In the realm of machinery and equipment, having a clear understanding of the various elements that constitute a device is essential. This section aims to provide insights into visual representations that help users grasp the relationships and functionalities of different components within a system. Such illustrations serve as valuable resources for both maintenance and assembly tasks.

By examining these visual aids, individuals can enhance their knowledge of how each part interacts and contributes to the overall performance of the apparatus. The clarity offered by these representations simplifies the process of troubleshooting and facilitates effective repairs, ensuring that users can keep their devices in optimal condition.

Moreover, familiarity with these depictions fosters confidence among users, allowing them to approach their projects with a greater understanding. This comprehensive approach ultimately leads to more efficient usage and longevity of the equipment in question.

Tanaka Parts Diagram Overview

This section provides an insightful look into the visual representation of various components within specific machinery. Such illustrations play a crucial role in understanding the organization and functionality of individual elements, aiding users in effective maintenance and repairs.

These visual aids typically include detailed layouts that highlight different sections, enabling easier identification of parts and their connections. Familiarity with these representations can significantly enhance the efficiency of troubleshooting processes.

| Component | Description |

|---|---|

| Element A | Key feature that performs a specific function. |

| Element B | Supportive component that aids in the operation. |

| Element C | Essential part ensuring seamless integration with others. |

Understanding Tanaka Equipment Components

The comprehension of various elements in outdoor machinery is essential for optimal functionality and maintenance. By familiarizing oneself with these components, users can enhance their operational skills and ensure the longevity of the equipment. Each piece plays a crucial role in the overall performance, making it vital to grasp their significance.

Key Elements of Machinery

Numerous constituents contribute to the effective operation of outdoor devices. These elements include the engine, transmission, and cutting mechanisms, among others. Each component interacts harmoniously, resulting in seamless performance. Recognizing how these parts work together can aid users in troubleshooting and repairs.

Maintenance and Care

Regular upkeep of each element is paramount to prolonging the lifespan of the equipment. Proper cleaning, lubrication, and inspection can prevent malfunctions and enhance efficiency. Understanding the role of each constituent allows for more effective maintenance practices, ensuring that the machinery remains in excellent condition.

Benefits of Using Parts Diagrams

Utilizing visual representations of components provides numerous advantages for users seeking to understand intricate systems. These illustrations serve as valuable resources for identifying individual elements, streamlining the assembly process, and enhancing overall comprehension of mechanical structures.

One of the primary benefits is the simplification of complex assemblies. By visually breaking down each element, users can easily locate and recognize the parts they need to work with, reducing confusion and errors. This clarity leads to increased efficiency during repairs or maintenance.

Moreover, these visual aids facilitate effective communication among users, technicians, and manufacturers. By using a standardized method to depict components, all parties can quickly grasp the necessary information, ensuring a smoother workflow and minimizing misunderstandings.

Additionally, these resources can serve as educational tools, helping users to gain a deeper understanding of how various elements interact within a system. This knowledge not only empowers individuals to troubleshoot issues independently but also fosters a greater appreciation for the intricacies of mechanical design.

In summary, leveraging visual representations of components enhances user experience, promotes efficient communication, and encourages learning, making them indispensable tools for anyone engaged in technical fields.

Common Tanaka Models and Diagrams

This section provides an overview of frequently encountered models and their corresponding illustrations, essential for understanding the assembly and functioning of various tools. These visuals serve as a valuable resource for users, enabling them to identify components and comprehend the overall structure of the devices.

Popular Models Overview

Several widely recognized variants are commonly utilized in different applications. These models cater to various needs, from light-duty tasks to more robust functionalities. Users can easily refer to the accompanying visuals to familiarize themselves with the unique features and specifications that distinguish each version.

Understanding Visual References

Illustrations serve as practical aids, offering insights into the arrangement and relationship between various elements. By consulting these visual references, individuals can enhance their knowledge and improve their handling of the equipment, ensuring better maintenance and operation.

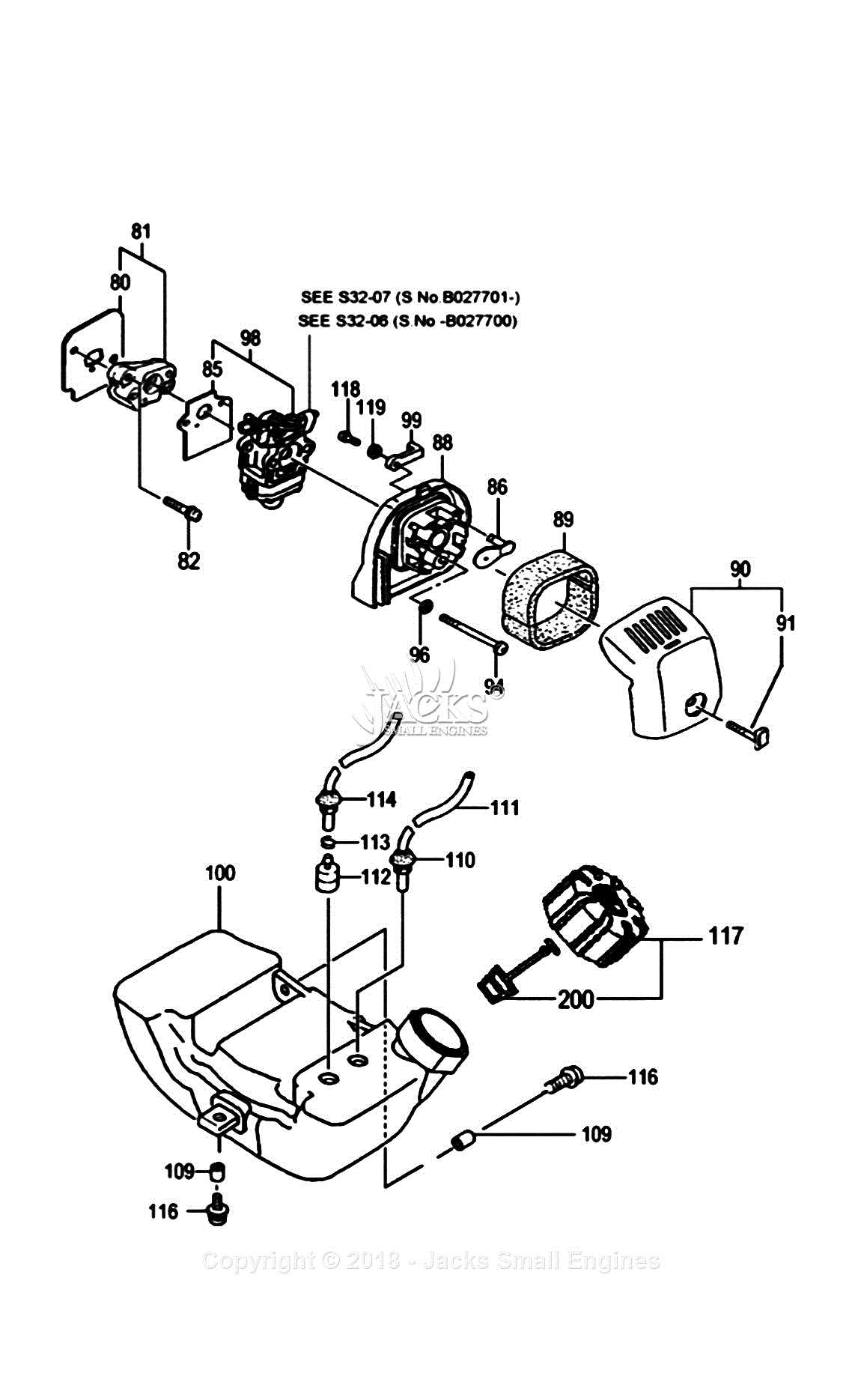

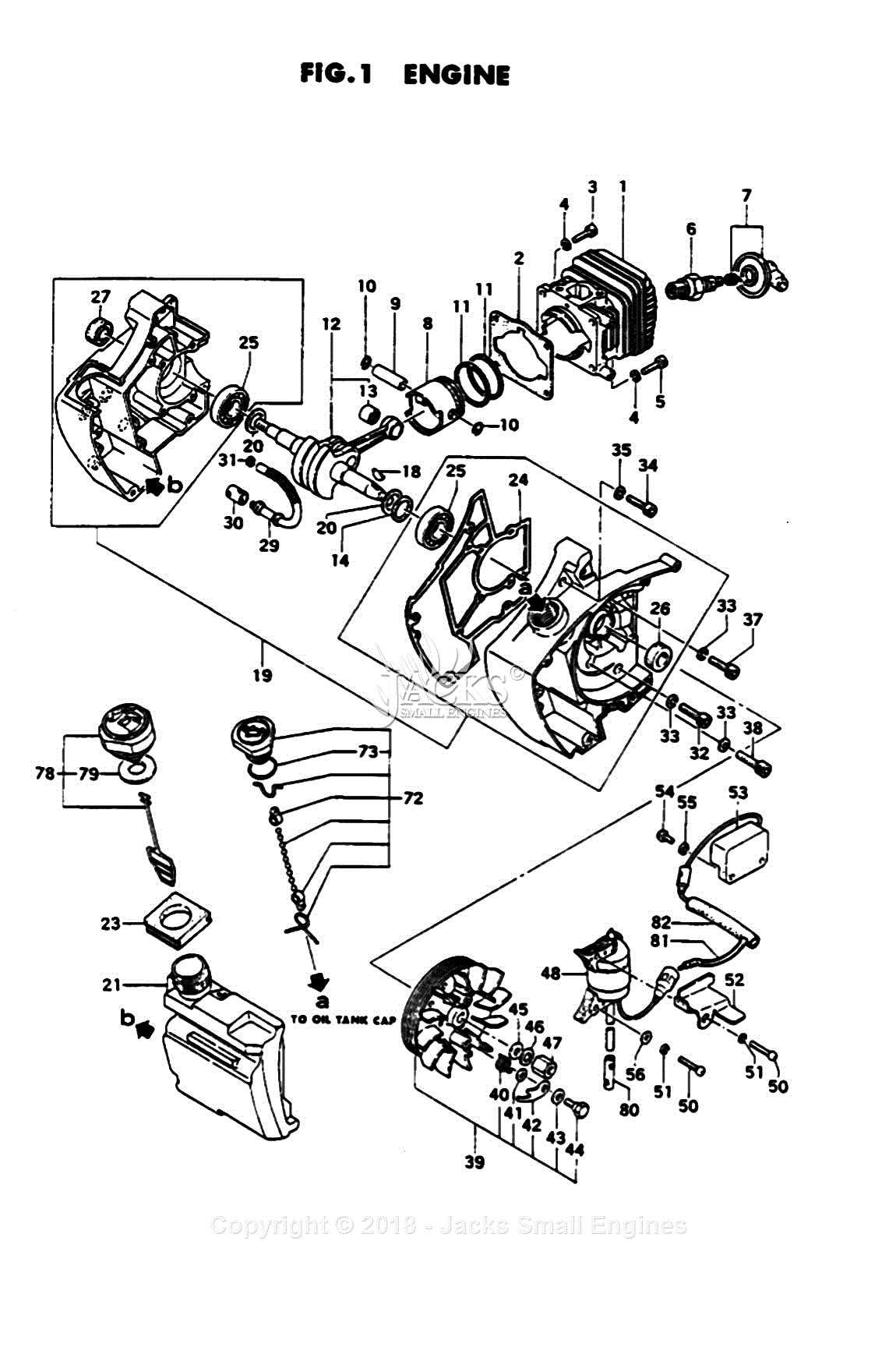

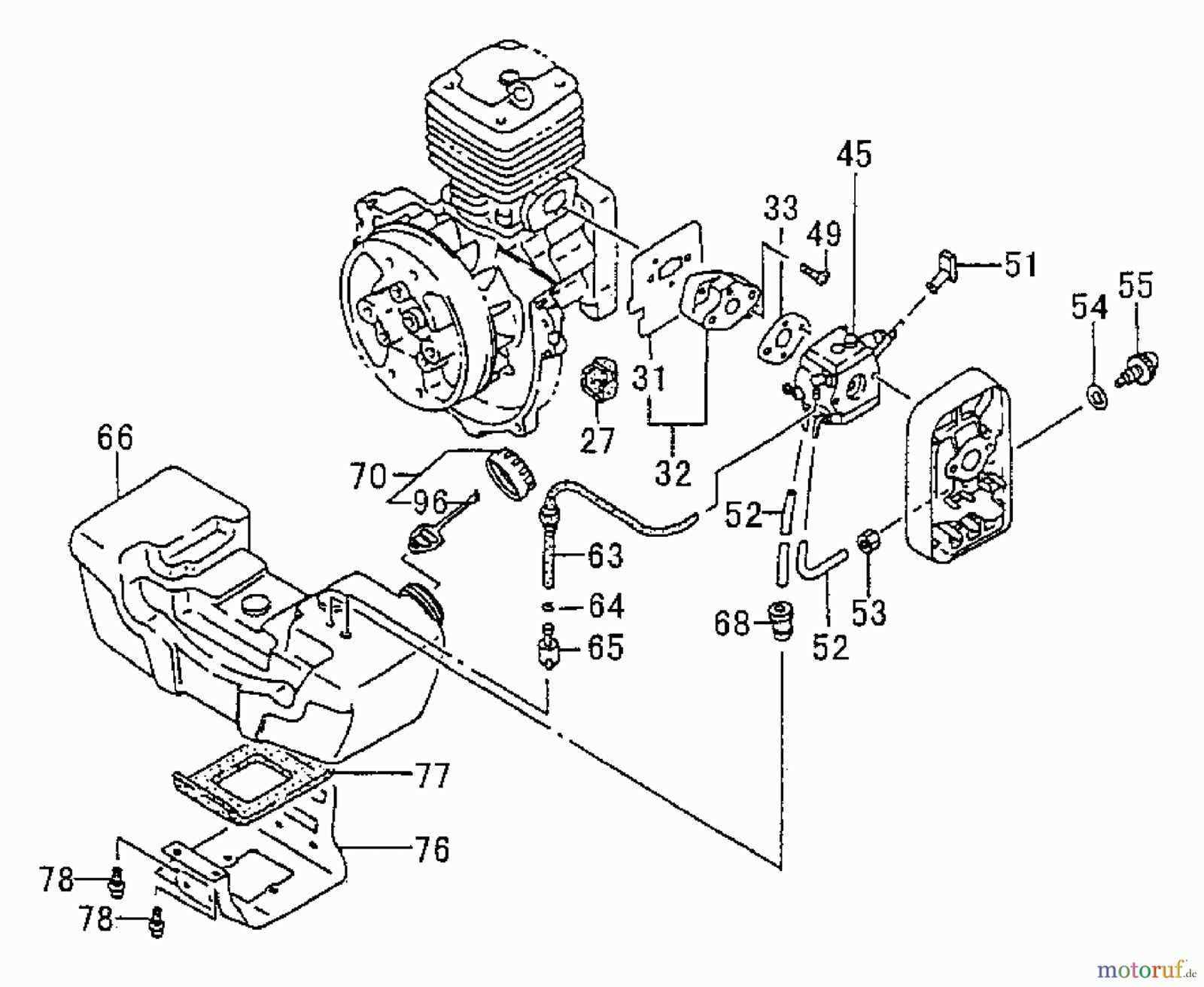

How to Read a Parts Diagram

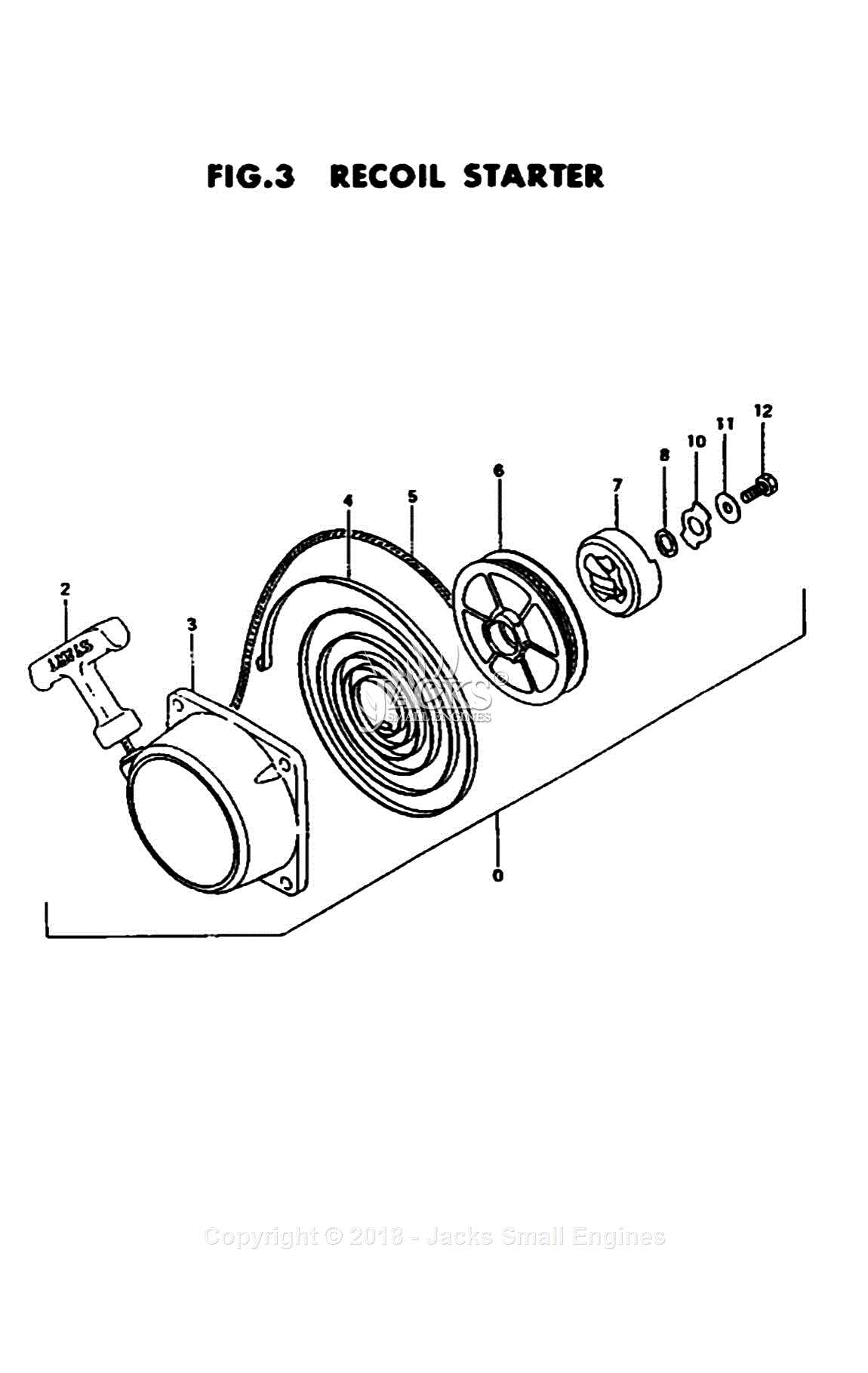

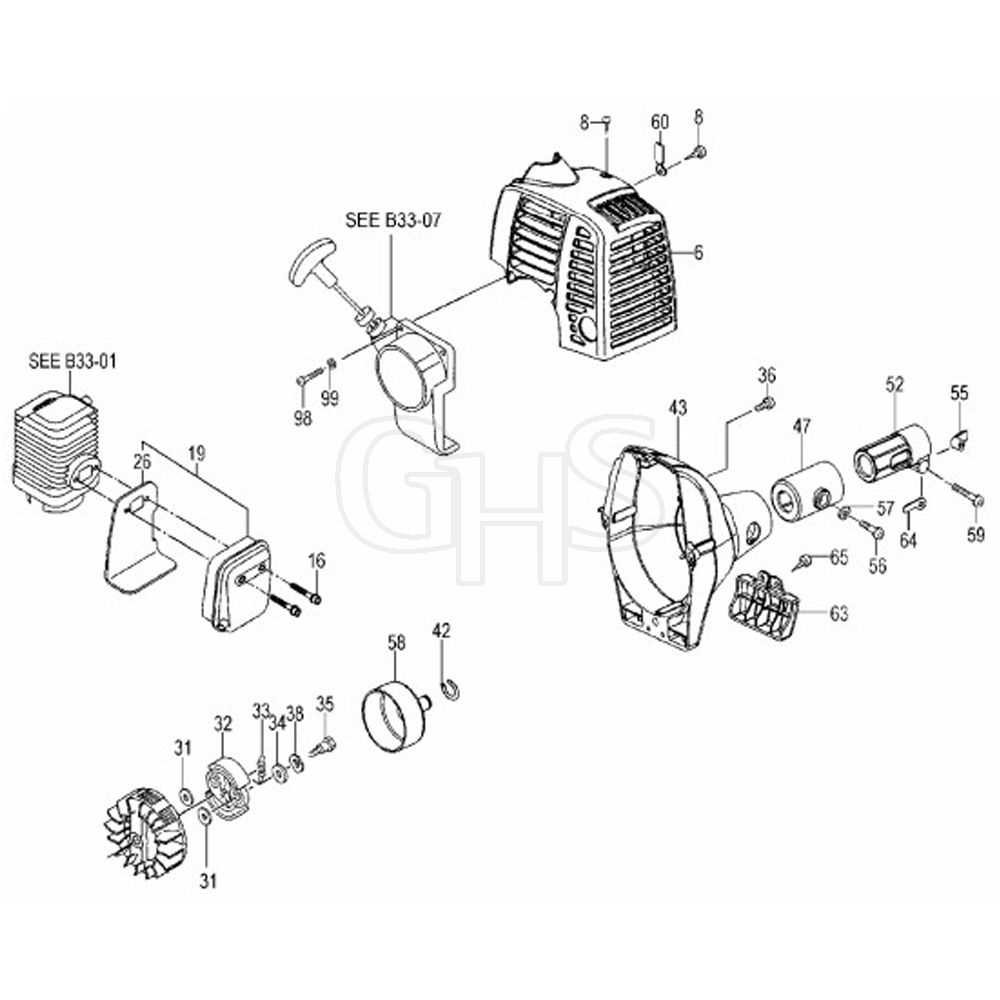

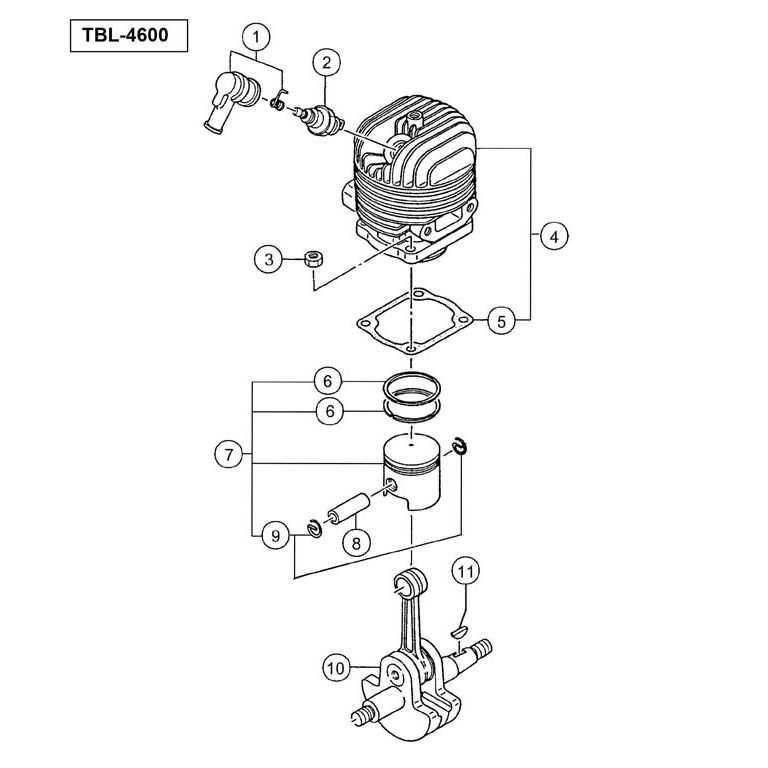

Understanding a visual representation of components is essential for efficient maintenance and repairs. These illustrations serve as valuable guides, enabling users to identify individual elements and their relationships within a system. By grasping how to interpret these images, one can streamline troubleshooting and enhance overall efficiency.

Initially, focus on familiarizing yourself with the layout of the illustration. Notice how the various segments are organized, often grouped by functionality or location within the device. This arrangement can provide insights into how different pieces work together. Additionally, pay attention to the accompanying labels and numbers, as these will usually correspond to a reference list or key that describes each item in detail.

As you delve deeper, recognize that colors and symbols may convey specific meanings. For instance, different hues might indicate whether a component is critical, optional, or in need of special attention. Understanding these visual cues can significantly aid in making informed decisions during maintenance tasks.

Finally, don’t hesitate to consult supplementary materials, such as manuals or online resources, that can offer further context and clarification. Combining the visual representation with additional information will enhance your comprehension and ensure a thorough understanding of the system.

Identifying Replacement Parts Easily

Finding suitable components for machinery can be a straightforward process when you have the right resources at your disposal. With the appropriate tools and information, identifying the necessary replacements can significantly enhance efficiency and ensure proper functionality. This section will explore effective strategies for easily locating the required elements.

Utilizing Visual References

One of the most effective methods for recognizing essential components is through visual references. These aids provide a clear representation of various elements, making it simpler to identify what is needed. Here are some tips for using visual resources:

- Refer to diagrams that showcase the structure of the device.

- Utilize labeled images to pinpoint specific components.

- Keep visual guides handy for quick consultations during maintenance.

Cross-Referencing with Manufacturer Information

Another reliable approach is to cross-reference with official documentation from the manufacturer. This ensures that you are looking for the correct elements that meet the required specifications. Consider the following:

- Consult user manuals that provide detailed descriptions of each component.

- Visit the manufacturer’s website for downloadable resources.

- Join forums or communities where others share insights and experiences regarding component identification.

Maintenance Tips for Tanaka Equipment

Proper upkeep is essential for ensuring the longevity and optimal performance of outdoor machinery. Regular care can prevent potential issues and enhance efficiency, making tasks easier and more enjoyable. Here are some vital suggestions to consider for maintaining your equipment.

Regular Cleaning

Keeping the machinery clean is crucial for preventing the buildup of dirt and debris, which can lead to malfunctions. Follow these steps:

- Use a soft brush or cloth to remove loose dirt.

- Wipe down surfaces with a damp cloth after each use.

- Inspect and clean air filters regularly to maintain airflow.

Routine Inspections

Conducting frequent inspections can help identify issues before they escalate. Pay attention to the following:

- Check for any signs of wear or damage on components.

- Ensure all fasteners are secure and tight.

- Examine fuel lines and connections for leaks or cracks.

By following these maintenance practices, you can prolong the life of your machinery and ensure it operates smoothly for years to come.

Where to Find Parts Diagrams Online

Locating visual representations of components can significantly aid in understanding assembly and maintenance procedures. These illustrations provide valuable insights into the specific elements of various devices, making repairs and replacements more straightforward. Online resources offer a range of platforms to access these essential visuals.

Here are some useful sources for acquiring visual guides:

| Resource | Description |

|---|---|

| Manufacturer Websites | Official sites often host detailed visuals, manuals, and resources for their products. |

| Online Retailers | E-commerce platforms frequently provide diagrams alongside product listings, assisting customers in identifying parts. |

| Repair Forums | Community-driven platforms can be treasure troves of shared resources, including visuals from experienced users. |

| Instructional Videos | Platforms like YouTube often feature tutorials that showcase components in action, sometimes including visuals as well. |

| Parts Distributors | Companies specializing in components usually provide diagrams to help customers locate and order the correct items. |

Importance of Accurate Parts Identification

Accurate identification of components is essential in various fields, ensuring smooth operation and maintenance of machinery. Recognizing the correct elements allows for efficient repairs and enhances the overall functionality of devices.

Precision in identifying individual components contributes to minimizing errors during the maintenance process. When the right elements are selected, it reduces the risk of damaging other parts and prolongs the lifespan of the equipment.

Furthermore, effective communication among technicians and service personnel relies heavily on proper identification. Clear understanding of each element ensures that everyone is on the same page, leading to quicker resolutions and improved service quality.

In addition, having accurate information aids in sourcing replacements when necessary. When specific components are identified correctly, it simplifies the procurement process and helps in finding suitable alternatives, ultimately saving time and resources.

Assembly Instructions Using Diagrams

Understanding how to put components together is crucial for achieving effective functionality in any device. Visual aids play a significant role in simplifying the assembly process, providing clear guidance on how individual elements fit together. By following structured illustrations, users can ensure that each piece is correctly positioned, which enhances overall performance.

To begin, gather all necessary components and familiarize yourself with each one through the provided visuals. These illustrations often include labels that indicate the specific location for each item, making it easier to identify where they belong. Pay close attention to any orientation or alignment details, as these factors can significantly affect the final assembly.

When assembling, follow the sequence outlined in the visuals carefully. Start with the foundational elements and gradually build up by adding subsequent pieces as indicated. This methodical approach helps to prevent errors and minimizes the risk of having to disassemble parts later due to incorrect placement.

Additionally, take note of any additional instructions or warnings highlighted in the illustrations. These notes can provide valuable tips on achieving a secure fit or avoiding common pitfalls. By adhering to these guidelines, you can confidently complete the assembly process and ensure that your device operates smoothly.

Frequently Asked Questions on Parts

This section aims to address common inquiries related to components and their functionality. Understanding these elements can enhance the overall experience and facilitate maintenance or replacements when necessary.

What should I consider when selecting components?

When choosing specific elements, it is crucial to evaluate compatibility with existing equipment, quality standards, and performance requirements. Additionally, consulting user manuals or manufacturer guidelines can provide valuable insights.

How can I ensure proper installation?

To guarantee correct installation, follow the provided instructions carefully. Utilizing the right tools and ensuring a clean working environment can also prevent potential issues. If uncertainty arises, seeking assistance from professionals or knowledgeable peers is advisable.

Comparing Tanaka Models’ Parts Layouts

In the realm of various machinery designs, understanding the configuration of components is crucial for effective maintenance and functionality. Each model presents unique arrangements, showcasing how different elements interact and contribute to the overall operation. This analysis highlights the similarities and differences found in these layouts, providing insights into their structural effectiveness.

Key Variations Among Models

The distinctions in component placements across models can significantly impact performance. For instance, certain configurations may enhance accessibility for repairs, while others prioritize compactness for improved efficiency. Identifying these key variations allows users to choose the most suitable design based on their specific requirements.

Common Features in Layouts

Despite the differences, several designs share common characteristics that facilitate ease of use and maintenance. Standardized elements across models simplify the understanding of their functions, allowing users to leverage their knowledge across different versions. Recognizing these shared features helps in mastering the operation and care of these machines.

Contacting Support for Parts Assistance

Reaching out for help regarding component support can significantly enhance the maintenance and performance of your equipment. When encountering issues or requiring replacements, it’s essential to understand the proper channels to ensure efficient assistance.

Methods of Communication

There are various ways to contact support for guidance on necessary replacements. Consider the following options:

- Phone support for immediate assistance.

- Email inquiries for detailed questions.

- Live chat options on the official website for quick responses.

Information to Provide

When contacting support, it’s crucial to have certain details ready to facilitate the process. This can include:

| Information Type | Description |

|---|---|

| Model Number | The specific identifier of your device. |

| Issue Description | A brief outline of the problem encountered. |

| Purchase Date | The date the device was acquired, if available. |

By preparing this information, you can streamline the support process and receive the assistance needed more efficiently.