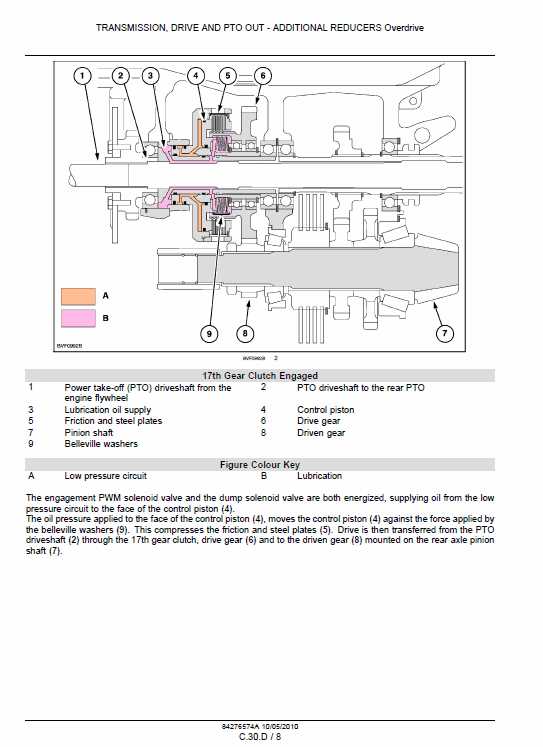

When it comes to the maintenance and repair of agricultural machinery, having a clear representation of the internal components is essential. Such illustrations provide a visual guide, helping operators and technicians identify each element’s function and location within the machine.

In the world of farming equipment, the importance of recognizing individual components cannot be overstated. A thorough comprehension of the machinery’s structure not only aids in efficient repairs but also enhances overall operational safety.

As we explore the intricacies of these visual aids, we will delve into the various elements that make up the machinery. Understanding these details is the ultimate key to ensuring that the equipment runs smoothly and reliably in the field.

Overview of New Holland T6030

This section provides a comprehensive look at a versatile agricultural machine designed for various tasks. Its robust engineering and efficient performance make it a favorite among farmers and operators alike.

| Feature | Description |

|---|---|

| Engine Power | Offers strong horsepower suitable for heavy-duty applications. |

| Transmission | Equipped with advanced transmission options for smooth operation. |

| Cab Comfort | Designed with operator comfort in mind, featuring ergonomic controls. |

| Versatility | Compatible with a wide range of implements for different agricultural needs. |

| Maintenance | Built for easy access to components, simplifying upkeep and repairs. |

Key Features of T6030 Model

This model stands out in its category, combining advanced technology with exceptional performance. Its design focuses on efficiency, making it suitable for a variety of agricultural tasks. Users can expect reliability and power, ensuring that their operations run smoothly and effectively.

Powerful Engine Performance

Equipped with a robust engine, this unit delivers impressive horsepower and torque. This capability allows it to tackle demanding tasks with ease, from plowing to hauling heavy loads. The engine’s efficiency also contributes to lower fuel consumption, making it a cost-effective choice for farmers.

Versatile Attachment Compatibility

One of the standout aspects is its ability to accommodate a wide range of attachments. This versatility enables users to adapt the machine for various applications, enhancing productivity. Whether for tillage, mowing, or other agricultural activities, it provides the necessary support for different tools, maximizing its utility.

Understanding Parts Diagram Importance

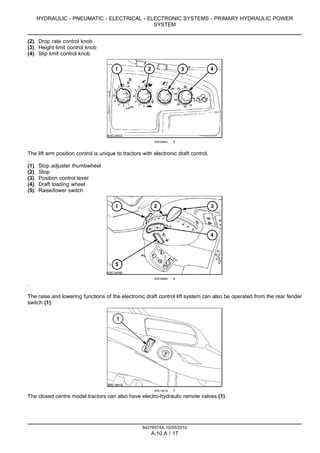

Having a clear visual representation of components is crucial for effective maintenance and repair. Such illustrations provide valuable insights into how each element interacts within the machinery. This understanding can significantly enhance troubleshooting processes, enabling technicians to identify issues quickly and accurately.

Comprehending these visuals aids users in recognizing the function of each element and its relevance to the overall operation. Moreover, it fosters a deeper appreciation for the complexity of the machinery, highlighting the precision required for assembly and disassembly. Proper utilization of these resources not only minimizes errors but also optimizes the efficiency of repair tasks.

How to Read Parts Diagrams

Understanding technical illustrations can be essential for effective maintenance and repair. These visual aids provide crucial information about the components and their arrangement, enabling users to identify and locate specific elements easily.

To effectively interpret these visuals, consider the following guidelines:

- Familiarize Yourself with Symbols: Different symbols may represent various items. Knowing these can help in quick identification.

- Pay Attention to Labels: Many illustrations include labels or numbers corresponding to a list of components. Cross-referencing these can clarify their function and placement.

- Observe the Layout: Understanding how parts are arranged can give insights into the assembly and disassembly processes. Recognizing connections and interactions between elements is key.

- Check for Notes: Additional annotations or notes may provide valuable information, such as maintenance tips or warnings regarding specific components.

By following these steps, one can gain a better understanding of technical visuals, making it easier to manage and troubleshoot machinery effectively.

Common Issues with T6030 Components

Understanding the frequent challenges associated with various machine elements is crucial for maintaining optimal performance and longevity. Components often experience wear and tear, leading to specific operational difficulties that can hinder productivity.

Some typical issues include:

- Hydraulic System Failures: Problems with hydraulic components can result in poor lifting capacity and inefficient operation.

- Engine Performance Declines: Decreased power output may arise from filter blockages or fuel quality issues.

- Transmission Irregularities: Gear shifting difficulties can occur due to low fluid levels or worn gears.

- Electrical System Malfunctions: Faulty wiring or connectors can lead to intermittent power issues and sensor failures.

- Cooling System Inefficiencies: Overheating can be caused by blocked radiators or failing thermostats.

Regular inspections and timely maintenance are essential to prevent these issues and ensure the machine operates smoothly. Addressing these common challenges promptly can significantly enhance overall functionality and durability.

Maintenance Tips for T6030 Parts

Proper upkeep is essential for enhancing the longevity and performance of your machinery components. Regular attention to specific areas can prevent unexpected breakdowns and costly repairs. Here are some practical suggestions to help maintain your equipment effectively.

Regular Inspections

- Conduct routine checks on all critical components to identify any signs of wear or damage.

- Look for leaks, cracks, or any irregularities that may indicate underlying issues.

- Ensure that all fasteners are securely tightened to prevent vibrations that can lead to further complications.

Cleaning and Lubrication

- Keep surfaces clean to avoid the accumulation of dirt and debris that can hinder functionality.

- Apply appropriate lubricants to moving parts to reduce friction and wear.

- Follow the manufacturer’s recommendations for lubrication intervals to maintain optimal performance.

Where to Find Replacement Parts

Locating suitable components for machinery can significantly enhance its performance and longevity. Whether you are a professional or a hobbyist, knowing where to seek high-quality substitutes is crucial for maintaining operational efficiency.

Online Retailers

Numerous online platforms offer a vast selection of components. These websites provide convenience and often feature competitive pricing. Consider the following options:

- Dedicated machinery websites

- General e-commerce platforms

- Specialty suppliers with expertise in specific brands

Local Dealers

Visiting nearby dealers can yield immediate results. They often stock essential items and can offer personalized assistance. Benefits of local sourcing include:

- Quick access to required components

- Expert advice from knowledgeable staff

- The possibility of examining items before purchasing

Comparing OEM and Aftermarket Parts

When it comes to machinery maintenance, choosing between original equipment manufacturer (OEM) components and aftermarket alternatives is a crucial decision for many operators. Understanding the distinctions between these options can significantly impact performance, reliability, and overall cost-effectiveness. This section explores the advantages and disadvantages of each type, enabling informed choices for equipment upkeep.

Quality and Performance

OEM components are specifically designed to meet the manufacturer’s standards, ensuring compatibility and reliability. In contrast, aftermarket options may vary in quality, as they are produced by third-party manufacturers. While some aftermarket products may match or even exceed OEM standards, others might fall short, leading to potential issues down the line. It’s essential to assess the manufacturer’s reputation and warranty when considering these alternatives.

Cost Considerations

Price is often a deciding factor in selecting between OEM and aftermarket options. OEM components typically come with a higher price tag due to their guaranteed quality and brand recognition. On the other hand, aftermarket alternatives can offer significant savings, making them an attractive option for budget-conscious operators. However, the potential for varying quality and performance should be carefully weighed against the initial cost savings.

| Feature | OEM | Aftermarket |

|---|---|---|

| Quality | High, standardized | Varies by manufacturer |

| Cost | Higher | Lower, often more economical |

| Compatibility | Guaranteed fit | May require verification |

| Warranty | Usually longer | Varies widely |

Essential Tools for Parts Replacement

When it comes to maintaining machinery, having the right instruments is crucial for ensuring smooth operation and longevity. This section focuses on the essential tools required to effectively replace components in agricultural equipment. By equipping yourself with these necessary implements, you can facilitate a seamless repair process and minimize downtime.

Among the primary tools, wrenches and socket sets are vital for loosening and tightening bolts and nuts, while screwdrivers are indispensable for various fastening tasks. Additionally, pliers can aid in gripping and manipulating small parts, ensuring accurate installation. A good-quality jack is also important for safely lifting the machinery, providing easy access to areas needing attention.

Moreover, a reliable tool organizer can help keep everything in place, allowing for quick access during repairs. Safety gear, such as gloves and goggles, should never be overlooked, as they protect you while working with heavy machinery. Having these essential tools on hand not only streamlines the replacement process but also enhances overall efficiency in equipment maintenance.

Best Practices for Component Installation

When it comes to the assembly of machinery elements, following established protocols is crucial for ensuring optimal functionality and longevity. Proper installation techniques not only enhance performance but also minimize the risk of future malfunctions. Understanding the essential practices can significantly contribute to the efficiency of operations.

Firstly, it is vital to prepare the workspace adequately. Ensure that all necessary tools and components are organized and within reach. A clutter-free environment promotes focus and reduces the likelihood of errors during the installation process.

Secondly, refer to the manufacturer’s specifications and guidelines. Adhering to the recommended procedures for each component ensures compatibility and reduces the risk of misalignment or damage. Always double-check that the components are clean and free of debris before installation.

Additionally, utilizing appropriate fastening methods is essential. Ensure that all bolts, screws, and fittings are tightened to the specified torque settings. Over-tightening can lead to stress fractures, while under-tightening may result in loose connections.

Finally, conduct a thorough inspection post-installation. Verify that all components are securely fastened and operational. Performing a test run can help identify any potential issues early, allowing for prompt adjustments and maintaining the overall integrity of the machinery.

Upgrades and Modifications for T6030

Enhancing the performance and functionality of agricultural machinery can significantly improve efficiency and productivity. Various upgrades and modifications can be implemented to tailor equipment to specific operational needs, ensuring optimal performance in diverse conditions.

One common upgrade involves the installation of advanced hydraulic systems. These systems can enhance lifting capacity and improve overall maneuverability, allowing for more efficient operation in various agricultural tasks. Additionally, integrating modern electronic controls can provide better precision and responsiveness, enhancing user experience.

Another beneficial modification is upgrading the tires or tracks, which can improve traction and reduce soil compaction. This change is especially important for operations in varied terrain and weather conditions. Implementing additional lighting options can also enhance visibility during early morning or late evening tasks, ensuring safety and efficiency.

Overall, these enhancements not only boost operational effectiveness but also extend the lifespan of the machinery, making them a valuable investment for any agricultural enterprise.

Frequently Asked Questions on T6030 Parts

This section aims to address common inquiries related to components and accessories associated with a particular agricultural machinery model. Understanding these elements is crucial for ensuring optimal performance and longevity of the equipment. Here, we provide clarity on various topics concerning the maintenance and replacement of essential items.

What are the most commonly replaced components?

Many users frequently seek to replace elements such as filters, belts, and seals, which are essential for the efficient operation of the machinery. Regular inspections help identify worn-out items that may need replacement to avoid operational downtime.

How can I identify compatible accessories?

To find suitable accessories, it is advisable to consult the manufacturer’s specifications or a reliable supplier. Ensuring compatibility is vital to maintaining the functionality and safety of the equipment.