In the world of machinery, having a clear understanding of how each component functions is essential for optimal performance and longevity. This section aims to illuminate the intricate connections and roles of various elements that contribute to the overall efficacy of your equipment.

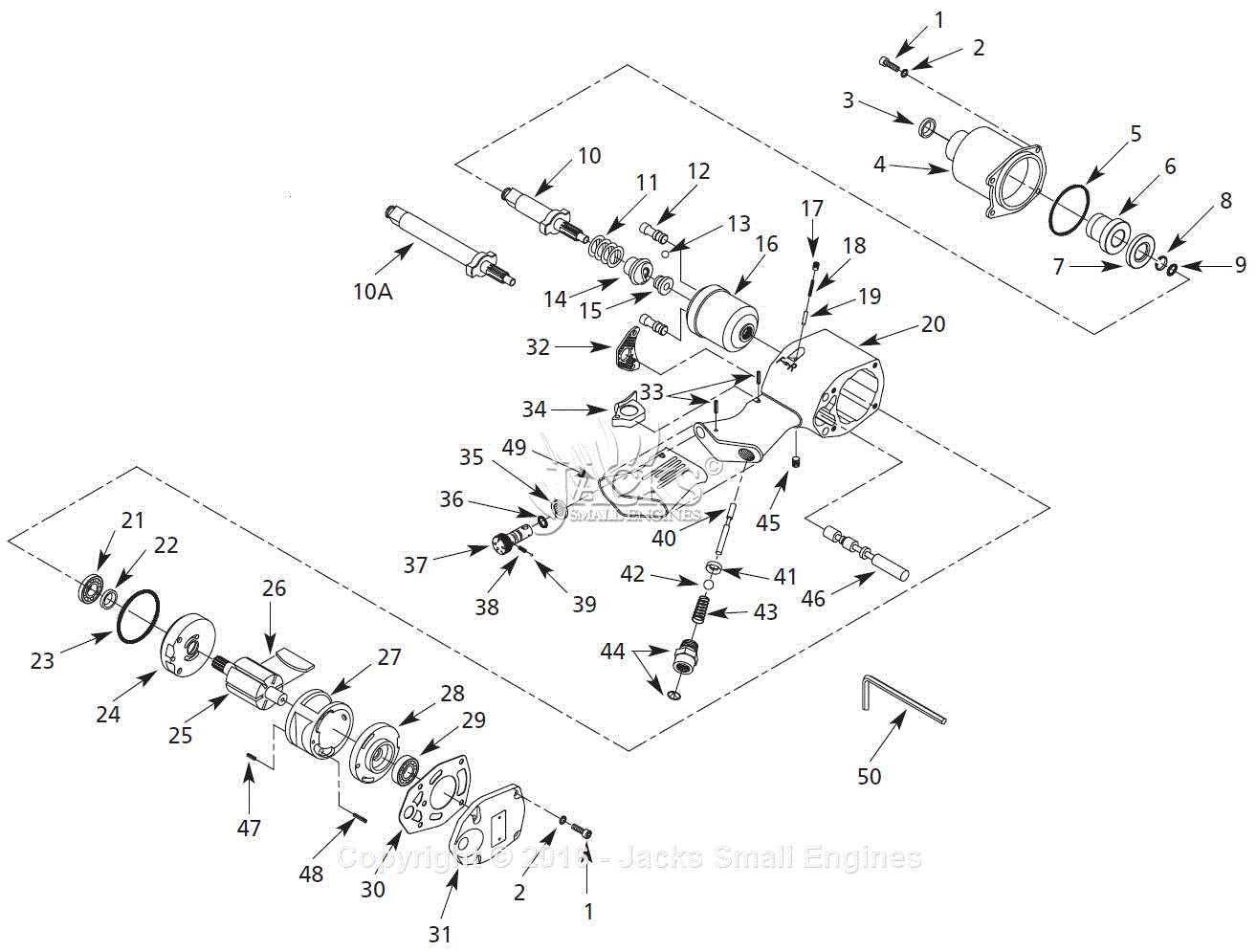

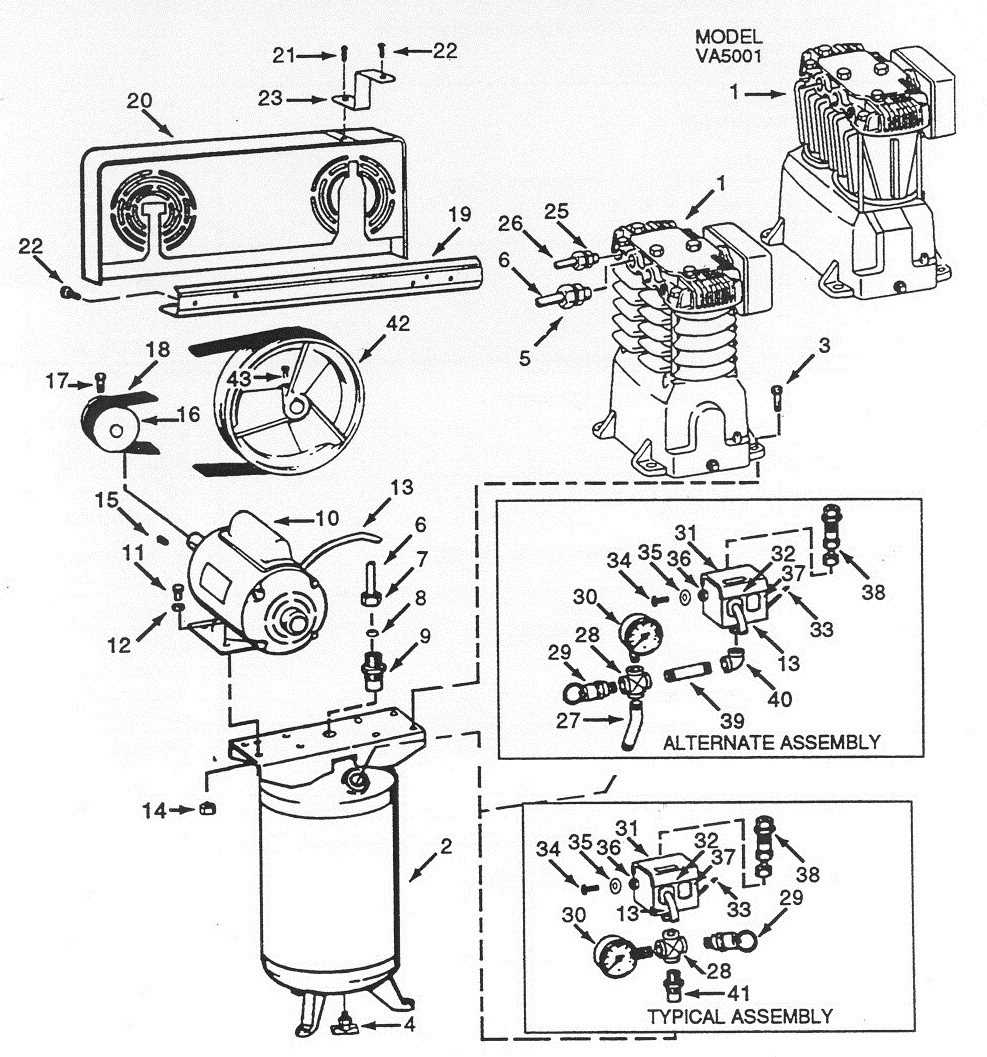

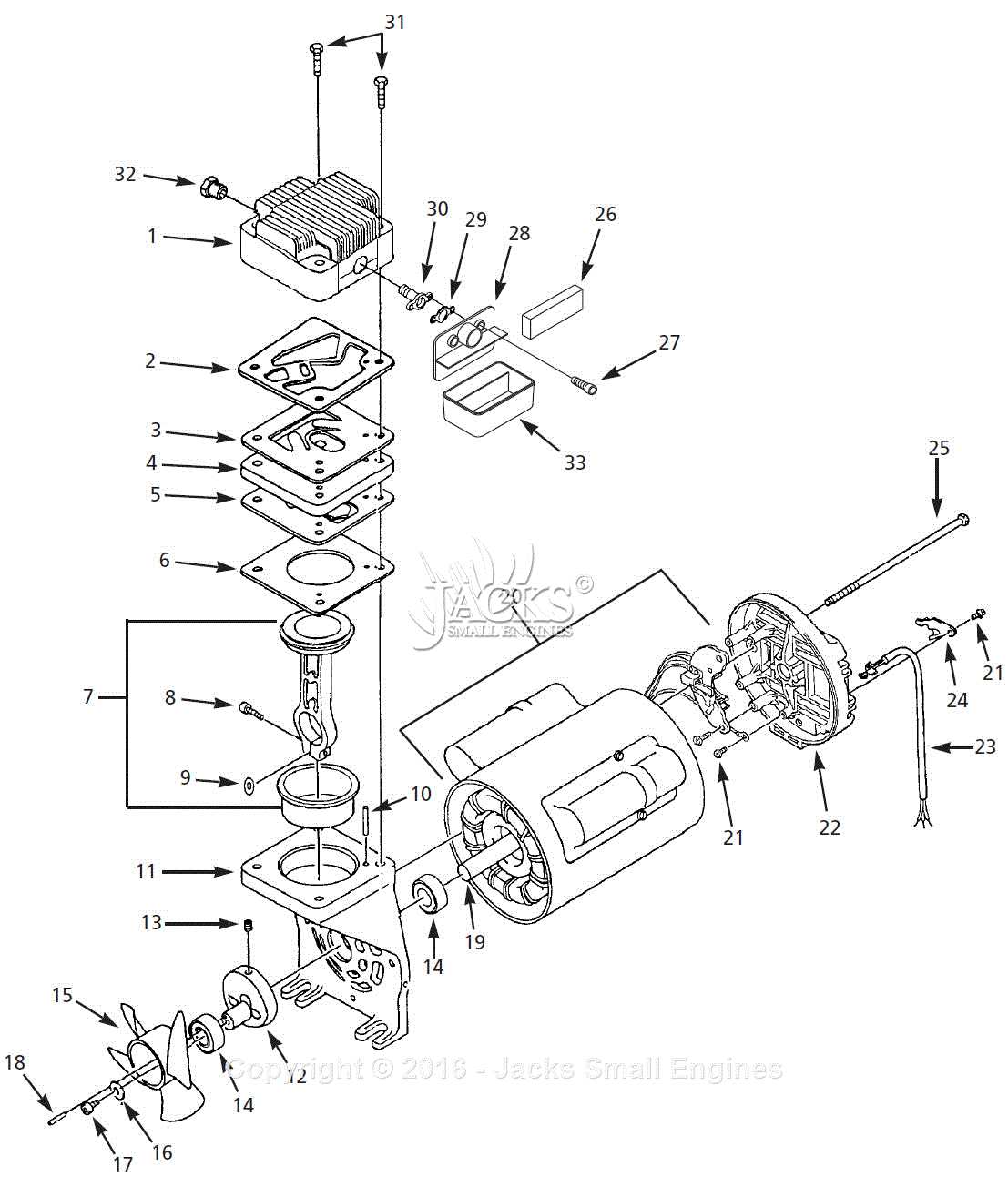

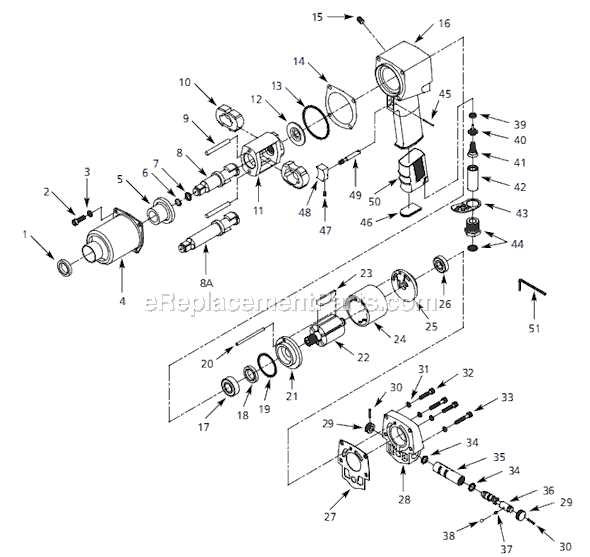

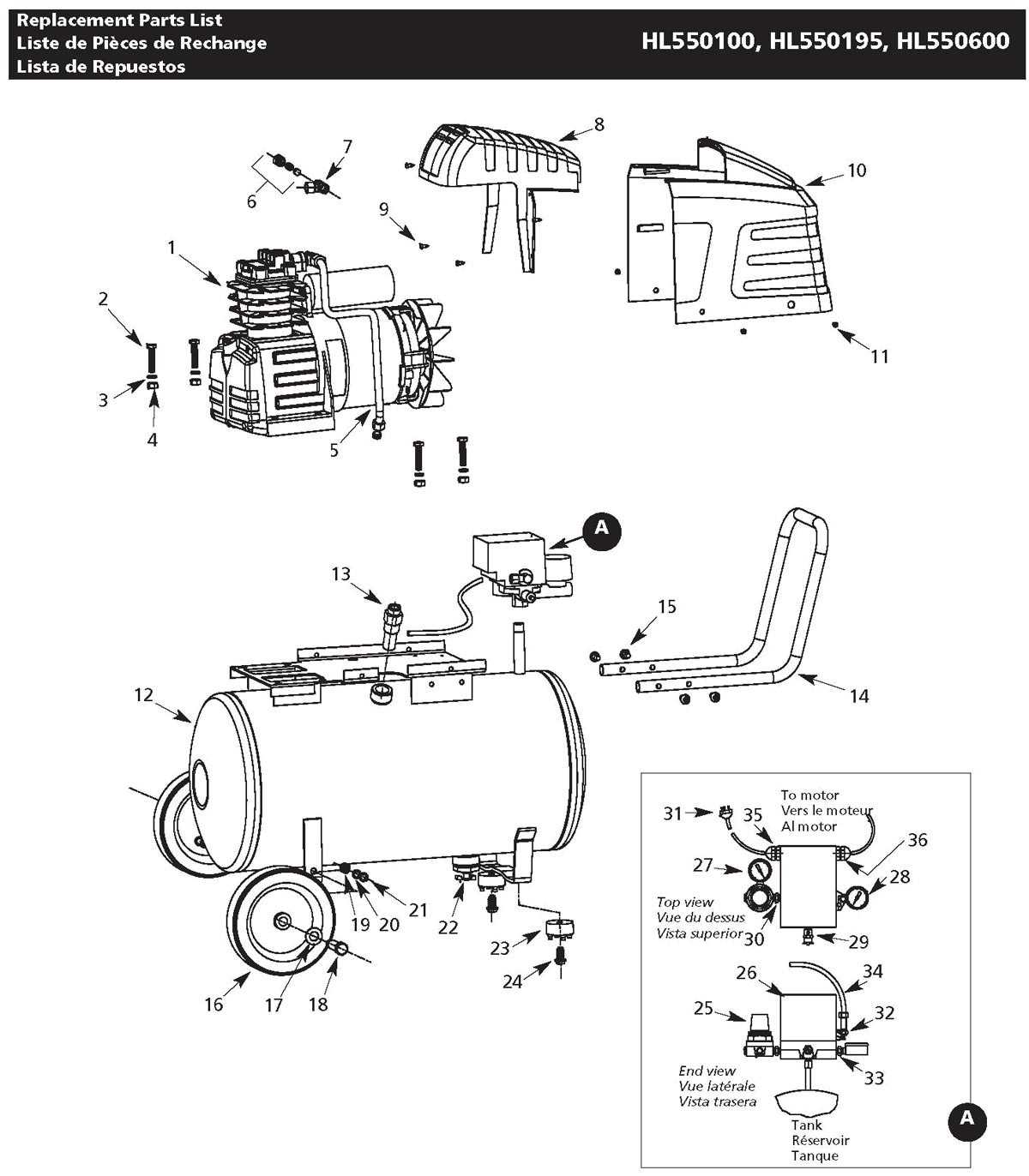

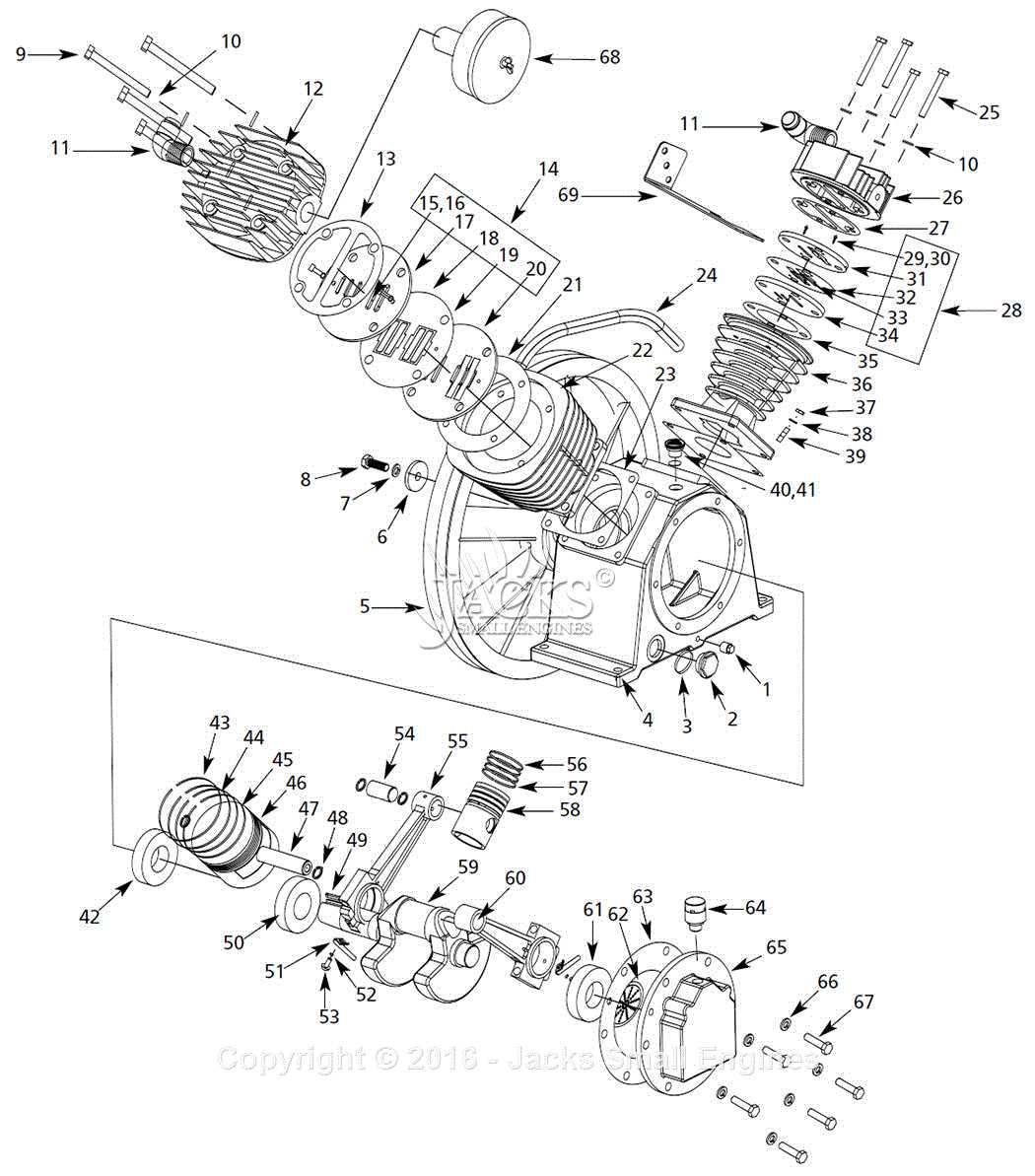

Visual representations play a crucial role in this process, offering insights into the assembly and disassembly of different segments. By examining these illustrations, users can easily identify and understand the essential features that facilitate proper operation.

Whether you’re a novice or a seasoned technician, delving into these visual guides will enhance your ability to maintain and troubleshoot effectively. The ultimate goal is to empower users with the knowledge required for efficient repairs and upgrades, ensuring that machinery remains in peak condition.

Understanding Campbell Hausfeld TL1002

This section aims to provide a comprehensive overview of a specific model within the realm of air compression tools. By exploring its components and functionality, users can gain valuable insights into its operational mechanisms and potential applications. Understanding these aspects can enhance user experience and maintenance practices.

Key Features and Functionality

The equipment is designed with a variety of features that cater to both professional and DIY enthusiasts. Its robust construction ensures durability, while its efficiency promotes effective air delivery for various tasks. The inclusion of adjustable settings allows users to tailor performance to specific requirements, making it versatile for numerous applications.

Maintenance and Care

Regular upkeep is essential to ensure longevity and optimal performance. Familiarizing oneself with the internal components can aid in timely servicing. Users are encouraged to consult the operational manual for specific maintenance guidelines, as proper care can prevent common issues and enhance overall functionality.

Overview of TL1002 Components

This section delves into the various elements that constitute the functionality of the model in question. Understanding these components is essential for maintenance and efficient operation, as each part plays a significant role in the overall performance. Familiarity with the individual elements will aid in troubleshooting and enhance the user experience.

Key Elements

The following table outlines the primary components and their respective functions:

| Component | Description |

|---|---|

| Motor | Powers the unit, converting electrical energy into mechanical energy. |

| Pump | Increases pressure, facilitating the movement of fluids or air. |

| Tank | Stores compressed air, ensuring a steady supply during operation. |

| Regulator | Controls the output pressure, allowing for adjustments based on specific tasks. |

| Hoses | Connect various components, enabling fluid or air transfer between them. |

Additional Features

Alongside the core parts, there are various additional features that enhance functionality, such as safety valves and gauges. These elements contribute to the safe and efficient use of the equipment, providing users with feedback and control over the system’s operation.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repair. Visual representations serve as valuable tools, enabling users to identify each element quickly and accurately.

- Enhances comprehension of complex systems.

- Aids in locating specific components easily.

- Facilitates troubleshooting and repairs.

- Improves the efficiency of reassembly processes.

By utilizing these visual aids, users can delve into the intricacies of their equipment, ultimately leading to enhanced performance and longevity.

Common Issues with TL1002 Models

Users often encounter several challenges with this specific equipment. Recognizing these common problems can enhance performance and prolong the lifespan of the unit. Many issues stem from maintenance practices, user error, or component wear over time.

Frequent Mechanical Failures

One of the most prevalent concerns involves mechanical breakdowns, which may include leaks or irregular pressure levels. Regular inspection and timely replacements of worn parts can mitigate these issues. Users should familiarize themselves with the signs of impending failure.

Electrical Problems

Another significant category of issues relates to electrical components. Users may experience inconsistent power supply or malfunctioning controls. These problems often arise from poor connections or outdated wiring. Ensuring proper electrical maintenance is crucial for optimal operation.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear overview of the individual elements, their arrangement, and how they interact within a system.

To effectively interpret these visuals, follow these guidelines:

- Familiarize Yourself with Symbols: Each element is usually represented by specific icons. Learning these can help you quickly identify parts.

- Study the Layout: Observe how components are organized. This gives insights into their relationships and functions.

- Refer to the Legend: A legend often accompanies the image, explaining the symbols and color codes used.

- Check for Numbering: Many illustrations include reference numbers that correlate with a list of components, aiding in identification.

By mastering these techniques, you will enhance your ability to navigate these visual aids and streamline your repair processes.

Identifying Key Replacement Parts

Understanding the essential components of a tool is crucial for maintaining its efficiency and prolonging its lifespan. Recognizing which elements may need replacement can prevent unexpected downtime and ensure optimal performance.

Here are some common components to consider when identifying replacements:

- Seals and Gaskets: These parts are vital for preventing leaks and maintaining pressure.

- Hoses: Ensure they are free from cracks or wear, as damaged hoses can hinder functionality.

- Filters: Regularly replacing filters helps maintain clean airflow and protects internal mechanisms.

- Valves: Check for any signs of corrosion or malfunction, which could affect operation.

- O-rings: These small yet crucial components provide sealing for various joints.

When assessing these elements, it’s important to refer to the manufacturer’s specifications to ensure compatibility and functionality. Keeping a list of frequently replaced components can also streamline the maintenance process.

Where to Purchase TL1002 Parts

Finding replacement components for your equipment can be a straightforward process if you know where to look. Several reliable sources offer a variety of options to ensure your device remains functional and efficient. Whether you are seeking to repair or maintain your machinery, it is essential to explore multiple avenues to secure the best deals and quality.

Online marketplaces are an excellent starting point. Websites specializing in tools and machinery often have a vast inventory, making it easy to locate specific items. Additionally, these platforms frequently provide user reviews, helping you gauge the reliability of the components.

Local hardware stores can also be a valuable resource. Many of these establishments carry a selection of parts or can order them for you. Building a relationship with your local suppliers can lead to helpful advice and recommendations on compatible items.

Lastly, consider reaching out to specialized retailers or manufacturers directly. They can offer insights into the availability of specific components and may provide options for ordering directly from the source, ensuring you receive authentic and high-quality replacements.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. Implementing a consistent maintenance routine not only extends the lifespan of your tools but also enhances their performance. Here are some essential practices to keep in mind.

Regular Inspection

- Check for wear and tear on all components.

- Look for any signs of leakage or corrosion.

- Inspect electrical connections for damage.

Proper Cleaning

- Clean the exterior surfaces regularly to prevent dust buildup.

- Remove debris from filters and air intakes.

- Use appropriate cleaners to avoid damaging surfaces.

Step-by-Step Repair Process

This section outlines a systematic approach to fixing common issues encountered with your equipment. By following these sequential steps, you can ensure a thorough and effective resolution to any problems that may arise.

Preparation

Before starting the repair, gather all necessary tools and materials. Ensure that the workspace is clean and organized, allowing for efficient workflow. Having a clear understanding of the components involved will significantly enhance the repair process.

Repair Steps

| Step | Description |

|---|---|

| 1 | Disconnect power source to ensure safety. |

| 2 | Inspect the unit for visible damage or wear. |

| 3 | Carefully disassemble components as needed. |

| 4 | Replace or repair any faulty parts identified. |

| 5 | Reassemble the unit and double-check all connections. |

| 6 | Reconnect the power source and test functionality. |

Following these steps will guide you through an effective repair, ensuring your equipment functions optimally once again.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is crucial to prevent injuries and damage. Adopting proper precautions can make the process more efficient and secure for everyone involved.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Disconnect power sources before beginning any repair work.

- Keep your workspace organized to minimize hazards.

Handling Tools and Equipment

- Use the right tools for each task to avoid accidents.

- Inspect tools regularly for wear and damage.

- Store tools safely when not in use to prevent tripping hazards.

Comparing TL1002 with Other Models

This section explores the differences and similarities between a specific model and its competitors, focusing on performance, features, and user experiences. Understanding these aspects helps potential users make informed choices based on their needs.

Key comparison points include:

- Power output and efficiency

- Weight and portability

- Durability and build quality

- Noise levels during operation

- Ease of maintenance and part availability

When examining various models, users should consider:

- How each model addresses specific tasks

- Consumer reviews and reliability ratings

- Price-to-performance ratio

- Compatibility with accessories and attachments

Ultimately, a thorough analysis of these factors provides insight into which option may be best suited for individual requirements.

User Experiences and Feedback

This section explores the insights and opinions shared by users regarding their encounters with a particular air compressor model. Feedback from individuals who have utilized this equipment provides valuable information on its performance, reliability, and overall satisfaction.

Positive Insights

Many users express enthusiasm about the efficiency and ease of use. The lightweight design and portability allow for convenient transportation, making it suitable for various tasks. Users appreciate the quick setup and ability to operate multiple tools effectively, enhancing productivity.

Areas for Improvement

While most feedback is favorable, some individuals highlight the need for improved durability. Concerns regarding specific components failing under heavy usage have been noted, prompting suggestions for better materials or design adjustments to increase longevity.

Resources for Further Learning

Expanding your knowledge in maintenance and repair can greatly enhance your skills and understanding. This section provides various materials and references that will assist you in mastering the intricacies of tools and equipment.

Online Tutorials and Guides

Numerous platforms offer comprehensive tutorials that cover everything from basic operations to advanced techniques. Websites such as YouTube feature experts sharing step-by-step processes, ensuring you grasp essential concepts effectively.

Books and Manuals

Consider investing in specialized literature that delves into technical specifications and maintenance practices. Manuals from manufacturers often provide the ultimate insights, while general repair books can broaden your overall knowledge.