In the realm of brewing exceptional coffee, a deep comprehension of the mechanisms involved in grinding is essential. Each element plays a vital role in achieving the perfect consistency and flavor profile. A thorough grasp of these components not only aids in maintenance but also enhances the overall brewing experience.

When exploring the intricate design of a grinder, one can identify various key elements that contribute to its functionality. From the motor that powers the device to the unique cutting mechanisms, every part is engineered for precision. Familiarity with these components can significantly improve the user’s ability to troubleshoot and optimize their equipment.

Moreover, understanding the relationship between the different parts provides insight into how adjustments affect performance. This knowledge empowers users to make informed decisions, whether they are fine-tuning their settings or addressing potential issues. By delving into the structure of these devices, coffee enthusiasts can elevate their brewing practices to new heights.

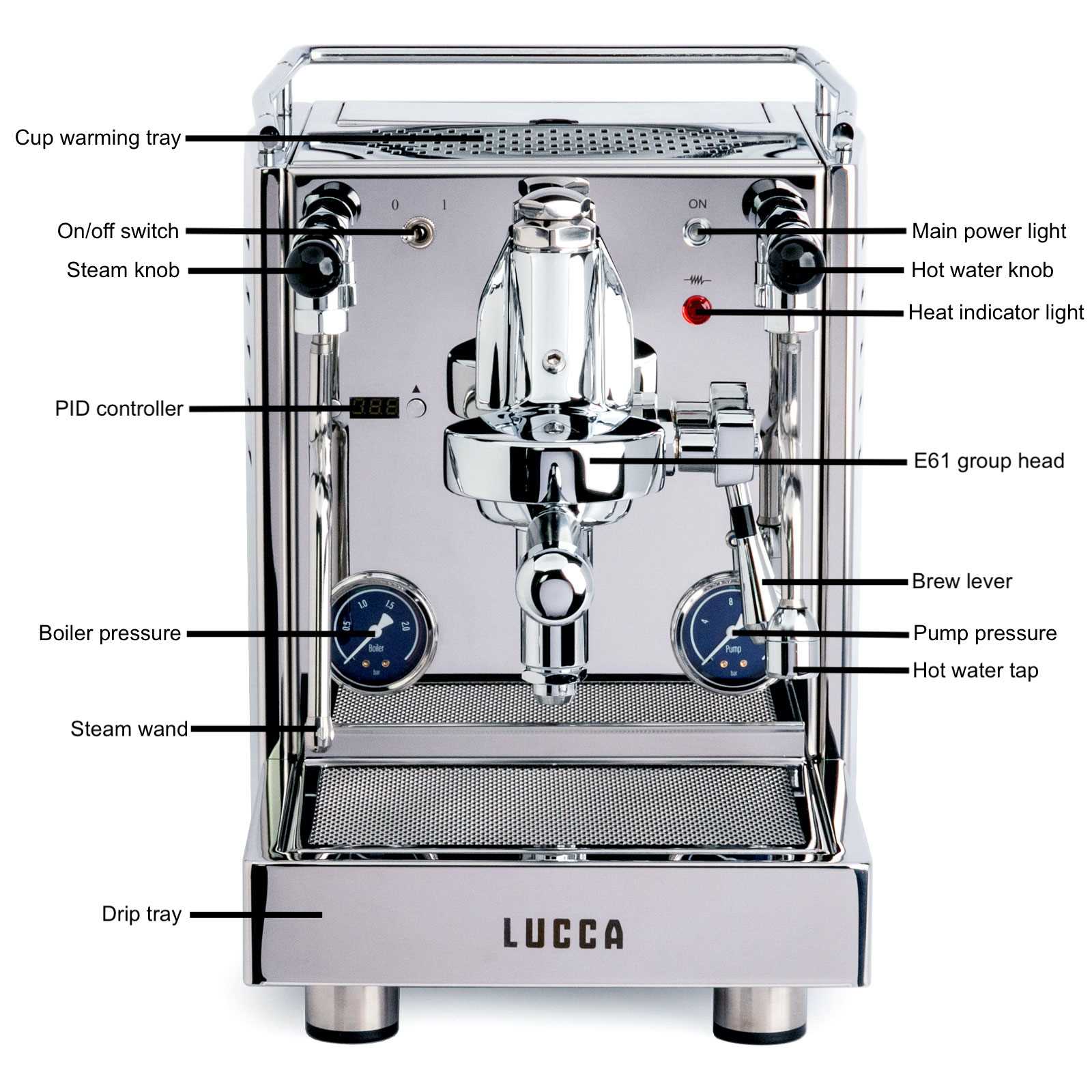

This section aims to provide a comprehensive overview of the essential components and mechanisms that contribute to the functionality of a popular grinding device. By examining the structure and design, users can gain valuable insights into the operation and maintenance of this appliance.

Key Components of the Grinding Device

Understanding the main elements of the grinder is crucial for anyone looking to optimize their experience. Each part plays a specific role in ensuring that the machine operates smoothly and effectively.

Maintenance and Troubleshooting

Regular upkeep and awareness of common issues can prolong the life of the grinding machine. Familiarizing oneself with the various elements allows users to troubleshoot problems and perform necessary repairs.

| Component | Description |

|---|---|

| Hopper | Holds the beans before they are ground. |

| Burrs | Sharp surfaces that crush the beans into grounds. |

| Motor | Powers the grinding action of the appliance. |

| Grind Settings | Allows users to adjust the coarseness or fineness of the grounds. |

| Grounds Bin | Collects the coffee grounds after grinding. |

Key Components of the Grinder

The functionality of a coffee milling device relies on several essential elements that work together to produce a consistent grind. Understanding these components is crucial for optimizing performance and ensuring longevity.

Grinding Burrs: These are the heart of the mill, responsible for crushing the beans into the desired size. The quality and design of the burrs significantly impact the uniformity and flavor profile of the coffee.

Motor: The motor powers the grinding mechanism, providing the necessary torque to process various types of beans efficiently. A reliable motor is vital for maintaining consistent grinding speed and performance.

Hopper: This component holds the coffee beans before they enter the grinding chamber. Its design can influence the ease of use and the amount of beans that can be processed at one time.

Adjustment Mechanism: This feature allows users to customize the grind size according to their brewing method. A precise adjustment system is essential for achieving the perfect extraction for different coffee styles.

Chamber: The grinding chamber houses the burrs and is designed to facilitate the flow of ground coffee while minimizing retention. Its shape and material can affect the milling process and the final product.

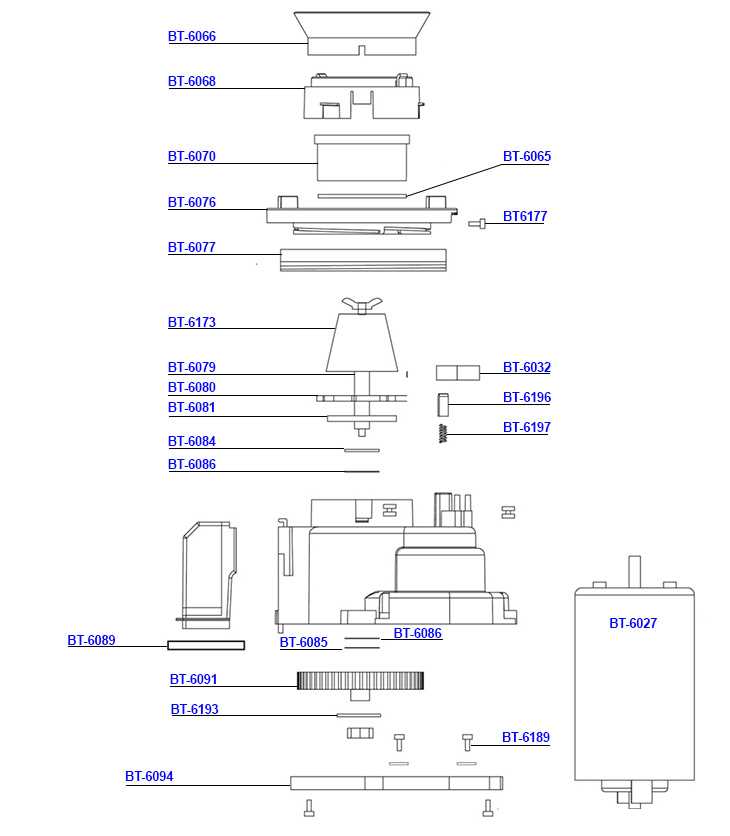

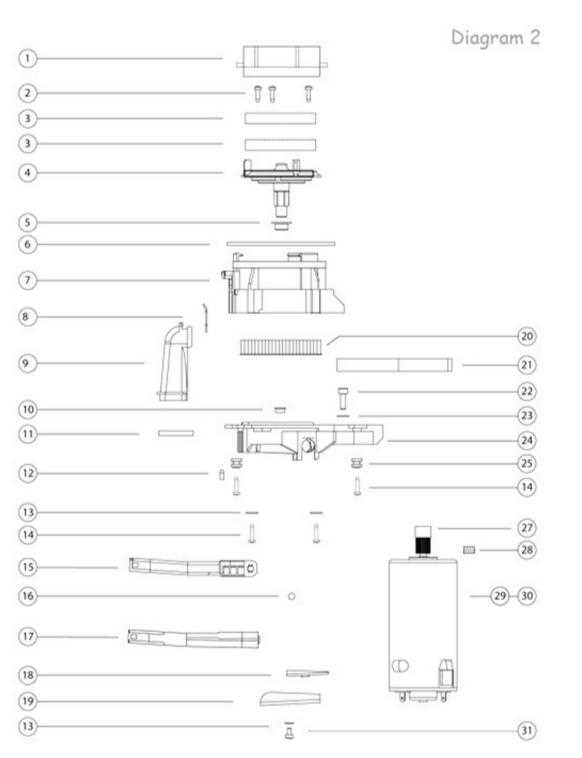

Exploring the Parts Diagram

This section delves into the visual representation of various components that make up a coffee grinder. Understanding this layout is essential for anyone looking to maintain, repair, or enhance the functionality of their equipment. By familiarizing yourself with each element’s location and role, you can effectively troubleshoot issues and ensure optimal performance.

Below is a detailed overview of the individual elements typically found in the design:

| Component Name | Description |

|---|---|

| Burrs | The grinding elements that crush the coffee beans into particles. |

| Hopper | The container that holds the coffee beans before they are ground. |

| Chamber | The area where the grinding takes place, often designed for efficient flow of grounds. |

| Motor | The power source that drives the grinding mechanism. |

| Adjustment Dial | A control for altering the coarseness of the grind, allowing for customization. |

Importance of Each Component

Understanding the significance of individual elements in a grinding mechanism is crucial for optimal performance and longevity. Each component plays a vital role in ensuring the device functions smoothly and efficiently, contributing to the overall quality of the coffee produced.

| Component | Function | Impact on Performance |

|---|---|---|

| Burrs | Crush and grind the coffee beans to achieve desired particle size. | Essential for flavor extraction and consistency in brewing. |

| Motor | Powers the grinding mechanism. | Directly affects grinding speed and efficiency. |

| Hopper | Holds the coffee beans before grinding. | Influences capacity and ease of use. |

| Chamber | Collects the ground coffee. | Affects the freshness and quality of the grounds. |

| Adjustment Mechanism | Allows for customization of grind size. | Critical for tailoring to various brewing methods. |

Common Issues with Parts

When dealing with coffee grinding equipment, users often encounter various challenges related to its components. Understanding these common issues can help in maintaining optimal performance and longevity of the device.

Frequent Challenges

- Wear and Tear: Over time, certain components may experience deterioration, leading to inefficient operation.

- Blockages: Coffee grounds can accumulate in certain areas, causing the machinery to function poorly.

- Misalignment: Components may become misaligned, affecting the grinding consistency.

- Electrical Issues: Problems with wiring or connections can disrupt power supply and functionality.

Preventive Measures

- Regular Cleaning: Periodically cleaning the device can prevent blockages and maintain efficiency.

- Routine Inspections: Checking for wear and alignment can help identify potential issues before they escalate.

- Using Proper Beans: Selecting the right coffee beans can reduce strain on the grinding mechanism.

- Following Guidelines: Adhering to the manufacturer’s recommendations for use and maintenance is crucial.

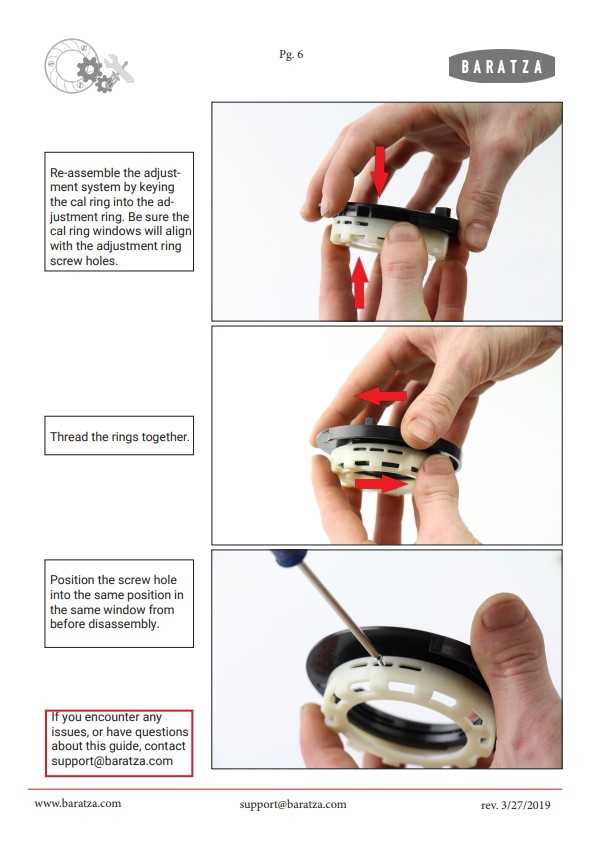

How to Replace Grinder Parts

Replacing components of your grinding device is essential for maintaining optimal performance and extending its lifespan. Whether you’re addressing wear and tear or enhancing functionality, this guide will help you navigate the replacement process effectively.

First, ensure the machine is unplugged to prevent any accidents. Gather the necessary tools, such as screwdrivers and pliers, to facilitate the disassembly. Carefully remove the outer casing by unscrewing any screws or clips that hold it in place. Take your time to avoid damaging any delicate parts during this step.

Once the outer shell is off, identify the components that require replacement. This could include the grinding burrs, motor, or any other internal mechanisms that have worn out. Follow the manufacturer’s recommendations for the proper replacement items and ensure they are compatible with your model.

After obtaining the new components, begin the reassembly by carefully placing each part in its designated location. Make sure everything is secured properly, and double-check your work before reattaching the casing. Finally, plug in the grinder and run a test to confirm that the new parts are functioning as intended.

Maintaining Your Baratza Encore

Regular upkeep of your coffee grinder is essential to ensure optimal performance and longevity. Proper maintenance not only enhances the quality of your brewed beverages but also prevents potential issues that may arise from neglecting the equipment.

Cleaning Procedures

To keep your grinder in top shape, follow these cleaning steps:

- Unplug the appliance before starting any cleaning tasks.

- Remove the hopper and empty any remaining beans.

- Use a soft brush to clear any residue from the grinding chamber.

- Wipe the exterior with a damp cloth to remove dust and fingerprints.

- Reassemble the grinder once everything is clean and dry.

Routine Maintenance Tips

In addition to regular cleaning, consider these maintenance tips:

- Check the grinder’s burrs periodically for wear and replace them as needed.

- Avoid using oily or flavored beans, as they can clog the grinder.

- Store the device in a dry place to prevent moisture damage.

- Schedule routine inspections to identify any potential issues early.

Tools Needed for Repairs

To successfully carry out maintenance or repairs on your grinding device, it is essential to have the right tools at your disposal. Proper equipment not only streamlines the process but also ensures that the job is done effectively, minimizing the risk of damage to the machine.

Commonly required tools include screwdrivers, which are crucial for removing and securing various components. Additionally, pliers can assist in gripping and manipulating small parts that may be difficult to handle. A clean, flat work surface is also beneficial, as it provides a safe area to organize and inspect parts during the repair process.

Moreover, having a multimeter can help diagnose electrical issues, while a brush set may be useful for cleaning sensitive areas of the equipment. By assembling these essential tools beforehand, you can enhance your repair experience and ensure that you are well-prepared for any task that arises.

Where to Find Replacement Parts

When it comes to maintaining your device, sourcing the right components is essential for ensuring longevity and smooth operation. Identifying the best locations to acquire these items can save time and money, while also ensuring the quality of your equipment.

Official Suppliers

Many prefer to rely on authorized distributors for acquiring specific elements. These sources often provide genuine components directly from the manufacturer, ensuring compatibility and reliability. By choosing official channels, you also gain access to potential support services and guarantees.

Third-Party Vendors

Alternatively, there are several independent sellers offering replacement elements. While some may provide cost-effective options, it’s crucial to verify the authenticity and quality of their offerings. Reviews and user feedback are helpful in determining trustworthy sources for your needed replacements.

Upgrading Parts for Better Performance

Enhancing the functionality of any device is achievable by replacing certain components with more efficient alternatives. A few carefully chosen upgrades can significantly improve both the longevity and overall output of the machine. This process can be as simple as exchanging a standard feature for one that offers better precision or durability.

Key Components to Consider

Several internal elements can be swapped to achieve smoother operation and faster results. For instance, upgrading mechanical parts to more resilient materials reduces wear over time, while improving essential mechanisms can enhance performance consistency.

Achieving Maximum Efficiency

Opting for more advanced technologies ensures the machine operates at optimal levels, even under heavy usage. Strengthening critical areas, such as motor efficiency and grinding precision, enables users to enjoy a more reliable and powerful experience, especially when handling high workloads.

Customer Support and Resources

For those seeking assistance or information about maintaining or enhancing their device, comprehensive support options are available. These solutions ensure that users can easily access guidance, troubleshooting advice, and other essential resources to keep their equipment running smoothly.

Contacting Technical Assistance

When encountering any issues or questions, reaching out to skilled support teams is an efficient way to resolve problems. Most service channels offer timely responses and personalized help, which can be essential for troubleshooting specific concerns.

Access to Manuals and Guides

Detailed guides and manuals are often provided to help users understand the functionality of their equipment. These documents typically cover installation procedures, maintenance tips, and optimization techniques. Having access to such materials ensures a smoother experience for users, empowering them to resolve minor issues on their own.

| Support Channel | Availability | Details |

|---|---|---|