The intricacies of modern lawn care machinery play a crucial role in maintaining lush, green landscapes. Knowledge of the various elements that contribute to their functionality empowers users to make informed decisions regarding maintenance and repairs.

For those looking to enhance their understanding, a comprehensive visual representation of the machine’s constituents can prove invaluable. This detailed overview enables enthusiasts and professionals alike to navigate the essential components with ease.

By exploring this topic, individuals can delve into the ultimate guide to ensuring optimal performance and longevity of their lawn care equipment. Whether it’s troubleshooting or upgrading, having a clear picture of the mechanisms at play is essential for any owner.

Understanding John Deere X300R

This section delves into a popular model of lawn care machinery designed for efficiency and ease of use. It offers an in-depth look at the components that contribute to its functionality and performance. Understanding the various elements can enhance the maintenance and operation experience for users.

| Component | Description |

|---|---|

| Engine | Powerful and reliable engine that ensures smooth operation and effective cutting performance. |

| Transmission | Automatic system that allows for seamless speed adjustments while maneuvering. |

| Deck | Durable cutting deck designed to deliver a precise and clean cut, enhancing the aesthetic of any lawn. |

| Wheels | Sturdy wheels that provide stability and traction on various terrains, ensuring a steady ride. |

| Controls | User-friendly controls that enable easy adjustments and enhance operator comfort. |

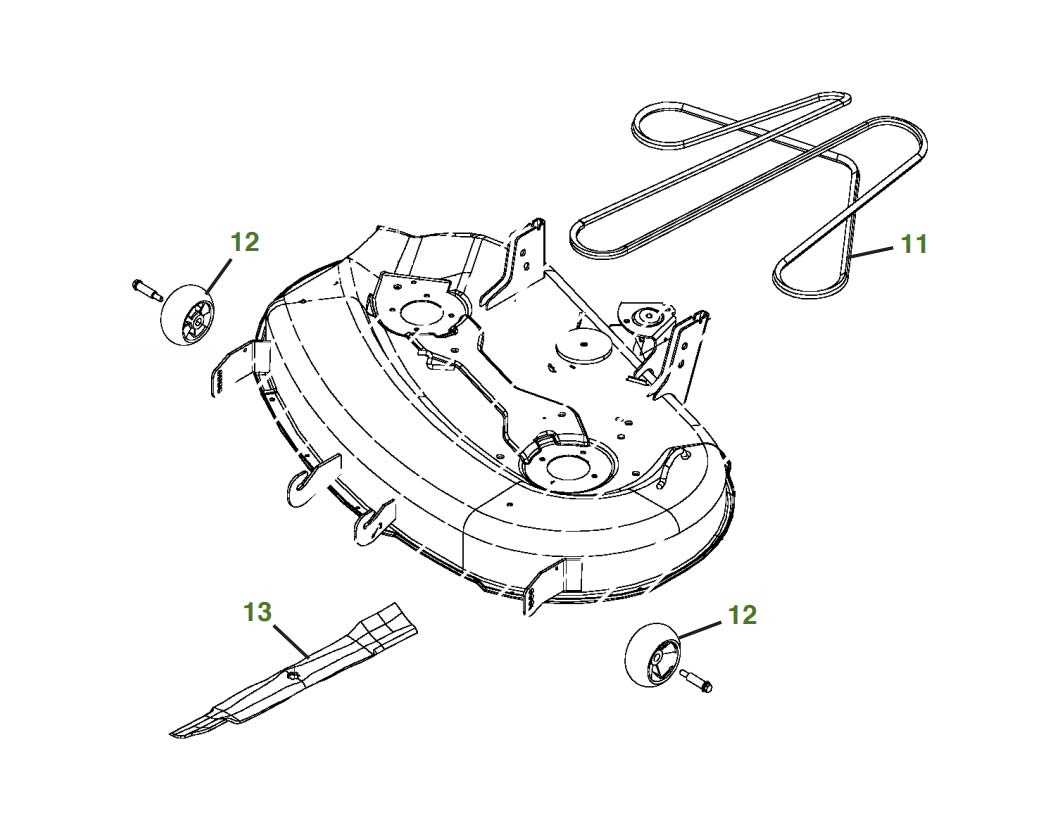

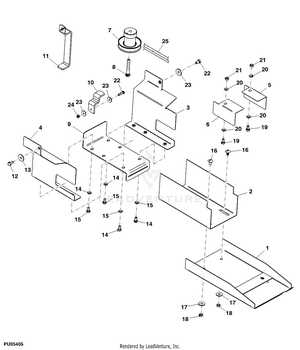

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide clarity, making it easier to identify individual elements and their relationships, which ultimately aids in efficient troubleshooting and assembly.

Enhanced Understanding

By utilizing graphical layouts, operators and technicians can quickly grasp the structure and functionality of equipment. This understanding reduces errors during repairs and allows for more effective communication among team members.

Streamlined Maintenance

Clear visuals facilitate organized maintenance practices. They serve as a reference guide, ensuring that each component is addressed appropriately, thus extending the lifespan of the machinery.

| Benefit | Description |

|---|---|

| Clarity | Visuals simplify complex structures. |

| Efficiency | Reduces time spent on repairs. |

| Communication | Facilitates better teamwork. |

| Durability | Promotes proper upkeep of equipment. |

Key Components of X300R

The essential elements of this model play a crucial role in its overall functionality and performance. Understanding these components can enhance maintenance and operational efficiency.

Engine: The heart of the machine, providing the necessary power to drive various operations efficiently.

Transmission: This system facilitates the smooth transfer of power from the engine to the wheels, ensuring optimal speed control.

Deck: A pivotal part designed for effective cutting, featuring adjustable heights to accommodate different grass types.

Wheels: Built for stability and maneuverability, these elements contribute to a smooth riding experience across varied terrains.

Controls: The interface allows operators to easily navigate functions, enhancing user experience and efficiency during use.

Understanding these fundamental components can lead to better maintenance practices and improved performance.

How to Read a Parts Diagram

Understanding an illustration of components is essential for effective maintenance and repair tasks. These visual guides provide a comprehensive layout, helping users identify and locate various elements within a system.

Here are key steps to effectively interpret such illustrations:

- Familiarize Yourself with the Key: Look for a legend that explains symbols and color codes used in the illustration.

- Identify Major Sections: Notice how the layout is divided into different segments, each representing specific areas or systems.

- Trace Connections: Follow lines or arrows that indicate how components interact and connect with each other.

- Reference the Parts List: Use the accompanying list to find detailed descriptions and specifications for each element.

By mastering these steps, you will ultimately enhance your ability to navigate and utilize these crucial resources efficiently.

Common Issues with X300R Parts

Understanding the frequent challenges faced with components of this lawn care machine can enhance maintenance and prolong its lifespan. Various elements may encounter wear or malfunction over time, impacting overall performance.

Frequent Component Failures

Key components often experience issues that require attention. Identifying these problems early can prevent more significant damage and costly repairs.

| Component | Common Issue | Symptoms |

|---|---|---|

| Engine | Overheating | Unusual noises, loss of power |

| Transmission | Slipping | Difficulty in shifting gears |

| Battery | Failure to start | Weak or no cranking sound |

Maintenance Tips

Regular checks and timely replacements of affected components can significantly improve reliability. Following a consistent maintenance schedule ensures optimal functioning and reduces the risk of breakdowns.

Where to Find Replacement Parts

Finding suitable components for your equipment can significantly enhance its performance and longevity. It’s crucial to source high-quality items that meet specific requirements for optimal functionality.

Online Retailers

Many online stores specialize in offering a wide selection of items. Websites like Amazon or specialized machinery suppliers provide convenient browsing options, enabling users to compare prices and read reviews.

Local Dealerships

Local dealerships often carry an array of components for various models. Visiting these establishments allows you to speak directly with knowledgeable staff who can assist in identifying the correct items for your needs.

Tools Needed for Repairs

Proper maintenance of equipment requires a set of essential instruments to ensure effective and efficient repairs. Having the right tools at hand not only speeds up the process but also minimizes the risk of damage to components. This section outlines the necessary items that every technician should have in their toolkit.

Basic Hand Tools: A good selection of hand tools is fundamental for any repair task. Wrenches, screwdrivers, and pliers are among the most frequently used items. Ensure you have various sizes to accommodate different fittings.

Specialty Tools: Depending on the complexity of the machinery, specialized tools may be required. These can include torque wrenches, socket sets, and specific adapters tailored to certain components. Investing in quality specialty tools can make challenging repairs much easier.

Cleaning Supplies: Maintaining a clean workspace is crucial. Cleaning agents, brushes, and cloths will help remove dirt and debris from parts, ensuring that everything operates smoothly post-repair.

Safety Gear: Personal protection is paramount during any repair work. Always wear gloves, goggles, and appropriate footwear to safeguard against potential hazards.

In summary, having a comprehensive set of tools and equipment enhances the repair experience, ensuring both safety and effectiveness. Being prepared is the key to successful maintenance.

Maintenance Tips for Longevity

To ensure the enduring performance of your machinery, regular upkeep is essential. Adopting a proactive approach can significantly enhance efficiency and lifespan, minimizing the need for repairs and replacements.

Regular Cleaning: Keeping your equipment free of debris and dirt prevents unnecessary wear and tear. Make it a habit to clean after each use.

Fluid Checks: Regularly inspect and replace oils and fluids as needed. This practice not only maintains optimal performance but also safeguards internal components.

Inspection of Parts: Frequently examine essential components for signs of damage or wear. Early detection can avert larger issues down the line.

Tire Maintenance: Ensure proper tire pressure and alignment to improve handling and reduce strain on the machinery.

Storage Practices: When not in use, store equipment in a dry, sheltered area to protect it from the elements and extend its longevity.

Comparing X300R to Other Models

When evaluating various riding lawn mowers, it’s essential to consider the distinct features and functionalities that set them apart. This comparison highlights key aspects such as performance, design, and user experience across different models, allowing potential buyers to make informed decisions based on their specific needs.

Performance: The power and efficiency of these machines can greatly vary. Some models excel in speed and cutting width, while others may prioritize maneuverability and terrain adaptability. Understanding these differences can guide users in selecting the most suitable option for their yard size and layout.

Design: The aesthetic and ergonomic design can significantly influence user satisfaction. While some machines boast sleek designs and comfortable seating, others focus on practicality and ease of maintenance. Comparing these elements helps in determining the ultimate choice for comfort during extended use.

User Experience: Features such as ease of operation, control layout, and maintenance accessibility play a crucial role in overall satisfaction. Models that offer intuitive controls and straightforward maintenance procedures often stand out, making them favorable for both novice and experienced users.

In conclusion, examining these factors provides a comprehensive understanding of how different machines stack up against one another, enabling users to choose the best fit for their lawn care needs.

Upgrading Parts for Performance

Enhancing the functionality of your equipment involves selecting superior components that optimize its capabilities. By focusing on key elements, you can achieve greater efficiency and longevity, ensuring that your machinery performs at its peak.

Choosing High-Quality Components

Opt for components made from durable materials that withstand wear and tear. Investing in top-tier alternatives can significantly enhance reliability and overall performance, making your machinery more resilient to demanding tasks.

Regular Maintenance and Upgrades

Incorporating a routine of inspections and timely upgrades will help maintain optimal performance levels. By addressing potential issues before they escalate, you can prolong the lifespan of your equipment and maximize its effectiveness in various applications.

Cost Considerations for Repairs

When it comes to maintaining machinery, understanding the financial implications of repairs is crucial. Various factors can influence the overall cost, impacting both short-term budgets and long-term investments.

- Labor Costs: Hiring skilled technicians can significantly affect repair expenses.

- Component Prices: The price of replacement items varies widely, often depending on brand and availability.

- Timeframe: Urgent repairs may incur additional charges due to expedited service.

- Maintenance History: Well-maintained equipment tends to require fewer costly repairs over time.

By evaluating these elements, operators can make informed decisions that ultimately enhance the longevity and efficiency of their machinery.

Customer Reviews and Feedback

Customer experiences play a crucial role in understanding the quality and reliability of equipment. This section aims to gather insights from users, highlighting their satisfaction, challenges, and overall impressions.

Below are some common themes found in customer reviews:

- Performance: Users often praise the efficiency and effectiveness of the machinery.

- Durability: Many reviews mention the long-lasting nature of the components, emphasizing value for money.

- Ease of Maintenance: Customers frequently comment on how simple it is to service and maintain their equipment.

Feedback from users provides an ultimate perspective that can guide potential buyers in their decision-making process.

- High-quality construction leads to fewer breakdowns.

- Excellent support from the manufacturer enhances user experience.

- Accessibility of replacement components is often highlighted.

Overall, customer feedback serves as a valuable resource for both current and prospective owners, facilitating informed choices and enhancing satisfaction.