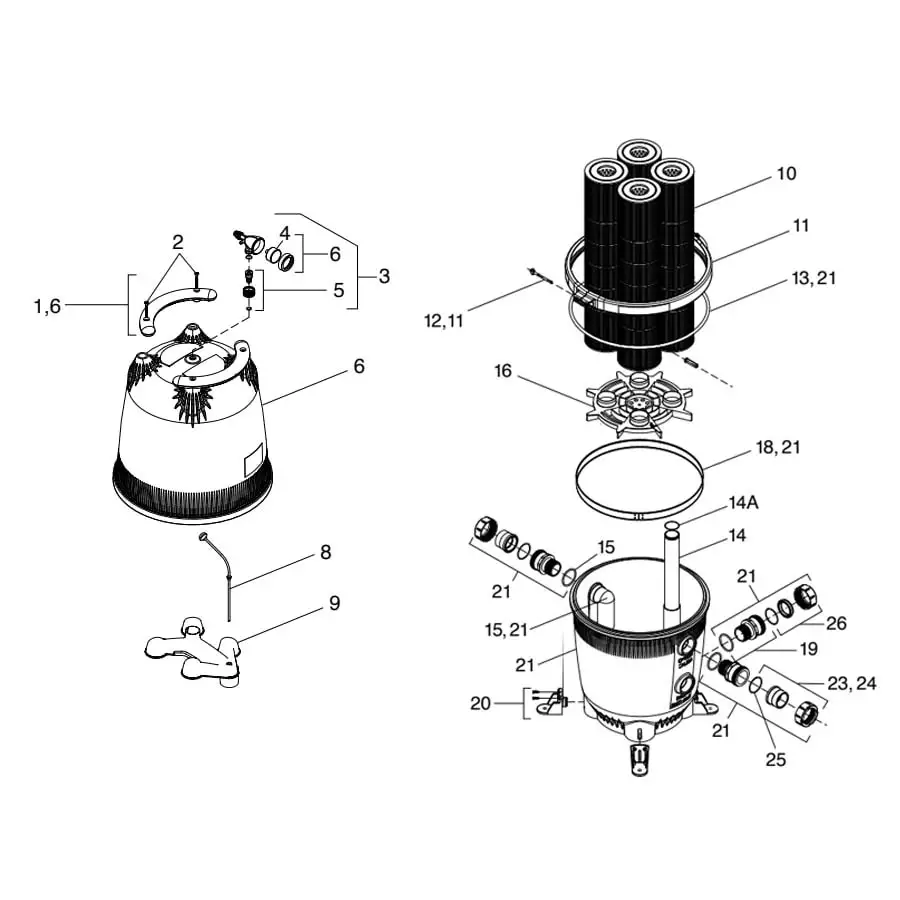

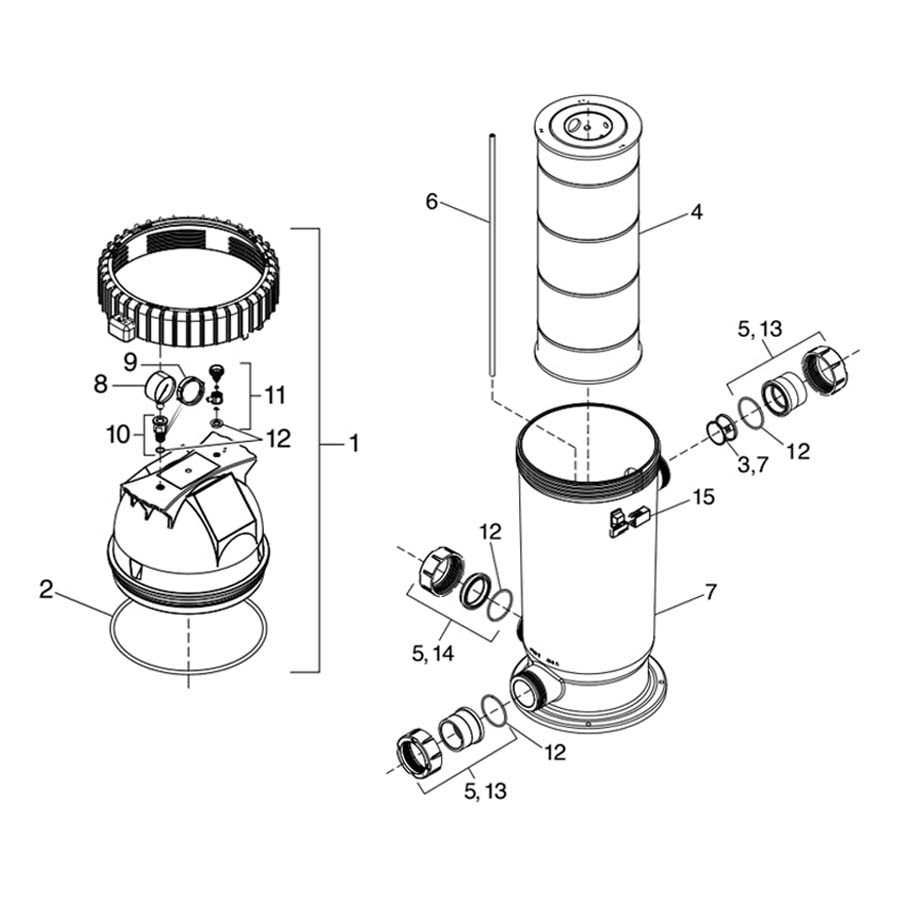

Key Parts of the Jandy CV460

This section provides an overview of the essential components that contribute to the functionality and efficiency of this particular model. Understanding these elements is crucial for maintenance and troubleshooting.

Main Components

- Filter Tank: The primary container where the filtration process occurs.

- Pressure Gauge: A device that measures the pressure within the system, ensuring optimal performance.

- Valve Assembly: Controls the flow of water, allowing for effective operation and maintenance.

- Strainer: A crucial part that captures debris, protecting the internal mechanisms.

Additional Elements

- Drain Plug: Facilitates easy removal of water for maintenance purposes.

- O-Rings: Provide seals that prevent leaks and ensure system integrity.

- Mounting Bracket: Secures components in place for stability during operation.

Exploring the CV460 Components

In this section, we delve into the various components that comprise the CV460 system, offering an insightful exploration of its intricate parts and their functions. Discovering the elements that make up this mechanism provides a deeper understanding of its operational dynamics.

Key Elements and Their Roles

- Essential components and their respective functions

- Understanding the roles played by each part within the system

- Analyzing the interconnections between components

By examining these parts in detail, we gain clarity on how they contribute to the overall functionality of the CV460, enhancing our comprehension of its operational intricacies.

Importance of Each Component

In understanding the functionality of each part within this system, we delve into the critical roles played by every element. Each component assumes a pivotal function, contributing uniquely to the overall operation and efficiency. By comprehending their significance, users gain insight into how these parts collaborate harmoniously to achieve optimal performance.

The Significance of Individual Elements

Every element in this setup serves a distinct purpose, ensuring seamless integration and reliable functionality. From essential mechanisms to intricate components, each part enhances the system’s capability to fulfill its designated tasks with precision and reliability.

Enhancing System Efficiency

By recognizing the importance of each constituent part, users can effectively maintain and optimize system performance. This awareness allows for proactive maintenance and troubleshooting, promoting longevity and sustained operational efficiency.

Common Issues with Jandy CV460

Every equipment may encounter various challenges over time, affecting its performance and reliability. Understanding the typical problems that can arise is crucial for effective maintenance and timely repairs. This section will explore some frequent concerns associated with this specific model, helping users identify and address them proactively.

Performance Inefficiencies

One of the most common issues reported involves a noticeable decline in operational efficiency. Users may experience reduced output or inconsistent performance, often attributed to clogged filters or worn components. Regular maintenance, including cleaning and timely replacements, is essential to prevent such issues.

Leakage Problems

Another significant concern relates to the occurrence of leaks, which can lead to substantial water loss and damage. These leaks may stem from faulty seals or deteriorated fittings. Regular inspections and prompt replacement of compromised parts can mitigate this risk, ensuring optimal functionality.

Maintaining Your CV460 Parts

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances functionality but also prevents costly repairs down the line. Here are some key practices to consider for keeping your components in top shape.

- Regular Inspections: Schedule routine checks to identify wear and tear early. Look for signs of corrosion or damage that could impact performance.

- Cleaning: Keep all surfaces free from debris and buildup. Use a soft cloth and appropriate cleaning solutions to avoid scratching any components.

- Lubrication: Apply lubricant to moving parts as recommended to reduce friction and wear. This helps in maintaining smooth operation.

- Replacement of Worn Components: Be proactive in replacing any elements that show significant signs of wear. Doing so ensures that the entire system functions effectively.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided by the manufacturer to ensure you are meeting specific requirements for your unit.

By following these practices, you can prolong the life of your machinery and enhance its efficiency, allowing it to perform at its best for years to come.

How to Replace Faulty Components

In this section, we will guide you through the process of swapping out defective parts in your system. Whether you’re dealing with malfunctioning elements or components showing signs of wear, the steps outlined below will assist you in ensuring seamless replacement.

Identifying the Issue

Before beginning any replacement, it’s crucial to accurately identify the problem area. Look for indicators such as irregular functionality, unusual noises, or visible damage. Understanding the root cause allows for targeted component replacement, optimizing system performance.

Once the problematic component is identified, proceed by carefully disconnecting any associated connectors or fasteners. Exercise caution to prevent unintended damage to surrounding parts.

Installing the New Component

After removing the faulty part, prepare the replacement component by ensuring compatibility and inspecting for any shipping-related damage. Align the new component correctly within its designated housing, utilizing secure fittings or mounting points.

Reconnect any necessary wiring or tubing, ensuring each connection is secure and aligned according to manufacturer specifications. Double-check for proper fit and function before proceeding to power up the system.

By following these steps methodically, you can effectively replace faulty components in your system, restoring optimal functionality without the need for extensive technical expertise.

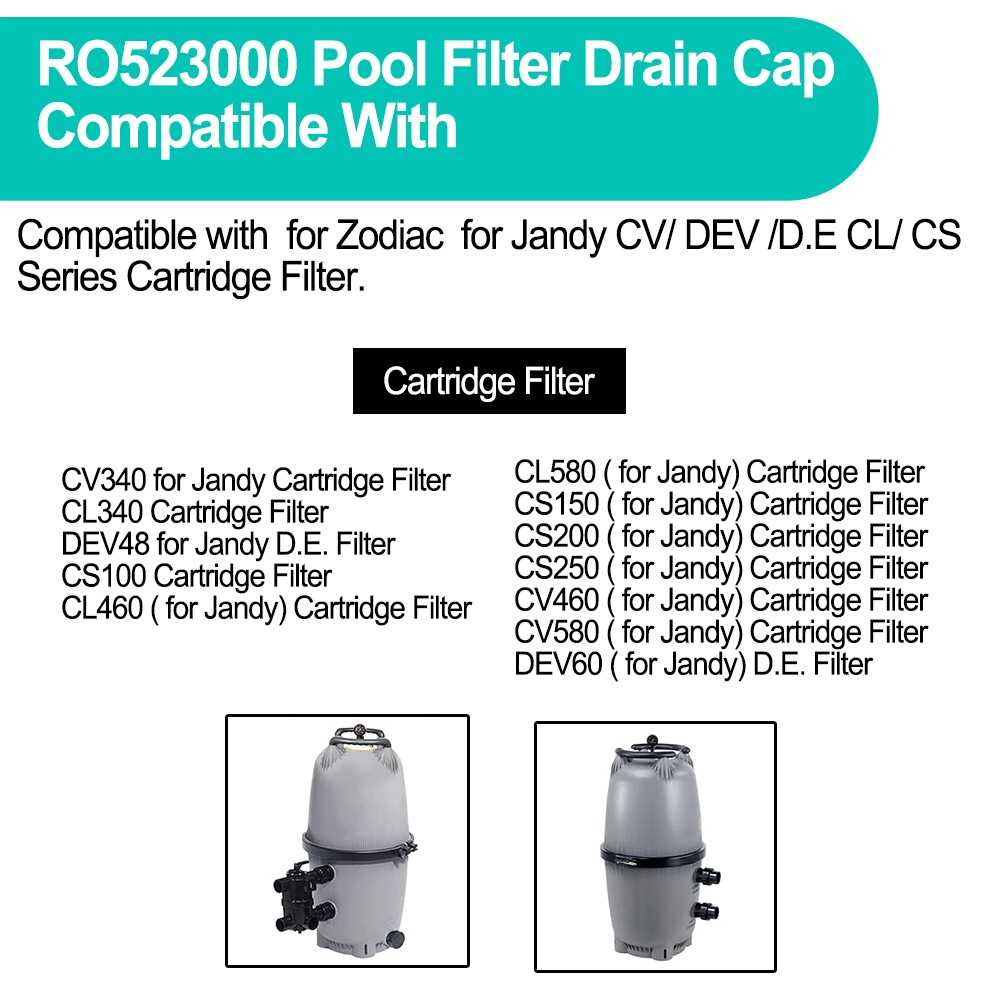

Finding Genuine Jandy Replacement Parts

Ensuring the longevity and efficiency of your pool equipment requires the use of authentic components. When it comes to maintaining optimal performance, sourcing high-quality replacements is crucial. This section will explore the significance of acquiring original items that match the specifications of your existing system.

Authentic components guarantee compatibility, durability, and reliability. They are designed to meet the original manufacturer’s standards, providing peace of mind that your system will function as intended. Avoiding generic alternatives can save you from potential malfunctions and additional repair costs.

To locate genuine replacements, consider reputable retailers and official distributors. Verify that the seller has a solid reputation for offering legitimate products. Additionally, consult user manuals or online resources for guidance on identifying specific requirements for your system.

Investing in authentic components not only enhances performance but also extends the lifespan of your equipment. By prioritizing quality over price, you can ensure that your system operates smoothly, providing a safe and enjoyable experience.

Tools Required for Assembly

When it comes to assembling equipment efficiently, having the right tools is essential for a smooth process. A well-equipped workspace can significantly impact the ease and accuracy of the task at hand. Below is a list of necessary instruments to ensure that assembly is carried out without any hitches.

| Tool | Purpose |

|---|---|

| Screwdriver | Used for driving screws into various components. |

| Wrench | Essential for tightening and loosening nuts and bolts. |

| Pliers | Useful for gripping and bending wires or small parts. |

| Measuring Tape | Helps ensure precise measurements during assembly. |

| Level | Ensures that components are installed evenly and accurately. |

| Utility Knife | Can be used for cutting various materials as needed. |

Assembly Instructions for CV460

This section provides a comprehensive guide for the assembly process of the specified model. Following these steps carefully will ensure proper functioning and longevity of the equipment.

Before you begin, make sure you have all necessary components and tools readily available. Review the list below to confirm you have everything required:

- All major components

- Assembly tools (screwdriver, wrench, etc.)

- Sealant or lubricants as needed

- Protective gear (gloves, goggles)

To ensure a smooth assembly process, follow these sequential steps:

- Prepare the workspace: Clear an area where you can work without interruptions.

- Check components: Inspect each item for damage or defects before starting.

- Assemble the base: Begin by securing the base components together using the provided fasteners.

- Attach the housing: Align and attach the housing to the base, ensuring a tight fit.

- Install internal mechanisms: Carefully insert internal components according to the specifications, making sure all connections are secure.

- Seal joints: Apply sealant to all joints to prevent leaks, if applicable.

- Final checks: Go through all connections once more to ensure everything is properly secured.

Upon completing the assembly, it’s advisable to perform a thorough inspection and testing to confirm that everything operates correctly. Proper assembly is crucial for optimal performance.

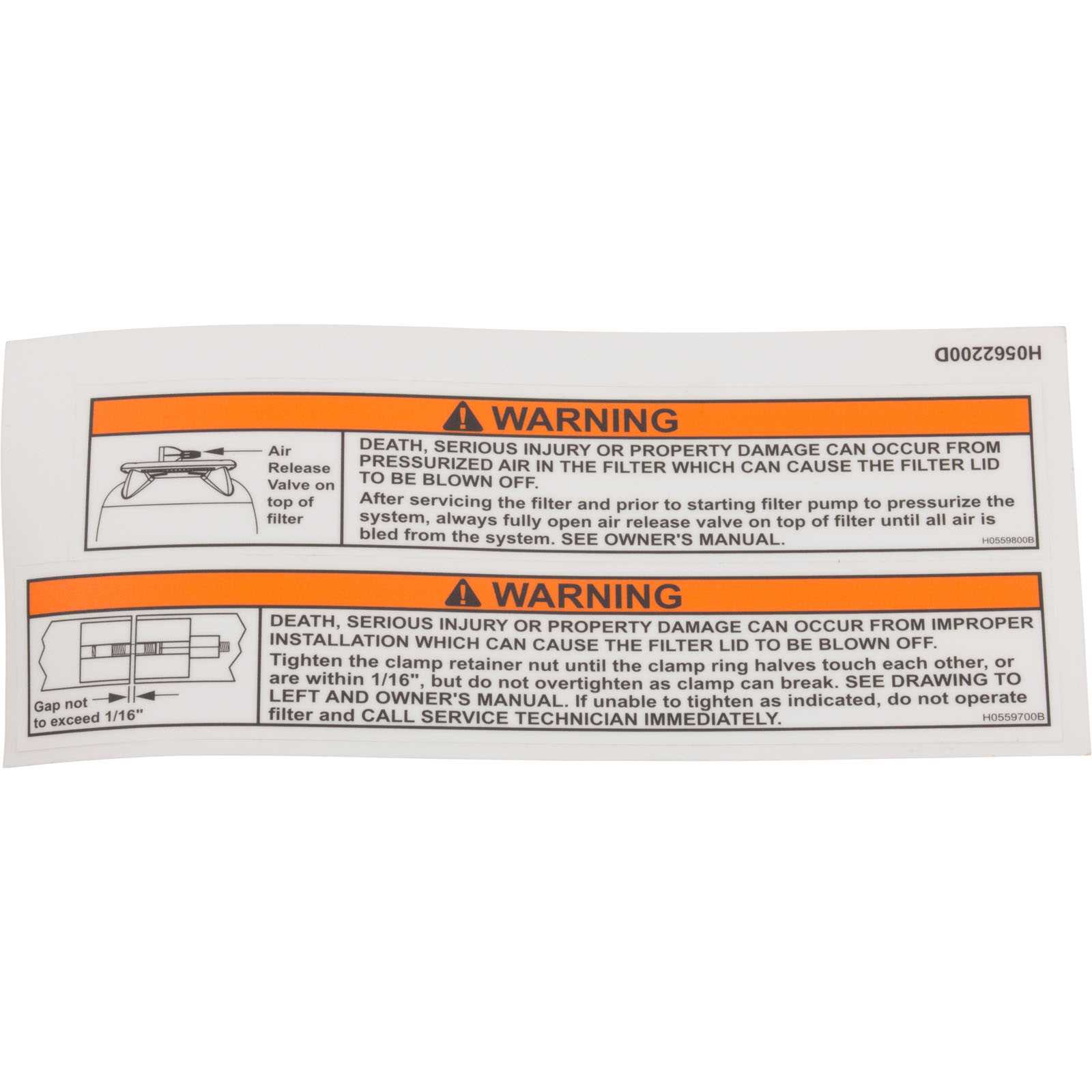

Safety Precautions for Repairs

When undertaking maintenance or repair tasks on any equipment, adhering to safety measures is crucial to prevent accidents and ensure a secure working environment. Proper precautions not only protect the individual performing the work but also help preserve the integrity of the equipment being serviced.

Here are essential safety practices to keep in mind:

- Read the Manual: Always consult the manufacturer’s manual before starting any repair work. It contains vital safety information and guidelines specific to the equipment.

- Disconnect Power: Ensure that the device is powered off and disconnected from any electrical source to avoid the risk of electric shock.

- Wear Protective Gear: Utilize appropriate safety equipment such as gloves, goggles, and masks to safeguard against injuries from sharp parts or harmful substances.

- Work in a Well-Lit Area: A well-illuminated workspace is essential for clear visibility, reducing the chance of mistakes during the repair process.

- Use Proper Tools: Employ the correct tools for the task to prevent damage to the equipment and minimize the risk of injury.

- Maintain a Clean Workspace: Keep the repair area organized and free from clutter to avoid accidents and ensure efficient work.

By following these precautions, individuals can significantly reduce risks and enhance their safety while performing necessary repairs on their equipment.

Frequently Asked Questions About CV460

This section addresses common inquiries regarding a particular model commonly used in pool and spa systems. Understanding the essential components and features can help users maintain optimal performance and troubleshoot issues effectively.

What maintenance is required for this model?

Regular upkeep includes cleaning filters, checking for leaks, and ensuring that all connections are secure. It is recommended to perform these checks every few weeks to avoid potential issues.

How often should I replace the components?

Replacement frequency depends on usage and environmental factors. Generally, it is advisable to inspect the parts every season and replace them as needed to maintain efficiency.

What are common signs of malfunction?

Users may notice unusual noises, decreased performance, or visible leaks. Addressing these symptoms promptly can prevent more significant problems down the line.

Is there a warranty for this model?

Most manufacturers provide a warranty covering specific parts and functionality. It’s essential to review the warranty details upon purchase to understand coverage and limitations.

Can I install it myself?

While some users may feel comfortable with DIY installation, it is recommended to seek professional assistance, especially for those unfamiliar with pool systems. Proper installation ensures safety and efficiency.