When navigating the intricate world of marine propulsion systems, one must recognize the significance of the mechanisms that facilitate seamless gear transitions. These essential components ensure optimal performance and enhance the overall efficiency of watercraft. A thorough understanding of these elements not only aids in troubleshooting but also empowers enthusiasts and professionals alike to maintain their vessels with confidence.

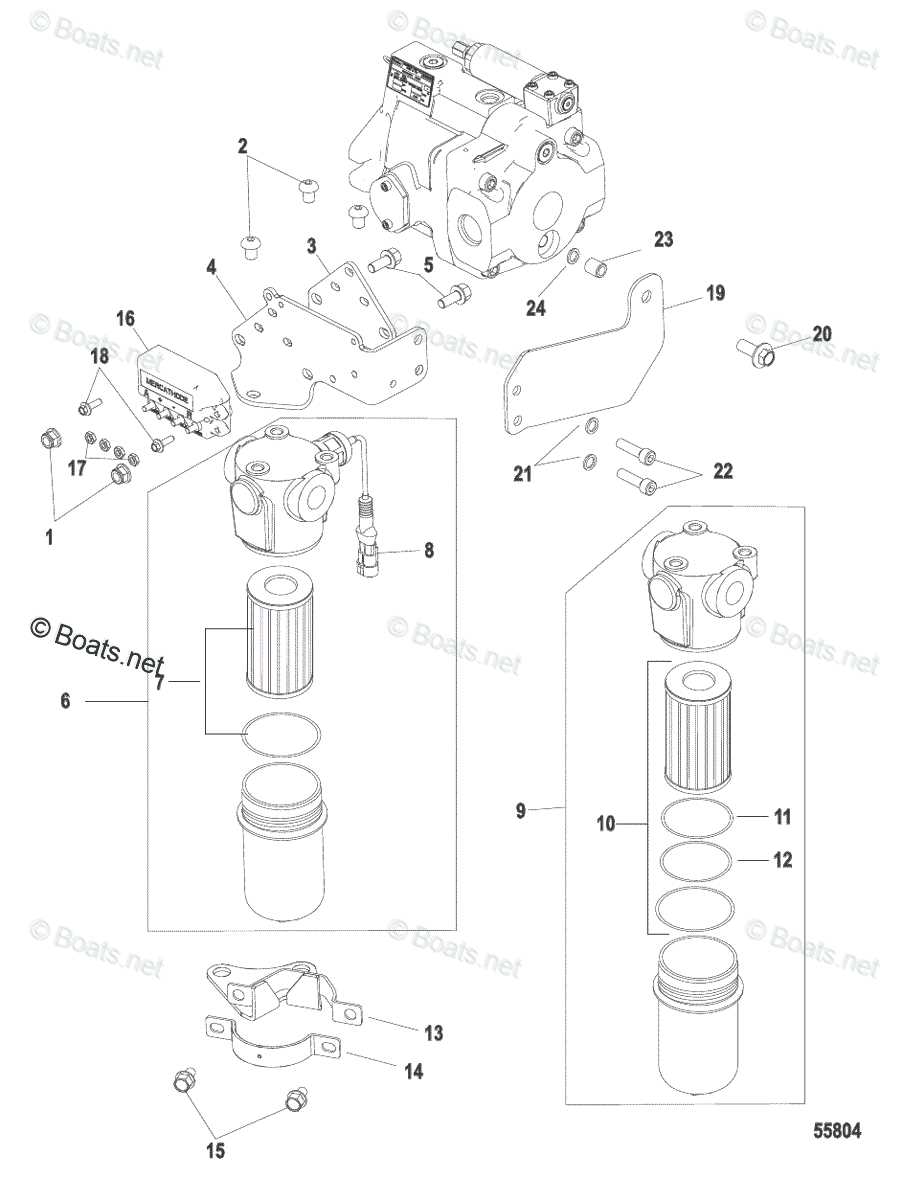

Visual aids play a crucial role in comprehending the arrangement and functionality of these intricate assemblies. By examining detailed representations, one can discern the various elements at play, their interconnections, and how they contribute to the overall operation. This insight is invaluable for anyone looking to enhance their knowledge or engage in maintenance tasks.

Moreover, familiarity with these critical components can prevent costly repairs and downtime, allowing for a more enjoyable experience on the water. Whether you are a seasoned mariner or a newcomer to the realm of aquatic machinery, understanding the intricacies of these systems is an essential aspect of responsible vessel ownership.

Understanding Mercruiser 3000 Shifter Mechanism

The operation of the control mechanism in marine propulsion systems plays a critical role in ensuring smooth transitions between various speeds and directions. This section delves into the intricate workings of this essential component, focusing on how it facilitates seamless engagement and disengagement for optimal performance.

Components and Functionality

Key elements of this system include levers, cables, and connectors, all working in unison to translate user input into mechanical motion. Understanding each component’s role provides insights into how they contribute to the overall efficiency and responsiveness of the vessel.

Tuning and Maintenance

Regular inspection and fine-tuning of the mechanism can significantly enhance functionality. Proper care not only extends the lifespan of the system but also ensures that the operator maintains ultimate control over the vessel, promoting a safer and more enjoyable experience on the water.

Key Components of Shifter Assembly

The assembly responsible for gear selection plays a crucial role in the operation of any marine engine. Understanding its essential elements can enhance maintenance and performance, ensuring smooth transitions between different modes of operation.

- Lever: The primary control used by the operator to select different gears.

- Linkage: The mechanism that connects the lever to the transmission, enabling movement.

- Mounting Bracket: Provides stability and secure attachment to the engine or control panel.

- Adjustment Screws: Allow fine-tuning of the lever’s position for optimal performance.

- Detent Mechanism: Ensures that the lever remains in the selected gear and prevents accidental shifts.

Each of these elements contributes to the overall efficiency and reliability of the assembly, making regular inspection and maintenance essential for longevity.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the assembly and maintenance of mechanical systems. They serve as essential guides, providing users with a visual representation that enhances understanding and ensures correct installation. Without these reliable references, errors may arise, leading to inefficiencies and potential hazards.

Facilitating Troubleshooting

Having clear visual aids simplifies the process of diagnosing issues. When components are represented accurately, identifying malfunctions becomes more straightforward, allowing for quicker resolutions and minimizing downtime.

Enhancing Safety

Correct visual references contribute significantly to operational safety. They help technicians understand the relationships between various elements, reducing the risk of accidents and ensuring that machinery operates within safe parameters. Ultimately, investing in quality illustrations is vital for effective maintenance and safe operation.

Common Issues with Shifter Parts

Understanding the common challenges that arise with control mechanisms is essential for maintaining optimal performance. Various components can wear out or become misaligned, leading to difficulties in operation. Identifying these problems early can save time and prevent further damage.

- Wear and Tear: Over time, frequent use can lead to degradation of materials, causing unreliable function.

- Misalignment: Incorrect installation or adjustments may result in components not aligning properly, making it hard to engage or disengage effectively.

- Corrosion: Exposure to moisture and other elements can lead to rust and corrosion, hindering the smooth operation of the mechanism.

- Loose Connections: Fasteners and joints may become loose over time, resulting in slack and imprecise control.

Regular inspection and maintenance are crucial in addressing these issues before they escalate. Keeping components clean and properly lubricated can enhance their longevity and functionality.

- Inspect regularly for any signs of wear.

- Tighten loose connections as needed.

- Replace corroded elements promptly to avoid further issues.

By being proactive and attentive, users can ensure a more reliable and enjoyable experience with their equipment.

How to Read Shifter Diagrams

Understanding technical illustrations related to transmission components can be crucial for effective maintenance and troubleshooting. These visuals serve as a guide, offering insight into the arrangement and function of various elements involved in gear operation.

Here are some key steps to effectively interpret these illustrations:

- Familiarize Yourself with Symbols:

- Different shapes represent various components, such as levers, cables, and gears.

- Arrows often indicate movement direction or flow of energy.

- Identify Key Components:

- Locate the main elements that you will be working with.

- Understand how each part interacts with others within the system.

- Follow the Flow:

- Trace the connections between components to comprehend their relationships.

- Pay attention to any notes or legends that provide additional context.

- Consult Manufacturer Resources:

- Look for specific documentation that may elaborate on the illustrations.

- Online forums and communities can also offer valuable insights and clarifications.

By systematically analyzing these illustrations, you’ll gain a clearer understanding of the mechanisms at play, leading to more effective repairs and enhancements.

Step-by-Step Shifter Repair Guide

This guide provides a comprehensive approach to restoring the functionality of your control mechanism. By following each step methodically, you can address common issues and enhance performance.

| Step | Description |

|---|---|

| 1 | Inspect the assembly for any visible damage or wear. |

| 2 | Remove any covers to access the internal components. |

| 3 | Clean all parts thoroughly to eliminate dirt and debris. |

| 4 | Check for worn-out pieces that may require replacement. |

| 5 | Lubricate moving parts to ensure smooth operation. |

| 6 | Reassemble the unit carefully, ensuring all components are secured. |

| 7 | Test the mechanism to verify that it functions correctly. |

Maintenance Tips for Shifter Systems

Regular upkeep of control mechanisms is essential for optimal performance and longevity. Implementing consistent maintenance practices can prevent issues and enhance overall functionality.

Routine Inspections

- Check for wear and tear on cables and connectors.

- Inspect for any signs of corrosion or rust.

- Ensure all components are securely fastened.

Lubrication

- Apply suitable lubricants to moving parts to reduce friction.

- Wipe off excess grease to prevent accumulation of debris.

- Re-lubricate at regular intervals as specified by the manufacturer.

Upgrading Mercruiser Shifter Components

Enhancing the control mechanisms of your marine vessel can significantly improve performance and responsiveness on the water. This process often involves replacing or upgrading various elements within the control system to achieve smoother operation and greater durability. By investing in high-quality components, boaters can enjoy a more reliable and efficient experience during navigation.

When considering upgrades, it’s essential to evaluate the benefits of improved materials and advanced designs that can withstand the rigors of marine environments. Upgraded components not only enhance functionality but also contribute to the overall aesthetic and value of your vessel.

| Component | Benefits | Recommended Upgrades |

|---|---|---|

| Control Levers | Smoother operation, ergonomic design | Aluminum or stainless steel options |

| Cables | Increased durability, reduced friction | High-performance, reinforced cables |

| Mounting Brackets | Enhanced stability, corrosion resistance | Marine-grade materials |

| Linkage Assemblies | Improved responsiveness, precise control | Upgraded bearings and pivot points |

Investing in these enhancements not only optimizes performance but also ensures safety and longevity. Regular maintenance combined with these upgrades can lead to a more enjoyable and efficient boating experience.

Identifying Genuine Parts vs. Counterfeits

In the world of mechanical components, distinguishing authentic elements from imitations is crucial for maintaining performance and safety. Counterfeit items often lack the quality and durability necessary for reliable operation, which can lead to increased maintenance costs and potential failures. Understanding the key characteristics that differentiate genuine products from their counterfeit counterparts can help consumers make informed decisions and ensure the longevity of their machinery.

Key Indicators of Authenticity

When evaluating components, examine the packaging for any discrepancies. Authentic products typically feature high-quality printing, clear labeling, and tamper-evident seals. Additionally, the presence of serial numbers or unique identifiers can serve as a valuable tool for verification. Always purchase from reputable distributors or authorized retailers, as they are more likely to provide legitimate items.

Common Signs of Counterfeits

Counterfeit components often exhibit poor craftsmanship, such as uneven finishes, incorrect dimensions, or inferior materials. If a product is offered at an unusually low price, it may be a red flag. It’s essential to research specifications and compare them to original items, as genuine elements will consistently meet industry standards and specifications. When in doubt, consult with professionals or manufacturer resources to confirm authenticity.

Common Misconceptions About Shifter Functionality

Understanding the mechanics behind control systems is crucial for effective operation. However, many users hold incorrect beliefs about how these mechanisms work, which can lead to confusion and operational issues. This section aims to clarify some of the prevalent myths surrounding these systems.

Myth 1: All Control Systems Operate Similarly

One common misconception is that all control mechanisms function in the same manner. In reality, various designs have unique features and operational principles that affect performance and handling.

Myth 2: Wear and Tear Don’t Impact Performance

Another prevalent belief is that regular use does not influence the effectiveness of these systems. However, wear and tear can significantly affect responsiveness and reliability, making maintenance essential.

| Myth | Truth |

|---|---|

| All mechanisms are the same | Each design has specific characteristics |

| Maintenance is unnecessary | Wear impacts performance significantly |

Tools Required for Shifter Repairs

When it comes to addressing issues with the control mechanisms in your vessel, having the right equipment is essential for an efficient and effective repair process. The following tools will help you navigate the task smoothly and ensure that all components are correctly handled.

| Tool | Purpose |

|---|---|

| Socket Set | Used for removing and securing bolts and nuts. |

| Screwdriver Set | Essential for unscrewing and fastening various components. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Wire Cutters | Used for cutting wires cleanly and precisely. |

| Flashlight | Illuminates hard-to-reach areas for better visibility. |

| Cleaning Supplies | Used for maintaining cleanliness of components and work areas. |

Equipped with these tools, you’ll be prepared to tackle any adjustments or replacements that may arise in your system’s control apparatus. Proper preparation is key to achieving a successful outcome.

Where to Find Replacement Parts

When it comes to sourcing components for your marine equipment, understanding the best avenues for procurement is essential. Various resources can help you locate the items you need, whether you’re aiming for OEM quality or aftermarket alternatives.

Online Marketplaces

Websites such as eBay and Amazon offer a wide range of options for purchasing essential components. You can often find new or gently used items at competitive prices. Remember to check seller ratings and reviews to ensure quality.

Local Marine Supply Stores

Visiting a nearby marine supply shop can provide immediate access to a variety of necessary components. Knowledgeable staff can also assist you in identifying the correct items for your specific needs. Networking with other boaters can lead to valuable recommendations.

Resources for DIY Shifter Projects

Embarking on a do-it-yourself venture for transmission mechanisms can be both rewarding and educational. Access to the right tools and information can greatly enhance the experience and ensure successful outcomes. Below are valuable resources to assist you in your journey.

Online Communities

- Forums dedicated to marine mechanics

- Social media groups focused on DIY projects

- Video tutorials on platforms like YouTube

Instructional Materials

- User manuals and technical guides

- Books covering marine engineering basics

- DIY blogs with step-by-step instructions