Understanding the configuration of various mechanical systems is essential for maintaining and repairing maritime propulsion units. By familiarizing yourself with the arrangement and interaction of individual elements, you can ensure the smooth operation and longevity of your marine engine. This section delves into the intricacies of these systems, providing valuable insights into their structure and function.

With numerous components working together, it’s crucial to have a clear visualization of how they are interconnected. This guide will explore the layout of essential mechanical and operational elements, helping you identify key areas for maintenance and troubleshooting. Whether you are an experienced mechanic or a beginner, this resource will provide the clarity needed to navigate complex engine systems.

In addition, this guide will offer a detailed look at the positioning and functionality of various mechanical elements, ensuring that each piece is understood within the broader context of engine performance. By breaking down the layout into accessible sections, you will gain a better grasp of the core systems powering your marine equipment.

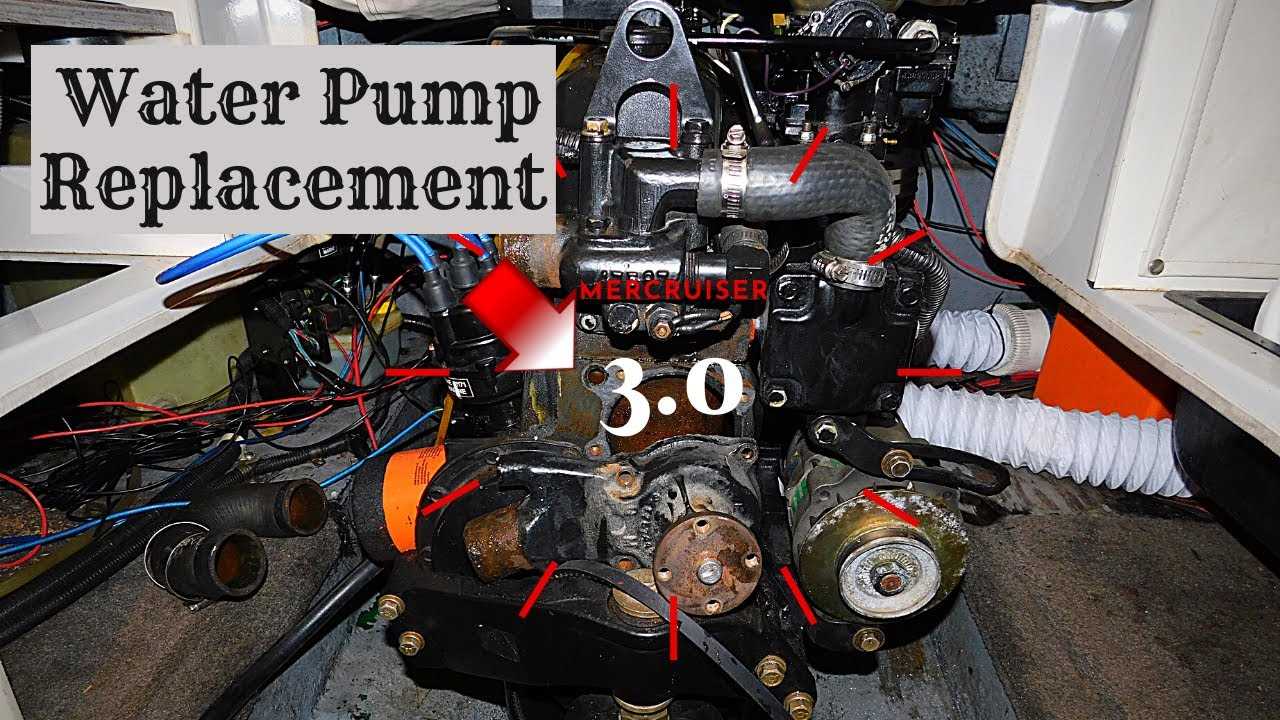

Essential Components for 3.0 Mercruiser Engines

When maintaining and optimizing an engine for marine applications, it is crucial to understand the vital elements that ensure smooth operation and longevity. These components work together to provide reliable performance, efficient fuel use, and overall durability.

- Fuel System: The fuel delivery system plays a critical role in maintaining proper engine function. It includes the fuel pump, injectors, and filtration units, ensuring consistent fuel flow to the combustion chambers.

- Ignition System: A well-tuned ignition setup is essential for efficient combustion. Key elements such as spark plugs, ignition coils, and timing mechanisms must be regularly checked to ensure proper firing sequences.

- Cooling Mechanism: Marine engines rely heavily on effective cooling solutions. The water pump, thermostats, and heat exchangers

Detailed Layout of Fuel System Components

The fuel delivery system is a critical aspect of ensuring smooth operation and consistent performance. This section provides a comprehensive overview of the various elements involved in the transportation and regulation of fuel within the engine. Each component plays a vital role in maintaining the engine’s efficiency, safety, and reliability.

Fuel Pump: The pump is responsible for transporting the liquid from the tank to the engine at the required pressure. A reliable pump ensures uninterrupted flow and optimal combustion.

Filters: Positioned along the supply line, filters remove impurities and contaminants from the liquid. This prevents blockages and ensures the system remains clean, safeguarding the engine from potential damage.

Regulator: The regulator is responsible for maintaining the correct pressure in the lines. This prevents overflows and ensures that the engine receives the right amount of fuel at all times.

Fuel Lines: These are

Cooling System Elements and Their Functions

The cooling mechanism plays a crucial role in maintaining optimal temperatures during engine operation. Understanding the various components involved in this process is key to ensuring effective performance and preventing overheating. Each element within the cooling structure serves a specific purpose, working together to regulate the flow of coolant and manage heat dissipation efficiently.

Component Function Thermostat Regulates the flow of coolant based on the engine’s temperature, ensuring that it operates within a safe range. Water Pump Circulates coolant through the system, pushing it through the engine and back to the radiator for cooling. Radiator Dissipates heat from the coolant as it passes through the fins, Exhaust Components Overview and Maintenance

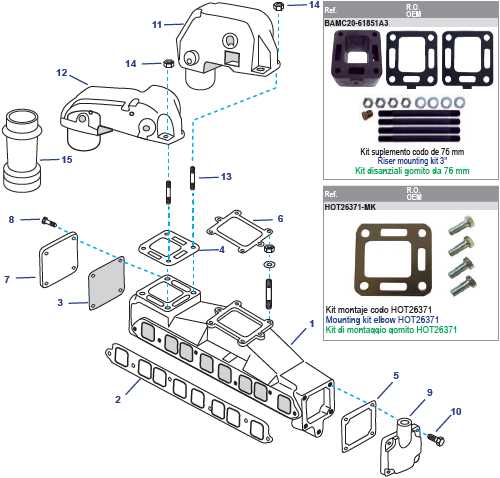

In marine engine systems, exhaust mechanisms play a critical role in ensuring the smooth removal of gases generated during operation. Proper maintenance and understanding of these elements are essential for optimal engine performance and longevity. This section provides an overview of the key components involved and their upkeep to prevent common issues associated with the exhaust system.

Key Exhaust Elements

The exhaust system consists of several crucial parts designed to channel and expel combustion gases efficiently. Regular inspections and timely maintenance can help avoid excessive wear, corrosion, and leaks, which can negatively impact the overall functioning of the engine.

Component Function Maintenance Tip Manifold Directs exhaust gases from the engine to the riser or elbow. Inspect for cracks Steering Mechanism Parts Breakdown

The steering system plays a crucial role in ensuring smooth and responsive control of the vessel. Understanding the components involved in this system helps in maintaining and troubleshooting potential issues that may arise over time. Each element of the mechanism works together to translate the operator’s input into precise movements, providing both maneuverability and safety on the water.

Key elements include the wheel, the column, linkages, and the assembly that connects these components to the directional unit. These components are designed to endure harsh marine environments, so regular inspections and maintenance are essential to ensure they function correctly and to extend their lifespan. Proper care can prevent wear, corrosion, and other common issues, ultimately preserving the reliability of the steering system.

Ignition System Parts and Replacement Guide

The ignition system is a crucial component in ensuring that your engine starts and operates smoothly. It consists of various elements that work together to create the necessary spark for combustion. Understanding these components and knowing when to replace them can enhance performance and reliability.

Below is a comprehensive overview of the key elements within the ignition setup, along with guidance on when to consider replacements. Proper maintenance can prevent issues and prolong the life of your engine.

Component Description Replacement Signs Spark Plug Transmits electrical current to ignite the air-fuel mixture. Hard starting, poor acceleration, or misfiring. Ignition Coil Converts battery voltage to a higher voltage to create a spark. Engine stalling, no-start condition, or rough idling. Distributor Cap Distributes high-voltage current to the correct cylinder. Corrosion, cracks, or carbon tracking. Ignition Wires Conducts electrical current from the ignition coil to the spark plugs. Visible damage, fraying, or wear. Starter Motor Engages the engine’s flywheel to start the engine. Grinding noise, clicking sound, or failure to start. Regular inspection and timely replacement of these components can significantly improve the reliability and performance of your engine. Always refer to the manufacturer’s specifications for the best practices in maintenance and replacement.

Lubrication System Components in Focus

The lubrication system in marine engines plays a vital role in ensuring smooth operation and longevity. This system is responsible for distributing oil to various engine components, reducing friction, and preventing wear and tear. Understanding the individual components of this system helps in maintaining optimal performance and addressing potential issues effectively.

Key Elements of the Lubrication System

At the heart of the lubrication system are several crucial elements, including the oil pump, oil filter, and oil cooler. The oil pump is responsible for circulating oil throughout the engine, maintaining the necessary pressure to lubricate moving parts. The oil filter ensures that any contaminants are removed from the oil before it reaches sensitive components. Finally, the oil cooler plays an essential role in regulating the temperature of the oil, preventing overheating and ensuring consistent performance.

Importance of Regular Maintenance

Regular maintenance of the lubrication system is essential for ensuring the longevity and reliability of the engine. This includes routine checks of the oil level and quality, timely oil changes, and inspections of the filtration and cooling components. By prioritizing these tasks, one can significantly reduce the risk of engine damage and enhance overall performance.

Electrical System Parts and Wiring Guide

This section provides a comprehensive overview of the electrical components and their connections within a marine engine system. Understanding these elements is crucial for ensuring proper functionality and safety. This guide covers various essential elements, their roles, and best practices for effective wiring management.

Essential Components of the Electrical System

The electrical setup in a marine engine includes several key elements. The battery serves as the primary power source, supplying energy for starting and running the engine, as well as powering onboard accessories. The alternator plays a vital role in recharging the battery while the engine is operating, ensuring a steady supply of electrical energy.

Wiring Considerations

Proper wiring is critical to the reliability and efficiency of the electrical system. It is important to use high-quality, marine-grade wires that can withstand the harsh conditions of a marine environment. Color-coding the wires helps in identifying connections easily, while using fuses protects the system from overloads. Regular inspections should be conducted to check for wear, corrosion, or loose connections, which could lead to electrical failures.

Propulsion System Key Elements Explained

The propulsion system of a marine vessel plays a crucial role in determining its efficiency and performance. Understanding the core components of this system is essential for ensuring smooth navigation and optimal operation. The interplay between these elements significantly affects the vessel’s speed, maneuverability, and overall functionality.

Main Components of the Propulsion System

- Engine: The heart of the propulsion mechanism, converting fuel into mechanical energy.

- Transmission: This element transmits power from the engine to the propeller, ensuring efficient energy transfer.

- Propeller: The key element that converts rotational energy into thrust, propelling the vessel through water.

- Shaft: A crucial link that connects the engine to the propeller, facilitating power delivery.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity.

Importance of Each Element

- Engine: A reliable and powerful engine is vital for achieving desired speeds and handling conditions.

- Transmission: Smooth operation and gear shifting capabilities enhance performance and reduce wear.

- Propeller: The design and size of the propeller influence thrust efficiency and fuel consumption.

- Shaft: Proper alignment and maintenance of the shaft are essential to prevent vibration and wear.

- Cooling System: Effective cooling extends the lifespan of components, reducing the risk of failure.

Throttle and Control System Components

The throttle and control system plays a crucial role in regulating engine performance and responsiveness. It encompasses various elements that work in unison to ensure smooth operation and efficient management of power delivery. Understanding these components is essential for effective maintenance and troubleshooting.

Key Elements of the System

Several integral components contribute to the functionality of the throttle and control system. These include the throttle body, control cables, and sensors, each serving a specific purpose in the overall mechanism.

Component Description Throttle Body The primary unit that regulates airflow into the engine, impacting acceleration and power output. Control Cables Cables that transmit input from the throttle lever to the throttle body, enabling driver control. Sensors Devices that monitor engine parameters and provide feedback for optimal performance adjustments. Importance of Regular Inspection

Regular examination of these components is vital for ensuring the system operates efficiently. Over time, wear and tear can affect performance, leading to sluggish acceleration or unresponsive controls. Addressing issues promptly can prevent more significant problems and enhance overall engine efficiency.

Understanding Drive Shaft and Transmission Parts

The components responsible for transmitting power from the engine to the propulsion system play a crucial role in marine mechanics. A clear grasp of these elements is essential for efficient operation and maintenance of the vessel’s performance. This section delves into the intricacies of the drive shaft and transmission assembly, exploring their functions and interrelationships.

The drive shaft serves as the primary conduit for transferring rotational energy. It connects the engine’s output to the transmission, enabling movement through the water. This element must withstand significant torque and stress during operation, necessitating robust construction and careful alignment.

Transmission components are vital for modulating the engine’s power delivery to the drive shaft. These parts ensure smooth gear shifts and optimize performance according to varying load conditions. Understanding the different types of transmissions, such as direct drive and reduction gear systems, is crucial for troubleshooting and maintenance.

Proper maintenance of the drive shaft and transmission is essential for longevity and reliability. Regular inspections for wear, lubrication, and alignment will prevent costly repairs and ensure seamless operation. Knowledge of these components will empower vessel owners to make informed decisions regarding their marine systems.