When it comes to maintaining and troubleshooting outdoor machinery, having a clear understanding of its various elements is crucial. This section focuses on a specific model, providing insights into its essential components and their functions. By familiarizing yourself with these key elements, you can enhance your ability to perform repairs and maintenance effectively.

Detailed visual references are invaluable for anyone looking to comprehend the intricate workings of machinery. They allow users to identify each element, understand its role, and recognize how it fits into the overall structure. Such illustrations serve as a guide, simplifying the process of diagnosing issues and facilitating repairs.

Whether you’re a seasoned technician or a novice enthusiast, grasping the layout and function of machinery components can significantly improve your maintenance skills. This knowledge empowers you to address challenges confidently and ensures that your equipment remains in optimal condition.

This section provides a comprehensive overview of a specific model of lawn mower, focusing on the essential components that contribute to its functionality. By examining the various elements involved, readers will gain insights into maintenance, repair, and overall efficiency.

1. Introduction to Lawn Mower Models

Understanding different lawn mower models is crucial for effective maintenance.

2. Key Features of the Selected Model

- Engine specifications

- Cutting width

- Transmission type

3. Importance of Maintenance

Regular upkeep ensures longevity and optimal performance.

4. Identifying Common Issues

- Unusual noises during operation

- Inconsistent cutting performance

- Difficulty in starting

5. Essential Components Overview

Familiarity with key elements enhances troubleshooting skills.

6. Maintenance Tips for Longevity

- Regular oil changes

- Cleaning air filters

- Sharpening blades

7. Troubleshooting Common Problems

Identifying and solving frequent issues can save time and resources.

8. When to Seek Professional Help

Knowing when to consult a technician is vital for complex repairs.

9. Parts Replacement Guide

- Common parts needing replacement

- How to source quality replacements

10. User Manual Reference

Consulting the user manual is a reliable source for specific information.

11. Frequently Asked Questions

- What are the recommended oil types?

- How often should the blades be sharpened?

12. Conclusion and Summary

Summarizing the main points reinforces the importance of understanding lawn mower components for effective operation.

Key Features of LA105 Model

The LA105 model is designed with a range of innovative characteristics that enhance its performance and usability. This equipment provides users with an efficient experience while maintaining high standards of quality and reliability.

One of the most notable aspects is its powerful engine, which ensures optimal operation across various terrains. Additionally, the cutting mechanism is engineered to deliver a clean and precise finish, allowing for a well-manicured appearance.

The user-friendly controls facilitate easy navigation and operation, making it suitable for both novice and experienced users. Furthermore, the model boasts a durable construction that withstands the rigors of regular use, ensuring longevity and reduced maintenance needs.

With features aimed at enhancing comfort, including ergonomic seating and adjustable settings, this model prioritizes the user experience. Overall, it combines functionality with ease of use, making it a valuable asset for any lawn care routine.

Importance of Deck Maintenance

Regular upkeep of lawn equipment components is crucial for optimal performance and longevity. Neglecting these areas can lead to decreased efficiency, increased wear, and potentially costly repairs. Proper care ensures that the equipment operates smoothly, providing a clean cut and a well-manicured appearance.

Benefits of Regular Upkeep

Maintaining these essential components not only enhances functionality but also extends the lifespan of the equipment. Regular inspection and servicing can prevent issues that may arise from dirt buildup or damage. This proactive approach contributes to a more efficient operation, reducing fuel consumption and improving the quality of the cut.

Key Maintenance Practices

To ensure optimal performance, consider the following maintenance practices:

| Practice | Description |

|---|---|

| Cleaning | Remove grass clippings and debris to prevent rust and corrosion. |

| Inspection | Check for wear and damage, addressing issues before they escalate. |

| Sharpening | Regularly sharpen blades to ensure a clean and efficient cut. |

| Lubrication | Apply lubricant to moving parts to minimize friction and wear. |

Common Issues with Deck Components

When it comes to lawn care machinery, the cutting assembly is a critical area that often encounters various challenges. Understanding these common problems can help in maintaining optimal performance and longevity of the equipment. Below are some typical issues that operators may face with these essential components.

1. Uneven Cutting

One of the most frequent concerns is achieving an uneven cut. This can stem from several factors:

- Worn or damaged blades that require replacement.

- Incorrect blade height adjustments leading to inconsistencies.

- Clogging due to debris accumulation within the assembly.

2. Excessive Vibration

Another prevalent issue is excessive shaking during operation. This can be caused by:

- Improperly balanced or misaligned components.

- Loose fasteners that need tightening.

- Worn bearings that require lubrication or replacement.

By addressing these issues promptly, operators can enhance the efficiency and effectiveness of their mowing equipment.

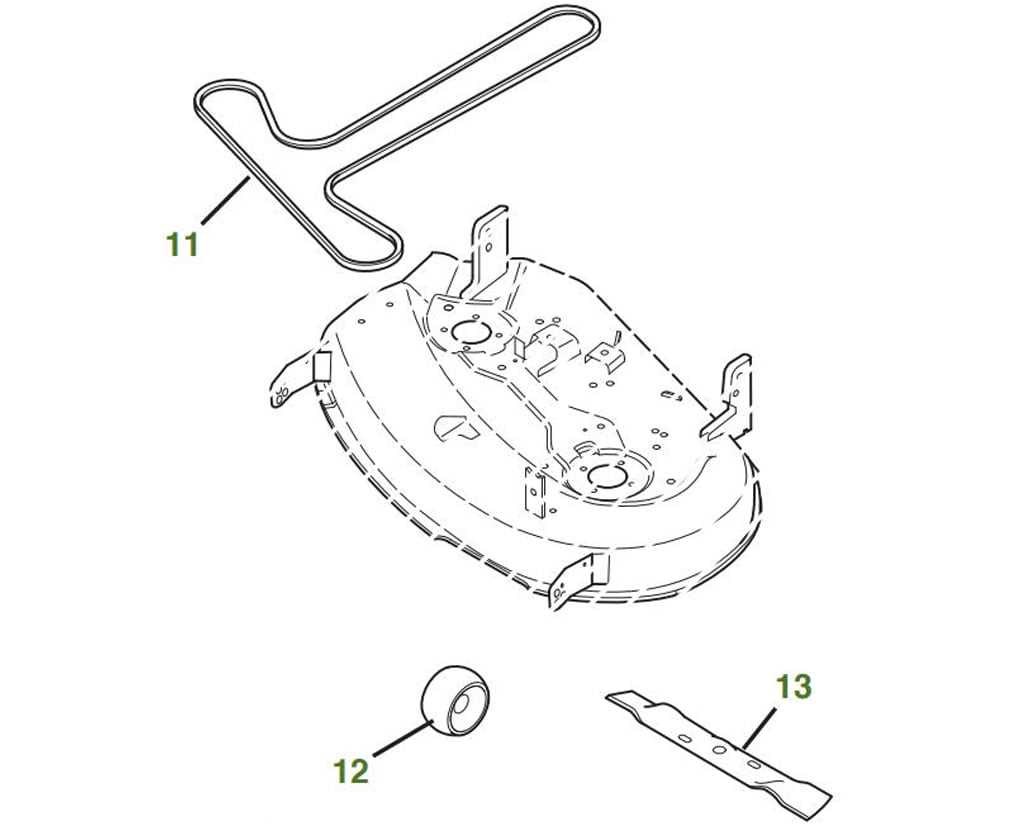

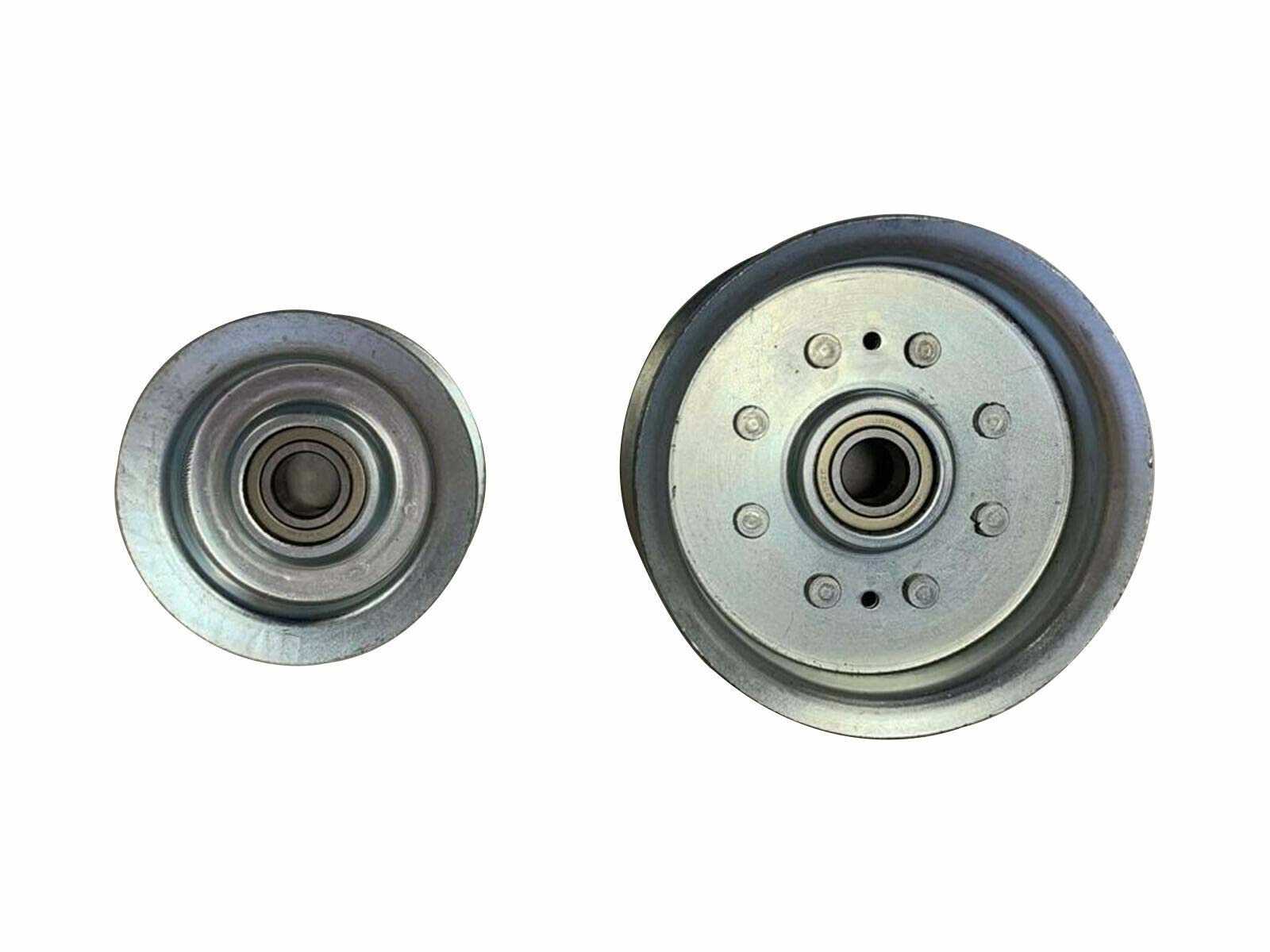

Identifying Deck Parts for Replacement

Understanding the components of your lawn equipment is essential for maintaining optimal performance and ensuring longevity. By recognizing the various elements that make up the mowing assembly, you can easily identify which ones require attention or replacement. This knowledge will help you keep your machine running smoothly and efficiently.

Start by familiarizing yourself with the structure of the assembly. Typically, it consists of several key elements, such as the housing, blades, and pulleys. Each component plays a vital role in the overall functionality of the machine. When examining these components, look for signs of wear or damage, such as rust, cracks, or dull blades.

To facilitate the replacement process, consider organizing the components by category. This approach will allow you to quickly access the required pieces and streamline the repair process. It is also beneficial to consult the manufacturer’s documentation or online resources for specific details about each element, ensuring that you select the appropriate replacements.

Finally, always prioritize safety when working on your equipment. Ensure that the machine is powered off and adequately secured before attempting any maintenance or replacements. By taking these precautions and understanding the various components, you can effectively manage your lawn care tasks.

Tools Needed for Maintenance Tasks

Proper upkeep of outdoor machinery requires a selection of essential instruments to ensure efficiency and longevity. Having the right tools on hand facilitates smooth operation and minimizes downtime during routine checks and repairs.

First and foremost, a reliable wrench set is crucial for tightening and loosening various fasteners. Additionally, a good socket set allows for easier access to hard-to-reach bolts. For precision adjustments, a screwdriver set with various head types is indispensable.

Another vital item is a multimeter, which helps diagnose electrical issues, ensuring that all components are functioning properly. To maintain sharpness, a blade sharpener is essential for keeping cutting edges effective. Finally, a cleaning kit will aid in removing debris and buildup, promoting optimal performance.

By equipping oneself with these necessary tools, maintaining outdoor equipment becomes a more manageable and effective process.

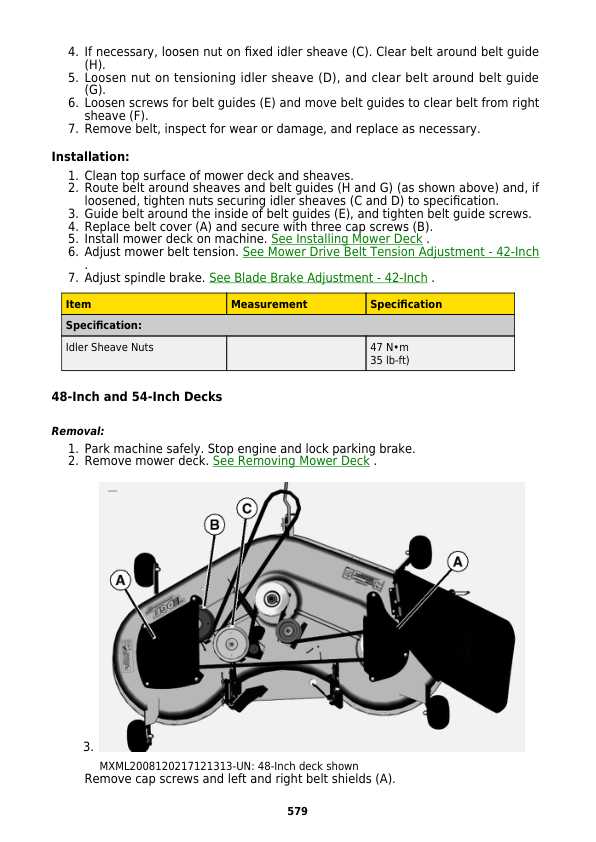

Step-by-Step Deck Disassembly Guide

This section provides a comprehensive approach to safely dismantling the cutting mechanism of your lawn equipment. Following these guidelines will ensure that you can perform maintenance or repairs effectively, allowing for optimal performance and longevity of your machine.

Preparation for Disassembly

Before you begin, make sure to gather the necessary tools, including wrenches, screwdrivers, and safety gloves. Disconnect the power source to prevent any accidental startups. Clear the workspace to ensure you have ample room to work without obstacles.

Removing Components

Start by taking off any external attachments that may obstruct access. Proceed to carefully unscrew and detach the various elements that hold the mechanism in place. As you remove each piece, keep them organized to facilitate reassembly later. It is advisable to take notes or photographs during this process to aid in putting everything back together accurately.

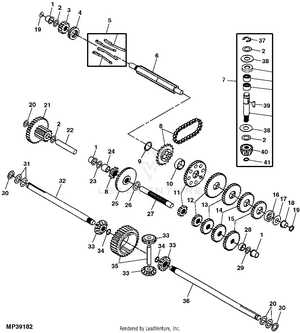

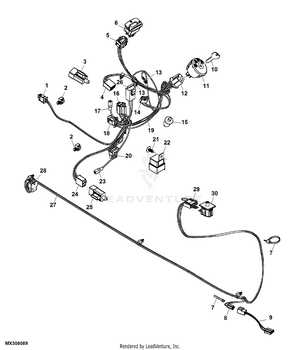

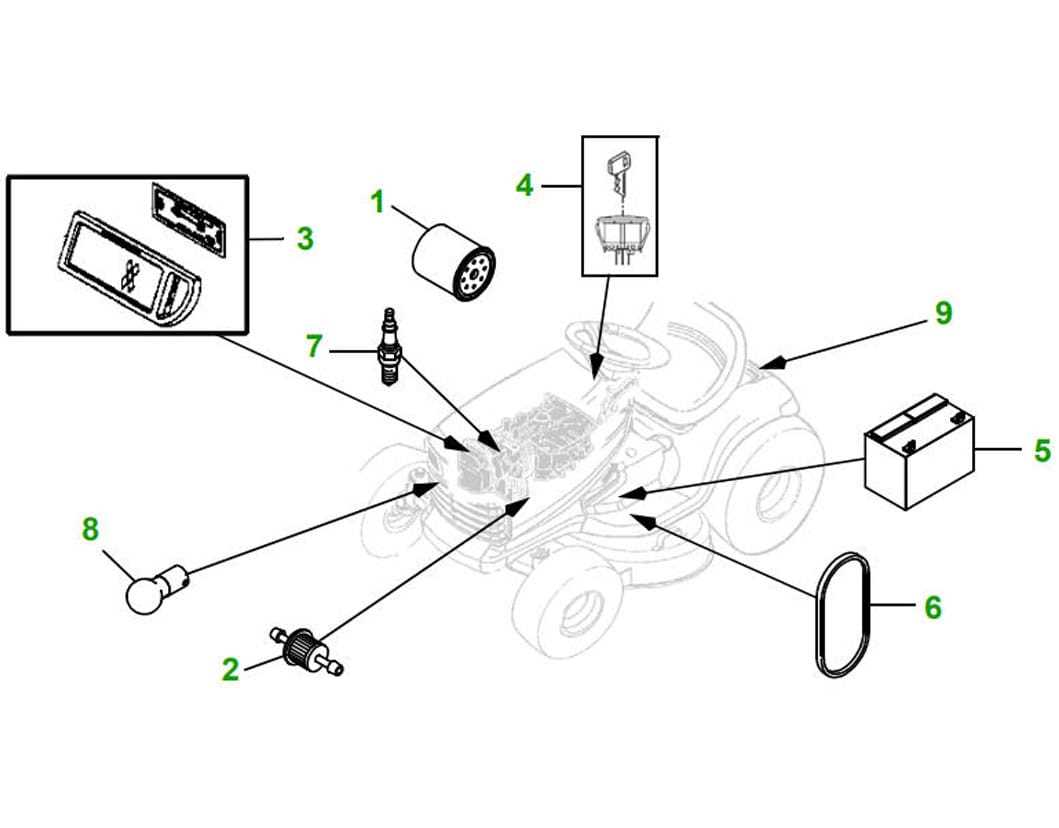

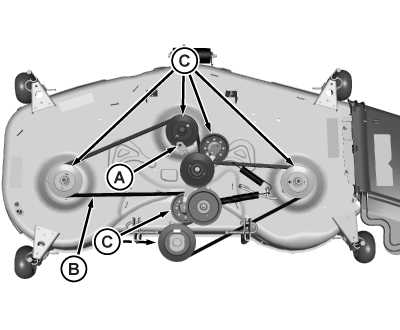

Visual Diagram of Deck Components

This section provides an insightful representation of the various elements that comprise the cutting assembly of a specific lawn maintenance machine. Understanding the layout and function of these components is crucial for effective maintenance and troubleshooting.

Each component plays a vital role in ensuring the optimal performance of the machinery. From the cutting blades to the housing, every part is designed for efficiency and durability. Visual aids can significantly enhance comprehension, allowing users to identify parts easily and understand their interconnections.

Utilizing a well-structured illustration aids in the identification of specific components, facilitating informed decision-making during repairs or replacements. Proper knowledge of the system’s layout contributes to better maintenance practices and longevity of the equipment.

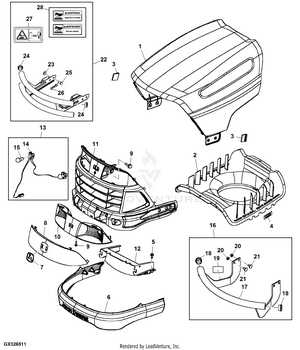

Replacement Parts Overview

Maintaining the efficiency and performance of your equipment requires understanding the essential components that may need to be replaced over time. Regular maintenance ensures longevity and optimal functionality. This section will provide insights into the various elements that play a crucial role in the overall operation.

Common Components to Replace

Several key components are vital for smooth operation. Here are some commonly replaced items:

- Belts

- Blades

- Filters

- Wheels

- Spindles

Replacement Considerations

When selecting new components, consider the following factors:

- Compatibility: Ensure that the replacement is suitable for your specific model.

- Quality: Opt for high-quality replacements to enhance durability.

- Warranty: Check if the part comes with a warranty for added assurance.

Being informed about these aspects will aid in making better decisions when it comes to upgrading or replacing essential components.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is essential for maintaining optimal performance and longevity. Using original replacements ensures compatibility and reliability, which can enhance the efficiency of your machinery. Here are some recommended sources to consider when seeking genuine items.

Authorized Dealers

- Visit local authorized dealers to explore their inventory.

- Check online platforms of these dealers for a wider selection.

- Inquire about warranty options and return policies.

Manufacturer’s Website

- Browse the official site for a catalog of available components.

- Utilize the search function to find specific items quickly.

- Sign up for newsletters to stay informed about promotions and new arrivals.

Online Retailers

- Explore reputable e-commerce sites that specialize in machinery components.

- Read customer reviews to assess the quality of the items offered.

- Compare prices to find the best deals without compromising on authenticity.

Local Repair Shops

- Visit nearby repair shops that may stock original items.

- Ask about their sourcing methods to ensure they provide genuine products.

- Consider building a relationship with a local shop for future needs.

Installation Tips for New Parts

When replacing components on your equipment, following proper installation techniques is crucial for optimal performance and longevity. Ensuring that each piece fits correctly and is secured can prevent future issues and enhance the functionality of your machinery.

Here are some essential tips to keep in mind during the installation process:

- Read the Manual: Always consult the user manual for specific instructions and guidelines related to the new components.

- Gather Necessary Tools: Before starting, collect all required tools to avoid interruptions during the installation.

- Clean the Area: Ensure the installation site is clean and free of debris to prevent contamination of new parts.

- Double-Check Compatibility: Verify that the new components are compatible with your machine model to avoid installation issues.

- Follow a Step-by-Step Process: Adhere to a systematic approach when installing each component to ensure nothing is overlooked.

After installation, it’s recommended to perform a thorough check to confirm that everything is correctly fitted and functioning. This proactive step can help in identifying any potential problems early, allowing for timely adjustments or repairs.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance and repairs on machinery is crucial to prevent accidents and injuries. Adhering to specific guidelines and precautions can help create a secure working environment. Below are some essential safety measures to consider before starting any repair tasks.

- Wear Protective Gear: Always use appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear to shield against potential hazards.

- Disconnect Power Sources: Before performing any maintenance, ensure that the machine is turned off and disconnected from its power source to avoid accidental starts.

- Work in a Well-Ventilated Area: Proper ventilation is essential, especially when using chemicals or working with fuel. This minimizes the risk of inhaling harmful fumes.

- Keep the Workspace Clean: A tidy workspace reduces the chance of accidents. Remove any tools, debris, or spills that could pose a risk.

Following these safety measures can significantly reduce the risk of injuries during repair activities, ensuring a more efficient and safe working environment.

Regular Maintenance Best Practices

Maintaining your equipment is essential for ensuring its longevity and optimal performance. Regular care can prevent unexpected breakdowns and improve efficiency. Following a systematic approach can help you stay on top of your maintenance tasks.

Here are some best practices to consider for effective upkeep:

- Schedule Regular Inspections: Conduct thorough checks on a routine basis to identify any signs of wear and tear.

- Clean After Use: Remove dirt and debris after each use to prevent buildup that can cause issues.

- Check Fluid Levels: Regularly inspect and refill fluids such as oil and coolant to ensure proper functioning.

- Sharpen Blades: Keep cutting components sharp for efficient performance and clean cuts.

- Replace Worn Parts: Timely replacement of damaged or worn components can prevent further damage.

By adhering to these guidelines, you can significantly enhance the reliability and effectiveness of your machinery, ensuring it serves you well for years to come.