When exploring the world of traditional textile creation tools, it’s essential to comprehend the various elements that contribute to their functionality. Each component plays a vital role in ensuring optimal performance and efficiency, allowing enthusiasts to engage in their craft with ease and precision. A thorough understanding of these features not only aids in maintenance but also enhances the overall crafting experience.

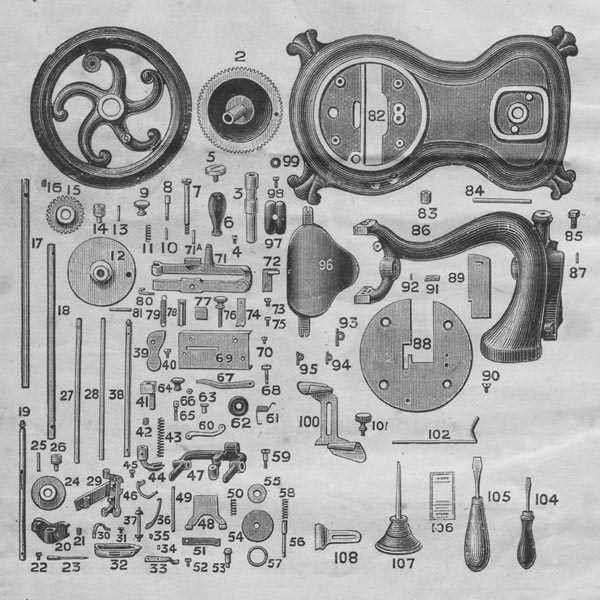

Identification of individual components is crucial for anyone looking to restore or enhance their crafting apparatus. From the intricate workings that drive the fabric manipulation to the external elements that ensure stability, knowing each piece’s function can greatly improve both novice and experienced crafters’ capabilities. By delving into these intricate details, users can appreciate the engineering marvels that support their artistic endeavors.

Mastering the layout and interaction of these vital components enables crafters to troubleshoot issues and optimize their equipment for various projects. Understanding how each element contributes to the overall mechanism empowers individuals to maintain their tools effectively, ensuring they remain in top condition for years to come. This exploration invites enthusiasts to deepen their appreciation for the craftsmanship behind these remarkable implements.

Understanding Vintage Singer Machines

Exploring the realm of classic textile crafting tools reveals a fascinating blend of artistry and engineering. These instruments, cherished by enthusiasts and collectors alike, offer a glimpse into the past, showcasing the intricate craftsmanship and innovative designs of their time. Understanding their components and functionality enhances the appreciation of these remarkable creations.

Components and Their Functions

Each element within these devices plays a crucial role in their operation. The framework provides stability, while the intricate mechanisms ensure precision in every stitch. Familiarity with these components allows users to effectively maintain their tools, ensuring longevity and optimal performance.

Restoration and Maintenance

Preserving the integrity of these cherished implements often requires careful attention and knowledge of their unique characteristics. Regular upkeep, including cleaning and lubrication, is essential for sustaining their functionality. Moreover, understanding how to source and replace worn components can revitalize these historical treasures, breathing new life into them for future generations to enjoy.

History of Singer Sewing Machines

The evolution of one renowned brand in the realm of fabric manipulation has significantly impacted the textile industry. Established in the 19th century, this company transformed the way people created and repaired garments, leading to increased efficiency and accessibility for both hobbyists and professionals. The journey began with innovative designs that made stitching more practical and widely adopted.

The Founding Era

In the early days, the founder recognized the need for an improved device that could streamline the process of joining materials. By combining various technologies, he laid the groundwork for a new era in textile work. Key developments during this time included:

- Introduction of mechanical systems that simplified operation.

- Innovative designs that appealed to a broader audience.

- Strategic marketing techniques that showcased the advantages of the product.

Expansion and Innovation

As the brand gained popularity, it began to expand its offerings and introduce new features. The commitment to quality and innovation led to several breakthroughs:

- The incorporation of electric power, enhancing usability.

- Development of specialized accessories to increase versatility.

- Adoption of durable materials that ensured longevity and reliability.

Throughout the years, this esteemed name has remained synonymous with creativity and craftsmanship, continually adapting to the changing needs of users around the world.

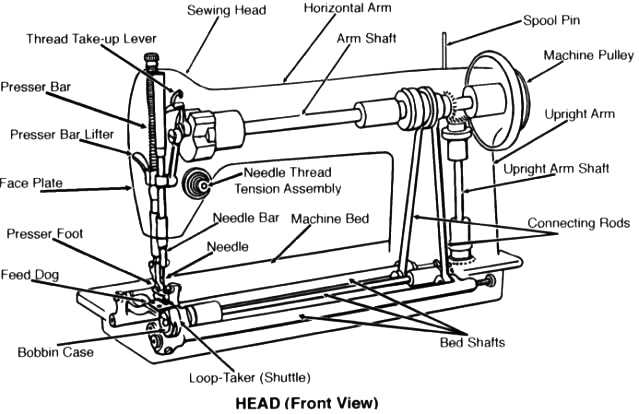

Common Parts of Vintage Models

This section explores the essential components found in classic craftsmanship devices, highlighting their functionality and significance in the overall operation. Understanding these elements can enhance your appreciation for the intricacies of such intricate tools.

Main Components

- Needle: A crucial element responsible for piercing the fabric and creating stitches.

- Foot: The attachment that holds the fabric in place during the crafting process.

- Bobbin: A small spool that holds the thread used for stitching from beneath the fabric.

- Tension Disc: Regulates the amount of thread tension for precise stitching.

- Handwheel: Allows manual movement of the needle and fabric, enabling precise control.

Supporting Elements

- Feed Dogs: These components move the fabric forward, ensuring even stitching.

- Thread Guide: Directs the thread from the spool to the needle, facilitating smooth operation.

- Foot Pedal: Controls the speed of the stitching process, allowing for varied crafting techniques.

- Body: The main structure housing all components, providing stability and support during use.

- Power Switch: Enables the operation and cessation of the device, ensuring user safety.

Recognizing these fundamental elements is essential for both enthusiasts and those seeking to restore or maintain classic craftsmanship devices.

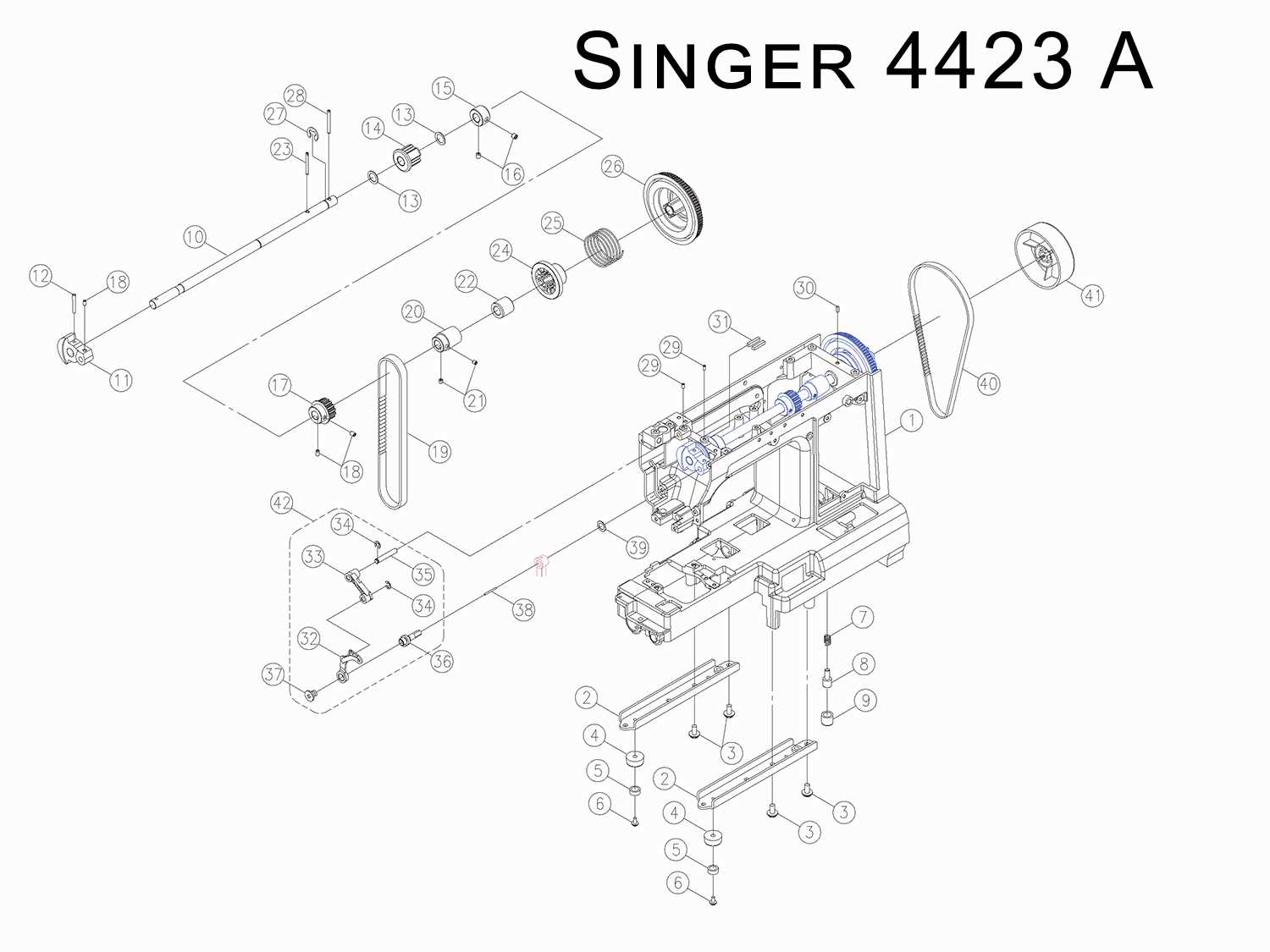

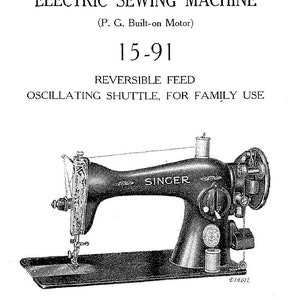

How to Identify Your Model

Determining the specific type of your device is essential for effective maintenance and restoration. Each unit is uniquely designed, and understanding its features can greatly assist in sourcing appropriate accessories and ensuring optimal functionality.

Start by examining the exterior for any labels or engravings that provide identification details. Often, the manufacturer includes a model number and year of production on the housing. Checking the user manual can also offer invaluable insights, as these documents frequently contain information about various versions.

If the label is worn or missing, consider inspecting key components. The configuration of the knobs, levers, and feed dogs may indicate specific characteristics that can lead to model identification. Additionally, researching online forums or databases dedicated to similar devices can yield useful information based on visual comparisons.

Once you gather sufficient data, compiling it systematically will help you pinpoint the exact model. This knowledge is not only vital for repairs but also enhances your understanding of the device’s historical significance and craftsmanship.

Essential Tools for Repairing Machines

Having the right equipment is crucial when it comes to restoring mechanical devices. A well-equipped toolkit can make the process more efficient and enjoyable, enabling you to tackle repairs with confidence. This section will explore key instruments that every enthusiast should consider for effective maintenance and restoration tasks.

Basic Instruments

To start, basic hand tools such as screwdrivers, wrenches, and pliers are fundamental for any repair job. Adjustable wrenches allow for flexibility when dealing with various sizes of fasteners, while precision screwdrivers help in accessing tight spaces. Investing in high-quality versions of these tools ensures durability and effectiveness in your endeavors.

Specialized Equipment

In addition to standard tools, having specialized equipment can significantly enhance your ability to perform intricate repairs. Lubricants and cleaning agents are vital for maintaining the smooth operation of components. Moreover, tools like calipers for precise measurements and magnifying glasses for detailed inspections can greatly assist in diagnosing issues and ensuring that every part functions optimally.

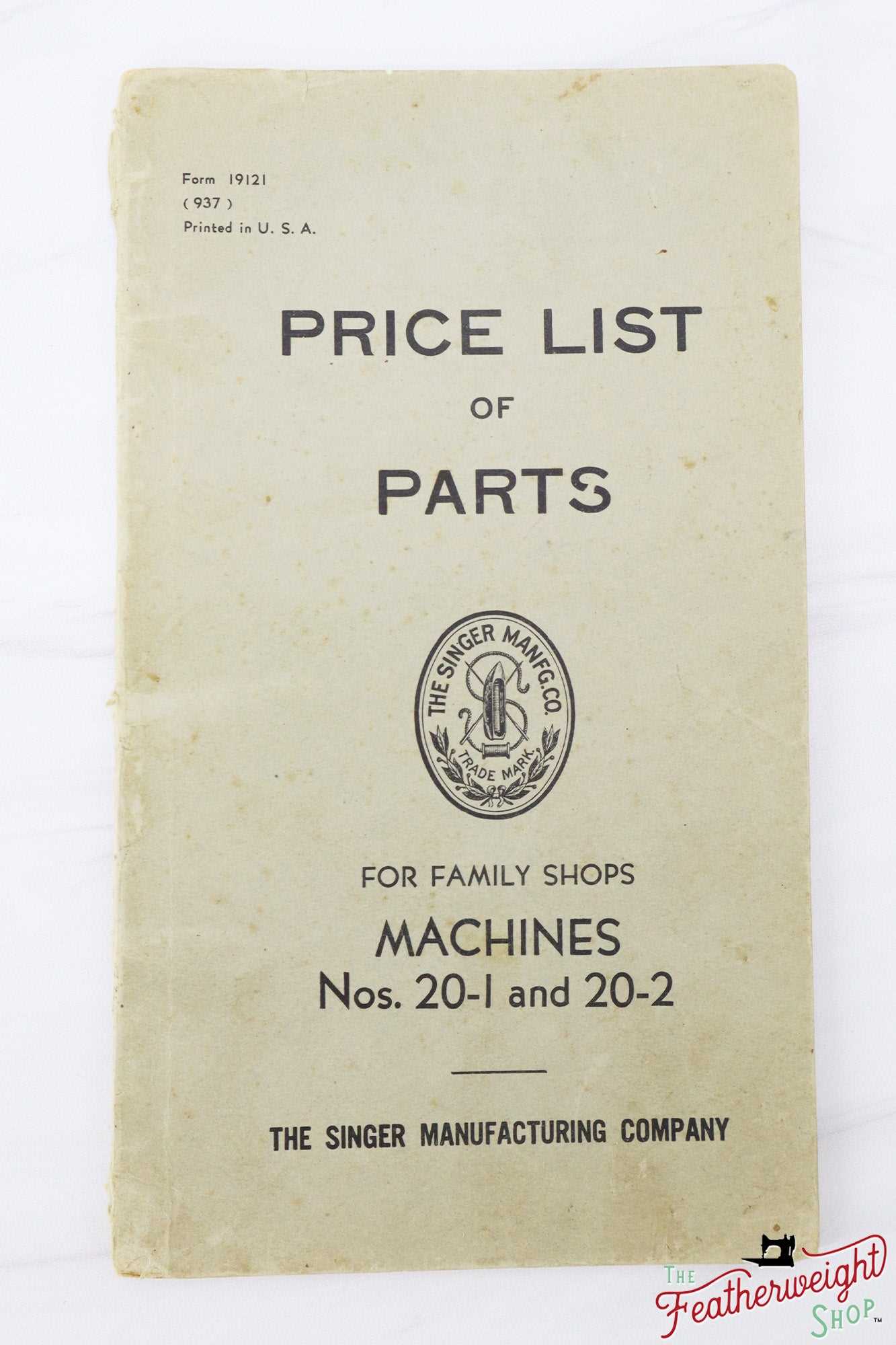

Locating Vintage Parts Online

Finding components for older crafting equipment can be a challenging yet rewarding endeavor. With a variety of resources available on the internet, enthusiasts can locate the specific items they need to restore or enhance their beloved tools. This section will explore effective strategies for navigating the online marketplace to uncover these valuable treasures.

Utilizing Specialized Marketplaces

Online platforms dedicated to hobbyists often offer a vast selection of rare and hard-to-find components. Websites that cater to collectors provide an array of options that may not be available through conventional retailers. By searching within these specialized marketplaces, users can connect with fellow enthusiasts and discover unique offerings.

Engaging with Online Communities

Joining forums and social media groups focused on restoration and crafting can greatly assist in the quest for elusive components. Members frequently share their experiences, recommendations, and resources. By actively participating in discussions and seeking advice, individuals can enhance their search and gain insights into the best places to find what they need.

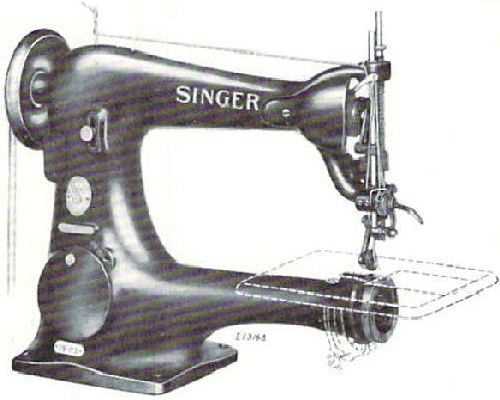

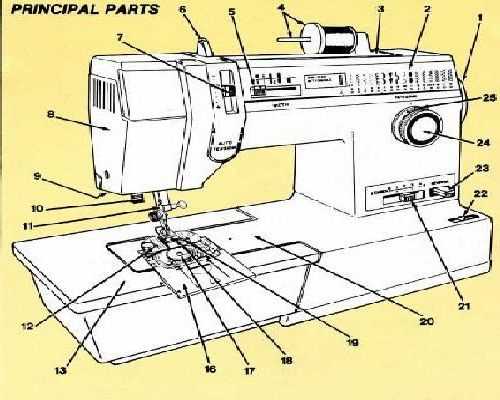

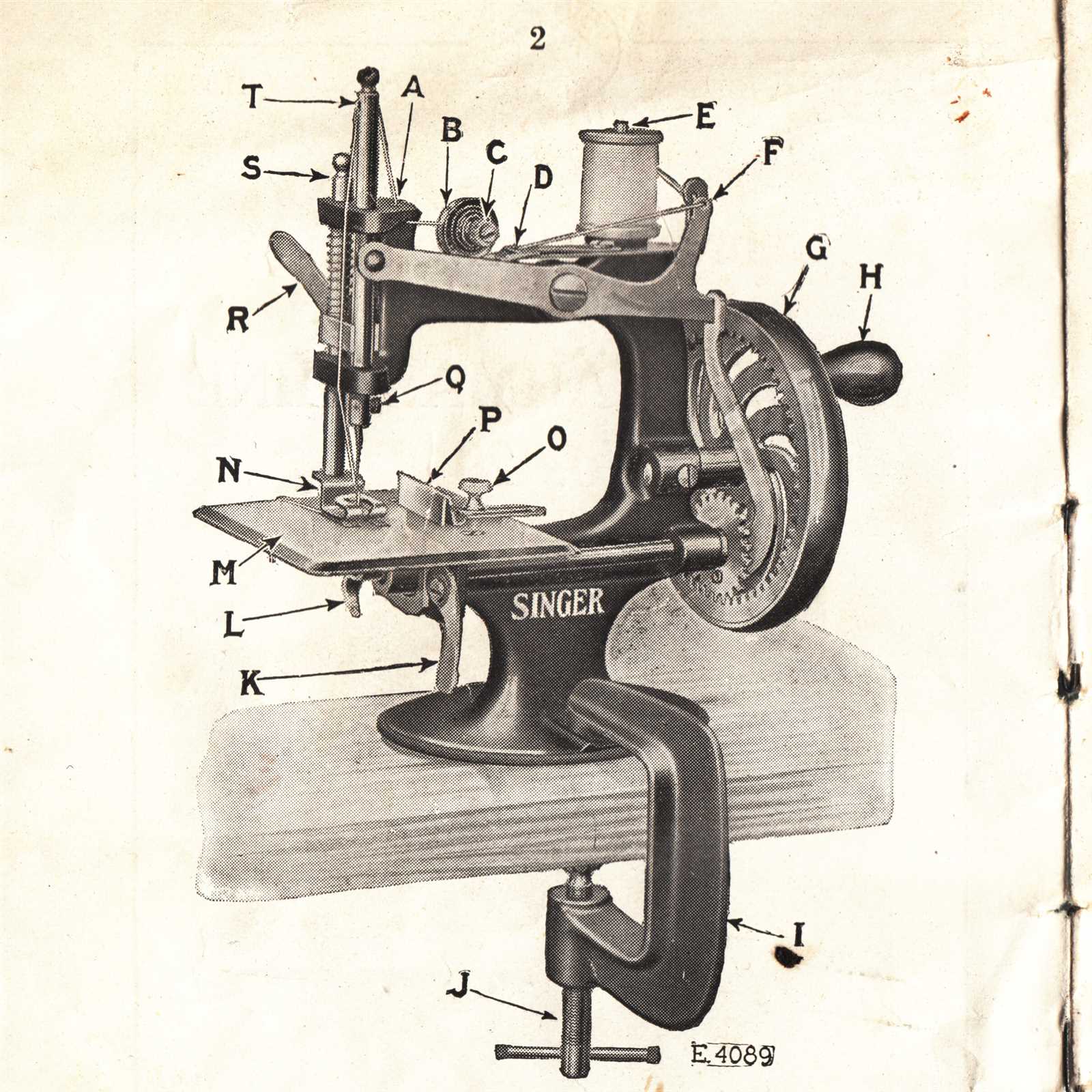

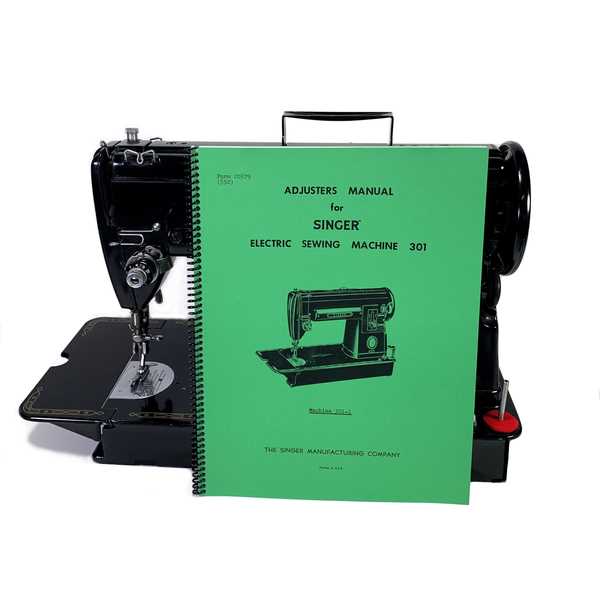

Visual Guide to Machine Components

This section aims to provide a comprehensive overview of the essential elements that constitute the functionality of various textile apparatuses. Understanding these components is crucial for effective maintenance and operation, ensuring that the device performs optimally throughout its lifespan.

Key Elements Overview

- Needle Holder: The part that securely holds the needle in place, allowing for precise stitching.

- Bobbin Case: A critical component that houses the bobbin, essential for feeding thread from below.

- Foot Pedal: The control mechanism that regulates the speed of operation, allowing users to have full command over the process.

- Thread Tension Mechanism: This feature controls the tightness of the thread, which is vital for achieving even stitches.

- Stitch Selector: A dial or lever that enables the user to choose different stitching patterns.

Functional Importance

Each of these components plays a vital role in the overall functionality and efficiency of the apparatus. Regular inspection and understanding of their operation can greatly enhance the user’s experience and prolong the device’s life. Here are some additional elements worth noting:

- Feed Dogs: These small, raised sections help move the fabric through the machine as stitching occurs.

- Throat Plate: The flat surface where the fabric rests, featuring openings that allow the needle to pass through.

- Motor: The power source that drives the entire system, influencing the speed and strength of the operation.

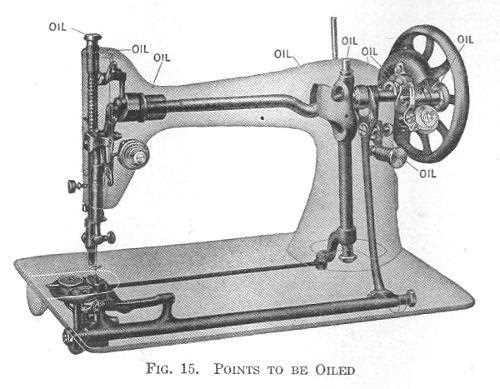

Maintenance Tips for Longevity

To ensure the enduring performance of your equipment, regular care and attention are essential. Implementing a consistent maintenance routine not only enhances functionality but also extends the lifespan of your apparatus. Here are some practical suggestions to keep your device in optimal condition.

Regular Cleaning: Dust and debris can accumulate over time, hindering the efficiency of your apparatus. Utilize a soft cloth and a brush to gently remove any dirt from the exterior and hard-to-reach areas. Pay special attention to nooks and crannies where particles may gather.

Lubrication: Keeping moving components well-lubricated is crucial for smooth operation. Use a high-quality lubricant designed for your specific device. Apply a few drops to the necessary areas, ensuring not to overdo it, as excess can attract more dirt.

Storage Considerations: Proper storage plays a significant role in the longevity of your equipment. Always keep it in a dry, cool place away from direct sunlight. Use a protective cover to shield it from dust and environmental factors when not in use.

Periodic Inspections: Schedule routine checks to identify any potential issues before they escalate. Look for signs of wear and tear, such as frayed cords or loose components, and address these concerns promptly to avoid further damage.

Professional Servicing: Consider having your apparatus professionally serviced at regular intervals. Experienced technicians can perform in-depth evaluations and maintenance that may not be possible through self-service. This proactive approach can save time and money in the long run.

By following these essential maintenance tips, you can ensure that your equipment remains reliable and efficient for many years to come.

Common Issues and Fixes

Maintaining and troubleshooting older equipment can often present unique challenges. Understanding the typical problems and their solutions can enhance the longevity and performance of these treasured items. Below are some frequently encountered issues and practical remedies to consider.

- Skipped Stitches:

- Check the needle to ensure it is the correct type and properly installed.

- Examine the thread tension and adjust as needed to achieve a balanced stitch.

- Inspect the bobbin to confirm it is wound evenly and placed correctly.

- Thread Jamming:

- Remove any tangled thread and clean the area around the tension assembly.

- Ensure the threading path is followed accurately from the spool to the needle.

- Use high-quality thread that matches the intended fabric type.

- Uneven Stitching:

- Verify the fabric is properly supported and not being pulled or pushed during use.

- Adjust the stitch length settings according to the thickness of the material.

- Regularly clean and lubricate the internal components to maintain smooth operation.

- Noise During Operation:

- Check for any loose screws or components that may need tightening.

- Lubricate moving parts to reduce friction and improve sound levels.

- Inspect belts and gears for wear or damage that may contribute to excessive noise.

By addressing these common concerns promptly, users can ensure their treasured apparatus continues to function optimally for years to come. Regular maintenance and attention to detail are key to preserving the integrity of such beloved items.

Upgrading vs. Restoring Machines

When it comes to enhancing or rejuvenating older textile equipment, enthusiasts often find themselves at a crossroads. The decision to modernize or bring back to life a classic device can significantly impact its functionality, aesthetic appeal, and overall value. Each approach offers distinct advantages and challenges that should be carefully considered before embarking on the journey.

Benefits of Upgrading

Modernization typically involves integrating contemporary features and technologies into older devices. This process can improve efficiency, increase compatibility with modern materials, and enhance user experience. For many, the allure of streamlined operations and advanced functionalities makes this option appealing. However, it may come at the cost of the original charm and authenticity that many collectors cherish.

Advantages of Restoration

On the other hand, revitalization focuses on returning an item to its former glory. This approach often emphasizes preserving historical significance and maintaining the original components. While restoration can be a labor-intensive endeavor requiring skill and patience, the outcome can provide immense satisfaction and a deeper connection to the past. Collectors and hobbyists often view well-restored pieces as treasures that carry stories and memories.

Safety Precautions While Repairing

When undertaking repairs on intricate devices, it is essential to prioritize safety to prevent accidents and ensure efficient work. Being aware of potential hazards and taking proactive measures can significantly reduce risks associated with mechanical upkeep.

First and foremost, always disconnect the power source before starting any repair. This simple step prevents accidental activation and protects against electrical shocks. Additionally, ensure that your workspace is well-lit and organized to avoid any unnecessary mishaps while handling small components.

Wearing appropriate protective gear is equally important. Use safety goggles to shield your eyes from debris, and gloves to protect your hands from sharp edges or chemicals. Furthermore, consider a dust mask if you are working with materials that generate fine particles.

Lastly, familiarize yourself with the specific characteristics of the device you are working on. Understanding its structure and functionality can help you anticipate issues and work more effectively. Always consult reliable manuals or resources to guide you through the repair process.

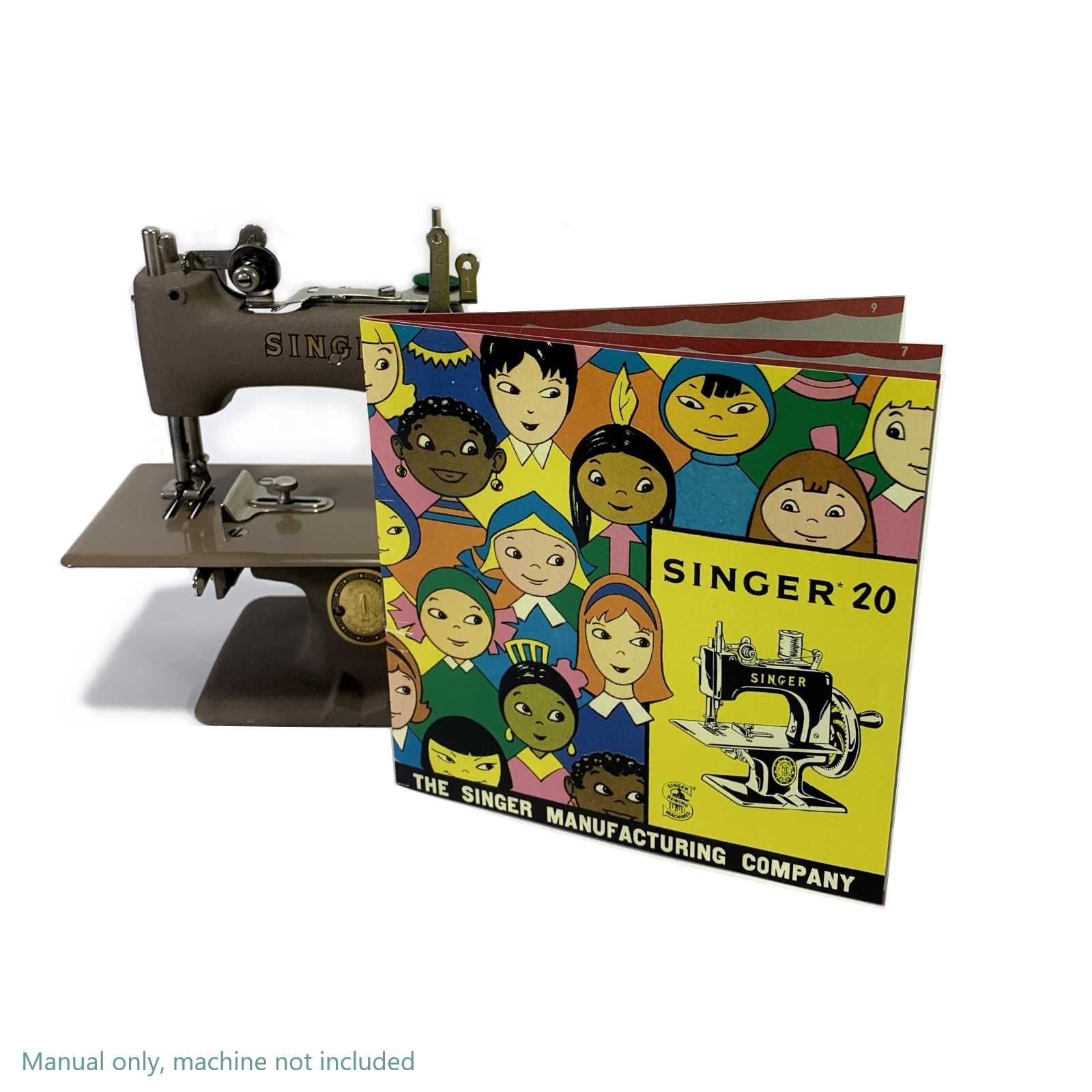

Resources for Singer Enthusiasts

For those passionate about classic textile devices, a wealth of materials and tools is available to enhance your experience. These resources can assist in maintaining, repairing, and appreciating these beloved creations. Whether you are a seasoned collector or a newcomer, accessing the right information is crucial for preserving these timeless treasures.

Below is a curated list of resources to support your journey:

- Online Forums:

- PatternReview – A community for sharing experiences and advice.

- Sewing.org – Offers tips and a platform to connect with fellow enthusiasts.

- Repair Guides:

- Sewing Machine Repair – Provides comprehensive troubleshooting and repair manuals.

- YouTube – Numerous tutorials are available for visual learners.

- Parts Suppliers:

- Parts.com – A reliable source for replacement components.

- Sewing Parts Online – Offers a wide variety of items for various models.

- Books and Publications:

Engaging with these resources will enrich your understanding and appreciation of these remarkable devices, ensuring they continue to inspire creativity for years to come.

Connecting with Vintage Sewing Communities

Engaging with enthusiasts of classic fabric crafting tools offers a unique opportunity to share knowledge, resources, and experiences. These communities foster a sense of belonging and provide a platform for individuals to connect over their shared passion for preservation and creativity. By participating in discussions, forums, and events, one can gain insights into techniques, restoration methods, and the history behind these cherished implements.

Online platforms and social media have become vital in building connections within these circles. Groups dedicated to discussing restoration techniques, sharing tips, and showcasing projects can enhance the crafting experience. These spaces not only offer support but also allow members to exchange ideas and collaborate on projects that celebrate the art of textile manipulation.

| Community Type | Description | Benefits |

|---|---|---|

| Online Forums | Websites where users post questions, share advice, and discuss various topics. | Access to a wealth of knowledge and resources. |

| Social Media Groups | Facebook and Instagram groups focused on sharing projects and tips. | Visual inspiration and real-time feedback from peers. |

| Local Clubs | Meetup groups that gather to discuss and work on projects. | Networking opportunities and hands-on learning. |

| Workshops | Classes or events that teach specific skills or techniques. | Structured learning and mentorship. |

Involvement in these communities enriches the experience of working with traditional crafting tools. Whether through online discussions or local meetups, the connections forged help preserve the art and history associated with these remarkable devices.