Understanding the various elements that constitute a robust all-terrain vehicle is essential for enthusiasts and mechanics alike. A comprehensive overview of these components not only enhances the maintenance experience but also improves performance on challenging terrains.

In this section, we will delve into the specifics of an all-terrain model, offering an ultimate guide to its inner workings. By breaking down the individual sections, users can gain valuable insights into how each part contributes to the overall functionality and durability of the machine.

Whether you are looking to replace a worn-out element or simply want to familiarize yourself with the vehicle’s architecture, this exploration will serve as an indispensable resource. Join us as we uncover the essential components that keep these machines running smoothly.

Understanding the Eiger 400 Model

The model in question represents a blend of robust engineering and practical design, catering to both leisure enthusiasts and those in need of a reliable workhorse. Its versatility makes it a popular choice for various terrains and applications, from recreational riding to agricultural tasks.

Key Features

- Powerful engine designed for efficiency and durability

- Advanced suspension system for enhanced stability

- All-terrain capability, making it suitable for diverse environments

- Ergonomic design that prioritizes rider comfort

Maintenance Considerations

- Regularly check fluid levels to ensure optimal performance.

- Inspect tires for wear and maintain proper pressure.

- Clean air filters to prevent engine strain.

- Schedule routine inspections for overall functionality.

Understanding these features and maintenance requirements can significantly enhance the longevity and reliability of the vehicle, ensuring it performs well under various conditions.

Key Features of the 2006 Eiger

This section explores the standout characteristics of a renowned all-terrain vehicle, focusing on its robust design and exceptional performance capabilities. With a blend of functionality and comfort, it caters to both recreational and utility needs.

Durability: Built to withstand harsh conditions, this vehicle features a rugged chassis and reliable components, ensuring longevity and resilience.

Powerful Engine: The robust powertrain delivers impressive torque and acceleration, making it ideal for tackling challenging terrains and heavy loads.

Advanced Suspension: Equipped with an advanced suspension system, it offers superior handling and a smooth ride, enhancing user experience on various surfaces.

Versatile Utility: Designed for both work and leisure, it includes ample storage options and towing capabilities, making it a practical choice for diverse applications.

Overall, this vehicle embodies a perfect balance of strength, efficiency, and versatility, making it a top choice among enthusiasts and professionals alike.

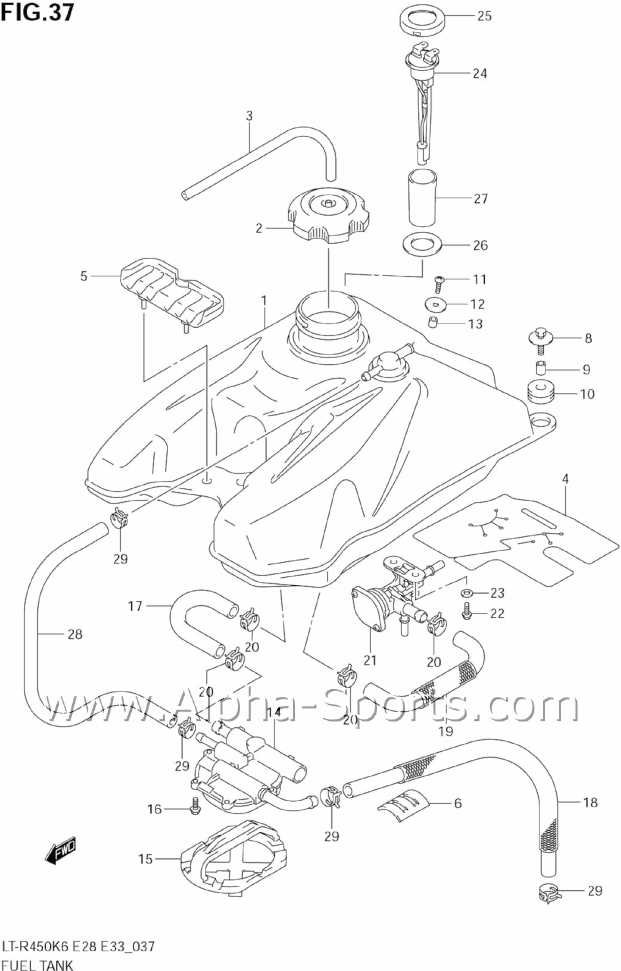

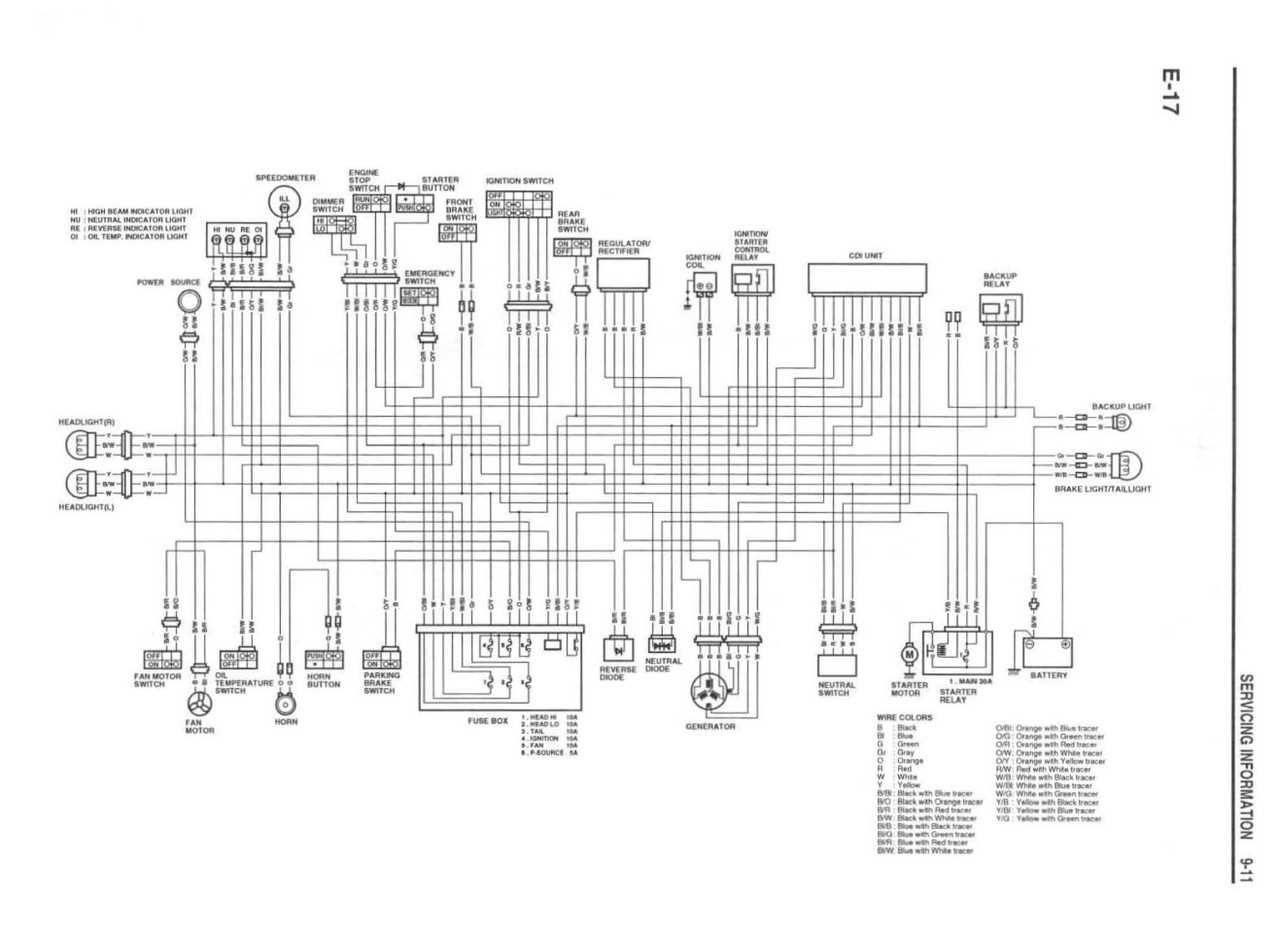

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and maintenance of machinery. These illustrations provide clarity, ensuring that users can easily identify each segment, its function, and its location within the overall system.

Benefits of Using Visual Guides

- Enhanced Understanding: Visual aids break down complex structures, making it easier for users to comprehend intricate systems.

- Efficient Repairs: Knowing the exact placement of each component allows for quicker troubleshooting and repairs.

- Informed Decisions: Users can make better choices when sourcing replacements or upgrades by understanding how parts interact.

Applications in Maintenance

- Routine Inspections: Regular checks are simplified when one can quickly refer to visual guides.

- Training and Education: New users can learn the layout and functionality of systems through detailed illustrations.

- Documentation Reference: These visuals serve as valuable resources for manuals and service guides.

Common Parts and Their Functions

This section explores the essential components of an all-terrain vehicle and their specific roles in ensuring optimal performance and reliability. Understanding these elements can enhance maintenance and troubleshooting efforts.

Key Components

- Engine: The heart of the vehicle, responsible for generating power.

- Transmission: Transfers power from the engine to the wheels, enabling movement.

- Suspension: Absorbs shocks and maintains stability, providing a smoother ride.

- Brakes: Essential for safety, allowing the vehicle to slow down or stop effectively.

Supporting Elements

- Battery: Supplies electrical energy for starting and powering accessories.

- Fuel System: Delivers the necessary fuel to the engine for combustion.

- Cooling System: Regulates engine temperature to prevent overheating.

- Exhaust System: Channels harmful gases away from the engine and reduces noise.

Where to Find Replacement Parts

Finding the right components for your all-terrain vehicle can be a straightforward process if you know where to look. Various sources provide both original and aftermarket options, ensuring that you can restore your vehicle to optimal performance. By exploring multiple avenues, you can compare prices and availability, making it easier to find exactly what you need.

Online Retailers

The internet is a treasure trove of resources for those seeking vehicle components. Websites dedicated to automotive supplies often stock a wide range of items. Major online retailers allow you to search by vehicle model, making it simple to locate specific components. Always check customer reviews and ratings to ensure quality.

Local Dealerships and Shops

Don’t overlook local dealerships and repair shops. They can provide genuine components and often have knowledgeable staff who can assist you in identifying the right items for your vehicle. Building a relationship with a local expert can also lead to personalized service and advice for maintenance and upgrades.

Tools Needed for Maintenance

Proper upkeep of your all-terrain vehicle requires a specific set of implements to ensure everything functions smoothly. Having the right tools at hand not only simplifies the maintenance process but also enhances safety and efficiency during repairs. Below, we outline essential tools that should be part of your maintenance kit.

Essential Hand Tools

To tackle basic tasks, a collection of hand tools is indispensable. This includes a variety of wrenches and screwdrivers in different sizes to handle bolts and screws. A quality socket set is also crucial for loosening or tightening various components. Don’t forget pliers, as they are helpful for gripping and manipulating parts in tight spaces.

Specialized Equipment

In addition to hand tools, having specialized equipment can greatly improve maintenance efficiency. A jack and jack stands are necessary for safely elevating the vehicle for undercarriage work. A tire pressure gauge and a tire inflator are important for keeping tires in optimal condition. Lastly, a comprehensive toolbox will help keep everything organized and readily accessible.

DIY Repair Tips for Owners

Taking on maintenance and repairs yourself can save time and money while enhancing your understanding of your vehicle. Here are some practical suggestions to help you tackle common issues effectively.

Basic Tools and Preparation

- Invest in a quality toolset that includes wrenches, sockets, and screwdrivers.

- Ensure you have a clean workspace with adequate lighting.

- Familiarize yourself with the owner’s manual for specific guidelines.

Common Repairs

- Regularly check and replace fluids, including oil and coolant.

- Inspect the battery and clean terminals to prevent corrosion.

- Examine tire pressure and tread; rotate them to promote even wear.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is paramount to prevent accidents and injuries. Adhering to proper guidelines not only protects the individual working on the machinery but also safeguards the equipment itself. Taking the time to prepare and follow essential precautions can lead to a more efficient and secure repair process.

First and foremost, always wear appropriate protective gear. This includes gloves, safety goggles, and steel-toed boots. Such equipment acts as a barrier against potential hazards like sharp objects, chemical spills, or heavy components that could cause injury.

Additionally, it is crucial to work in a well-ventilated area. Proper airflow reduces the risk of inhaling harmful fumes and ensures that any flammable substances are safely dissipated. Keeping the workspace organized is equally important; a tidy environment minimizes the chances of accidents caused by tripping over tools or materials.

Finally, always disconnect the power source before starting any repairs. This simple step prevents unintended operation of machinery, which can lead to severe injuries. By following these basic safety measures, individuals can create a secure and effective environment for conducting repairs.

Upgrading Your Eiger 400

Enhancing the performance and functionality of your all-terrain vehicle can significantly improve your riding experience. Whether you’re seeking increased power, better handling, or improved aesthetics, there are numerous modifications to consider that can elevate your machine to new heights.

Performance Enhancements

- Exhaust System: Upgrading the exhaust can improve airflow, leading to better engine performance.

- Air Filter: A high-flow air filter increases the amount of air entering the engine, boosting power.

- ECU Tuning: Adjusting the engine control unit can optimize fuel maps for enhanced efficiency.

Suspension and Handling

- Install upgraded shocks for improved stability on rough terrain.

- Consider adding sway bars to enhance cornering performance.

- Upgrade tires to provide better traction and control in various conditions.

Common Issues and Solutions

Every vehicle can face a range of challenges over time. Understanding these potential problems and their corresponding remedies is essential for maintaining optimal performance and longevity. Below are some frequent concerns along with practical solutions.

-

Starting Problems:

Vehicles may struggle to start due to battery issues or faulty ignition systems.

- Check battery connections and charge the battery if necessary.

- Inspect the ignition components for wear and replace if needed.

-

Overheating:

Excessive engine temperature can lead to serious damage.

- Ensure coolant levels are adequate and check for leaks in the system.

- Examine the radiator for blockages or damage.

-

Transmission Issues:

Shifting difficulties may arise, affecting overall performance.

- Check the transmission fluid levels and condition.

- Look for signs of leaks and address them promptly.

-

Electrical Failures:

Electrical components may malfunction, causing various system failures.

- Inspect fuses and replace any that are blown.

- Test wiring for corrosion or damage and repair as necessary.

Addressing these issues promptly can enhance the vehicle’s performance and prevent further complications. Regular maintenance checks are recommended to identify and resolve problems before they escalate.