In the realm of agricultural equipment, effective maneuverability is crucial for optimal performance and productivity. Each machine relies on a network of mechanisms that ensure precision and reliability during operation. Grasping the intricacies of these components is essential for operators and technicians alike.

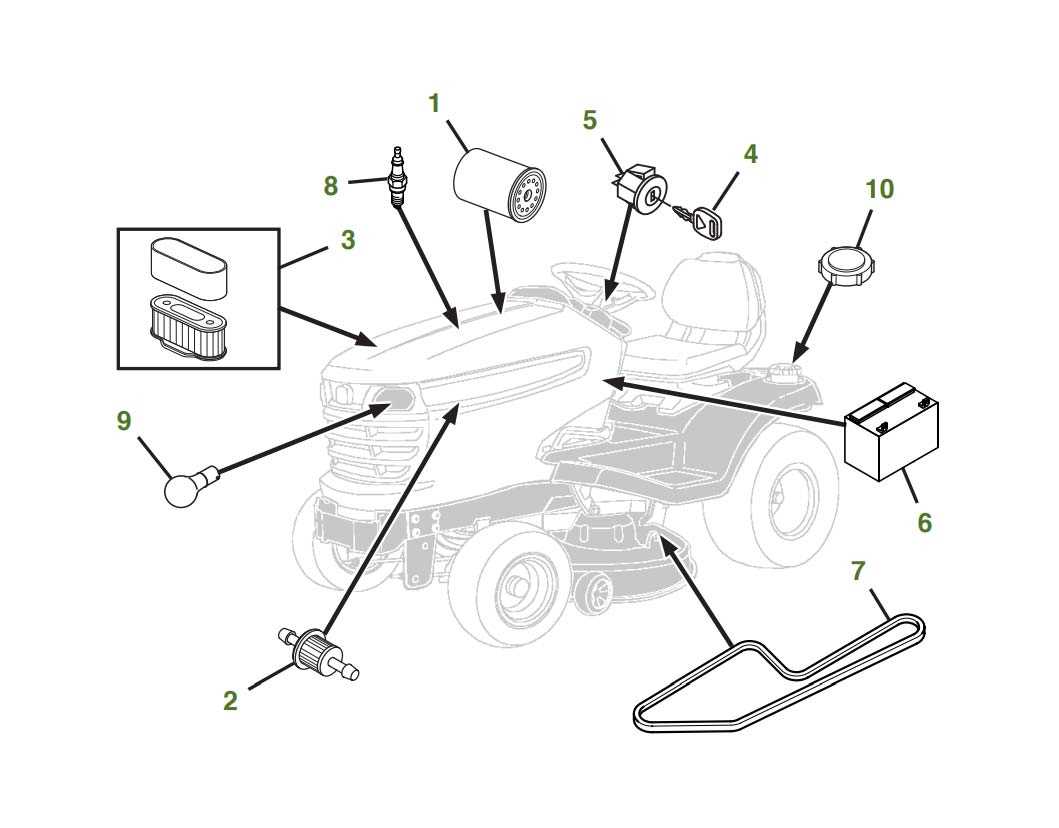

Exploring the layout and functionality of these vital systems not only enhances maintenance strategies but also empowers users to troubleshoot issues more efficiently. A comprehensive visual representation can serve as an invaluable tool in this learning process.

Whether you are a seasoned professional or a novice, gaining insights into the architecture of these control mechanisms can significantly enhance your understanding of machinery dynamics. Ultimately, delving into this topic will equip you with the knowledge necessary for successful operation and upkeep.

Understanding John Deere Steering Components

Exploring the intricacies of guidance mechanisms in agricultural machinery reveals the essential elements that contribute to effective maneuverability. A well-designed control system ensures optimal handling and responsiveness, significantly impacting operational efficiency.

Key Elements of Guidance Systems

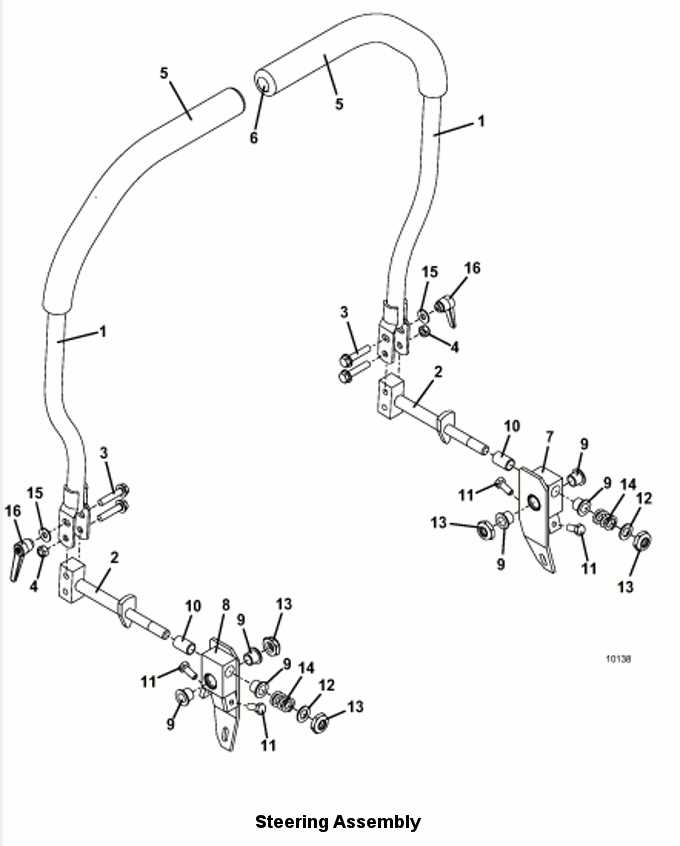

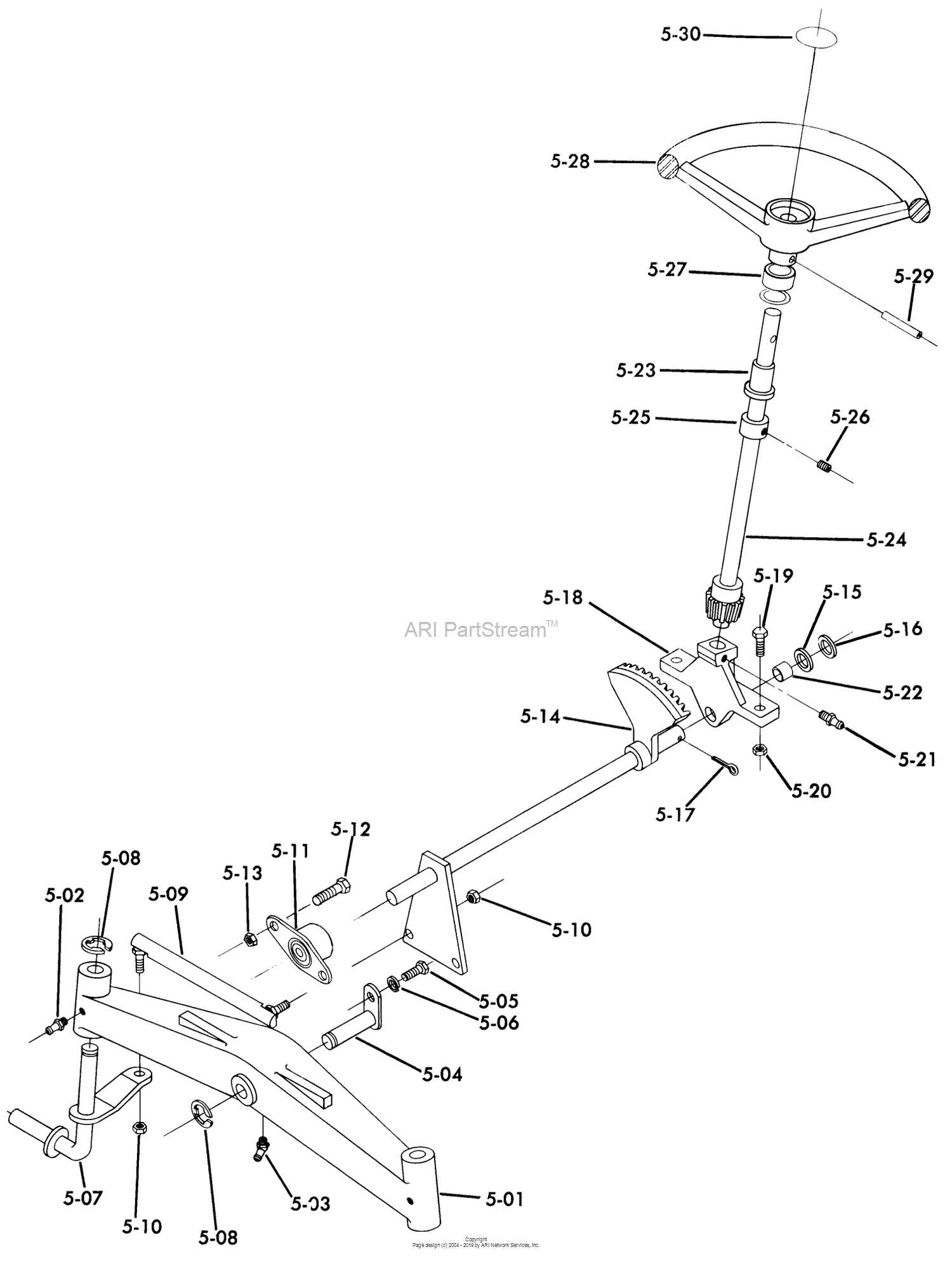

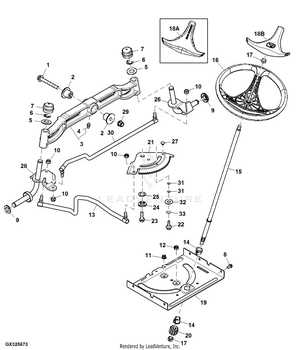

The core components of a navigation assembly work in unison to provide seamless control. Each element plays a vital role in translating the operator’s input into precise movements. Understanding these components is crucial for maintenance and troubleshooting.

| Component | Description |

|---|---|

| Wheel Mechanism | Facilitates movement and direction changes. |

| Control Arm | Links the operator’s input to the wheel mechanism. |

| Pivot Assembly | Allows for smooth directional adjustments. |

| Linkage System | Connects various components for coordinated operation. |

Maintenance and Care

Regular inspection and care of these components are vital for maintaining performance. Addressing wear and tear promptly ensures longevity and reliability, allowing for continued productivity in the field.

Importance of Steering System Diagrams

Understanding the layout and functionality of various components is crucial for maintaining and repairing complex machinery. Visual representations serve as essential tools that facilitate clearer comprehension of how different elements interact within a system. This knowledge not only aids technicians but also enhances efficiency in troubleshooting and repairs.

Clarity and Efficiency

Detailed visual guides provide clarity that written instructions often lack. By illustrating the arrangement and connections of components, these visuals allow for quicker identification of issues. Technicians can pinpoint problems rapidly, leading to reduced downtime and improved productivity.

Training and Skill Development

For newcomers in the field, visual schematics are invaluable educational resources. They enhance the learning process by offering a tangible reference point, enabling trainees to develop a comprehensive understanding of the machinery. Mastering these diagrams fosters greater confidence and skill in handling complex tasks.

Common Issues with Steering Parts

Many vehicle operators encounter various challenges related to directional control components. Understanding these common problems can help in maintaining optimal performance and ensuring safety on the road.

- Worn Components: Over time, elements like bushings and linkages can wear down, leading to decreased responsiveness.

- Misalignment: Improper alignment can cause uneven wear and affect handling, making it difficult to maintain a straight path.

- Fluid Leaks: Hydraulic systems are susceptible to leaks, which can reduce efficiency and create additional strain on the system.

- Noisy Operation: Unusual sounds during movement often indicate issues, such as insufficient lubrication or damaged parts.

- Play in the Mechanism: Excessive play can compromise control, making it harder to maneuver effectively.

Addressing these issues promptly can enhance performance and prolong the lifespan of the vehicle’s directional control system.

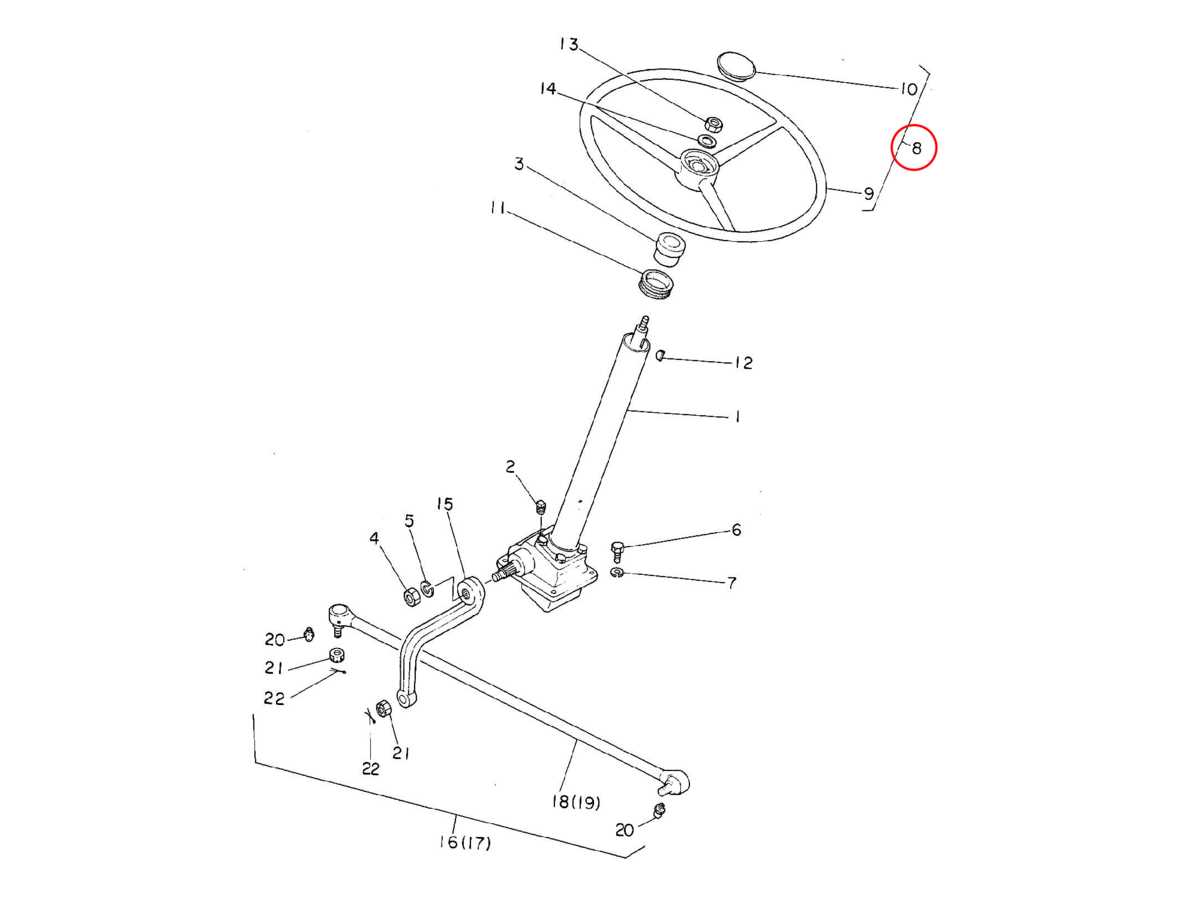

How to Read Steering Diagrams

Understanding intricate illustrations related to control mechanisms is essential for effective maintenance and repair. These visuals serve as a roadmap, detailing the various components and their interconnections. By familiarizing yourself with the symbols and layout, you can efficiently diagnose issues and identify necessary replacements.

Begin with Familiarization: Start by reviewing the key symbols and notations commonly used. Each element typically represents a specific component or function, allowing for quicker comprehension.

Follow the Flow: Observe how the elements are interconnected. Tracing the flow of operation will help you understand how each part contributes to the overall functionality.

Refer to Legends: Many illustrations include a legend or key. Utilize this to clarify any symbols you may find confusing, ensuring a complete grasp of the system.

Take Notes: As you study the illustration, jot down any observations or questions. This practice enhances retention and can guide you in troubleshooting effectively.

Practice with Real Examples: Apply your knowledge by examining actual machinery. Hands-on experience solidifies understanding and reveals nuances that diagrams alone may not convey.

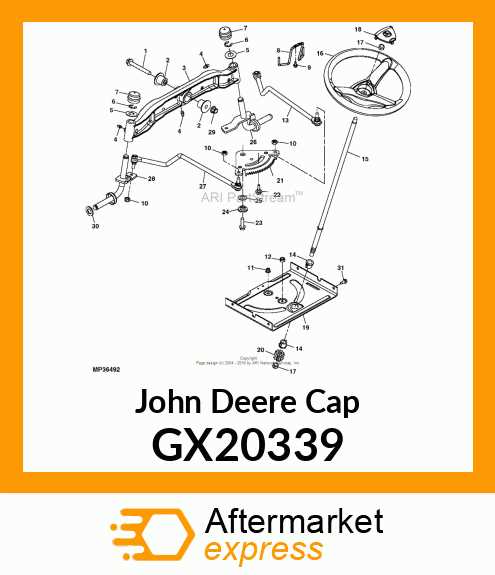

Identifying Steering Part Numbers

Understanding the specific components within a vehicle’s control system is crucial for effective maintenance and repairs. Accurately identifying the unique identifiers associated with these elements can streamline the process of sourcing replacements and ensuring compatibility. A thorough approach involves examining various resources and utilizing available tools to facilitate this identification.

To begin, consulting the official service manual or catalog related to your vehicle model can provide valuable insights. These documents typically list part numbers along with detailed descriptions, making it easier to match components. Additionally, online databases and forums dedicated to enthusiasts often feature comprehensive listings and user experiences that can assist in pinpointing the correct identifiers.

Another effective method is to physically inspect the components in question. Many elements are stamped or labeled with their corresponding numbers, providing a straightforward way to verify what you need. Keep in mind that variations may exist between different models and production years, so cross-referencing information is essential for accuracy.

In cases where original documentation is unavailable, reaching out to authorized dealers or experienced mechanics can yield helpful advice and guidance. They often possess extensive knowledge of the inventory and can assist in locating the correct identifiers for your vehicle’s system.

Maintenance Tips for Steering Systems

Regular upkeep is essential for ensuring optimal performance and longevity of guidance mechanisms in vehicles. Proper maintenance not only enhances safety but also improves handling and responsiveness, leading to a better overall experience.

Routine Checks

Conducting frequent inspections helps identify wear and tear early. Look for signs of leakage, unusual noises, or play in the mechanism.

Lubrication Practices

Keeping components well-lubricated reduces friction and wear. Use appropriate lubricants recommended for your specific system to maintain smooth operation.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Lubrication | Every 500 hours |

| Professional Check-up | Annually |

Aftermarket vs. Original Parts Comparison

The choice between alternative components and factory-manufactured items is crucial for equipment maintenance and performance. Understanding the distinctions can significantly impact functionality and longevity.

Original components are designed specifically for particular machinery, ensuring compatibility and adherence to manufacturer standards. This can lead to optimal performance and reliability.

On the other hand, aftermarket alternatives often offer cost-effective solutions, with a variety of options available. While these can be beneficial, they may sometimes compromise on quality or fit, leading to potential issues in the long run.

Ultimately, the decision should consider factors such as budget, intended use, and personal preferences, allowing for a balanced approach to equipment maintenance.

Tools Needed for Steering Repairs

When addressing issues related to vehicle direction control, having the right equipment is crucial for effective maintenance and repair. Utilizing appropriate tools ensures that the process is efficient and reduces the risk of further complications.

| Tool | Description |

|---|---|

| Wrench Set | Essential for loosening and tightening bolts in the assembly. |

| Screwdriver Set | Needed for removing and installing screws on various components. |

| Pliers | Useful for gripping, bending, and cutting wire or other materials. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Ball Joint Separator | Aids in removing and replacing ball joints without damaging the components. |

| Fluid Catch Pan | Helps collect any fluids that may leak during the repair process. |

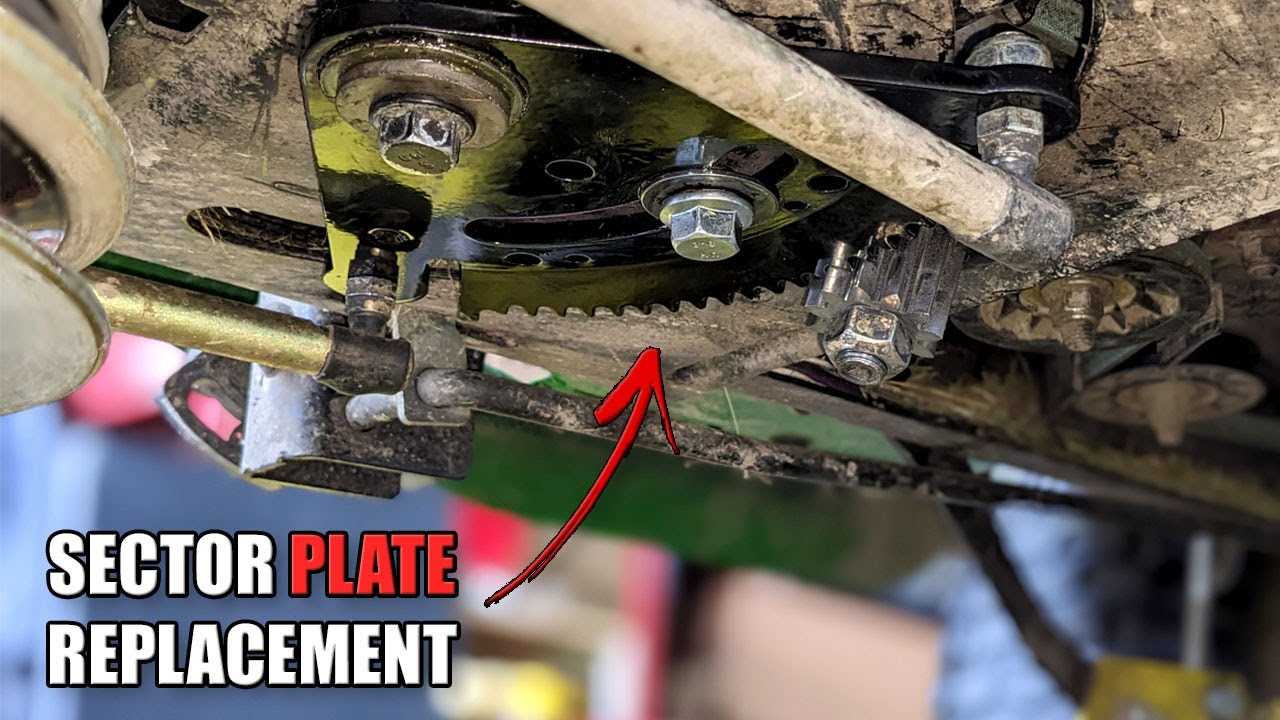

Step-by-Step Steering Replacement Guide

This guide provides a comprehensive approach to replacing the directional control mechanism in your equipment. Following these steps will ensure a smooth process and optimal performance.

- Gather all necessary tools and components.

- Safely elevate the machine and secure it on a stable surface.

- Remove any obstructions that may hinder access to the control assembly.

- Disconnect the existing mechanism carefully to avoid damage.

- Compare the new assembly with the old one for compatibility.

- Install the new mechanism, ensuring proper alignment.

- Reconnect all necessary connections and components.

- Test the functionality of the new assembly before finalizing.

Following this structured approach will help you achieve the ultimate replacement efficiently.

Where to Find Quality Diagrams

Finding reliable visual references for machinery components can significantly enhance your repair and maintenance efforts. Accurate illustrations help ensure that you understand the configuration and assembly of various elements, ultimately leading to more effective troubleshooting and part replacement.

Online Resources

The internet is a treasure trove of information. Many dedicated websites offer comprehensive collections of visual references, often categorized by brand and equipment type. Manufacturer websites frequently provide detailed guides and technical documentation, making them a primary source for accurate illustrations. Additionally, community forums and discussion boards can be excellent places to share and obtain diagrams from experienced users.

Local Dealerships and Workshops

Another valuable resource lies within local dealerships and service workshops. Expert technicians often have access to proprietary materials and manuals that are not available online. Visiting these locations can provide you with firsthand insights and potentially high-quality illustrations tailored to your specific machinery needs. Don’t hesitate to ask for assistance or recommendations when seeking visual guides.