The internal structure of small marine engines often intrigues boat enthusiasts and professionals alike. Understanding the intricacies of the mechanisms that power these machines helps ensure optimal performance and longevity. This section will explore the key components of such an engine, highlighting how various elements work together to provide seamless operation.

Whether you are performing maintenance, repairs, or upgrades, gaining knowledge of the individual elements and their arrangement is crucial. Knowing where each element fits within the overall system can make it easier to troubleshoot and maintain peak engine efficiency.

By delving into the specific configurations, you will gain insight into the roles that these components play in ensuring a smooth and reliable boating experience. This exploration will give you a comprehensive understanding of the layout and connections within the motor.

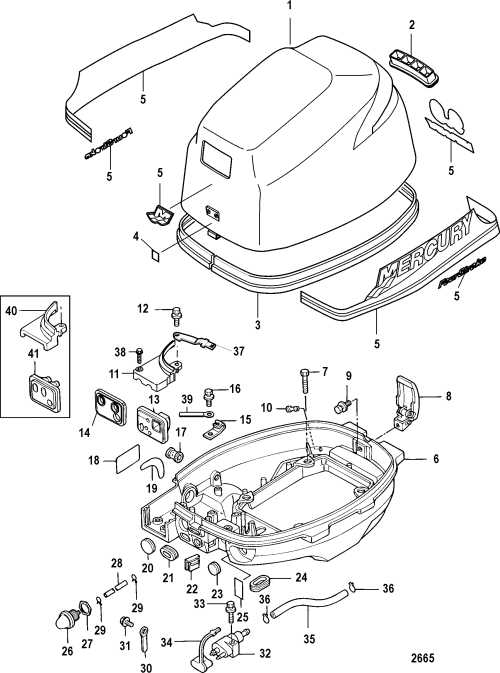

Mercury 9.9 2-Stroke Engine Overview

This engine model offers reliable performance for small boats, featuring a compact design and straightforward mechanics. Known for its balance between power and efficiency, it is ideal for both recreational users and those who need a dependable motor for light-duty activities on the water.

Key Features of the Engine

- Lightweight construction for ease of transport and installation.

- Durable build that ensures longevity even in challenging conditions.

- Optimized fuel consumption, offering a balance between power and efficiency.

Benefits of Using This Engine

- Simplicity in maintenance due to fewer components and a straightforward design.

- Quiet operation, making it suitable for relaxed boating environments.

- Efficient power

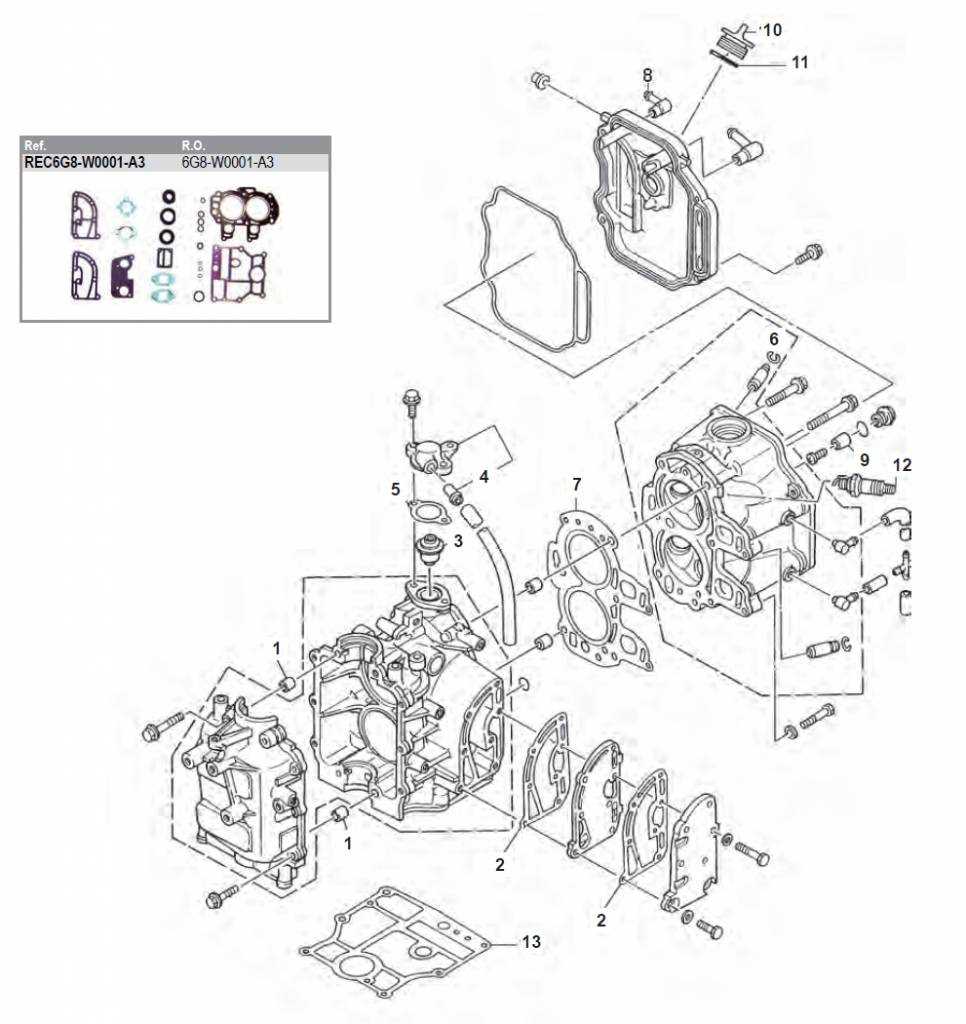

Main Components of the 9.9 Motor

This section focuses on the essential elements that make up the structure of this small engine, emphasizing its functionality and performance. Each part plays a vital role in ensuring the smooth operation of the entire unit, contributing to its reliability and efficiency.

- Powerhead: This is the core of the engine, housing the combustion system that converts fuel into mechanical power.

- Fuel System: The system that ensures a steady supply of fuel to the motor, including the carburetor and fuel pump.

- Ignition System: Responsible for starting the engine by generating the spark needed to ignite the fuel-air mixture in the cylinders.

- Cooling System:

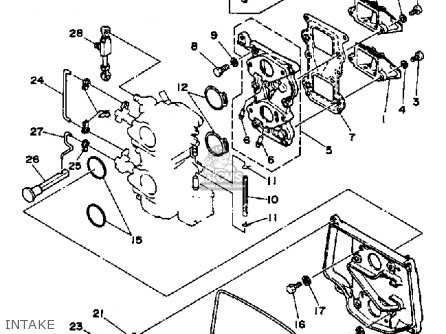

Fuel System Parts and Functionality

The fuel system plays a crucial role in ensuring efficient operation of any marine engine. It is responsible for delivering the necessary fuel to the engine, helping maintain proper performance and ensuring smooth functionality. Understanding the components involved in the fuel system can aid in troubleshooting and maintaining optimal performance.

Main Components of the Fuel System

- Fuel Tank: This is the storage unit for the fuel. It is designed to securely hold gasoline and supply it steadily to the engine.

- Fuel Lines: Flexible hoses that transport gasoline from the tank to the engine, ensuring a consistent and safe flow.

- Primer Bulb: This hand-operated device helps initiate fuel flow by building pressure within the fuel lines, preparing the engine for start-up.

- Fuel Pump: A mechanical or electrical component that moves gasoline from the tank to the carb

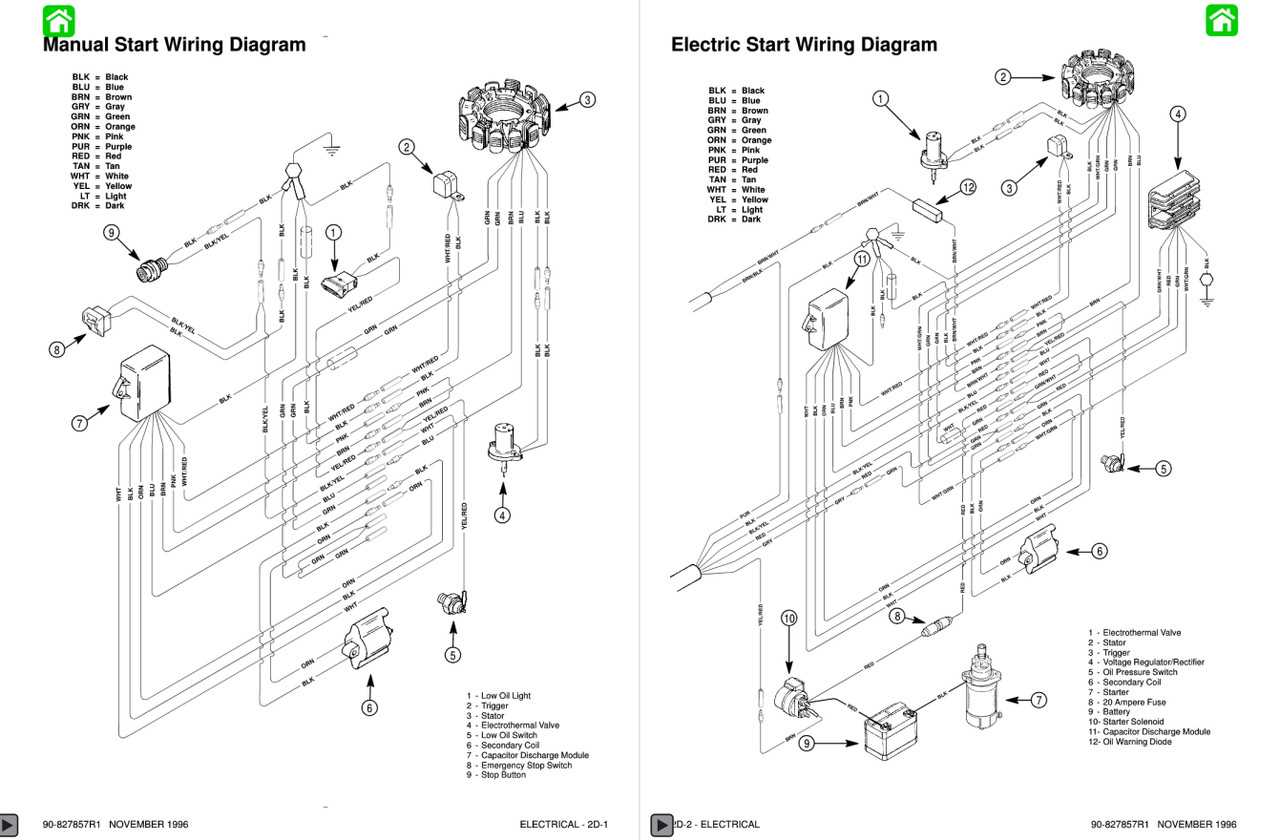

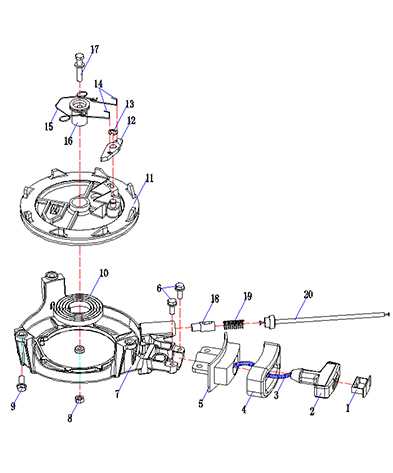

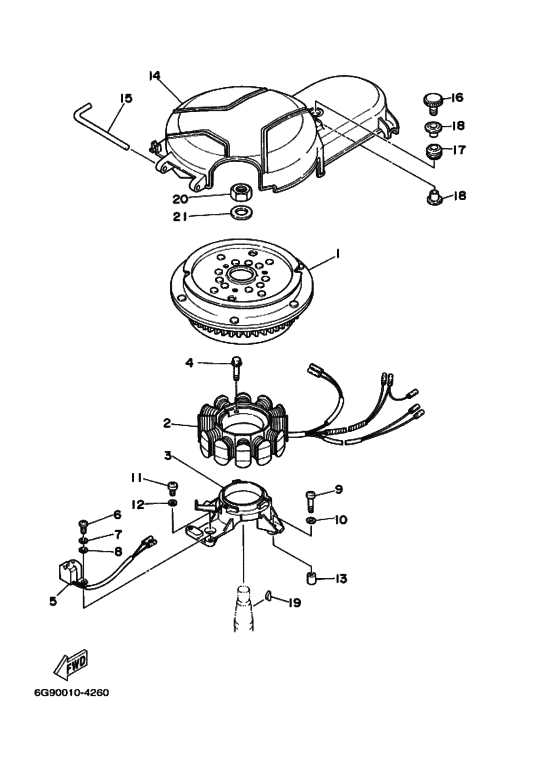

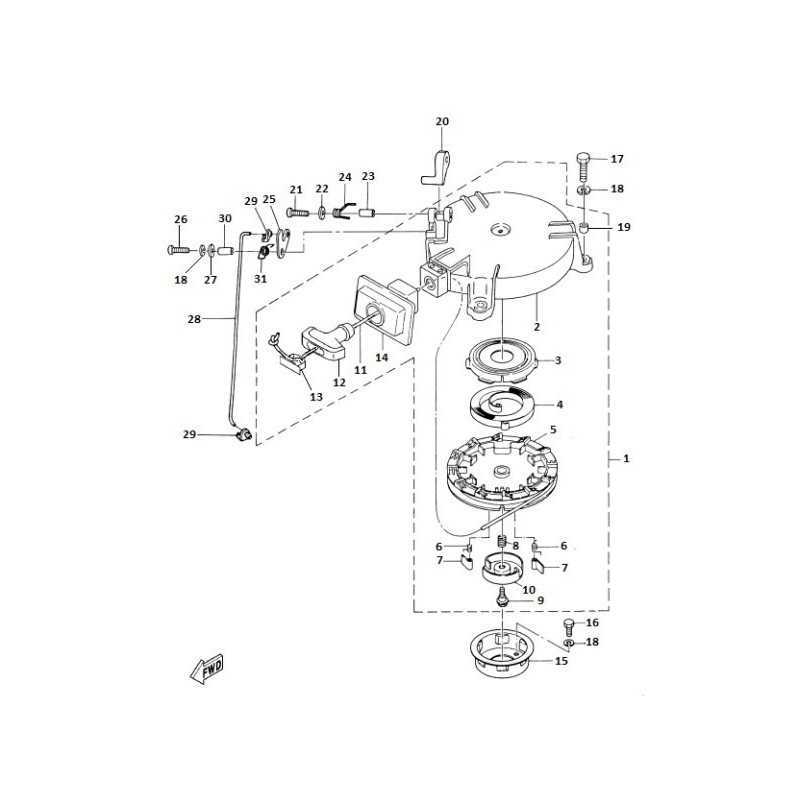

Ignition System and Key Components

The ignition system plays a crucial role in ensuring the engine operates smoothly by delivering the necessary spark to ignite the fuel-air mixture. It consists of several interconnected components that work together to generate and distribute the electrical energy required for combustion. Understanding the key elements of this system can help maintain the engine’s performance and ensure reliable operation.

Ignition Coil is one of the primary components responsible for transforming low voltage from the battery into the high voltage needed to create a spark. It serves as a bridge between the power source and the spark plugs, ensuring a steady flow of energy.

Spark Plugs are essential for igniting the fuel in the combustion chamber. These small devices receive the high voltage from the coil and create the spark that starts the combustion process, which powers the engine.

The Flywheel contains magnets that help generate electricity when it spins,

Cooling System Elements and Layout

The cooling system plays a crucial role in maintaining the temperature of an engine during operation. Its components work together to ensure efficient heat exchange and prevent overheating. Understanding the arrangement and function of each element is key to ensuring the engine runs smoothly over extended periods of use.

Main Components of the Cooling System

The system consists of various parts that work in unison to circulate water or coolant through the engine. These components ensure proper temperature control and optimize performance. Below is a table outlining the essential elements involved in this process:

Component Function Water Pump Circulates water throughout the engine to absorb and remove excess heat. Thermostat Regulates Exhaust System Structure and Parts

The exhaust system is a crucial component of any internal combustion engine, designed to efficiently channel gases produced during combustion away from the engine. This system not only helps maintain optimal performance but also minimizes harmful emissions and noise. Understanding its structure and individual components is essential for maintenance and troubleshooting.

Components of the Exhaust System

The main elements of the exhaust system include the exhaust manifold, which collects gases from the engine, and the exhaust pipe, which directs these gases toward the atmosphere. Additionally, the system features a muffler that reduces noise and a catalytic converter that helps reduce emissions by converting harmful substances into less harmful ones.

Functionality and Maintenance

Regular maintenance of the exhaust system is vital for ensuring engine efficiency and compliance with environmental regulations. Inspecting components for rust, leaks, and blockages can prevent performance issues. Proper care also extends the lifespan of the system and contributes to a quieter operation.

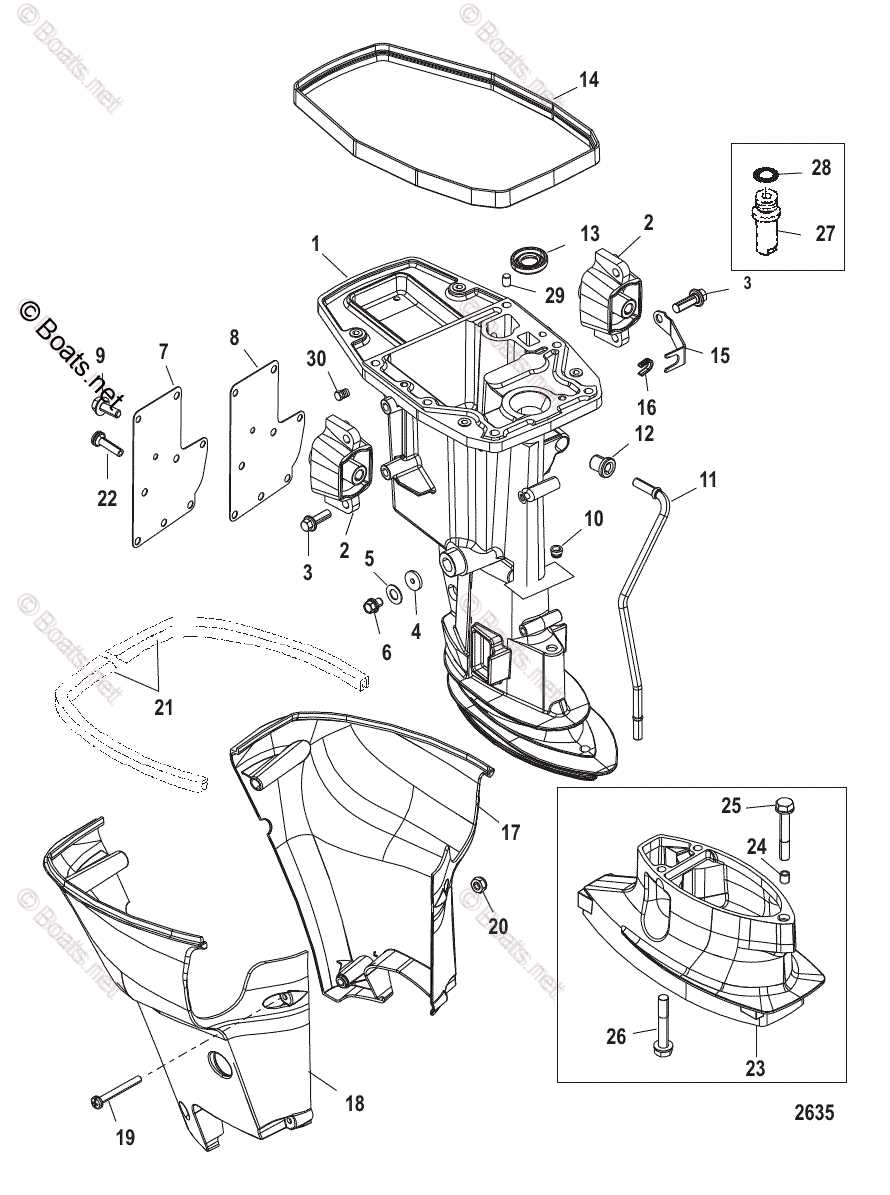

Propeller and Lower Unit Components

The propeller and lower unit play crucial roles in the performance and efficiency of marine engines. Understanding the various elements within these sections is essential for maintenance and optimal operation. Each component contributes to the overall functionality, ensuring smooth navigation and power delivery.

The propeller, responsible for thrust, must be chosen carefully to match the engine’s specifications and the intended use of the vessel. Various shapes and sizes influence performance, making selection a critical aspect of marine engineering. The lower unit houses vital mechanisms that connect the engine to the propeller, enabling the transmission of power effectively.

Component Description Propeller Blades Essential for generating thrust by converting engine power into forward motion. Hub Connects the propeller to the shaft, providing stability and strength. Lower Unit Housing Protects internal components and supports the gear assembly. Gear Ratio Affects the torque and speed characteristics of the propulsion system. Trim Tab Helps to stabilize the vessel and improve handling at various speeds. Gearcase and Driveshaft Overview

The gearcase and driveshaft are essential components in outboard motor systems, playing a crucial role in transferring power from the engine to the propeller. This section delves into the functionality and structure of these parts, highlighting their importance in ensuring optimal performance and reliability on the water.

Functionality of the Gearcase

The gearcase houses various gears and mechanisms that facilitate the transfer of rotational force. It is designed to withstand high pressures and forces, ensuring smooth operation even under demanding conditions. The proper functioning of the gearcase is vital for maintaining the efficiency and speed of the watercraft.

Driveshaft Characteristics

The driveshaft connects the engine’s output to the gearcase, allowing for the transfer of torque. It must be robust enough to handle the stresses imposed during operation while remaining lightweight to enhance overall performance. Additionally, the driveshaft must be properly aligned to prevent excessive wear and ensure longevity.

Component Function Key Features Gearcase Transfers engine power to the propeller Durable materials, precision engineering Driveshaft Connects engine output to the gearcase Lightweight, high-strength construction Carburetor Assembly and Parts Details

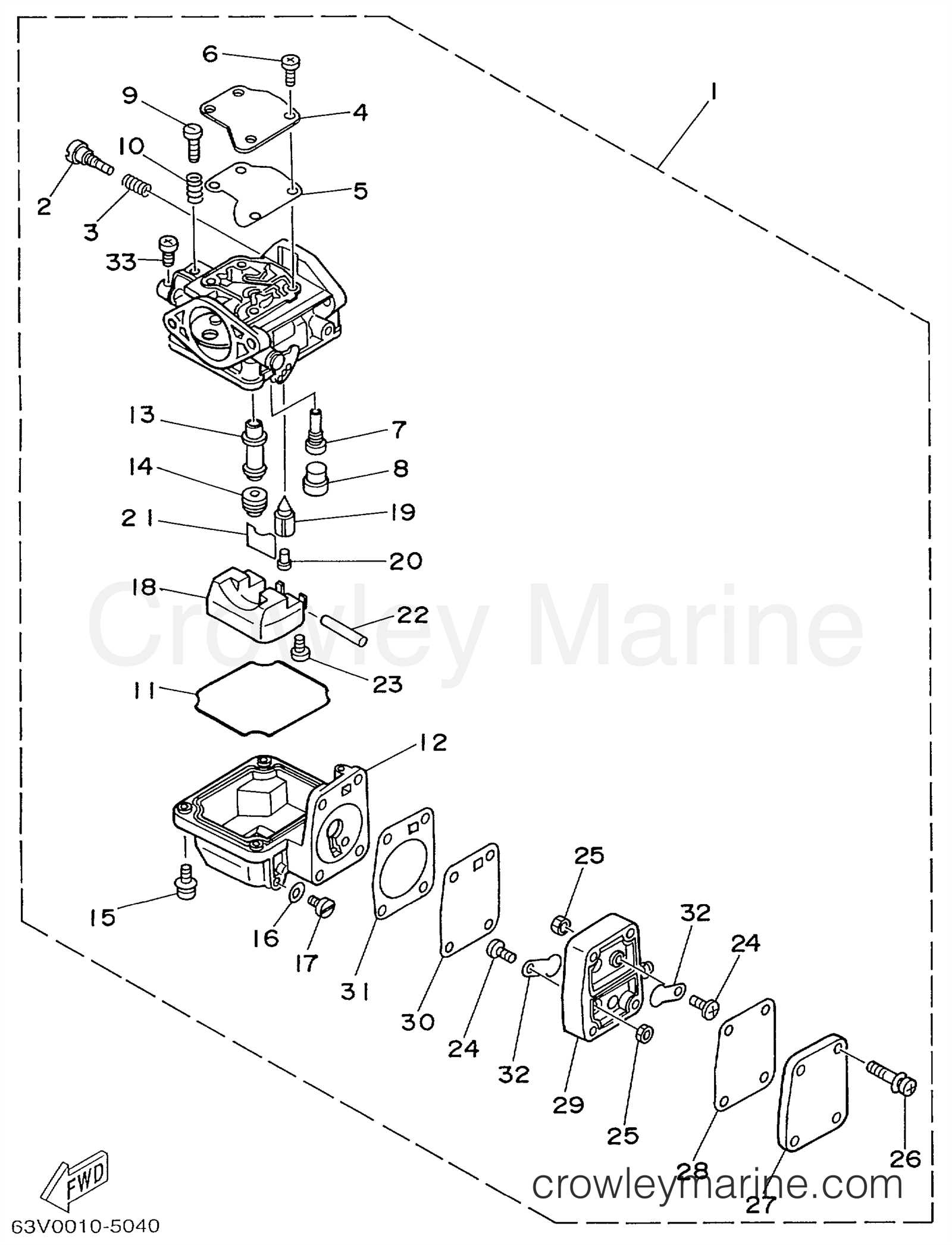

The carburetor is a crucial component in the operation of outboard engines, playing a vital role in mixing air and fuel for combustion. Understanding its assembly and the individual elements involved is essential for proper maintenance and troubleshooting. This section provides insights into the construction and functionality of the carburetor, highlighting key components that contribute to its efficiency.

Here are the primary components of the carburetor assembly:

- Float Chamber: Maintains a constant fuel level, ensuring optimal performance.

- Jet: Controls the amount of fuel entering the airflow, crucial for mixture quality.

- Throttle Valve: Regulates the engine’s power output by controlling airflow.

- Choke Valve: Assists in starting the engine by enriching the fuel mixture.

- Needle Valve: Regulates fuel flow from the float chamber to the jet.

- Gasket: Seals the carburetor to prevent air and fuel leaks.

Proper assembly and maintenance of these elements are essential for optimal engine performance. Regular inspection and cleaning of the carburetor can prevent issues such as clogging or inefficient fuel delivery, ensuring reliable operation.

When disassembling the carburetor, follow these steps to ensure proper handling:

- Remove the air intake cover carefully.

- Detach the fuel lines and any electronic connections.

- Unscrew the carburetor from the engine mount.

- Take apart the float chamber and inspect internal components.

- Clean all parts thoroughly before reassembly.

By understanding these aspects of the carburetor, users can enhance their knowledge of engine functionality and improve maintenance practices.

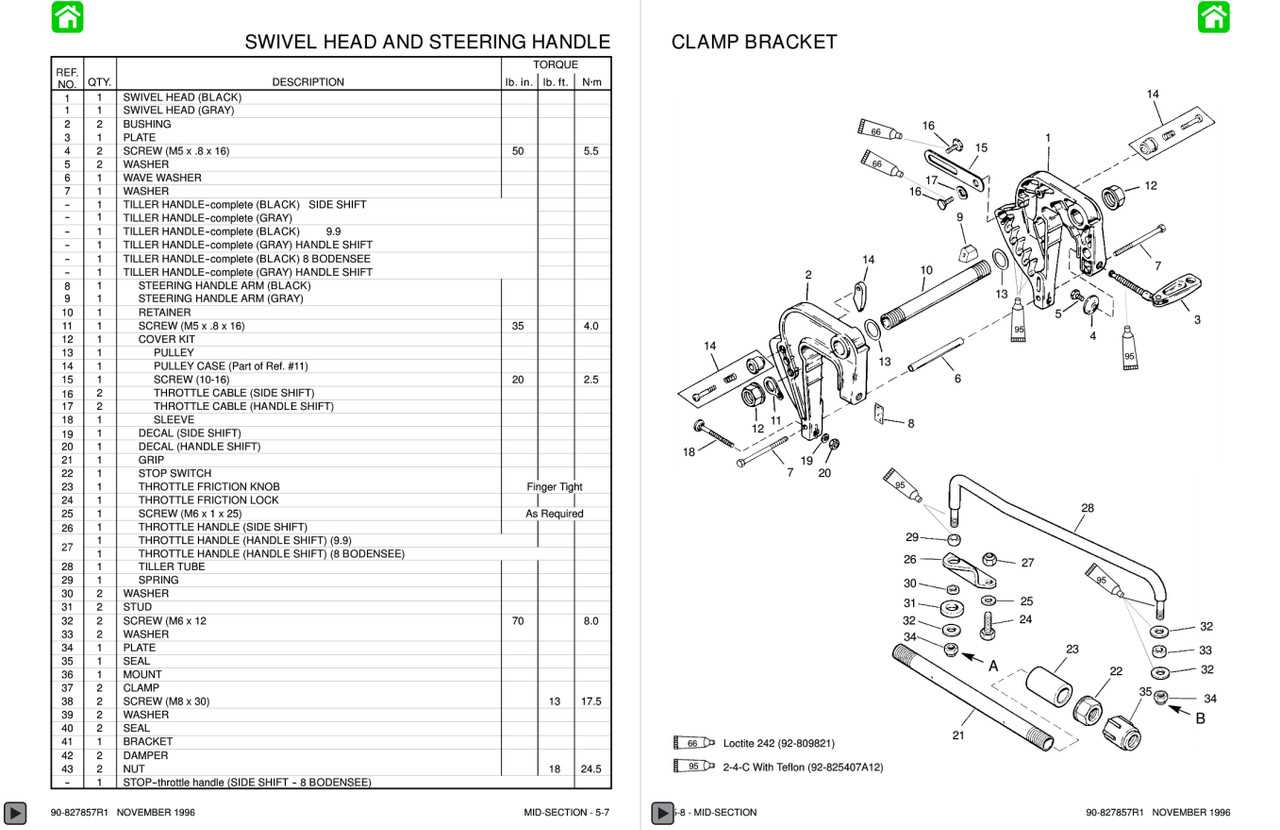

Electrical Components and Their Role

The electrical system in a marine engine is crucial for its performance and reliability. This section highlights the various electrical elements, explaining their significance and how they contribute to the overall functionality of the motor. Understanding these components is essential for proper maintenance and troubleshooting.

Key Electrical Elements

Among the vital electrical components are the ignition system, battery, and wiring harness. Each part plays a distinct role in ensuring the engine operates smoothly and efficiently.

Functionality Overview

The ignition system is responsible for initiating the combustion process, while the battery supplies the necessary power for starting the engine and powering electrical accessories. The wiring harness connects these components, facilitating communication and ensuring proper electrical flow.

Component Function Ignition System Ignites the fuel-air mixture for combustion. Battery Provides electrical power for starting and accessories. Wiring Harness Connects components for efficient electrical flow.