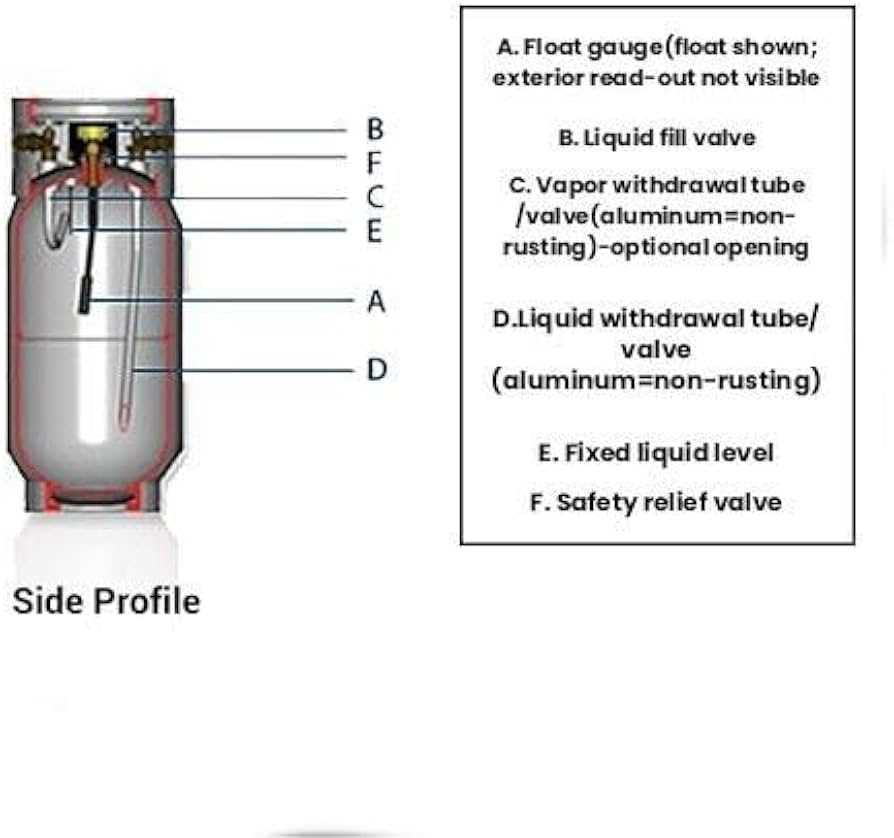

In this section, we delve into the essential elements that constitute a gas storage solution. By exploring these components, readers can gain insight into how each part functions to ensure safety and efficiency in usage. Familiarity with these components is crucial for anyone working with or maintaining gas-related systems.

The intricacies of a gas container reveal various mechanisms that work together seamlessly. From the mechanism that controls the flow to safety features designed to prevent accidents, each element plays a significant role. Recognizing the importance of these elements can enhance one’s understanding of the overall operation.

Moreover, having a visual representation of these components can significantly aid in comprehending their layout and function. This knowledge not only facilitates better maintenance practices but also empowers users to identify potential issues before they escalate. Equipped with this understanding, users can approach their gas systems with confidence and responsibility.

and tags: Understanding Propane Tank Components

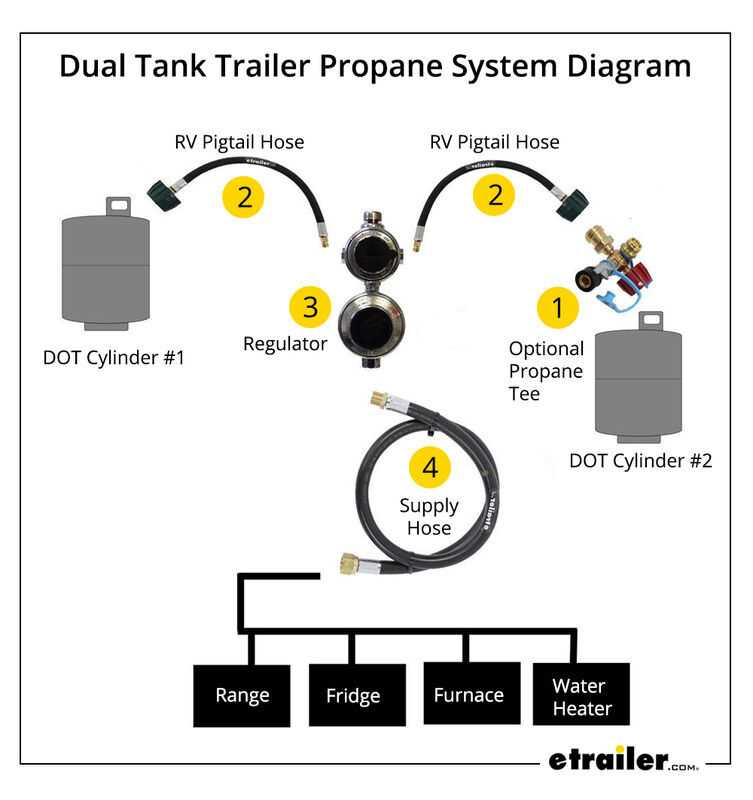

Understanding the key elements of a fuel storage system is essential for safety and efficiency. Each component plays a crucial role in regulating and controlling the flow of gas, ensuring smooth operation. From managing pressure to facilitating proper connections, these elements are designed to maintain the overall integrity of the system.

Valves serve as the control points, allowing or restricting the flow of gas. They ensure that the flow is properly regulated and can be closed during maintenance or emergencies. Gauges provide real-time monitoring of internal levels, helping users assess the current status at a glance, while other key features offer protection against overpressure

Essential Parts of a Propane Tank

The system that stores and supplies a commonly used gas for heating and cooking is composed of various critical elements. Each component plays a vital role in ensuring safe and efficient handling, from storing the fuel to delivering it to appliances. Understanding the key elements of this structure helps users operate and maintain it correctly.

Valves and Gauges

At the heart of the mechanism are valves and gauges. These regulate the flow of the fuel and measure pressure levels, allowing users to control the supply and monitor safety levels. They are crucial for preventing overflows and leaks.

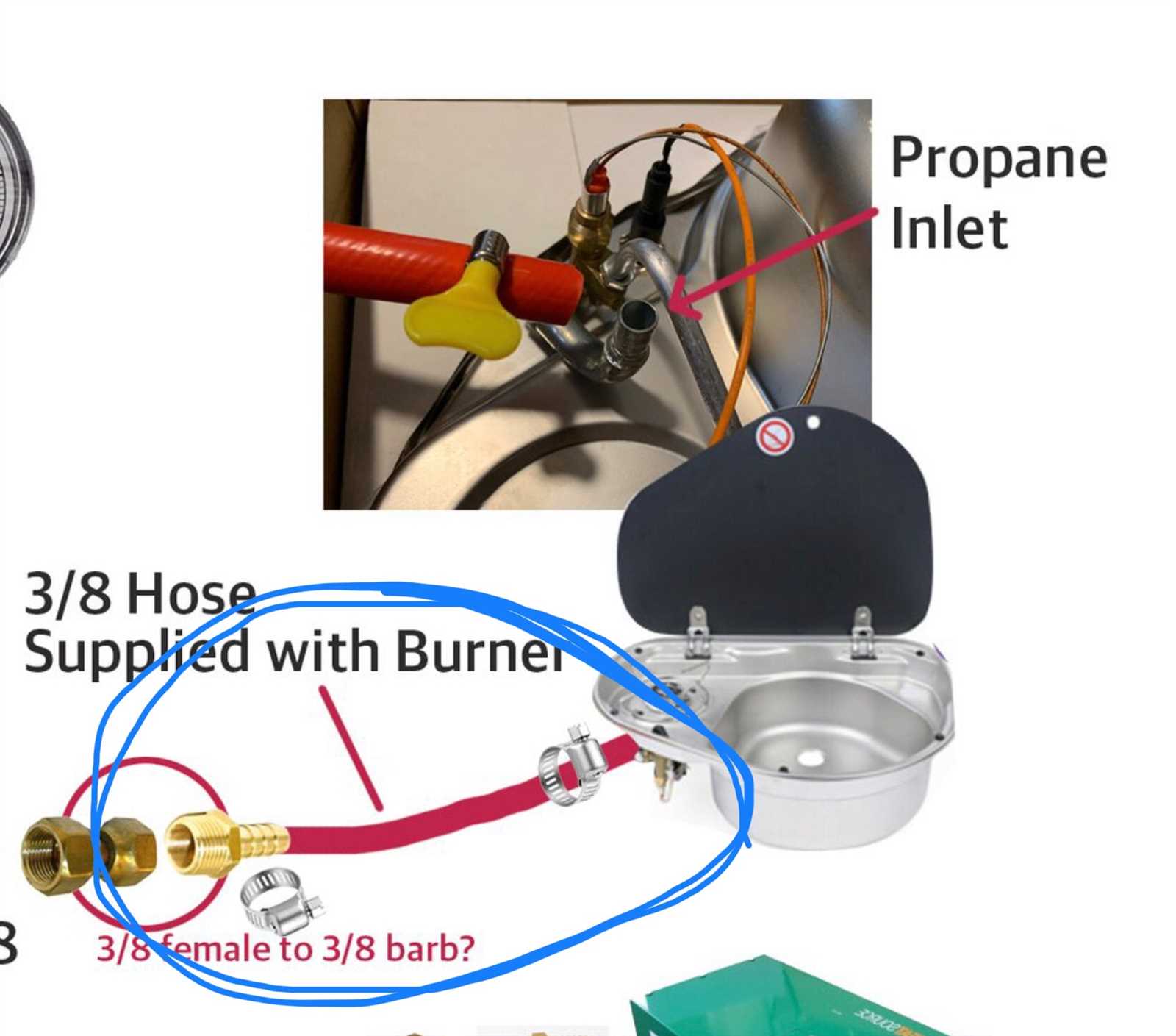

Connectors and Hoses

Connecting components ensure the safe transfer of gas from the storage unit to the appliance. Hoses and connectors must be tightly secured

Functionality of the Pressure Relief Valve

The pressure relief valve is a crucial component in ensuring the safety and efficiency of systems that store pressurized gases. It plays a vital role in maintaining the correct balance by releasing excess pressure when necessary, preventing dangerous build-ups that could lead to malfunctions or accidents.

How the Valve Operates

When the internal pressure exceeds a predefined limit, the valve automatically opens to allow controlled release of gas. Once the pressure is stabilized, the valve closes,

How the Dip Tube Works

The dip tube plays a crucial role in ensuring efficient operation by guiding the flow of liquid from the container to where it’s needed. It operates by channeling fluid from the bottom of the vessel through a long tube that extends to the lower part of the reservoir. This mechanism allows for consistent movement of the liquid, even when the container is not completely full, optimizing usage without waste.

How it functions: The tube essentially acts as a straw, pulling liquid from the lowest point of the container. As the substance is drawn upward, it remains in a usable state, ensuring continuous delivery. Without this system, the ability to access the contents efficiently would be hindered, especially as the levels drop inside the container.

The design is simple yet effective, providing a steady flow of fluid through a process that relies on basic physics.

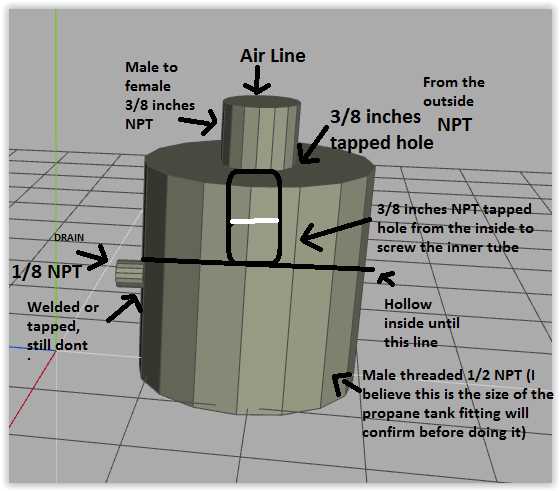

The Role of the Coupler

The coupler serves as a crucial link between the fuel source and the connected equipment. It ensures a secure and leak-free connection, allowing the smooth transfer of energy. This component plays a significant role in maintaining safety and efficiency in the entire system, preventing potential malfunctions and ensuring seamless operation.

- Acts as a secure connection point between the energy supply and appliances.

- Prevents leaks by creating a tight seal during use.

- Contributes to the safety of the entire setup by minimizing risks associated with poor connections.

- Supports consistent performance, ensuring reliable energy flow.

Significance of the Filling Valve

The filling valve plays a crucial role in ensuring the safe and efficient refueling process. This component controls the flow of liquid into the container, preventing overflows and maintaining the necessary balance during the refueling operation. It is essential to understand how this valve functions to ensure proper maintenance and long-term reliability.

Key Functions

- Regulates the flow during the refilling process

- Prevents excessive pressure buildup inside the container

- Ensures a secure seal to avoid leaks

Importance in Safe Handling

Proper functioning of this valve is vital for safe handling and storage. It reduces risks of accidents by minimizing the chances of liquid escape and pressure mismanagement. Regular inspection and maintenance of this element can significantly enhance the durability

Safety Features in Propane Tanks

Proper handling and security mechanisms are essential to ensure the safe use of fuel containers in various environments. These systems are designed to prevent leaks, regulate pressure, and minimize risks associated with improper handling or damage.

Pressure Relief Valves

A crucial element in these fuel systems is the pressure relief valve, which prevents excessive buildup inside the container. This valve automatically releases excess gas if internal pressure reaches unsafe levels, helping to avoid potential hazards.

Shut-off Mechanisms

Another important safety feature is the shut-off mechanism. It stops the flow of gas in the event of an emergency or malfunction. This ensures that gas is contained, reducing the risk of accidents and enhancing overall safety for users and surrounding areas.

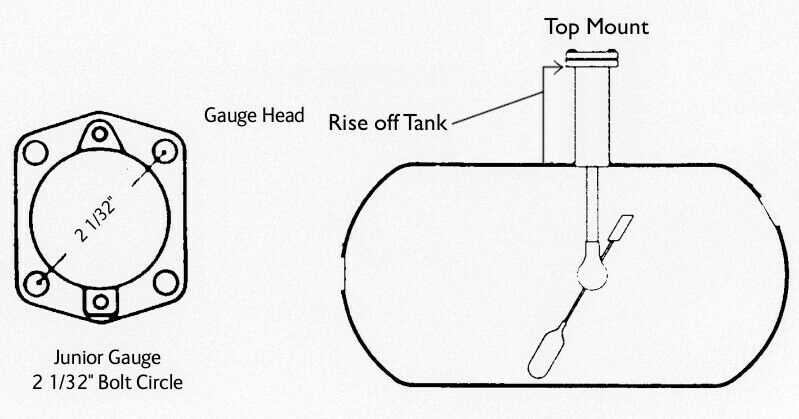

Inspecting the Tank Gauge

Regular checks of the gauge are crucial to ensure the system is functioning as expected. This component provides essential information about the contents and helps prevent unexpected interruptions. By learning how to properly examine the indicator, users can maintain a smooth and efficient operation of the system.

Steps to Follow

First, locate the gauge on the exterior of the container. Carefully observe the needle position, which should give an accurate reading of the current level. It’s important to verify that the indicator is functioning without any visible damage or malfunction. If the reading seems off, further inspection may be needed.

Common Issues

A common issue could be stuck or misaligned needles. If the pointer doesn’t move, it could indicate that the gauge needs cleaning or a possible replacement. Regularly inspecting the gauge for these potential problems ensures it continues to provide reliable information.

Understanding the Valve Assembly

The valve assembly is a crucial component in many pressurized systems, managing the flow and release of gases or liquids. Its role is essential for regulating internal pressure, ensuring safety, and maintaining proper control over the contents within the system. Proper understanding of its function helps to avoid potential hazards and ensures smooth operation.

Key parts of the valve assembly work together harmoniously to achieve these goals. Below is a breakdown of the most important elements:

- Shut-off mechanism: Controls the opening and closing, allowing for safe control of the substance within the container.

- Pressure relief valve: Automatically opens to release excess pressure, protecting the system from potential overpressure.

- Connector: Ensures a secure attachment point, preventing leaks and ensuring

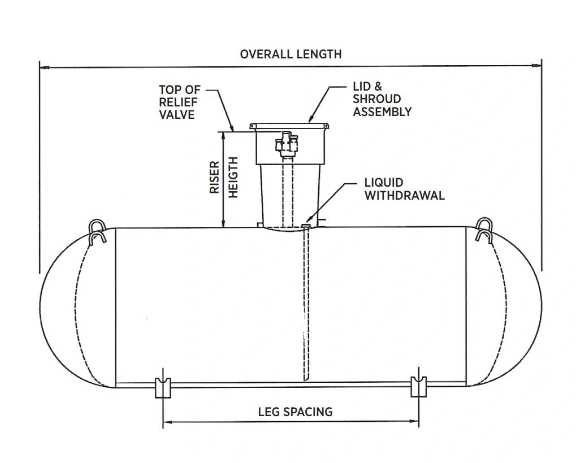

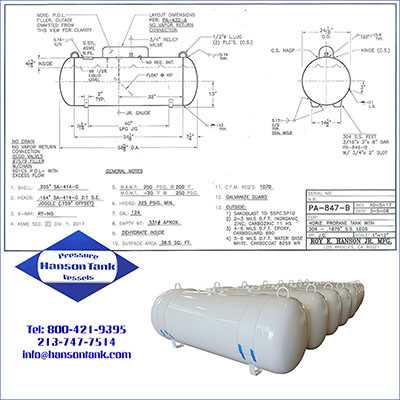

Importance of the Base Support

The foundation of any container plays a crucial role in ensuring its stability and functionality. A well-designed support base helps maintain balance, especially when placed on uneven surfaces, preventing unnecessary tipping or movement. This structural element contributes to the overall safety of the system, particularly during use or transportation.

Additionally, the base provides a strong platform, which minimizes wear and tear over time. Proper support can also extend the lifespan of the container by reducing the pressure exerted on more vulnerable components. Ensuring that the base is secure and level is essential for both longevity and safe operation.

Propane Tank Maintenance Tips

Regular upkeep is essential for ensuring the longevity and safe operation of fuel storage containers. Proper care helps prevent leaks and enhances performance, ultimately providing peace of mind for users. By following a few simple guidelines, one can maintain the functionality of these storage solutions effectively.

Inspect for Wear and Tear

Regular inspections are crucial in identifying any signs of damage or corrosion. Check for rust, dents, or any unusual odors that could indicate a potential issue. Timely detection can prevent more significant problems and ensure safe usage.

Store Safely

Ensure that the storage unit is kept in a well-ventilated area away from flammable materials. Proper storage conditions help reduce the risk of accidents and enhance the overall safety of the setup. Always follow local regulations regarding safe storage practices.

Common Issues with Tank Components

Understanding the frequent challenges associated with storage containers is essential for ensuring their effective operation. Various elements within these systems can encounter issues that may lead to reduced performance or safety hazards.

One prevalent concern involves leaks, which can arise from faulty seals or damaged fittings. Such leaks not only diminish efficiency but can also pose significant safety risks. Regular inspections and timely maintenance can help identify and rectify these problems before they escalate.

Another common issue is corrosion, which affects the longevity of storage units. Exposure to environmental factors can lead to deterioration of materials, necessitating periodic assessments to maintain structural integrity. Implementing protective measures can mitigate this risk.

Additionally, improper pressure levels within the system can result in operational inefficiencies. Monitoring gauges and ensuring appropriate calibration are crucial steps in preventing pressure-related complications. Awareness of these issues is vital for maintaining optimal functionality.

Reading a Propane Tank Diagram

Understanding the layout of a fuel container is essential for effective use and safety. Familiarity with the components and their functions enables users to handle the equipment responsibly and efficiently. This section will delve into the essentials of interpreting a schematic representation of a fuel storage unit.

Key elements often found in such illustrations include:

- Filling Valve: The point where the fuel is added, typically located at the top of the container.

- Relief Valve: A safety feature that releases excess pressure to prevent explosions.

- Regulator: A device that controls the pressure of the gas being released for use.

- Gauge: An indicator that shows the amount of fuel remaining inside the unit.

- Liquid Withdrawal Port: A connection used to draw fuel from the liquid phase of the container.

When studying a schematic, it is crucial to recognize the symbols and labels that denote these features. Each component plays a vital role in ensuring the functionality and safety of the entire system.

Being able to accurately interpret these illustrations can enhance one’s knowledge and confidence in managing fuel storage units effectively.