When it comes to maintaining and optimizing your machinery, a clear visual representation of its components can be invaluable. Recognizing how each element functions and fits together enhances both performance and longevity. This guide delves into the intricacies of a specific model, offering insights that empower users to effectively manage their tools.

By exploring the layout of the individual elements, enthusiasts and professionals alike can gain a deeper appreciation for the engineering behind their equipment. Whether you’re troubleshooting issues or planning upgrades, knowing the arrangement and function of each piece is essential. This overview serves as a roadmap to navigate through the essential features, ensuring that every operation runs smoothly.

Equipped with this knowledge, users can confidently approach repairs and enhancements, ultimately fostering a more efficient and effective work environment. Let’s take a closer look at the various components that contribute to the overall success of your machinery.

Overview of Campbell Hausfeld Compressors

This section provides a comprehensive look at the innovative equipment known for their reliability and efficiency in various applications. These machines are essential tools for both professionals and enthusiasts, delivering power and performance to tackle a range of tasks.

Key Features

- Durability and Longevity

- User-Friendly Design

- Versatile Applications

- Energy Efficiency

Popular Models

- Portable Units

- Stationary Variants

- Heavy-Duty Options

Understanding these aspects helps users make informed decisions when selecting the right equipment for their needs.

Importance of Air Compressor Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and troubleshooting. Diagrams serve as valuable tools for users, providing a visual representation of essential elements, which facilitates easier identification and repair processes.

Here are some key reasons why these visuals are important:

- Enhanced Understanding: Visual aids help users grasp complex systems more easily, making it simpler to locate specific elements.

- Efficient Troubleshooting: When issues arise, diagrams allow for quick reference, enabling faster diagnosis and resolution of problems.

- Improved Maintenance: Regular upkeep becomes more manageable with clear depictions of where components are situated, ensuring no part is overlooked.

- Guided Assembly: For those assembling machinery, diagrams offer step-by-step guidance, reducing the risk of errors during the setup process.

- Safety Assurance: By knowing the arrangement of elements, users can work more safely, avoiding potential hazards associated with improper handling.

In summary, these illustrations are invaluable resources that contribute to better performance and longevity of equipment.

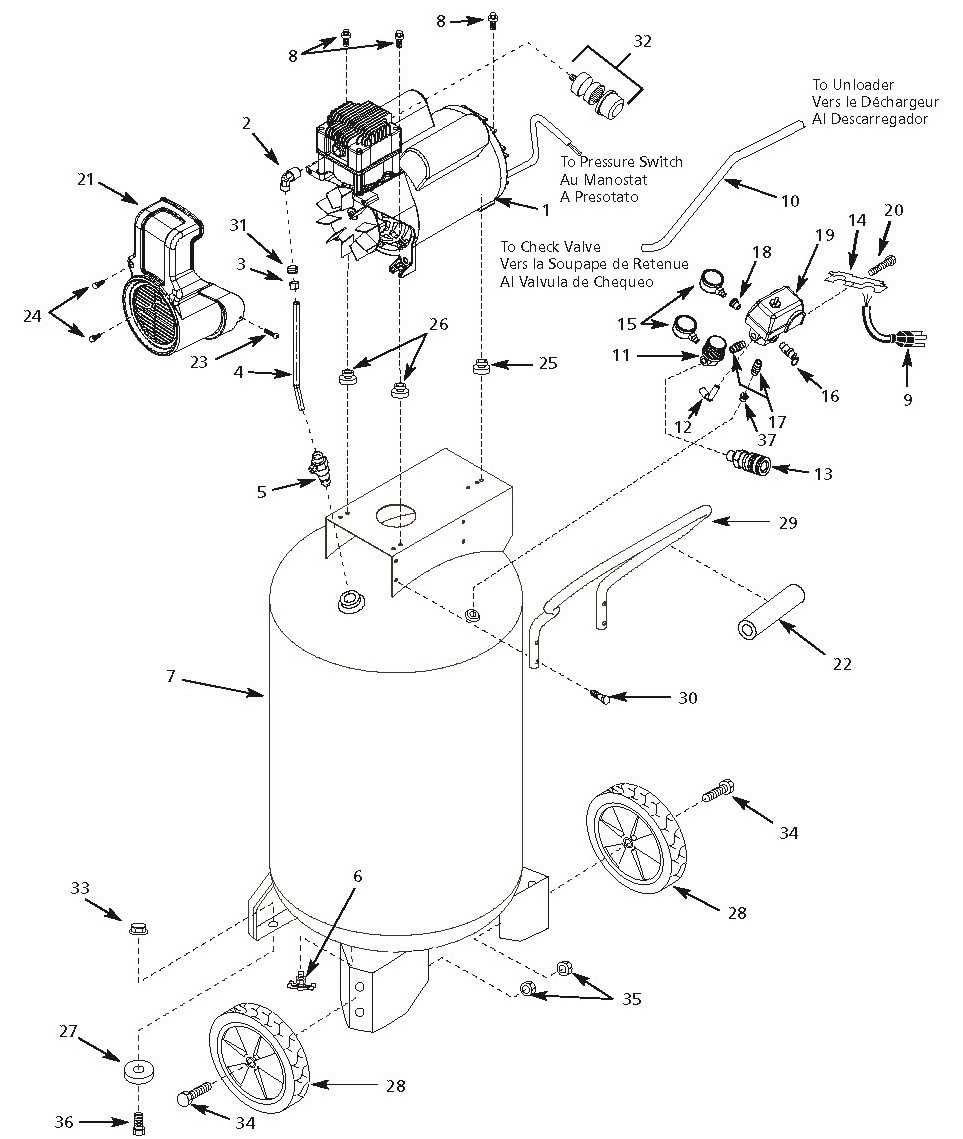

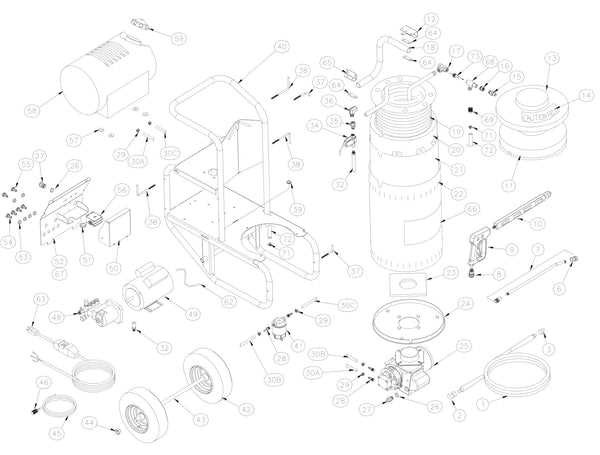

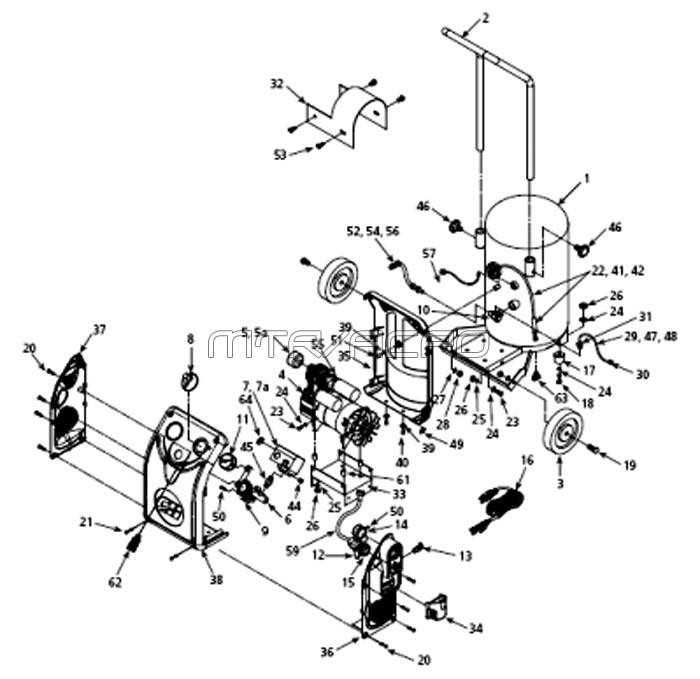

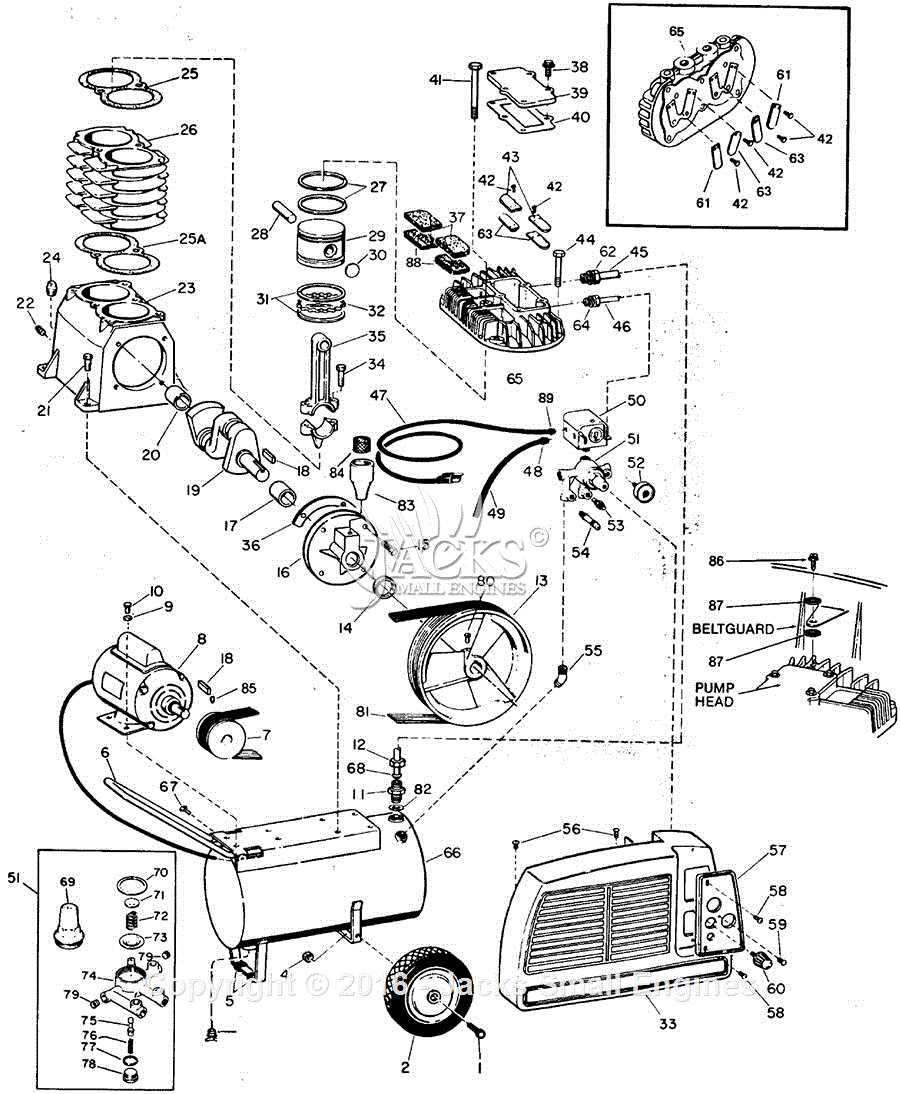

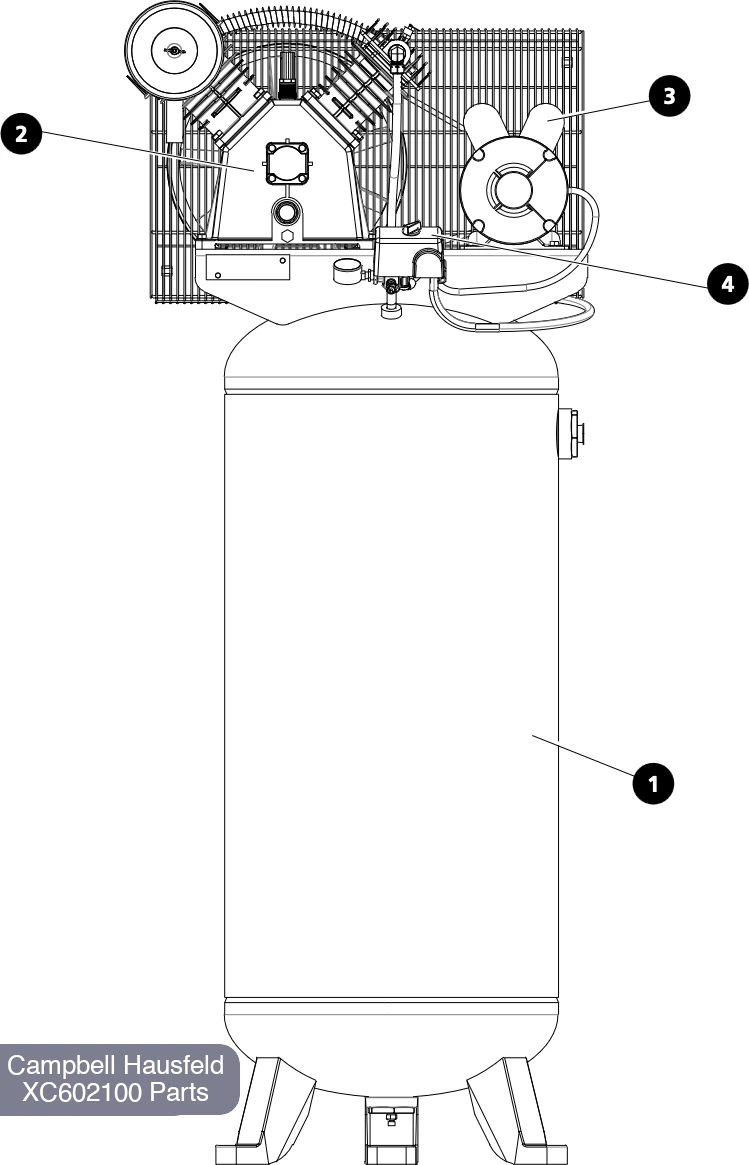

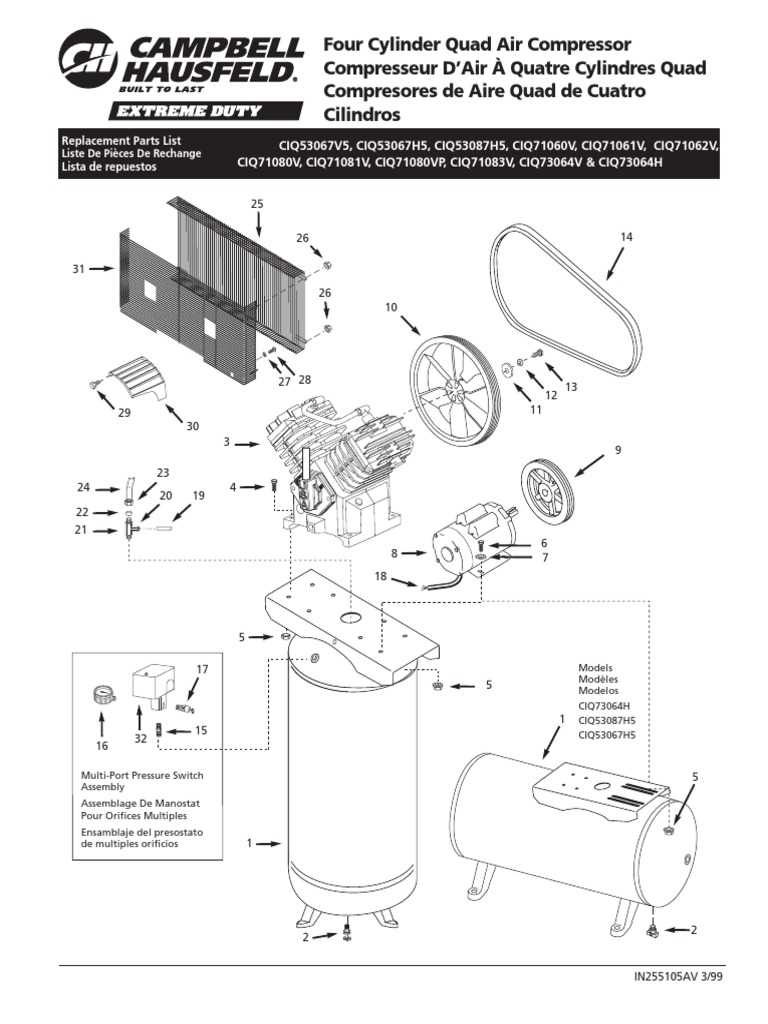

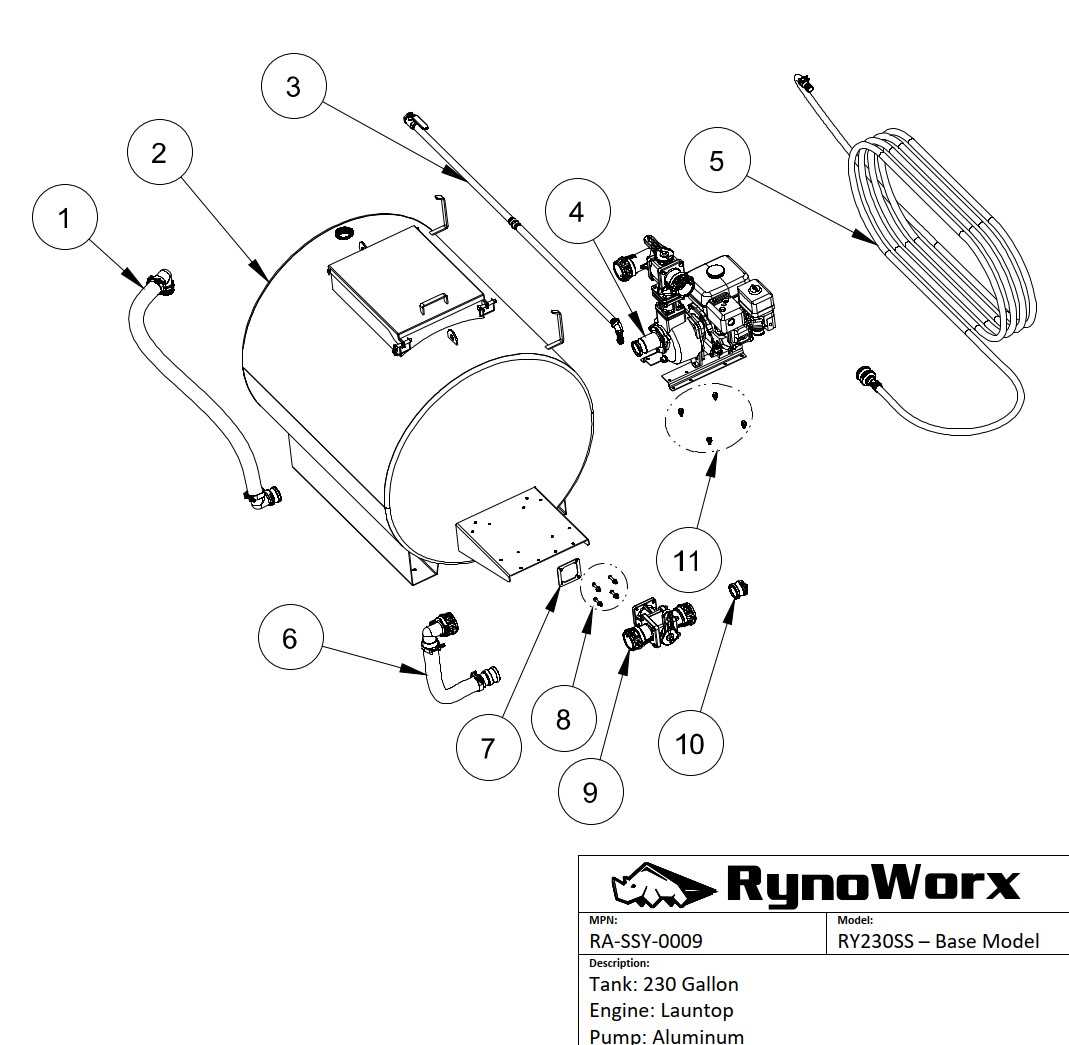

Key Components of 20 Gallon Models

Understanding the essential elements of these 20-gallon units is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity, contributing to the overall efficiency of the equipment.

The motor serves as the powerhouse, driving the entire system, while the tank stores the compressed substance, providing a reservoir for various tasks. A pressure switch regulates the output, ensuring consistent flow, and a gauge allows users to monitor the levels for accuracy. Additionally, the manifold connects multiple components, facilitating seamless operation, while the drain valve enables easy maintenance.

Accessories like hoses and connectors enhance usability, making these models versatile for various applications. Familiarizing oneself with these key parts enables users to make informed decisions regarding repairs and upgrades, ultimately improving functionality and reliability.

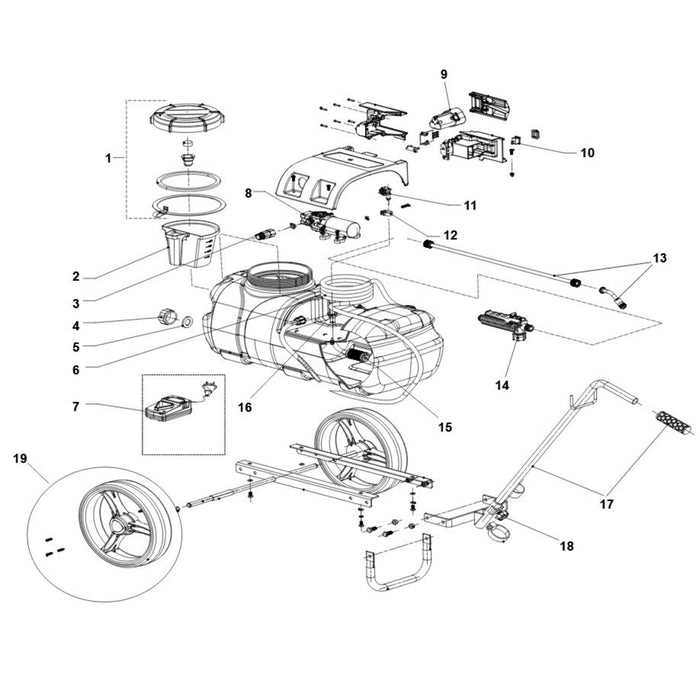

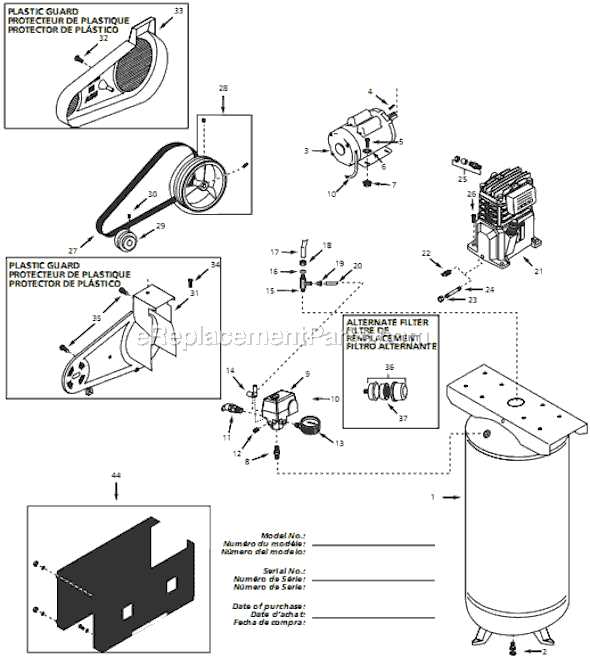

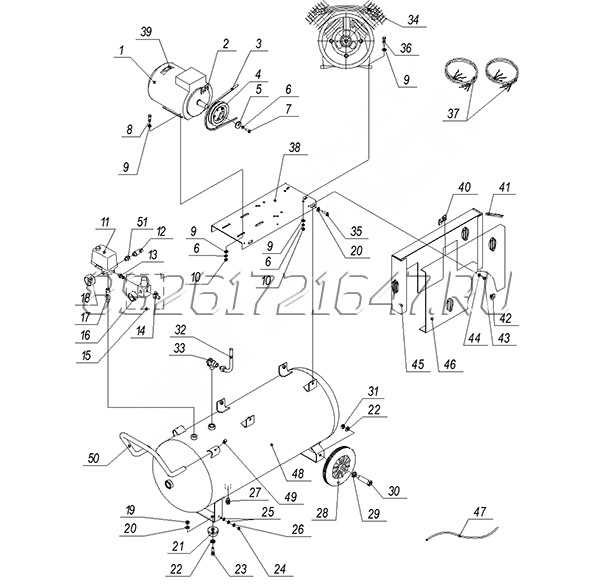

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear guide to identifying and organizing various elements of machinery, allowing users to comprehend how each piece functions within the whole. Familiarity with these graphics can simplify the troubleshooting process and enhance overall efficiency.

Identifying Components

Start by examining the labeled sections of the illustration. Each part is typically marked with a number or letter, correlating to a list that describes its function and specifications. Pay attention to the scale and orientation, as this can affect your understanding of how components fit together.

Understanding Connections

Look for lines or arrows that indicate connections between elements. These notations often represent flow paths, attachment points, or other relationships critical to the operation of the system. Recognizing these connections will aid in diagnosing issues and ensuring proper assembly.

Common Issues with Compressors

In the realm of mechanical devices designed to increase pressure, various challenges can arise that may hinder their performance. Understanding these common problems is crucial for effective troubleshooting and maintenance.

Frequent Challenges

- Loss of pressure: This often indicates leaks or worn components.

- Overheating: Insufficient cooling or extended operation without breaks can lead to excessive heat.

- Noise levels: Unusual sounds may suggest internal damage or misalignment.

Preventive Measures

- Regular inspections: Check for wear and tear to prevent sudden failures.

- Proper lubrication: Ensure all moving parts are adequately greased to reduce friction.

- Clean filters: Regularly replacing or cleaning air intake filters helps maintain efficiency.

Identifying Replacement Parts Easily

When it comes to maintaining equipment, knowing how to locate the right components is crucial. This process not only saves time but also ensures optimal performance of your tools. By utilizing resources like schematics and part catalogs, you can simplify the search for necessary replacements.

Understanding the Components

Familiarizing yourself with the various elements involved in your machinery can significantly enhance your efficiency. Start by categorizing each section, which allows for a clearer view of what is required when a part needs replacing. Here is a breakdown of common categories:

| Category | Description |

|---|---|

| Mechanical | Includes moving parts that are vital for function. |

| Electrical | Encompasses wiring and components that provide power. |

| Accessories | Additional tools that enhance usability or performance. |

Finding the Right Resources

Utilize online platforms, manufacturer websites, and local retailers to gather information on the specific components you need. Many suppliers offer detailed guides and visual aids that can assist in making informed decisions. Make sure to cross-reference any findings with your original documentation for accuracy.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your device, allowing you to enjoy reliable operation for years to come. Here are some essential practices to keep in mind.

| Tip | Description |

|---|---|

| Regular Inspection | Check for any signs of wear or damage. Early detection can prevent major issues. |

| Clean Components | Keep all parts free from dust and debris to maintain optimal functioning. |

| Check Fluid Levels | Ensure that all necessary fluids are at appropriate levels to avoid overheating. |

| Follow Manufacturer Guidelines | Adhere to the specific recommendations provided for maintenance schedules and procedures. |

| Store Properly | When not in use, keep your equipment in a dry and safe environment to protect it from environmental damage. |

Implementing these tips can greatly enhance the performance and reliability of your device, ensuring it serves you well for an extended period.

Safety Precautions During Use

Ensuring a secure working environment is crucial when operating equipment that generates pressurized air. Understanding the risks associated with such machinery can help prevent accidents and injuries.

Always wear appropriate personal protective equipment, including safety goggles and gloves, to safeguard against potential hazards. Additionally, maintain a clear workspace free from obstacles to avoid tripping or falling.

Before starting the device, inspect it for any signs of damage or wear. Regular maintenance checks will enhance performance and prolong the lifespan of the machinery.

Be mindful of the recommended operating pressure, as exceeding limits can lead to catastrophic failures. Familiarize yourself with the emergency shut-off procedures to ensure swift action in case of malfunction.

Finally, ensure proper ventilation in the area to prevent the buildup of harmful fumes and maintain a safe environment for all users.

Finding Genuine Replacement Parts

When maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Using high-quality replacements ensures that your device operates smoothly and minimizes the risk of future complications. This section delves into effective strategies for locating these essential items.

1. Official Manufacturers: Start by visiting the official website of the manufacturer. They often provide a comprehensive list of available components along with specifications, ensuring you find exactly what you need.

2. Authorized Dealers: Seek out authorized dealers who specialize in the brand. These vendors are more likely to offer genuine items and can provide valuable insights about compatibility and installation.

3. Online Marketplaces: Explore reputable online marketplaces, but exercise caution. Always check seller ratings and reviews to avoid counterfeit goods. Look for listings that explicitly state the authenticity of the components.

4. Community Forums: Engage with online communities and forums dedicated to your equipment. Members often share experiences and recommendations for reliable sources of genuine replacements.

5. Warranty Considerations: Remember that using unauthorized items may void warranties. Always check your warranty terms to ensure compliance when sourcing replacements.

Prioritizing genuine components not only enhances performance but also extends the lifespan of your equipment, making the search worthwhile.

Tools Required for Assembly

Successfully assembling your equipment necessitates the right set of tools. Having the appropriate instruments not only ensures a smoother process but also contributes to the overall efficiency and safety of the task at hand. Below are essential tools you will need to facilitate a seamless assembly experience.

Basic Hand Tools

To begin with, a collection of basic hand tools is vital. This typically includes a screwdriver set, a wrench set, and pliers. These tools will assist in securing components and making necessary adjustments. Ensure that the tools are of good quality to avoid stripping screws or damaging fittings.

Specialized Instruments

In addition to basic tools, some specialized instruments may be required. A torque wrench can be essential for applying the correct amount of force when fastening bolts. Furthermore, having a level on hand ensures that your assembly is perfectly aligned. For tasks involving more complex components, consider a multimeter for checking electrical connections.

Upgrading Your Air Compressor

Enhancing your pneumatic equipment can significantly improve its performance and efficiency. By investing in quality components and making thoughtful modifications, you can elevate the overall functionality, ensuring it meets your evolving needs.

Considerations for Improvement: Evaluate the current setup and identify areas where enhancements can be made. Upgrading to a more powerful motor or incorporating a larger tank can provide greater output and longer run times, ultimately leading to improved productivity.

Maintenance Matters: Regular upkeep is crucial. Replacing worn-out filters and lubricating moving parts not only extends the lifespan but also enhances performance. This attention to detail can make a substantial difference in operation quality.

Accessories to Boost Efficiency: Adding tools such as pressure regulators, moisture separators, and hoses can optimize functionality. These accessories help in managing output pressure and maintaining cleanliness, which are vital for achieving the best results.

In summary, thoughtful upgrades and diligent maintenance can transform your equipment into a more reliable and efficient asset for any task.

FAQs About Campbell Hausfeld Products

This section addresses common inquiries regarding a popular brand’s tools and equipment. Users often seek clarification on various aspects, from maintenance to functionality, ensuring they make informed decisions.

What maintenance is required for optimal performance?

Regular checks, including oil levels and air filters, are essential. Additionally, keeping the unit clean and inspecting for wear can significantly enhance longevity.

Where can I find replacement components?

Replacement items can typically be sourced through authorized dealers or online retailers. It’s advisable to refer to the manufacturer’s website for specific recommendations and compatibility.