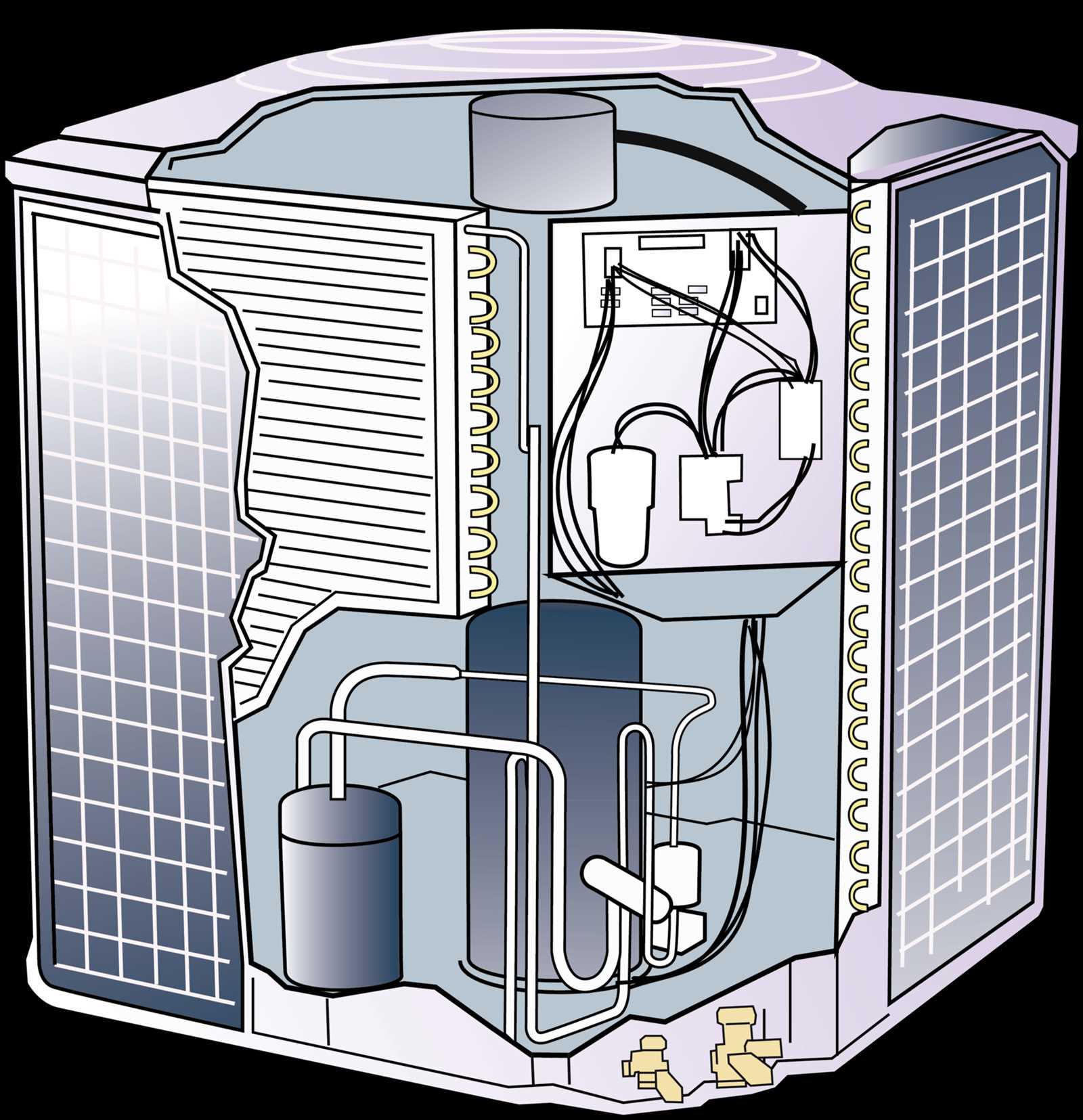

The intricate world of thermal regulation technology encompasses various elements that work harmoniously to achieve optimal climate control. These mechanisms are designed to transfer energy efficiently, ensuring comfort and sustainability in various environments.

Within this realm, each individual component plays a crucial role, contributing to the overall functionality and efficiency of the system. By examining these elements, one can gain insight into how they interact and support each other in maintaining desired temperatures.

This exploration invites readers to delve into the specific features and functions of these vital components, revealing their significance in the broader context of energy management. Understanding their configuration is essential for anyone looking to optimize performance and enhance system longevity.

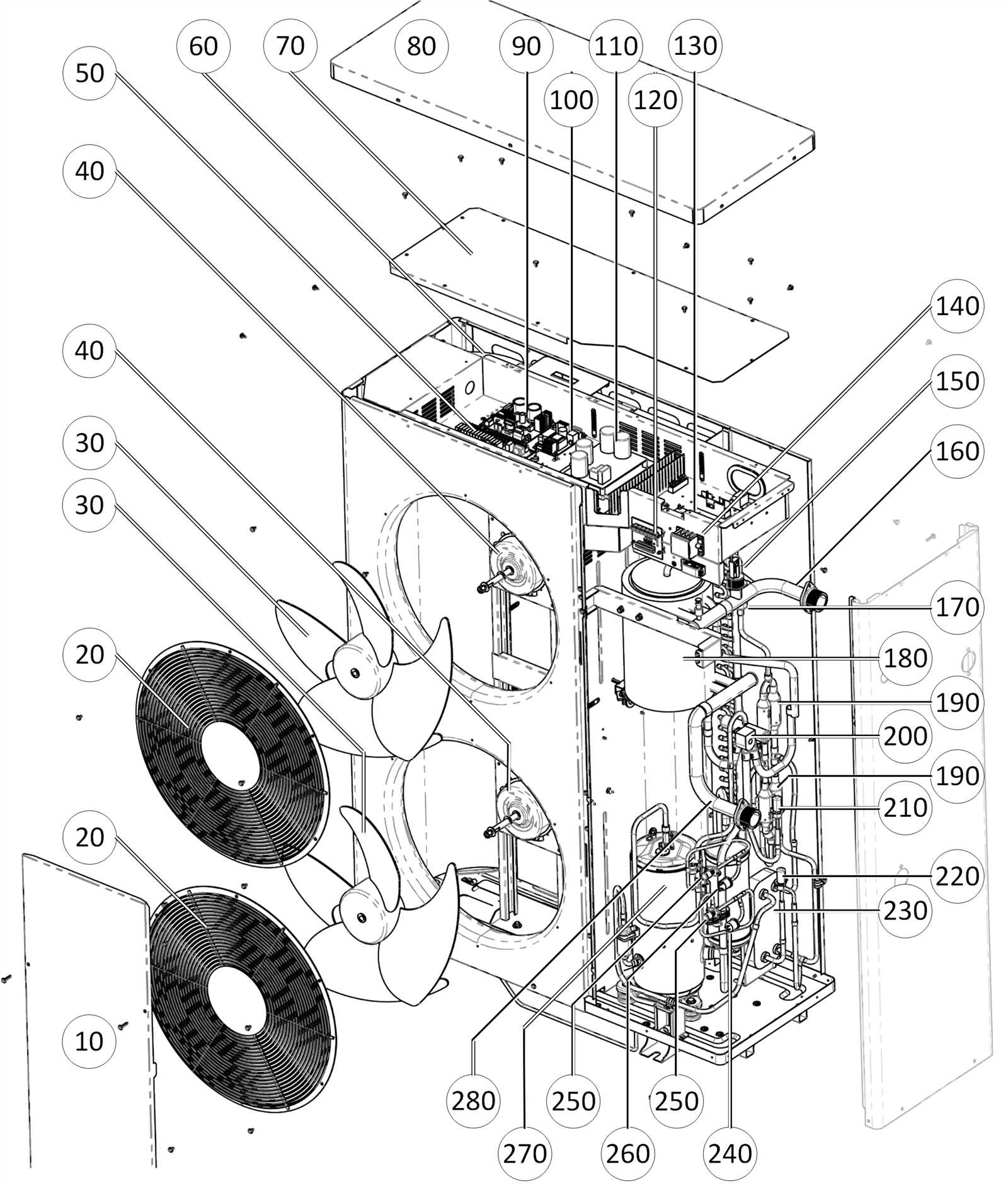

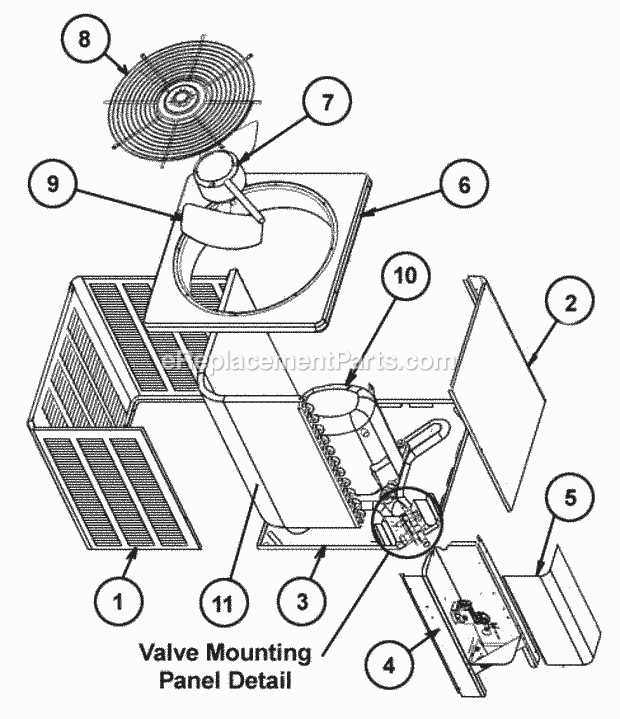

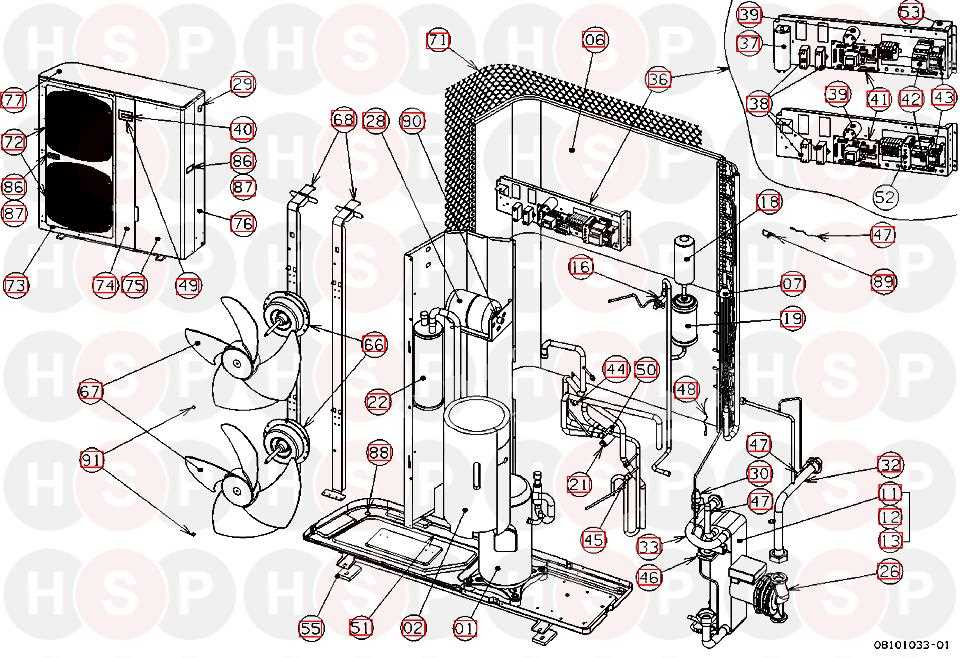

Understanding Heat Pump Components

The efficient operation of a climate control system relies on several key elements that work in harmony. Each component plays a crucial role in the overall functionality, ensuring optimal performance and energy efficiency. A comprehensive understanding of these integral units can enhance both maintenance practices and troubleshooting efforts.

Compressor: This essential unit compresses the refrigerant, increasing its pressure and temperature, which is vital for the subsequent transfer of thermal energy.

Condenser: Here, the heated refrigerant releases its energy, transforming from a gas back to a liquid. This process is fundamental for providing warmth to the living space.

Evaporator: In this component, the refrigerant absorbs heat from the surrounding environment, evaporating into a gas. This phase is crucial for cooling applications.

Expansion Valve: Acting as a throttle, this unit regulates the flow of refrigerant, reducing its pressure before it enters the evaporator. This process allows the refrigerant to absorb more heat effectively.

Reversing Valve: This component allows for the direction of refrigerant flow to be altered, enabling the system to switch between heating and cooling modes.

Understanding these critical components not only aids in efficient operation but also empowers users to recognize potential issues and implement appropriate solutions, ensuring longevity and reliability of the system.

Key Parts of a Heat Pump

This section explores the essential components that contribute to the overall functionality of an energy-efficient climate control system. Understanding these elements is crucial for effective maintenance and optimal performance.

- Compressor: The core element responsible for circulating the refrigerant and increasing its pressure.

- Condenser: This component releases absorbed warmth to the external environment during the cooling process.

- Evaporator: Here, the refrigerant absorbs warmth from the surrounding area, facilitating heat transfer.

- Expansion Valve: This mechanism regulates the flow of refrigerant, allowing it to expand and cool.

- Refrigerant: A specialized fluid that transitions between liquid and gas, enabling heat exchange.

Each of these elements plays a pivotal role in ensuring the system operates efficiently, delivering the desired comfort levels.

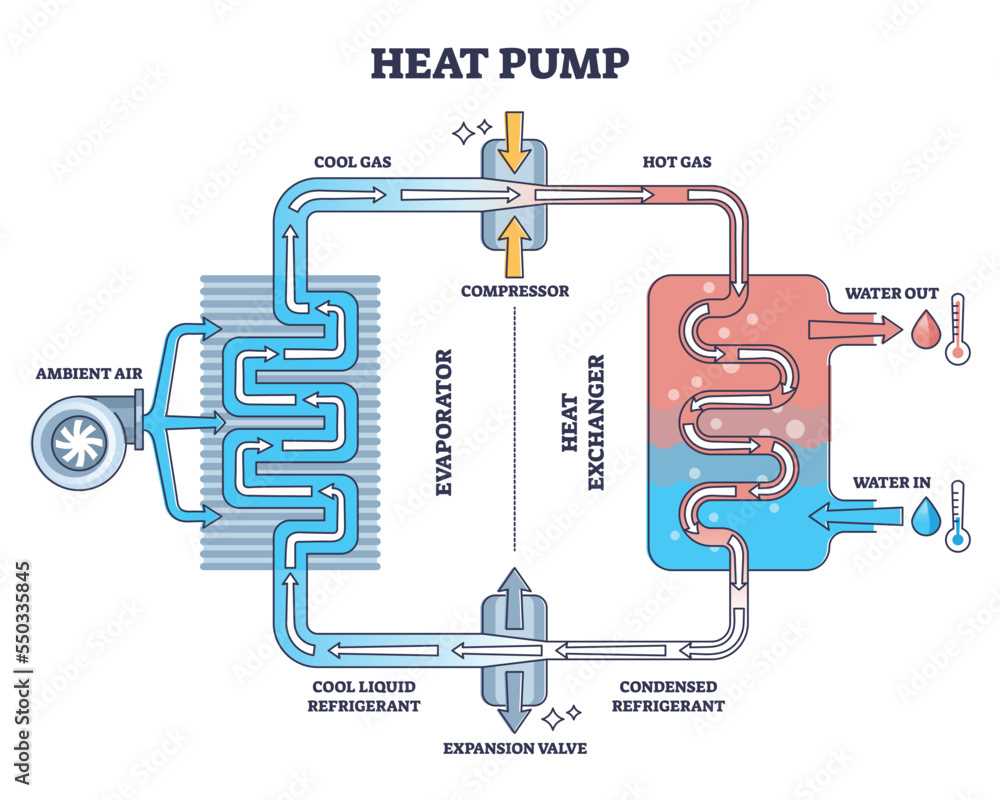

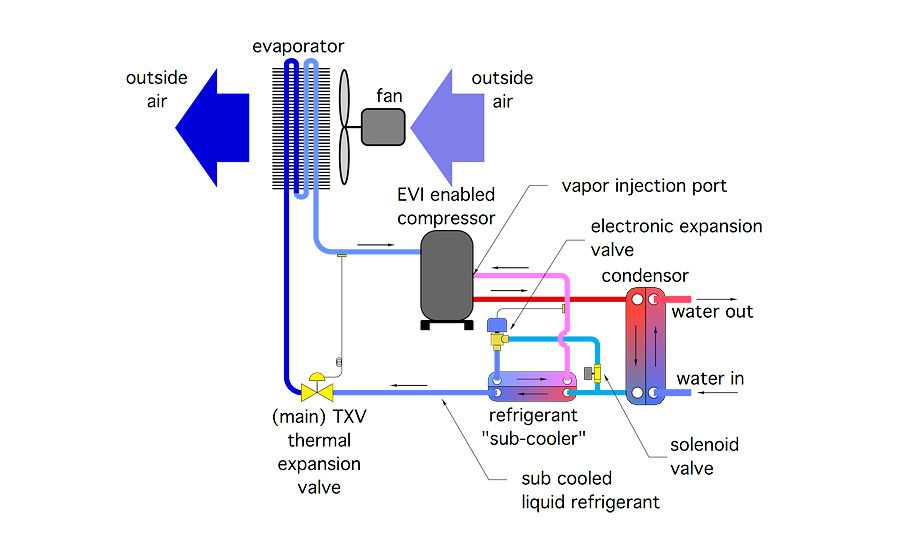

How Heat Pumps Work Together

This section explores the collaboration of various components in a thermal management system, highlighting their interdependence and the seamless operation that leads to efficient climate control. Understanding these interactions allows for better comprehension of how energy is transferred and utilized effectively within a given environment.

Components Interaction

The various elements within this system serve distinct roles while working in unison to achieve optimal performance. The compressor, for instance, plays a critical role in circulating refrigerant, while the condenser and evaporator facilitate heat exchange. Each component’s function is vital, as their synchronization determines the overall efficiency and effectiveness of the system.

System Efficiency

Maximizing efficiency is a primary goal of these interconnected elements. When each component operates at peak performance, the entire system benefits from reduced energy consumption and enhanced temperature regulation. Regular maintenance and timely updates to individual parts can significantly impact the system’s longevity and operational costs, ensuring it continues to meet energy demands efficiently.

Common Types of Heat Pumps

There are several variations of systems designed for thermal transfer, each tailored to specific environments and needs. Understanding these types allows for better selection based on efficiency, climate, and application.

Air-Source Systems: These units draw warmth from the surrounding atmosphere, making them ideal for moderate climates. They are known for their adaptability and ease of installation.

Ground-Source Systems: Utilizing the Earth’s consistent temperature, these systems are highly efficient and effective for various applications. They require more upfront investment due to installation complexity.

Water-Source Systems: These models extract energy from nearby water bodies, offering excellent efficiency in suitable locations. Their performance greatly depends on the water temperature throughout the year.

Hybrid Systems: Combining multiple sources, these units optimize energy usage and can switch between different modes based on conditions, providing flexibility and enhanced efficiency.

Function of the Compressor

The compressor plays a crucial role in the overall operation of a thermal management system. Its primary task is to manipulate the refrigerant, enabling efficient transfer of thermal energy between different areas. By adjusting the pressure and volume of the refrigerant, it facilitates the movement of thermal energy, ensuring optimal performance throughout the cycle.

Role in Refrigeration Cycle

During the refrigeration cycle, the compressor draws in low-pressure refrigerant vapor from the evaporator. As it compresses this vapor, it increases both its pressure and temperature. This transformation is vital, as it prepares the refrigerant for the next stage in the process, where it will release the absorbed thermal energy in the condenser.

Efficiency and Performance

A well-functioning compressor significantly enhances the system’s efficiency. It must operate smoothly to minimize energy consumption while maximizing thermal transfer. Regular maintenance and timely repairs are essential to ensure that the compressor remains in peak condition, directly influencing the overall effectiveness of the entire system.

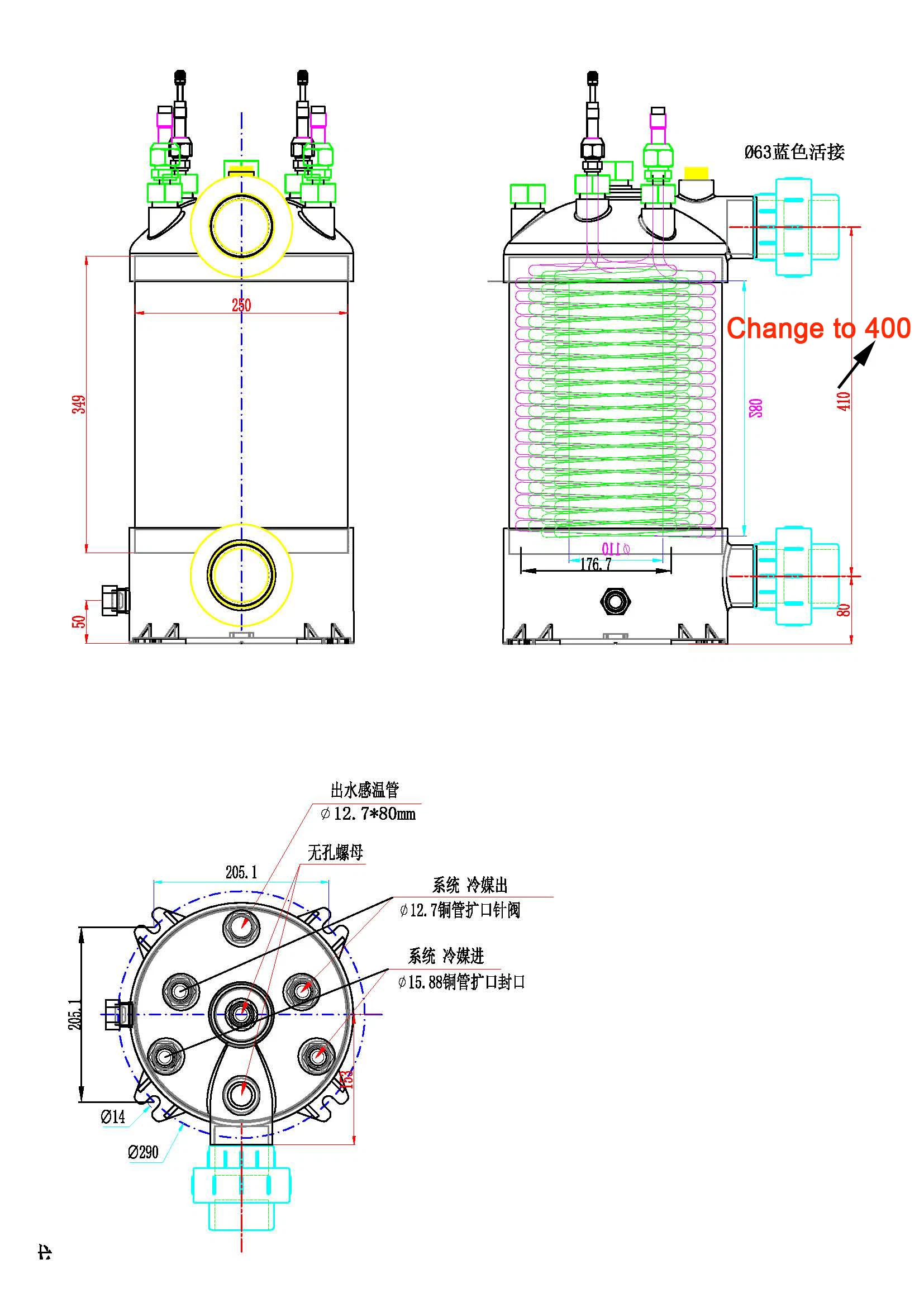

Role of the Condenser Explained

The condenser plays a crucial role in transforming gaseous substances into a liquid state, facilitating the transfer of energy within a system. This essential component is pivotal for maintaining efficiency and ensuring optimal performance.

Functionality of the Condenser

During operation, the condenser absorbs heat from the refrigerant, causing it to condense. This process releases energy, allowing the fluid to cool and transition to a liquid form. As a result, it significantly contributes to the overall effectiveness of the system.

Importance in Energy Transfer

By efficiently converting vapor into liquid, the condenser enhances the system’s ability to circulate and redistribute thermal energy. Its effectiveness directly impacts the ultimate performance and reliability of the entire mechanism.

Evaporator’s Importance in Heat Transfer

The evaporator plays a crucial role in the thermal exchange process, facilitating the transformation of liquid into vapor. This transformation is essential for efficient energy management in various systems. By absorbing surrounding warmth, it contributes significantly to the overall performance and efficiency of the cycle.

Its primary function involves absorbing thermal energy, which allows for effective cooling or heating, depending on the system’s design. Understanding its operation is vital for optimizing performance and enhancing energy efficiency.

| Function | Description |

|---|---|

| Thermal Absorption | Captures warmth from the environment to facilitate phase change. |

| Efficiency Improvement | Enhances overall system efficiency by optimizing energy use. |

| Cooling Effect | Provides a cooling effect in refrigeration systems by removing heat. |

Expansion Valve Mechanics Unveiled

The expansion valve plays a crucial role in regulating the flow and pressure of refrigerant in cooling systems. Its primary function is to manage the transition of refrigerant from a high-pressure state to a lower one, facilitating the absorption of thermal energy. Understanding the mechanics behind this component reveals its significance in maintaining system efficiency and performance.

How It Works

This device operates through a simple yet effective principle. As the refrigerant enters the valve, its pressure decreases significantly, causing a drop in temperature. This transformation is essential for maximizing the cooling effect in the evaporator. The valve’s design typically includes a diaphragm and a needle, which work together to adjust the flow based on the system’s demands. This responsive action ensures optimal performance under varying conditions.

Key Features

One notable characteristic of the expansion valve is its ability to modulate refrigerant flow. Pressure differentials and thermal sensing play integral roles in this modulation, allowing the valve to adapt to changes in temperature and load. Additionally, the materials used in its construction enhance durability and reliability, making it a vital element in any cooling setup. Understanding these features can lead to improved maintenance practices and longer lifespan for the entire system.

Electrical Elements in Heat Pumps

This section explores the crucial components that govern the functionality and efficiency of thermal transfer systems. Understanding these electrical elements is vital for optimal operation and maintenance, ensuring longevity and performance in various applications.

Key Components

Among the essential elements are compressors, which facilitate the movement of refrigerant, and relays, that control electrical flow. Additionally, thermostats play a significant role in regulating temperature, making them indispensable for user comfort and energy management.

Control Systems

The sophistication of control systems cannot be overlooked. These systems integrate sensors and controllers to monitor and adjust performance, maximizing efficiency. Effective communication between these elements is the ultimate key to achieving desired outcomes in thermal regulation.

Refrigerants Used in Heat Pumps

Understanding the substances responsible for transferring thermal energy is crucial for efficient climate control systems. These fluids play a vital role in the functioning of such mechanisms, ensuring optimal performance and sustainability.

Types of Refrigerants

- Hydrochlorofluorocarbons (HCFCs)

- Hydrofluorocarbons (HFCs)

- Natural Refrigerants

- Ammonia (NH3)

- Carbon Dioxide (CO2)

- Hydrocarbons (Propane, Isobutane)

- New Alternatives

- Hydrofluoroolefins (HFOs)

- Refrigerant Blends

Considerations for Selection

- Environmental impact

- Energy efficiency

- System compatibility

- Cost and availability

Maintenance of Heat Pump Parts

Proper upkeep of the components within a thermal management system is essential for ensuring optimal performance and longevity. Regular attention to these elements can prevent unexpected breakdowns, improve efficiency, and reduce energy costs. Understanding the various aspects of maintenance can help users achieve reliable operation throughout the year.

Regular Inspection

Conducting routine assessments is crucial for identifying wear and tear before it escalates into significant issues. Visual checks should focus on signs of damage, corrosion, or unusual wear. Additionally, listening for unusual sounds during operation can provide insights into potential malfunctions. Addressing minor concerns promptly can lead to greater system reliability.

Cleaning and Servicing

Maintaining cleanliness within the unit is vital for efficient operation. Dust and debris can accumulate on various surfaces, hindering performance. Regular cleaning of filters and coils should be prioritized to ensure optimal airflow and heat exchange. Furthermore, scheduling periodic professional servicing can help maintain all internal mechanisms, enhancing overall functionality and extending the system’s lifespan.

Signs of Component Failure

Recognizing the early indicators of malfunction within a system is crucial for maintaining efficiency and preventing costly repairs. Various symptoms may arise, signaling that certain elements are not functioning as intended. Understanding these signs can help in taking timely action and ensuring optimal performance.

Common Symptoms

One of the most noticeable signs of malfunction is unusual noise during operation. If you hear grinding, hissing, or rattling sounds, it may indicate wear or failure in specific components. Additionally, inconsistent temperature output can be a major red flag; if the environment remains too hot or too cold, the system might not be regulating effectively.

Visual Indicators

Physical inspection can reveal critical issues as well. Look for leaks or condensation around components, which could signify refrigerant loss or other fluid-related problems. Unusual wear on belts and connections should also not be overlooked. If any parts appear burnt or discolored, it’s often a sign that the equipment is struggling to operate properly. Early detection of these visual cues can lead to more straightforward solutions and improved longevity.

Innovations in Heat Pump Technology

The advancement of thermal management systems has ushered in a new era of energy efficiency and sustainability. Recent breakthroughs focus on enhancing performance, reducing environmental impact, and maximizing user convenience.

Smart technology integration is revolutionizing the way these systems operate. With the incorporation of IoT capabilities, users can now monitor and control their devices remotely, leading to optimized energy usage.

Furthermore, improved refrigerants are being developed to minimize greenhouse gas emissions, aligning with global environmental standards. These innovations not only enhance efficiency but also promote a more sustainable future.

Another significant trend is the shift towards modular designs, allowing for easier upgrades and maintenance. This flexibility ensures that systems can adapt to evolving energy demands without major overhauls.

Ultimately, these advancements signify a commitment to creating more effective and environmentally friendly solutions, marking a pivotal moment in the evolution of thermal management technologies.