The arrangement of various elements within a marine propulsion system is crucial for optimal performance and maintenance. A well-organized schematic can greatly assist in identifying the individual components that contribute to the overall functionality of the machinery. This understanding is essential for both enthusiasts and professionals who seek to enhance their knowledge or undertake repair tasks.

By examining detailed representations of these systems, one can gain insights into how each piece interacts with others, ensuring smooth operation. Such illustrations serve not only as a guide for troubleshooting but also as a valuable resource for anyone looking to deepen their comprehension of marine technology.

Whether you are a seasoned technician or a curious learner, familiarizing yourself with the intricacies of these layouts can lead to more informed decisions and successful maintenance practices. Embracing this knowledge empowers individuals to tackle challenges confidently and ensure longevity in their aquatic endeavors.

Understanding Johnson Outboard Components

The components of marine propulsion systems play a crucial role in ensuring efficient performance and reliability. Familiarizing oneself with these elements enhances the overall experience and maintenance of watercraft. This section aims to provide insights into the various elements that contribute to optimal functionality.

Each element serves a specific purpose, working in harmony to propel the vessel smoothly through water. Understanding these components not only aids in troubleshooting but also helps in making informed decisions regarding repairs and upgrades.

By gaining knowledge about the intricate workings of these systems, users can appreciate the design and engineering that go into crafting reliable marine machinery. This understanding fosters a deeper connection with the equipment and promotes better care and management.

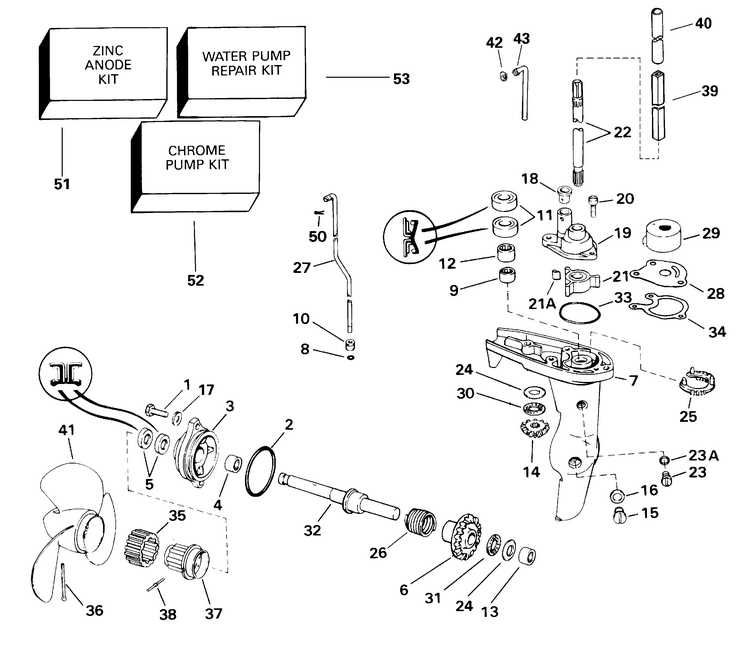

Overview of Outboard Motor Parts

This section aims to provide a comprehensive understanding of the various components that make up a marine propulsion system. Each element plays a crucial role in ensuring efficient operation and performance on the water.

Key Components

- Engine: The heart of the system, responsible for generating power.

- Propeller: Translates the engine’s power into thrust for movement.

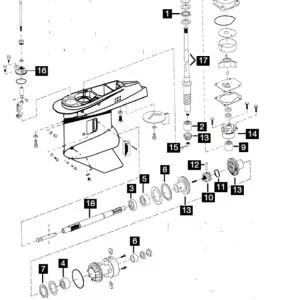

- Gear Case: Houses the gears that transfer power from the engine to the propeller.

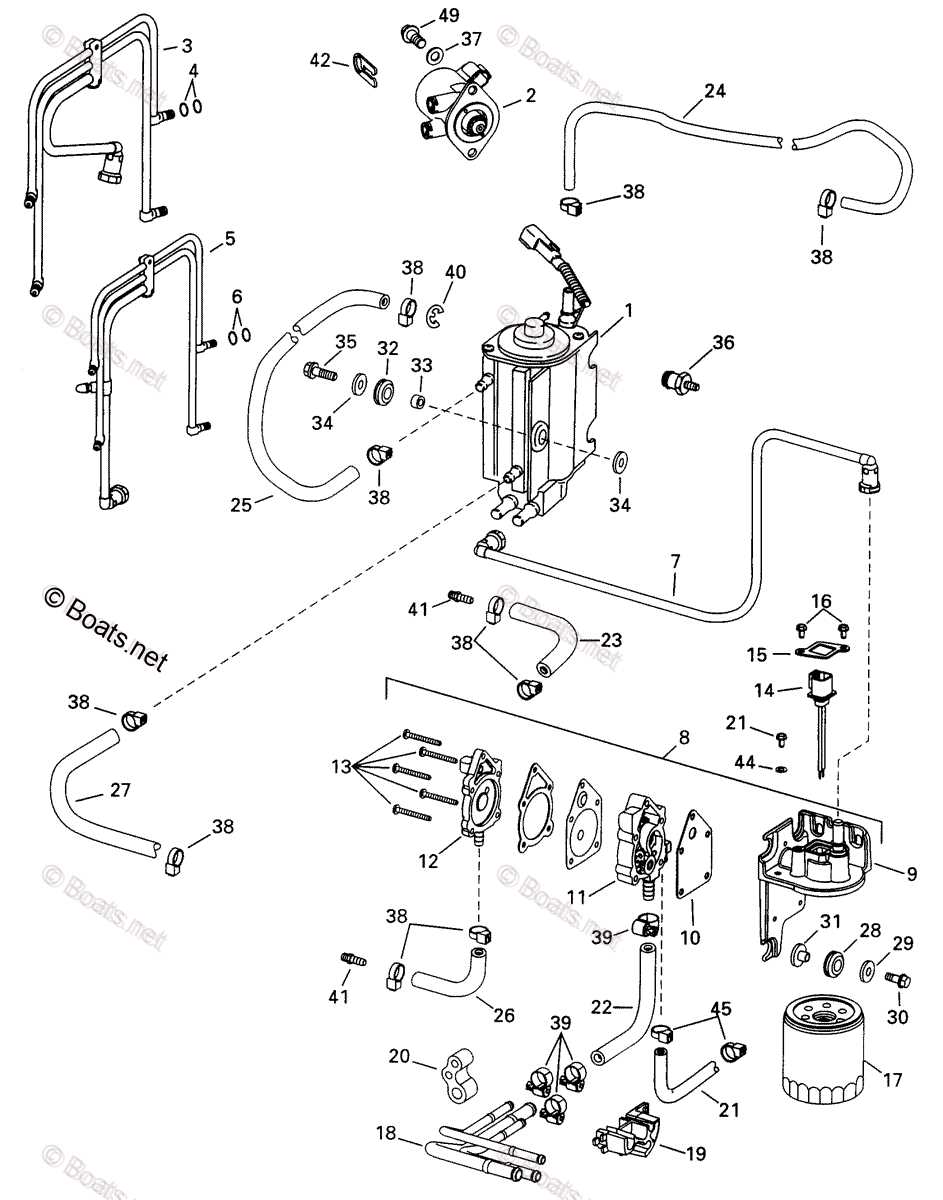

- Cooling System: Maintains optimal temperature to prevent overheating.

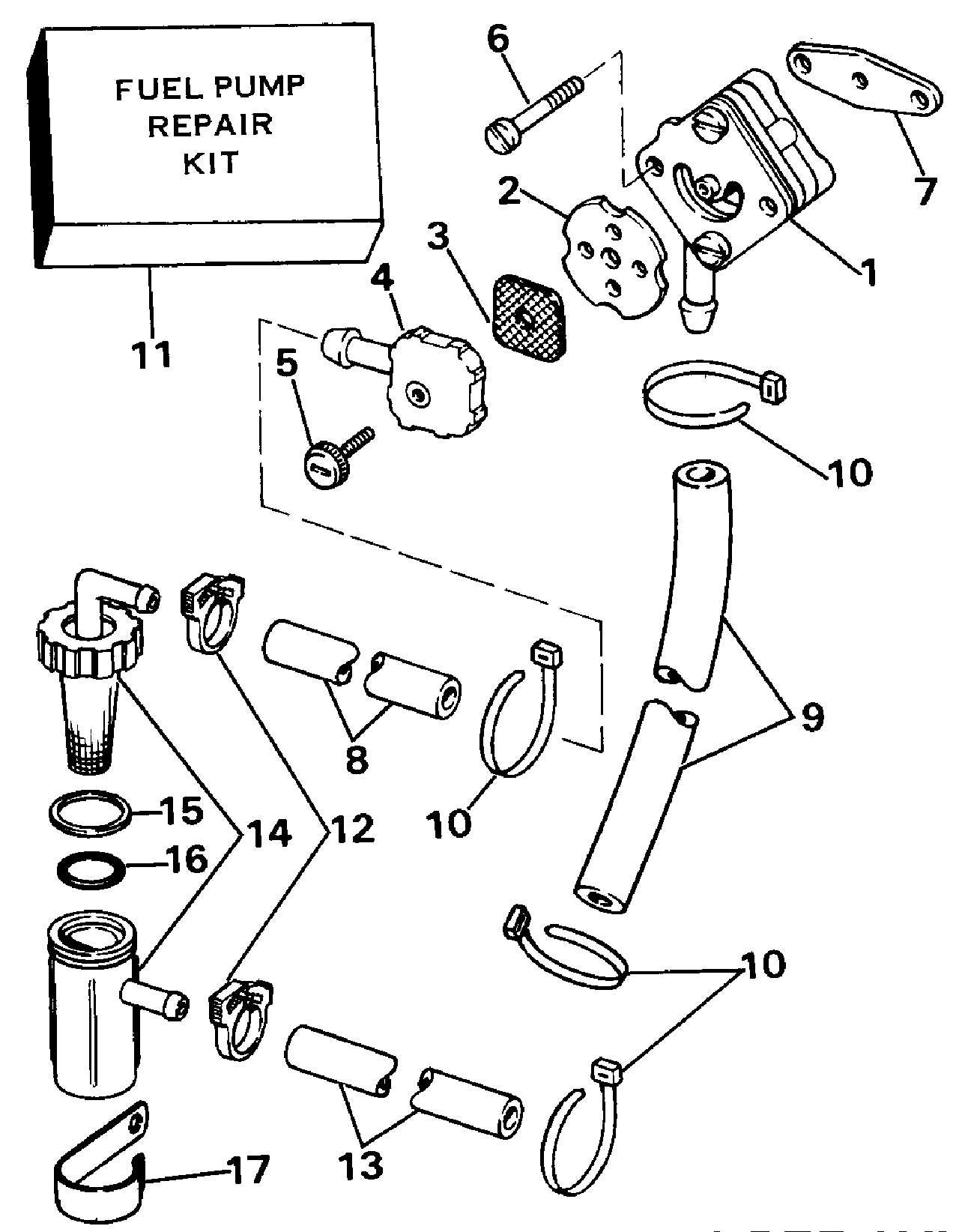

- Fuel System: Supplies the necessary fuel for combustion.

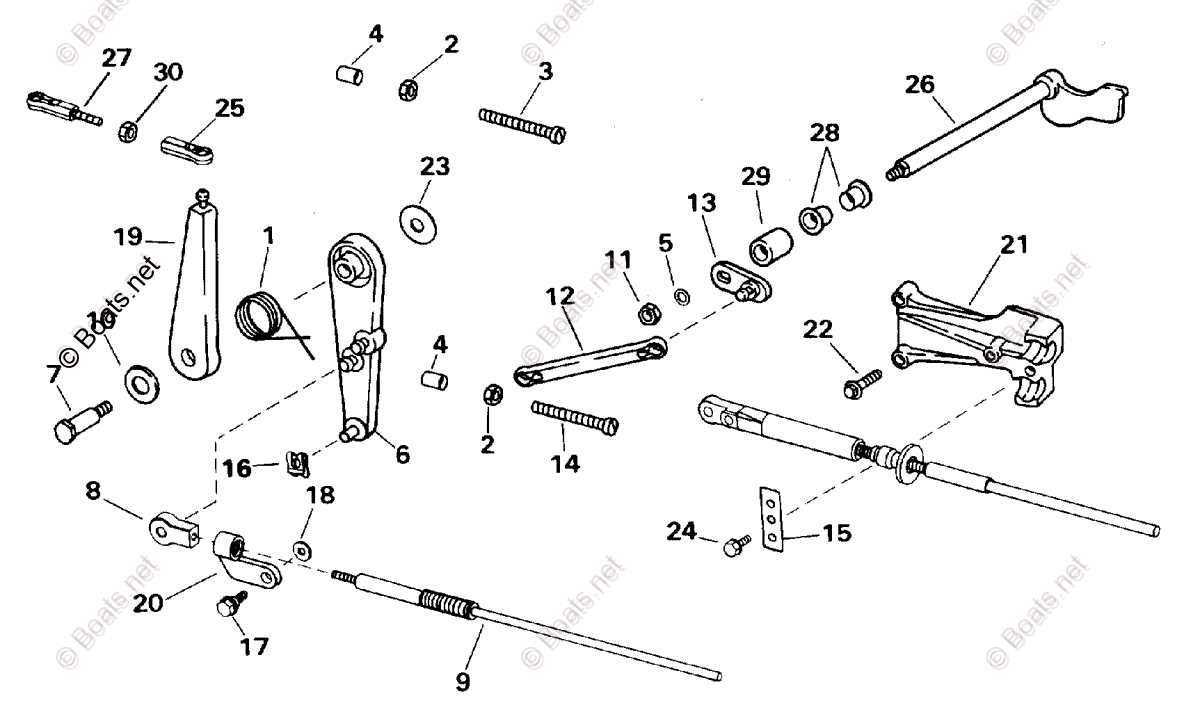

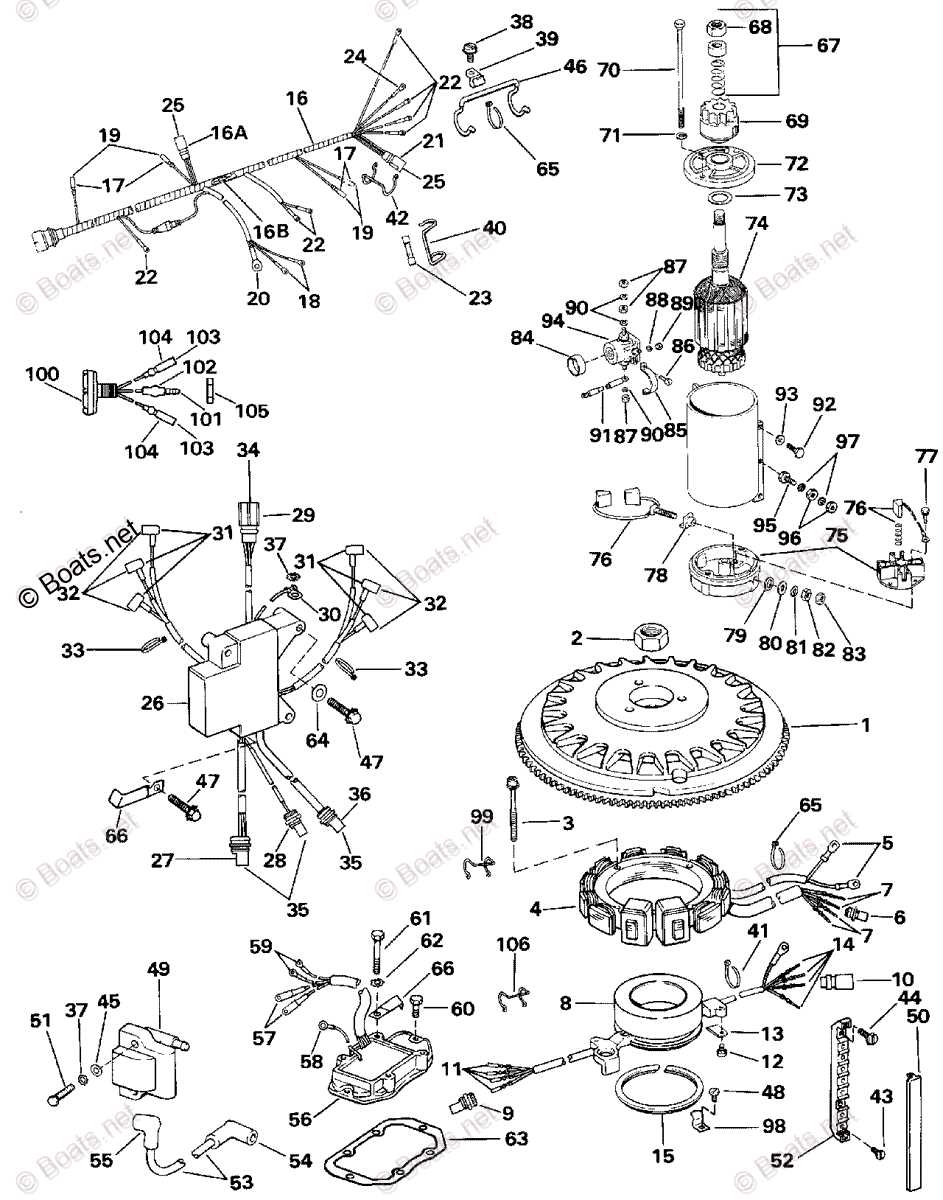

Supporting Elements

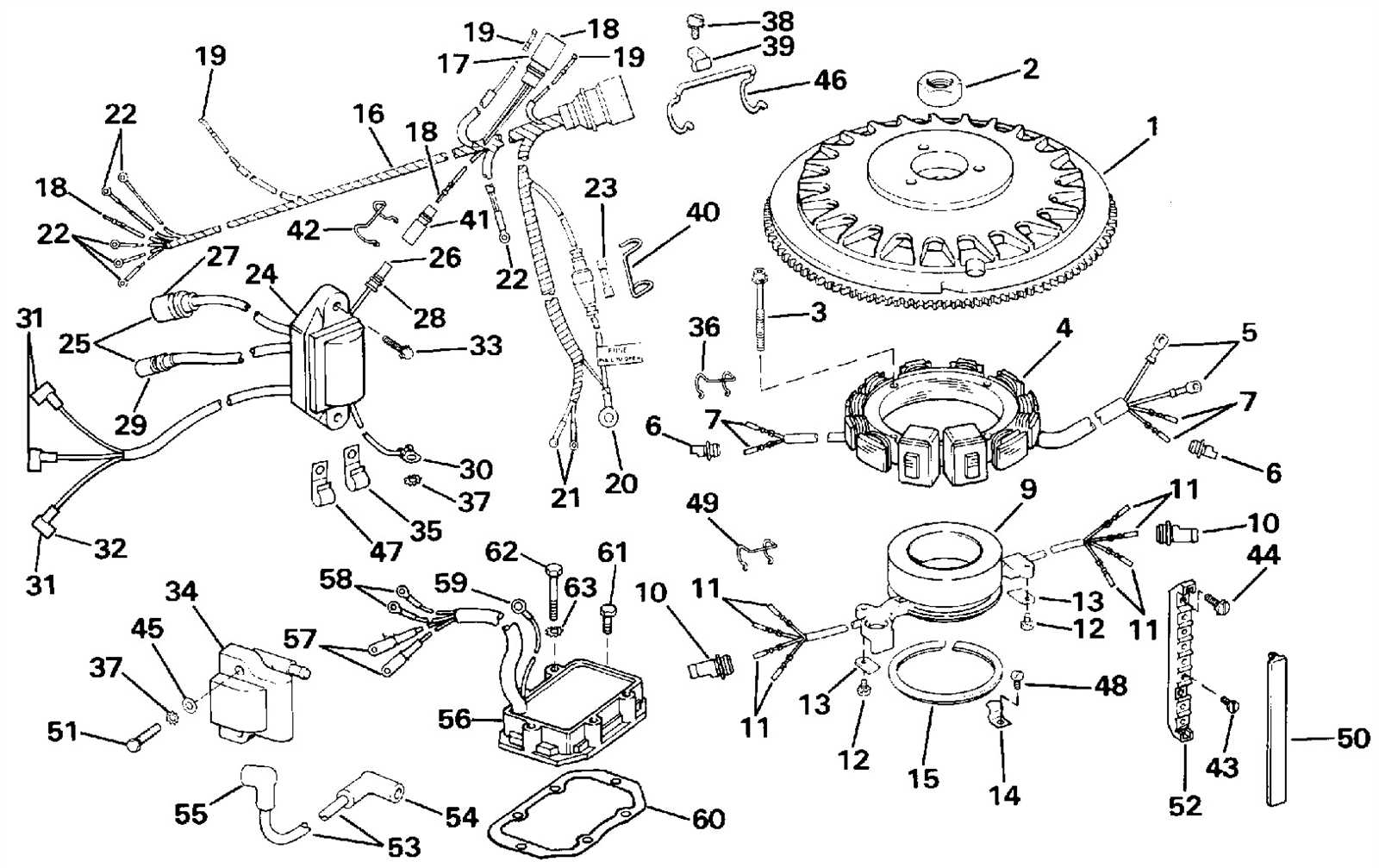

- Electrical System: Powers various accessories and ensures ignition.

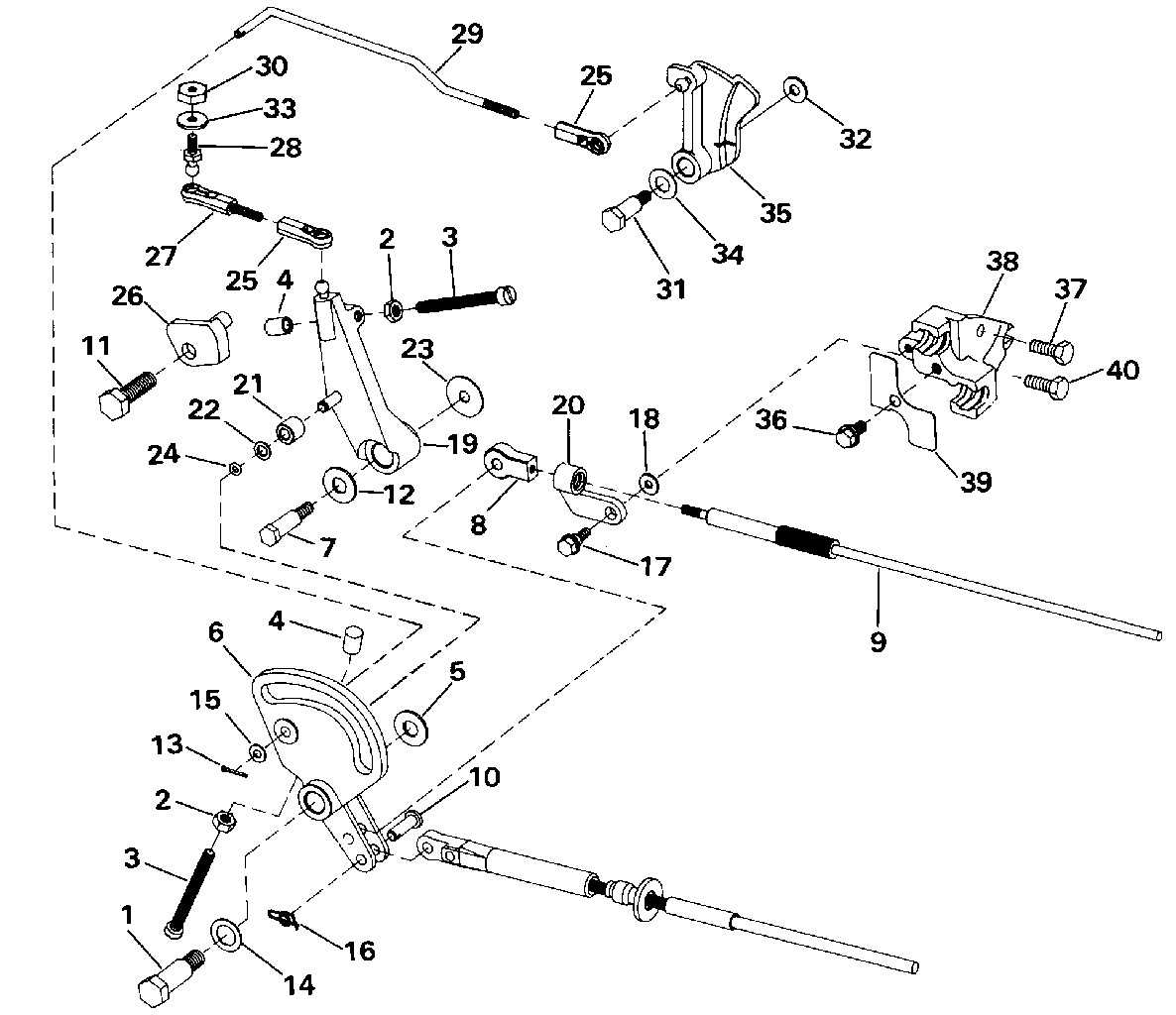

- Steering Mechanism: Allows for directional control while navigating.

- Trim and Tilt: Adjusts the angle of the propulsion unit for better performance.

Understanding these components is essential for maintenance and troubleshooting, contributing to the longevity and reliability of the marine vessel.

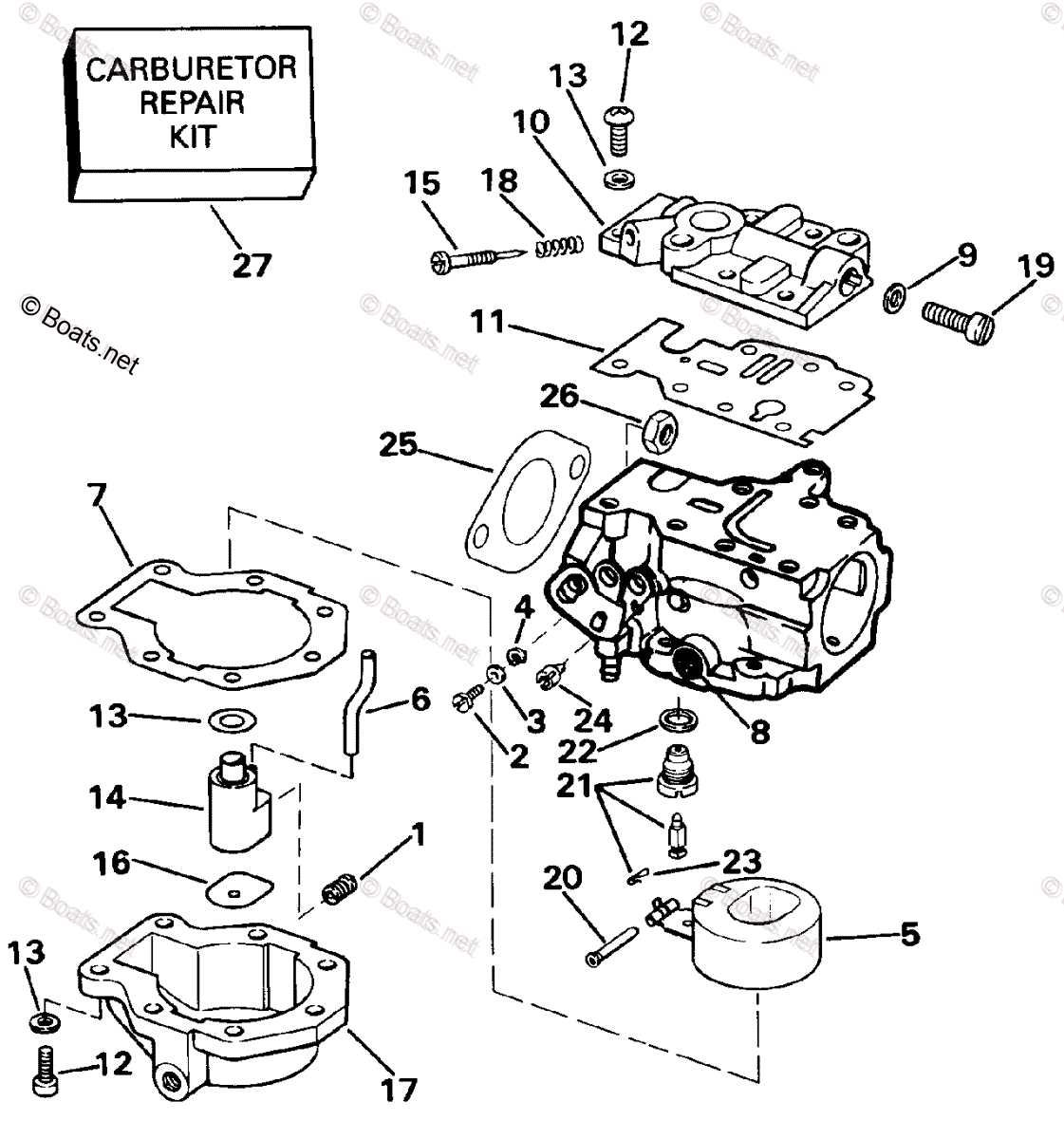

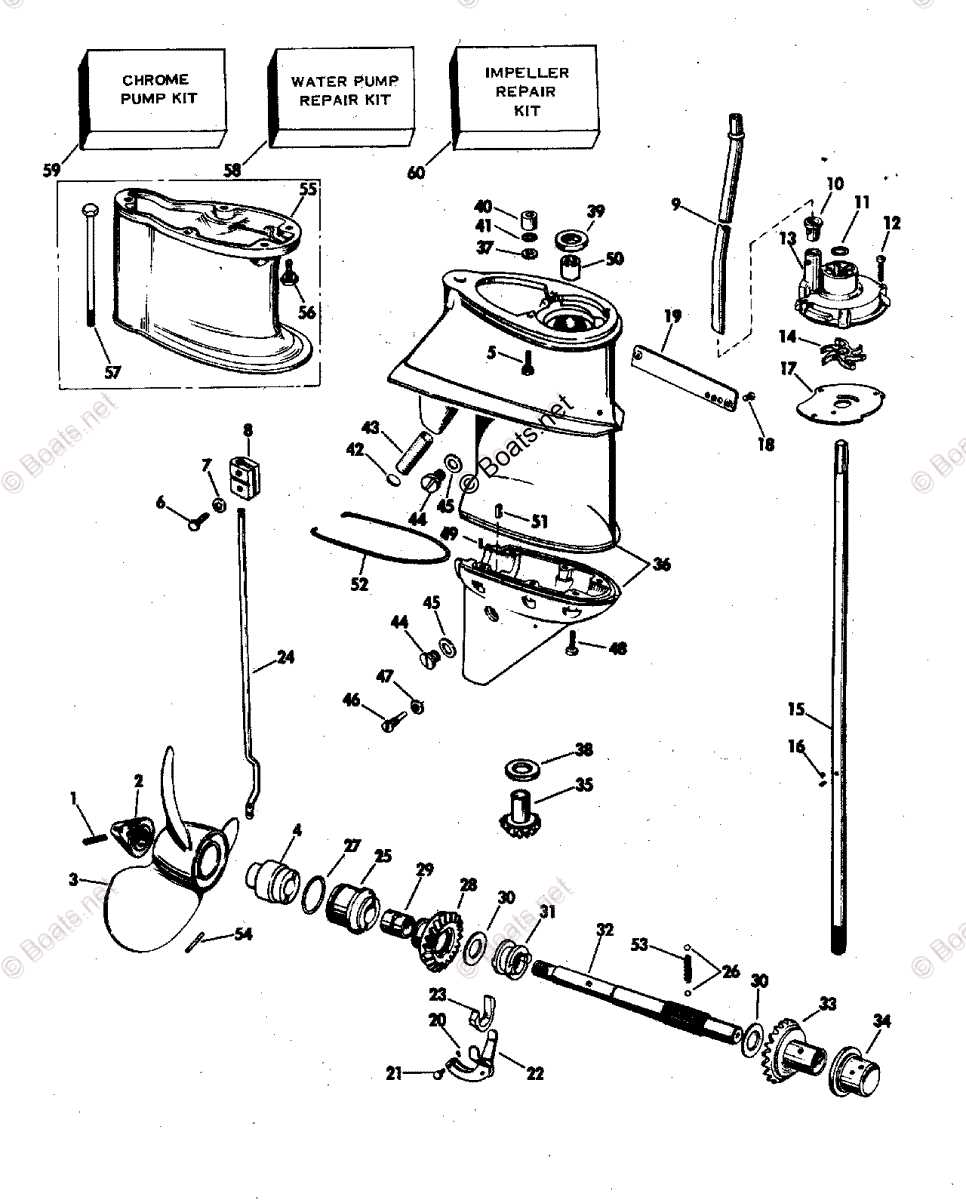

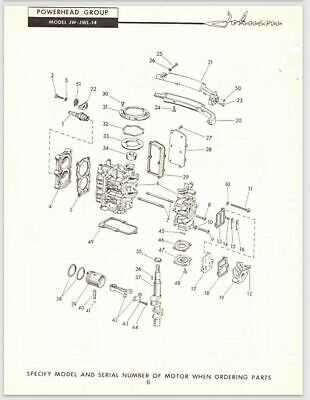

Importance of Diagrams in Repair

Visual representations play a crucial role in the maintenance and restoration of mechanical devices. They serve as essential tools that facilitate understanding of complex systems, ensuring that technicians can effectively diagnose issues and implement solutions.

Enhancing Understanding

By breaking down intricate mechanisms into simpler visual elements, these illustrations help to clarify the relationships between various components. This clarity not only aids in troubleshooting but also assists in reassembly after repairs, reducing the risk of errors.

Streamlining the Repair Process

Moreover, such visuals can significantly accelerate the repair process. Technicians can quickly reference the layout and functions of different parts, allowing for more efficient work. This efficiency ultimately leads to reduced downtime and improved performance of the equipment.

Common Issues with Johnson Motors

Many boat engines encounter specific challenges that can affect their performance and reliability. Understanding these frequent problems can help owners maintain their machinery effectively.

- Fuel System Problems: Clogged filters and fuel lines can lead to poor engine performance.

- Electrical Failures: Issues with wiring and connectors may cause starting difficulties or power loss.

- Overheating: Insufficient cooling due to blocked passages can result in serious engine damage.

- Oil Leaks: Seals and gaskets can wear out, leading to leaks that compromise performance.

- Ignition Troubles: Faulty spark plugs or ignition coils can cause misfires and reduced efficiency.

Regular maintenance and inspections are vital to identify these issues early and ensure smooth operation.

Parts Identification for Efficient Maintenance

Understanding the various components of your vessel is crucial for optimal upkeep and longevity. By recognizing each element, you can enhance performance and prevent potential issues.

- Comprehensive Overview: Familiarize yourself with all essential elements that contribute to overall functionality.

- Regular Inspection: Conduct routine checks to identify wear and tear, ensuring timely replacements.

- Documentation: Maintain detailed records of all components to streamline repairs and servicing.

Efficient identification of these components not only aids in effective maintenance but also enhances the overall sailing experience.

How to Read Outboard Diagrams

Understanding the layout of motor components is essential for effective maintenance and repairs. These visual representations serve as guides, allowing users to navigate various sections and identify crucial elements without confusion.

Begin by familiarizing yourself with the symbols used in these illustrations. Each symbol typically represents a specific component, which is often labeled for easy recognition. This knowledge will enhance your ability to pinpoint parts quickly.

Next, pay attention to the connections and flow indicated in the visuals. Understanding how different elements interact can help you grasp the overall function of the system, making troubleshooting more straightforward.

Lastly, consult accompanying documentation or manuals for further clarification. Combining these resources with the visual aids will deepen your understanding and improve your hands-on skills.

Essential Tools for Parts Replacement

Replacing components in your watercraft can be a straightforward task if you have the right tools at your disposal. Having the appropriate instruments not only simplifies the process but also ensures that the job is completed effectively and safely.

Here are some fundamental tools that every enthusiast should consider:

- Socket Set: A versatile socket set is crucial for loosening and tightening bolts with ease.

- Wrenches: Both adjustable and fixed wrenches are essential for various nuts and fittings.

- Screwdrivers: A collection of different types and sizes will help in managing screws effectively.

- Pliers: Needle-nose and standard pliers can assist in gripping and manipulating small components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Utility Knife: Useful for cutting and trimming materials as needed during repairs.

- Cleaning Supplies: Brushes and cloths for maintaining cleanliness during and after the replacement process.

Having these tools readily available will make the component replacement process smoother and more efficient, ultimately leading to better performance and longevity of your vessel.

Where to Find Quality Replacement Parts

Finding reliable components for marine engines is essential for maintaining optimal performance. Various sources offer a range of options, ensuring you can locate the right pieces for your needs. Whether you’re a seasoned enthusiast or a novice, knowing where to look can make all the difference.

Authorized Dealers and Retailers

Authorized dealers provide an assurance of quality, offering genuine components that meet the manufacturer’s specifications. Visiting these locations allows you to consult with knowledgeable staff who can guide you in selecting the appropriate items.

Online Marketplaces

Numerous online platforms specialize in marine components, featuring a vast selection at competitive prices. When purchasing through these channels, ensure you check customer reviews and ratings to gauge the reliability of the sellers.

Step-by-Step Guide to Repairs

This section provides a comprehensive overview of the repair process for marine engines. Understanding the various components and their functions is essential for effective maintenance and troubleshooting. By following these steps, you can ensure optimal performance and longevity of your equipment.

1. Preparation: Before starting any repairs, gather the necessary tools and equipment. Ensure your workspace is organized and free from distractions. Having everything at hand will facilitate a smoother repair process.

2. Diagnosis: Identify the issues by conducting a thorough inspection. Look for signs of wear, leaks, or any unusual sounds. Document your findings to keep track of potential problems.

3. Disassembly: Carefully take apart the engine components, taking note of their arrangement. Use labeled containers to keep small parts organized. This step is crucial for a seamless reassembly later on.

4. Cleaning: Remove dirt and debris from the components using appropriate cleaning solutions. A clean working area enhances visibility and prevents contamination during the repair process.

5. Replacement and Repair: Address any damaged components by replacing or repairing them as needed. Ensure that all replacements are compatible and of high quality to maintain performance standards.

6. Reassembly: Once repairs are complete, reassemble the engine carefully. Follow your initial documentation to ensure all parts are returned to their correct positions.

7. Testing: After reassembly, conduct a series of tests to verify that everything is functioning correctly. Monitor performance closely and make adjustments if necessary.

8. Maintenance: Regular maintenance is key to preventing future issues. Establish a routine for inspections and servicing to keep your marine engine in top condition.

Safety Tips for Outboard Maintenance

Ensuring safety during maintenance activities is essential for a seamless experience with your watercraft. By following specific precautions, you can prevent accidents and enhance the longevity of your equipment.

First and foremost, always work in a well-ventilated area to avoid inhaling harmful fumes. Ensure that you wear appropriate personal protective equipment, such as gloves and goggles, to safeguard against potential injuries.

Additionally, be cautious with fuel and oil handling; store them in designated containers and keep them away from heat sources. Regularly inspect your tools for any damage before use to prevent malfunctions that could lead to accidents.

Finally, familiarize yourself with the maintenance manual for your equipment. Understanding the specifications and guidelines can significantly contribute to a safer and more effective upkeep process.

Upgrading Your Johnson Outboard

Enhancing your marine engine can significantly improve performance and extend its lifespan. By focusing on key components and modern technologies, you can elevate your vessel’s efficiency and reliability. This section explores various options for upgrading your equipment, ensuring a smoother experience on the water.

Essential Components to Consider

When thinking about improvements, prioritize critical elements such as fuel systems, ignition components, and cooling mechanisms. Upgrading these parts not only boosts overall functionality but also optimizes fuel consumption, leading to better mileage. Consider investing in high-quality replacements that promise durability and enhanced performance.

Incorporating Modern Technology

Integrating contemporary innovations can further enhance your marine experience. Features like digital monitoring systems and advanced steering mechanisms provide improved control and real-time feedback. These enhancements can lead to more precise navigation and safer operation, allowing you to enjoy your time on the water with confidence.

Regular Maintenance for Longevity

Ensuring optimal performance of marine engines involves consistent care and attention. Regular upkeep not only enhances functionality but also extends the lifespan of the equipment, safeguarding your investment for years to come.

Key Maintenance Practices

- Routine inspections for signs of wear and tear

- Regular fluid changes to maintain efficiency

- Cleaning components to prevent buildup and corrosion

- Checking electrical systems for reliability

Seasonal Considerations

- Preparing for winter storage to avoid damage

- Conducting pre-season checks for readiness

- Monitoring performance throughout usage to identify issues early

Resources for Johnson Outboard Owners

For enthusiasts and operators of marine engines, having access to reliable information and tools is essential for maintenance and performance enhancement. Various resources are available to support owners in optimizing their aquatic experiences, ensuring smooth operation and longevity of their equipment.

Online Communities and Forums

Joining dedicated online platforms allows users to exchange insights, ask questions, and share experiences. These forums often provide invaluable tips from fellow enthusiasts, fostering a sense of community among users who are passionate about their marine adventures.

Manufacturer Support and Documentation

Accessing official resources from manufacturers can significantly aid in understanding maintenance requirements and technical specifications. Detailed manuals, instructional videos, and troubleshooting guides serve as a great reference for both novice and experienced users looking to enhance their knowledge.