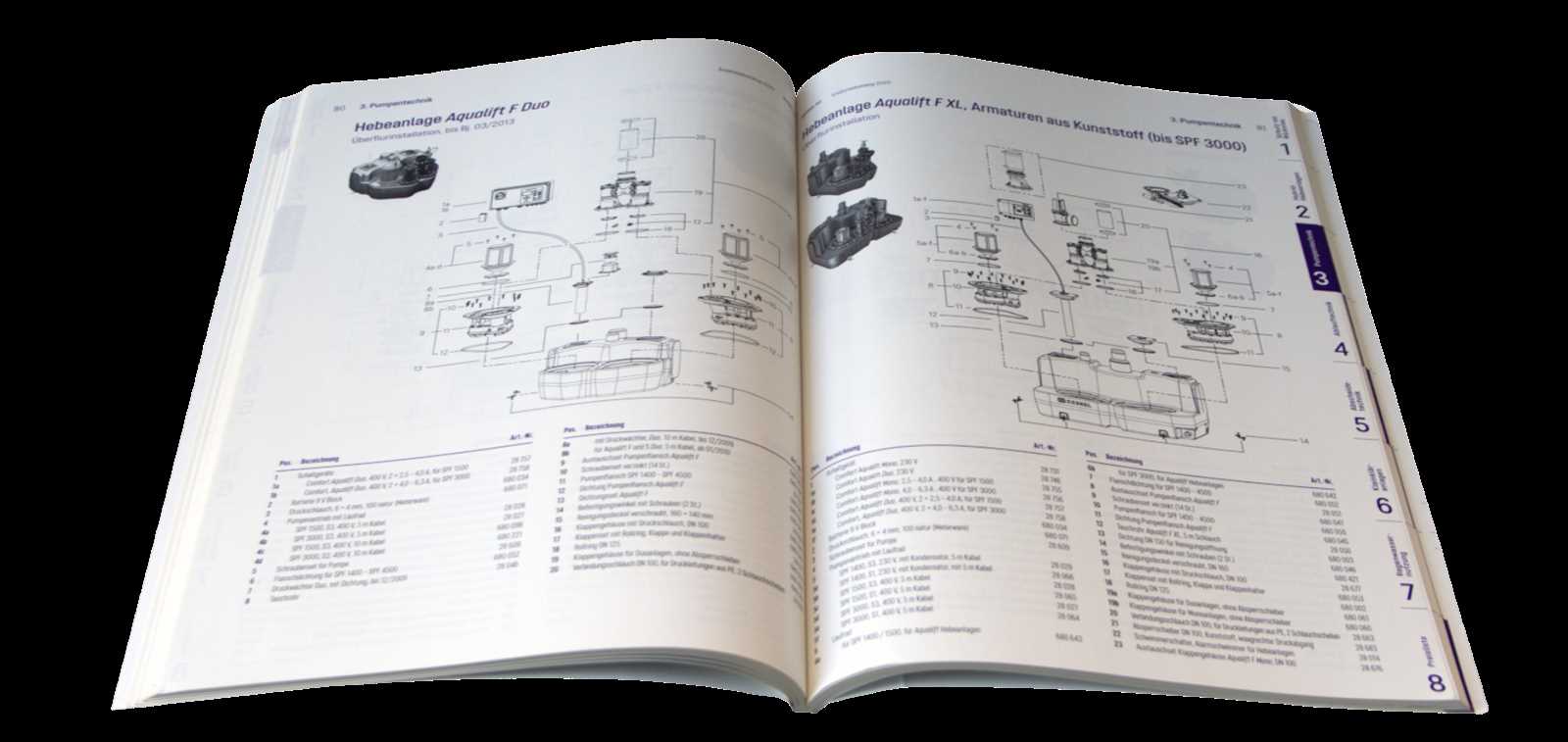

Understanding the internal structure and connections within a vehicle is essential for ensuring efficient maintenance and troubleshooting. The intricate layout of various elements under the hood can be overwhelming, especially for those unfamiliar with the system’s complexities. A clear representation of these interconnected pieces helps in identifying potential issues and planning repairs.

By delving into the arrangement of different mechanisms, you gain valuable insights into how the system operates as a whole. These overviews not only simplify technical procedures but also enhance the overall efficiency of repair work. In this section, we will explore how to interpret detailed schematics to make sense of the key elements involved.

From connectors to electrical pathways, knowing where each component is situated and how they work together is vital. With this knowledge, even complex systems can become manageable, making repairs faster and more reliable. Let’s examine the key areas and how they interact to form a cohesive and functional system.

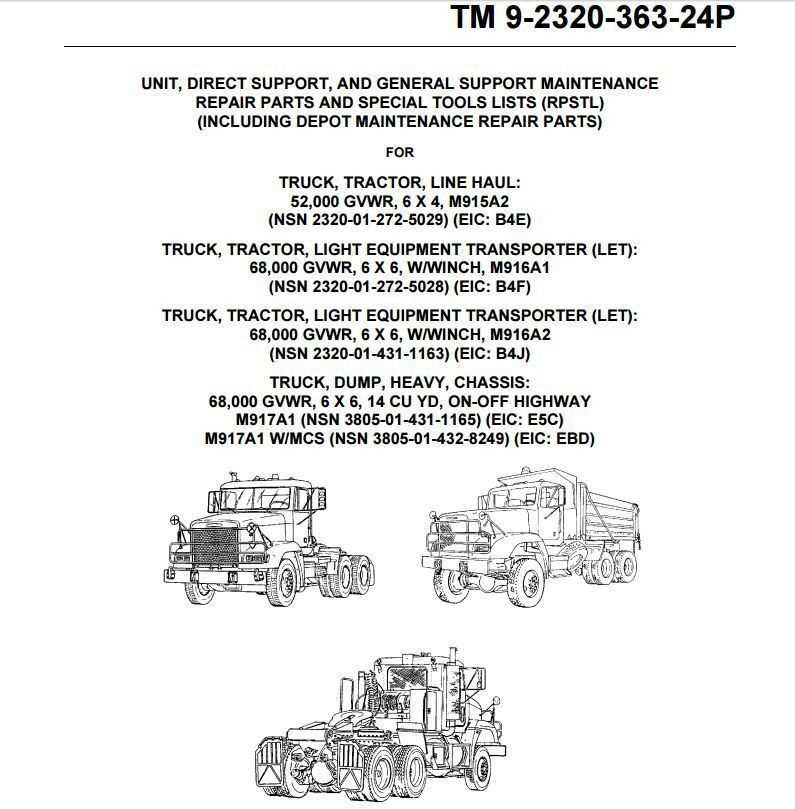

Understanding the Structure of Freightliner Trucks

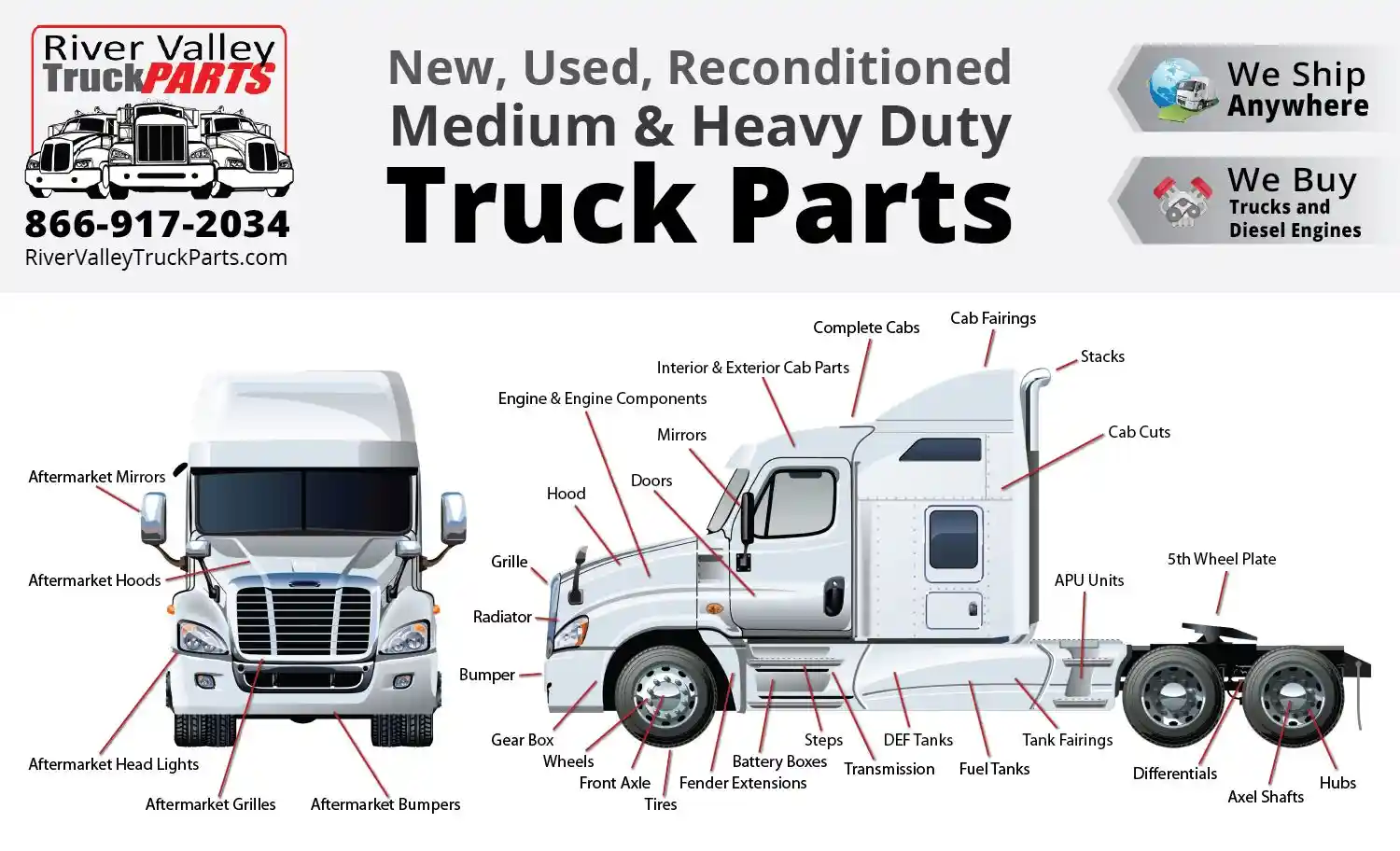

The architecture of large transport vehicles is a complex system composed of numerous key elements working together to ensure functionality and durability. These vehicles are designed for heavy loads and long-distance travel, which requires a thoughtful approach to their overall construction. Each component plays a vital role in maintaining the stability, safety, and efficiency of the truck.

Main Structural Components

At the heart of these trucks is the robust chassis, which serves as the foundation for all other elements. The frame provides strength and support, allowing the vehicle to handle immense weight. Additionally, a sophisticated suspension system ensures a smooth ride, even when carrying heavy cargo.

Power and Control Systems

Power is delivered through an engine designed for high-performance under demanding conditions. Along with the engine, the transmission and braking systems are integral to controlling the vehicle, offering precision and reliability when navigating various terrains.

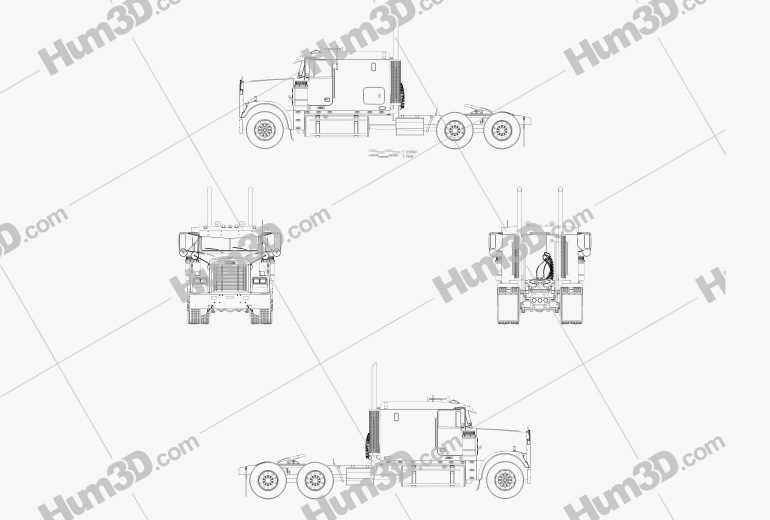

Key Components of the FLD 120 Model

This vehicle is renowned for its durable structure and efficient functionality. Various elements are carefully designed to ensure reliable performance on the road. Each part plays a vital role in maintaining the overall efficiency of the truck.

Engine and Filtration System

One of the core aspects of this model is its powerful engine, supported by high-quality filtration systems. These systems, including oil and fuel filters, are essential for maintaining clean internal operations and ensuring smooth engine function. By preventing contaminants from entering the engine, these filters significantly enhance the truck’s longevity.

- Engine Oil Filter

- Fuel Filter

- Air Filter

Suspension and Steering

The suspension and steering components ensure a comfortable and controlled driving experience. Shock absorbers and the steering system are designed to

Exploring Engine System Diagrams

Understanding how various components of a vehicle’s motor system work together is crucial for maintenance and troubleshooting. These illustrations provide insight into the intricate connections and key mechanisms that drive functionality. By examining each element, users can gain a clear view of how power is generated and distributed within the system.

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Injector | Delivers fuel into the combustion chamber at the precise moment needed for ignition. | ||||||||||||

| Turbocharger | Increases engine power by forcing more air into the combustion chamber, enhancing efficiency. | ||||||||||||

| Cooling System | Maintains optimal engine temperature to prevent overheating and ensure smooth operation. | ||||||||||||

| Exhaust Manifold | Collects

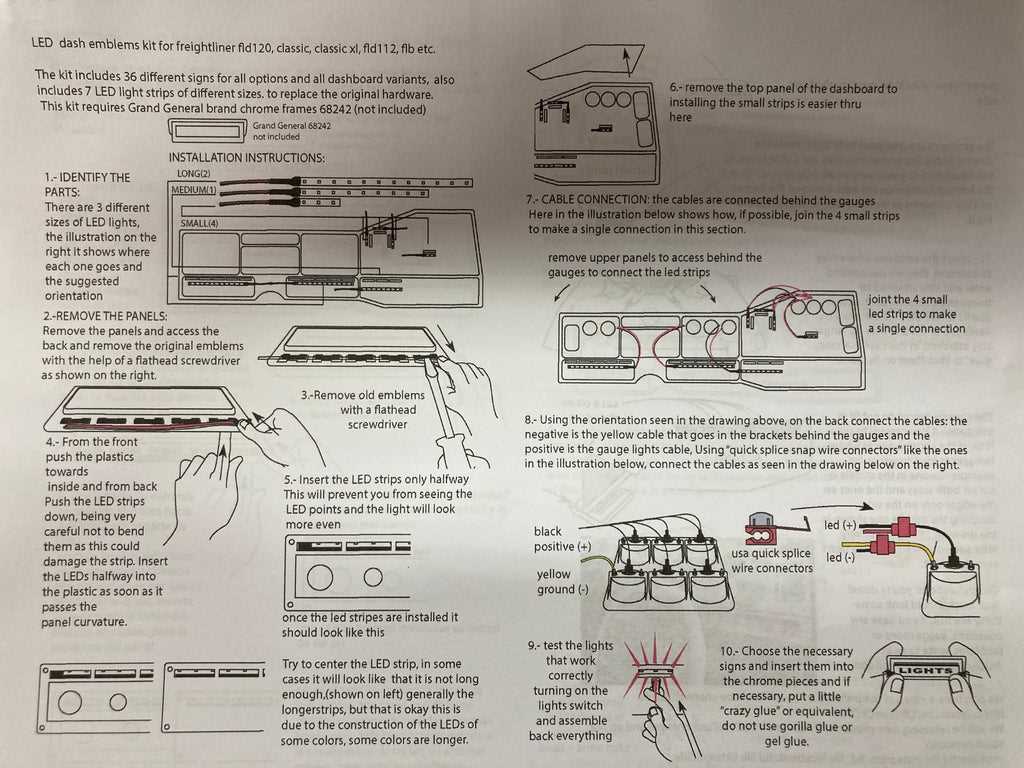

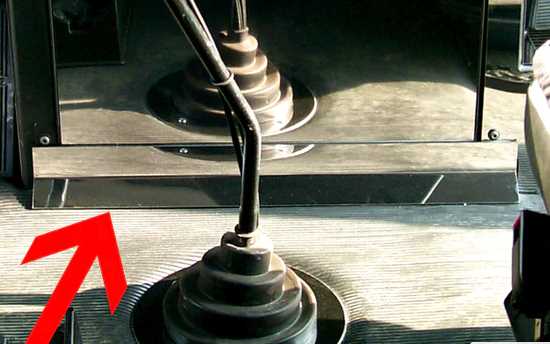

Electrical Layout and Wiring Overview

The electrical system in a heavy-duty vehicle plays a vital role in ensuring the proper functioning of all its components. Understanding how the wiring is organized helps in both routine maintenance and troubleshooting, as it highlights key areas where connections are critical. This overview provides a structured look at the various circuits and how they are integrated into the overall design of the vehicle. Main Electrical Components

At the core of the system are several essential components that manage power distribution and control. These elements are interconnected through wiring harnesses, relays, and fuses. Each element has a specific function within the electrical system.

Wiring Structure and Pathways

The wiring in the vehicle is designed with precision, ensuring that power is delivered efficiently to various systems. The wires are bundled into harnesses, which reduce clutter and protect them from damage. Key areas to focus on include:

Brake System Configuration GuideThe brake system plays a crucial role in ensuring the safety and performance of any heavy-duty vehicle. Understanding how the various components work together can help maintain optimal efficiency and avoid potential failures. This guide outlines the key elements of the braking system, explaining their functions and configurations.

Proper configuration and regular maintenance of these components are essential for ensuring the system functions smoothly under different driving conditions. Cabin Design and Interior FeaturesThe design of a vehicle’s interior plays a crucial role in ensuring comfort, functionality, and an overall enjoyable driving experience. This section explores the various elements that contribute to an efficient and aesthetically pleasing cabin, emphasizing the thoughtful arrangement and selection of materials that enhance the driver’s and passengers’ experience. Comfort and Ergonomics

Comfort is paramount in any vehicle, particularly for long journeys. The following features contribute significantly to a pleasant driving environment:

Technology and Connectivity

Modern vehicles incorporate various technologies that enhance usability and entertainment:

Fuel System and Efficiency Insights

The performance and longevity of any heavy-duty vehicle significantly depend on the efficiency of its fuel delivery system. Understanding how this essential network operates is crucial for maximizing output and minimizing consumption. A well-maintained fuel mechanism not only ensures optimal power but also contributes to reducing emissions and lowering operational costs. Components within the fuel assembly play a vital role in regulating flow, pressure, and filtration. Filters are essential in preventing contaminants from reaching the engine, thus enhancing its performance and lifespan. Regular replacement of these filters is necessary to maintain fluidity and efficiency. Additionally, the pump is responsible for transporting the fuel from the tank to the engine, ensuring a steady supply under varying conditions. A malfunctioning pump can lead to insufficient fuel delivery, negatively impacting performance. Moreover, injectors must be monitored and serviced to ensure they are atomizing fuel correctly, promoting optimal combustion. This process not only enhances power output but also improves fuel economy. The interplay between these components determines overall efficiency, making it imperative to regularly inspect and maintain the entire fuel system. Suspension and Chassis OverviewThe structural foundation of any heavy-duty vehicle plays a crucial role in its overall performance and stability. Understanding the components that contribute to this system is essential for maintaining optimal handling and comfort during operation. This section delves into the key elements that make up the undercarriage, focusing on their functions and importance in vehicle dynamics. At the heart of the chassis system are several critical components:

In addition to these main components, various accessories and adjustments enhance performance:

Proper maintenance and understanding of these systems can significantly enhance the durability and functionality of the vehicle, ensuring it performs reliably under various conditions. Cooling System Parts and Operation

The cooling mechanism in heavy-duty vehicles is vital for maintaining optimal engine temperature and preventing overheating. This system comprises several key components that work in harmony to circulate coolant, dissipate heat, and ensure efficient operation of the engine. Understanding the function and interrelation of these elements is crucial for effective maintenance and troubleshooting. Key Components of the Cooling Mechanism

The primary elements of this system include the radiator, water pump, thermostat, and hoses. The radiator is responsible for cooling the heated coolant that has circulated through the engine. The water pump propels the coolant throughout the system, ensuring a continuous flow. The thermostat regulates the temperature by controlling coolant flow based on the engine’s heat level. Hoses connect these components, allowing the fluid to move efficiently. Operational Principles

The cooling system operates by circulating coolant from the engine to the radiator, where it dissipates heat. As the engine runs, the coolant absorbs heat and becomes hot, then travels to the radiator, where airflow cools it before it returns to the engine. This cycle continues, preventing the engine from overheating and maintaining optimal performance. Transmission Components and FunctionalityThe transmission system in heavy-duty vehicles plays a crucial role in managing power transfer from the engine to the wheels. It consists of various elements that work together to ensure smooth gear shifts and optimal performance under different driving conditions. Understanding the key components of this system helps in diagnosing issues and performing effective maintenance. Below are the primary elements involved:

Each component plays a vital role in the functionality of the transmission system. Proper understanding and maintenance of these parts can significantly impact vehicle performance and longevity. Steering Mechanism and Controls ExplainedThe steering mechanism plays a pivotal role in the overall functionality and safety of any vehicle. It ensures precise maneuverability, enabling the driver to navigate through various terrains and conditions effectively. Understanding this system, including its components and how they work together, is essential for maintaining optimal performance and safety. Key Components of the Steering SystemThis system comprises several critical parts that facilitate the control of the vehicle’s direction. Each component has a specific function that contributes to the overall efficacy of steering. Here’s a brief overview of the primary elements:

Understanding Steering ControlsSteering controls encompass the various inputs provided by the driver to guide the vehicle. These controls can range from manual systems to advanced electronic steering technologies that enhance response and precision. Familiarity with these controls can significantly improve driving experience and vehicle handling. |