The intricate workings of any heating system can often seem daunting. Understanding the individual elements that contribute to its efficiency is crucial for effective maintenance and troubleshooting. This section aims to illuminate the key components and their interconnections, providing a comprehensive overview for both novices and seasoned technicians alike.

Each element plays a vital role in the overall functionality, from the energy source to the distribution mechanism. By exploring these components, readers will gain insights into how they interact, ensuring optimal performance and longevity. Equipped with this knowledge, one can make informed decisions regarding repairs and enhancements.

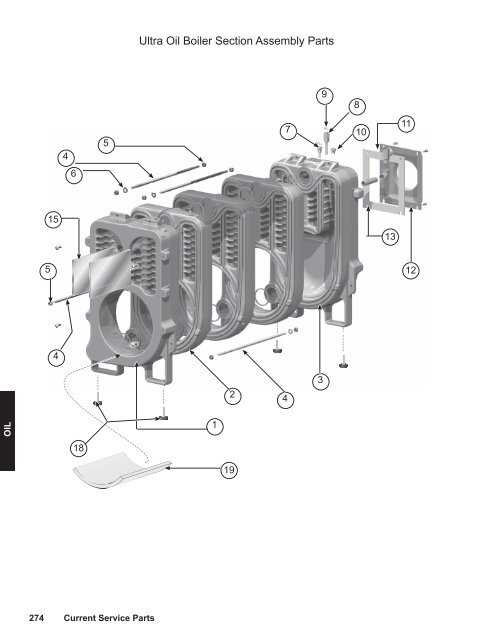

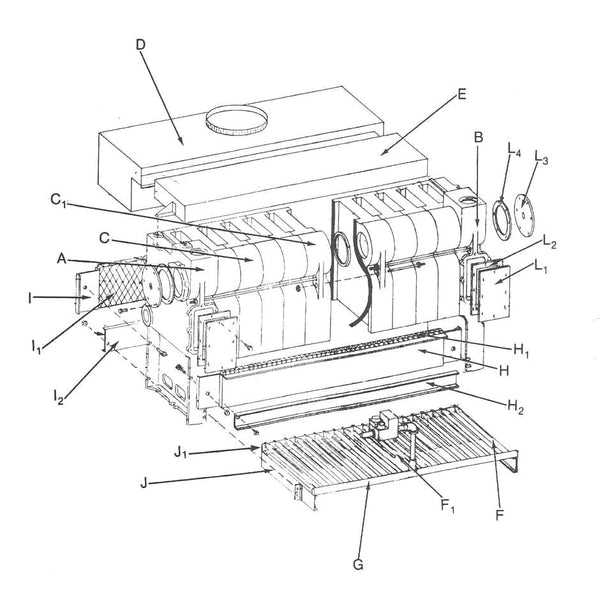

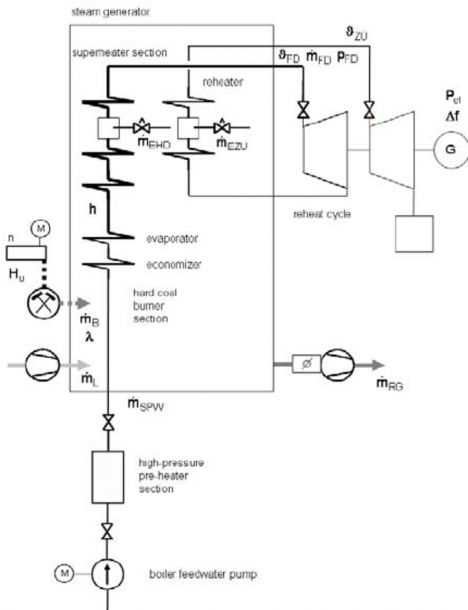

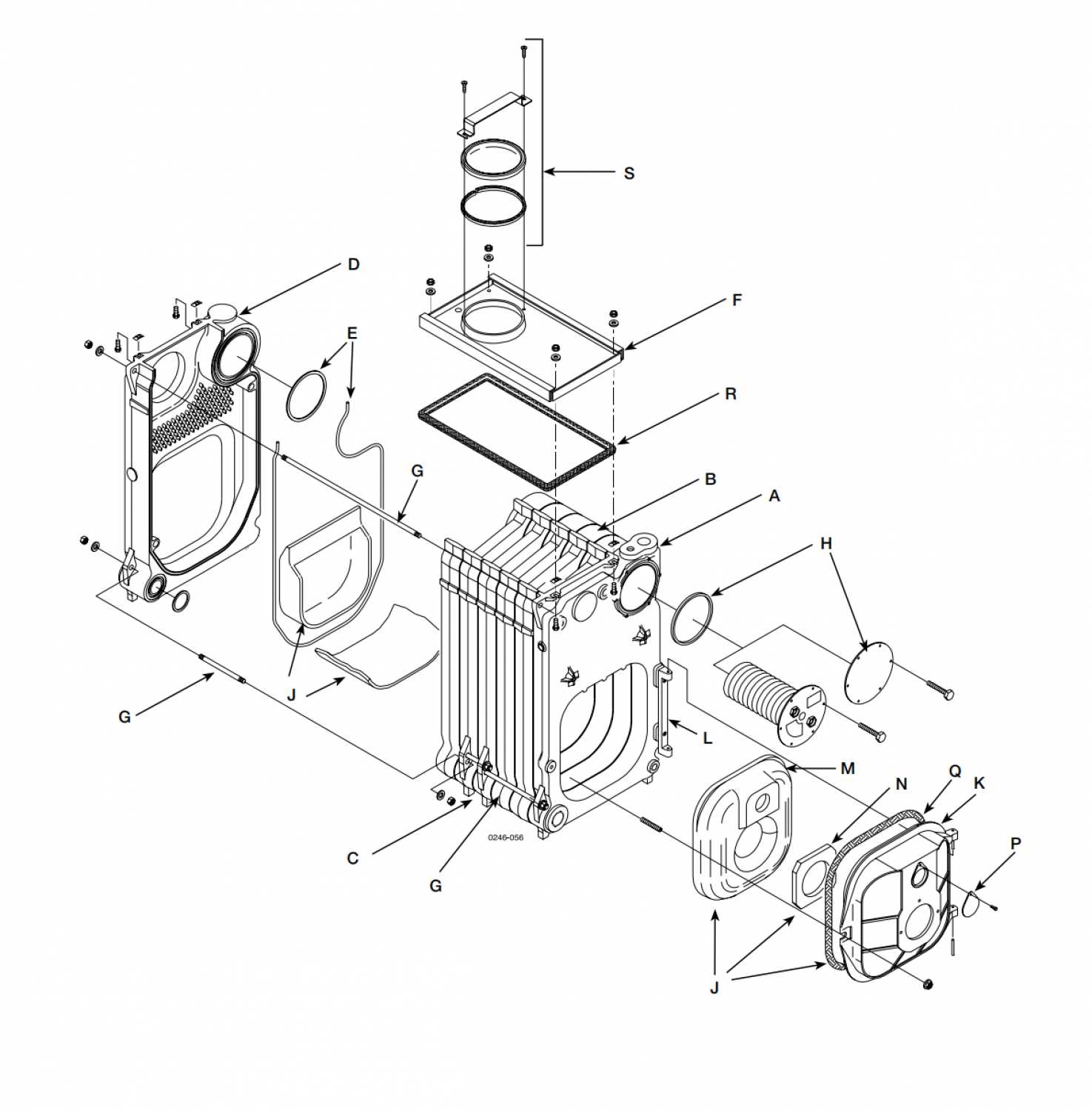

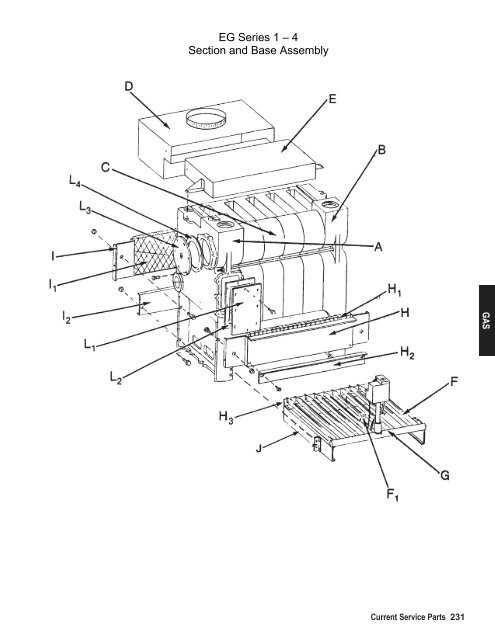

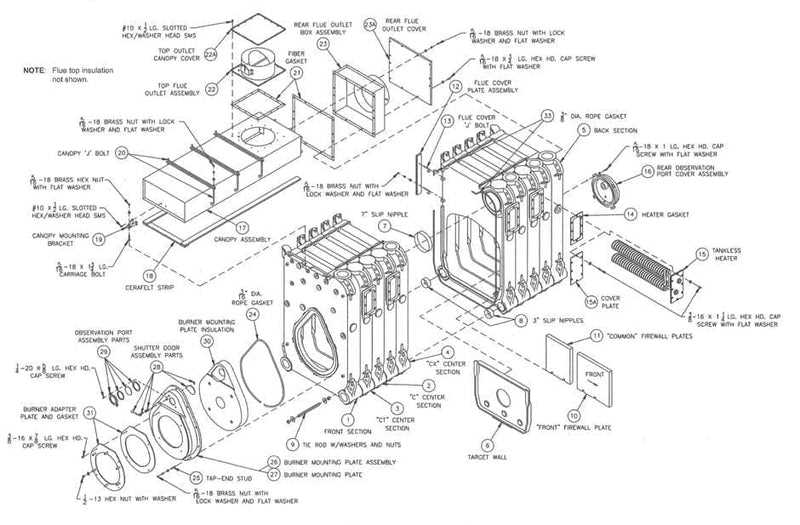

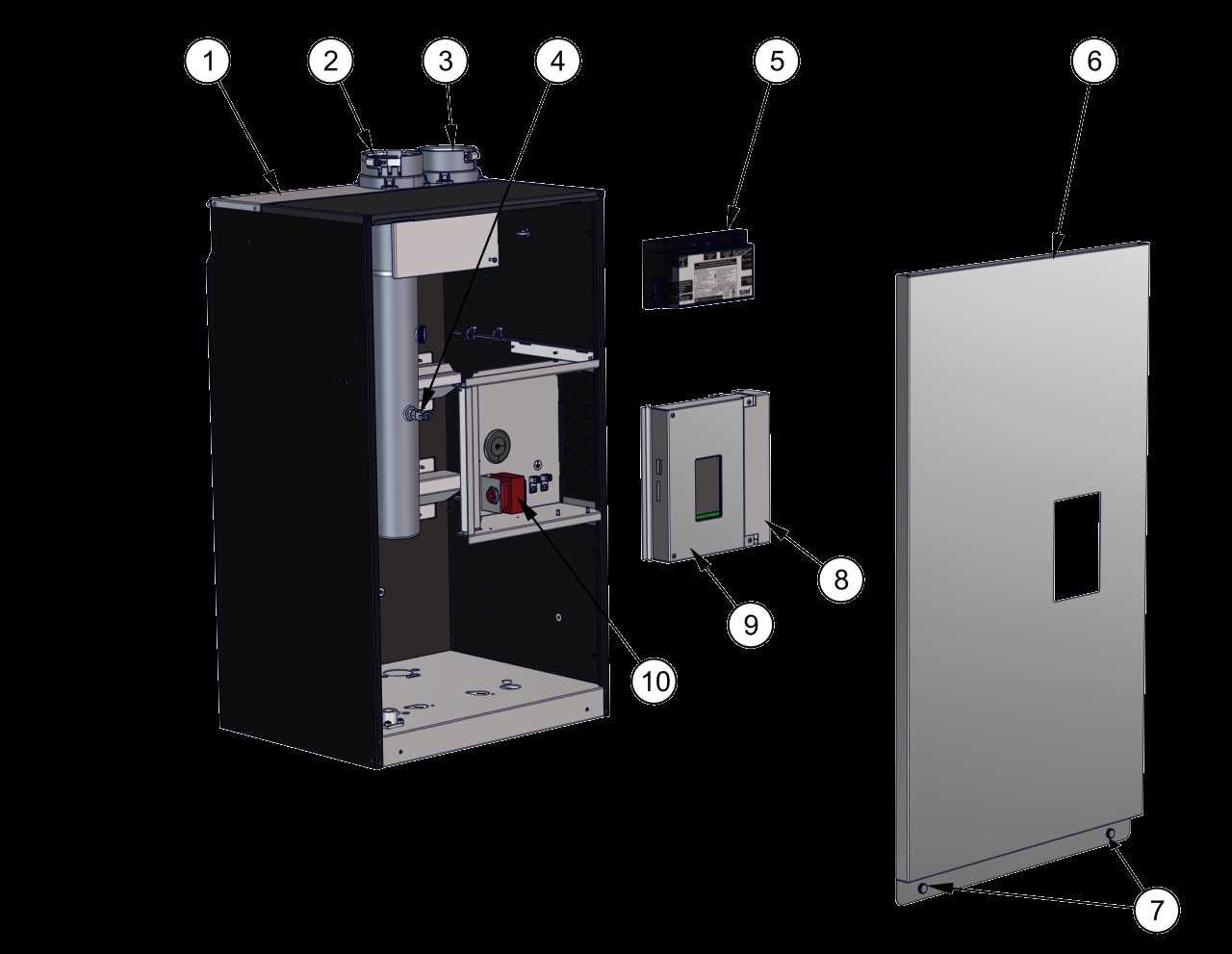

To facilitate a deeper understanding, detailed illustrations will accompany each component, enabling readers to visualize the relationships between different parts. This ultimate guide will serve as a valuable resource for anyone looking to delve into the mechanics of their heating system.

Understanding Weil McLain Boilers

This section aims to explore the intricacies and functionalities of heating systems produced by a well-known manufacturer. These systems are designed to provide efficient and reliable warmth to residential and commercial spaces.

Key features include:

- Durability and longevity

- Energy efficiency ratings

- Variety of models suitable for different needs

Common components of these heating units are essential for their operation:

- Heat exchanger

- Burner assembly

- Control system

- Expansion tank

Understanding the overall system allows for better maintenance and improved performance, ensuring that users maximize the benefits of their heating solutions.

Components of a Weil McLain Boiler

Understanding the essential elements of a heating system is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance and longevity of the entire unit. Below are the key components typically found in these heating systems.

- Heat Exchanger: This element transfers heat from the combustion gases to the water, allowing for effective heating.

- Burner: Responsible for mixing fuel and air for combustion, the burner is essential for generating heat.

- Control System: This includes thermostats and safety controls that regulate temperature and ensure safe operation.

- Pump: Circulates hot water throughout the system, delivering heat to radiators or other heating elements.

- Expansion Tank: Accommodates the expansion of water as it heats, preventing pressure buildup.

- Flue Pipe: Ventilation system that directs exhaust gases away from the unit and out of the building.

Each of these components must work in harmony to ensure that the heating system functions effectively and reliably. Regular maintenance and understanding of each part can help extend the lifespan of the entire system.

How to Read Boiler Diagrams

Understanding the layouts and schematics associated with heating systems is essential for effective troubleshooting and maintenance. These illustrations provide crucial insights into the arrangement and function of components, enabling users to diagnose issues and ensure optimal performance.

Key Elements of Diagrams

When examining these illustrations, focus on the following critical elements:

- Symbols: Familiarize yourself with the common symbols used to represent various components, such as valves, pumps, and control systems.

- Connections: Pay attention to lines that indicate how different elements are interconnected, including water flow paths and electrical circuits.

- Labels: Look for labels that specify component names, model numbers, and specifications that aid in identification.

Steps for Effective Reading

- Start with the Overview: Examine the entire layout to get a sense of how the system operates as a whole.

- Identify Key Components: Locate primary elements and understand their roles within the system.

- Trace Flow Paths: Follow the routes indicated by lines to visualize the movement of fluids and signals.

- Consult Documentation: Use manuals or technical documents to clarify any symbols or connections that are unclear.

By mastering these aspects, you can confidently navigate and interpret these essential illustrations, leading to more efficient maintenance and troubleshooting practices.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of heating systems requires regular upkeep. Neglecting this aspect can lead to significant issues that compromise performance and safety. Understanding the value of consistent maintenance helps in preserving functionality and preventing costly repairs.

Regular maintenance provides several benefits:

- Enhanced Efficiency: A well-maintained system operates more effectively, leading to lower energy costs.

- Extended Lifespan: Routine checks can identify wear and tear early, prolonging the life of the equipment.

- Improved Safety: Regular inspections reduce the risk of hazardous situations, ensuring a safe environment.

- Cost Savings: Preventive maintenance is often less expensive than addressing major failures.

- Consistent Performance: Keeping components in optimal condition ensures reliable heating throughout the season.

To maintain a heating system effectively, consider implementing the following practices:

- Schedule regular professional inspections to assess system health.

- Replace filters as recommended to ensure clean airflow.

- Check for leaks or unusual noises during operation.

- Keep the area around the equipment clear of debris.

- Monitor system performance and address any fluctuations promptly.

By prioritizing maintenance, users can enjoy a well-functioning system that meets their heating needs efficiently and safely.

Common Issues with Boiler Parts

In any heating system, certain components can present challenges that may impact performance and efficiency. Understanding these potential pitfalls is crucial for maintaining optimal operation. Regular inspection and awareness of common problems can prevent significant disruptions and costly repairs.

One frequent issue arises from wear and tear, which can lead to leaks or diminished functionality. Over time, seals and gaskets may degrade, causing fluid loss and pressure inconsistencies. Addressing these symptoms early can save time and resources.

Another concern is sediment buildup, which can obstruct the flow of fluids and decrease heating efficiency. This accumulation often results from mineral deposits, particularly in areas with hard water. Regular flushing can mitigate this problem and ensure smooth operation.

Electrical malfunctions are also a common source of frustration. Faulty wiring or malfunctioning sensors can disrupt the ignition process or affect temperature regulation, leading to erratic performance. Conducting routine checks of electrical components can help identify issues before they escalate.

Finally, improper maintenance practices can exacerbate existing problems. Neglecting regular servicing can allow minor issues to develop into major failures. Establishing a consistent maintenance schedule is essential for prolonging the life of the system and ensuring reliable performance.

Replacement Parts Availability

Access to essential components is crucial for maintaining the efficiency and longevity of heating systems. A reliable supply of these elements ensures that any necessary repairs can be conducted promptly, minimizing downtime and maintaining comfort.

- Local Distributors: Check nearby suppliers for immediate availability.

- Online Retailers: Numerous websites offer a wide selection of components with convenient delivery options.

- Manufacturer Direct: Contacting the original manufacturer can provide access to specific items not available elsewhere.

It is advisable to keep an inventory of frequently needed elements to facilitate quick repairs. This proactive approach can prevent delays and enhance overall system performance.

Identifying Boiler Models and Types

Understanding different heating units is essential for effective maintenance and replacement. Each model has unique features that can impact performance and efficiency. Familiarity with these variations helps users select the appropriate system for their needs.

Common Types of Heating Units

- Condensing Systems

- Combi Units

- Traditional Systems

- High-Efficiency Models

Key Identification Features

- Manufacturer Specifications

- Capacity Ratings

- Fuel Source

- Efficiency Standards

Safety Features in Weil McLain Boilers

Modern heating systems incorporate a variety of safety mechanisms designed to protect both the equipment and the user. These essential elements ensure safe operation and help to prevent accidents, making them a critical aspect of any efficient heating unit.

Emergency Shutoff Systems

One of the key safety features is the emergency shutoff system. This mechanism allows for immediate cessation of operation in case of malfunction, minimizing risks associated with overheating or pressure build-up. Regular maintenance ensures that these systems function effectively, providing peace of mind for users.

Flame Monitoring and Detection

Another vital component is the flame monitoring system. This technology detects the presence of a flame and can shut down the unit if it goes out unexpectedly, preventing the accumulation of unburned fuel. Proper installation and routine checks are crucial to maintain the reliability of this feature.

Benefits of Upgrading Components

Enhancing key elements of a heating system can lead to significant improvements in efficiency, performance, and longevity. By investing in modern components, homeowners and businesses can experience a range of advantages that contribute to overall comfort and cost savings.

Improved Energy Efficiency

One of the primary benefits of updating system elements is enhanced energy efficiency. Modern technologies often consume less energy while providing superior heating output. By reducing energy consumption, users can lower their utility bills and decrease their carbon footprint, making it a win-win situation for both the environment and personal finances.

Enhanced Reliability and Safety

Upgrading to newer components also improves the reliability and safety of the system. Older parts may be more prone to failures, leading to unexpected breakdowns. Newer technologies come equipped with advanced safety features that help prevent malfunctions and hazards, ensuring peace of mind for users. Investing in upgrades means investing in a safer and more dependable heating solution for any space.

Installation Guidelines for Homeowners

Proper installation of heating systems is crucial for ensuring efficiency and safety in your home. This section outlines essential steps and considerations that homeowners should follow to achieve a successful setup. Understanding these guidelines can help prevent issues and enhance the overall performance of the system.

Pre-Installation Preparations

Before beginning the installation process, it is important to gather the necessary tools and materials. Additionally, ensuring that the workspace is clear and accessible will facilitate a smoother installation. Homeowners should also verify that they have all required permits and adhere to local building codes.

| Item | Description |

|---|---|

| Tools | Wrenches, screwdrivers, pliers, and a level |

| Materials | Pipes, fittings, insulation, and sealants |

| Safety Gear | Gloves, goggles, and masks |

Installation Process

Once preparations are complete, the installation can commence. Start by positioning the unit according to the manufacturer’s recommendations. It is vital to connect all necessary components, ensuring that fittings are secure to prevent leaks. After installation, conduct a thorough inspection and testing to verify that everything operates correctly.

Wiring Schematics Explained

Understanding wiring schematics is essential for effective troubleshooting and maintenance of heating systems. These diagrams provide a visual representation of electrical connections and component layouts, allowing technicians to navigate complex systems with ease.

Key Components

- Power Source: The origin of electrical supply.

- Control Circuit: Manages the operation of the system.

- Safety Devices: Protect the system from faults.

- Actuators: Mechanisms that control system functions.

Reading the Diagram

- Identify Symbols: Familiarize yourself with common electrical symbols.

- Follow Connections: Trace wires to understand how components interact.

- Check Labels: Pay attention to labels for clarity on component functions.

Energy Efficiency Tips for Boilers

Maximizing energy efficiency is crucial for optimizing heating systems and reducing operational costs. Implementing certain strategies can significantly enhance performance and minimize waste, ultimately leading to a more sustainable approach.

Regular maintenance is essential; scheduling annual inspections ensures that all components function effectively. Cleaning filters and checking for leaks can prevent energy loss. Upgrading to programmable thermostats allows for better temperature control, adjusting heating according to your schedule.

Insulating pipes and the heating unit itself helps retain heat, improving overall efficiency. Additionally, investing in high-efficiency models can provide significant energy savings over time. Lastly, consider the use of alternative energy sources, such as solar, to complement your existing system.