In the realm of machinery and equipment, having a clear understanding of the layout and functionality of various elements is crucial. This knowledge not only aids in effective maintenance but also enhances the overall efficiency of the device. Familiarity with how components interact allows users to optimize performance and address issues more effectively.

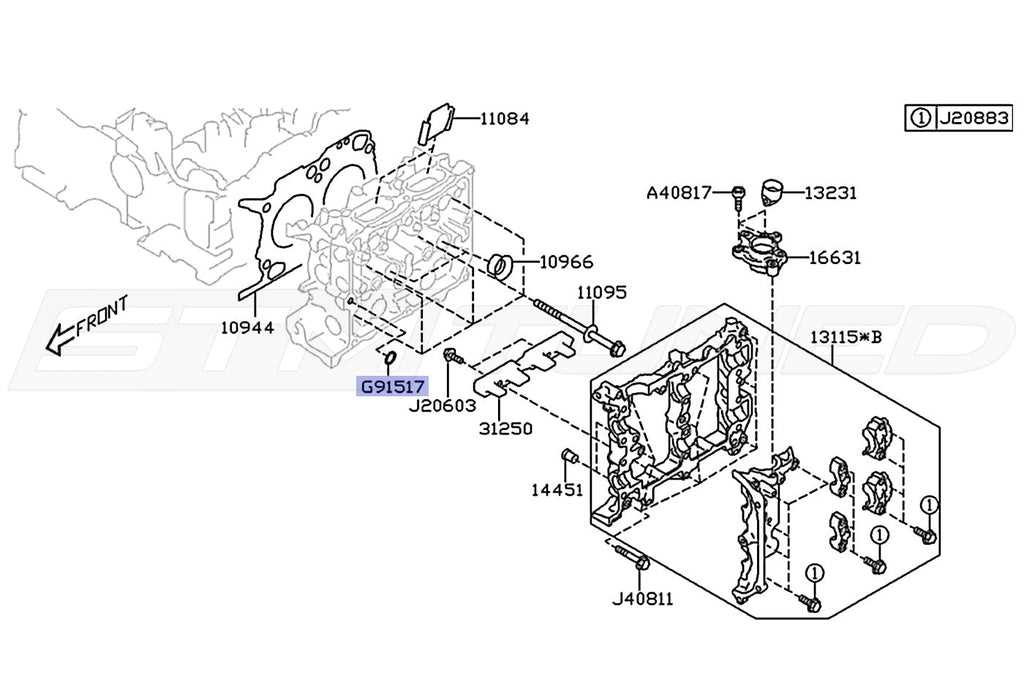

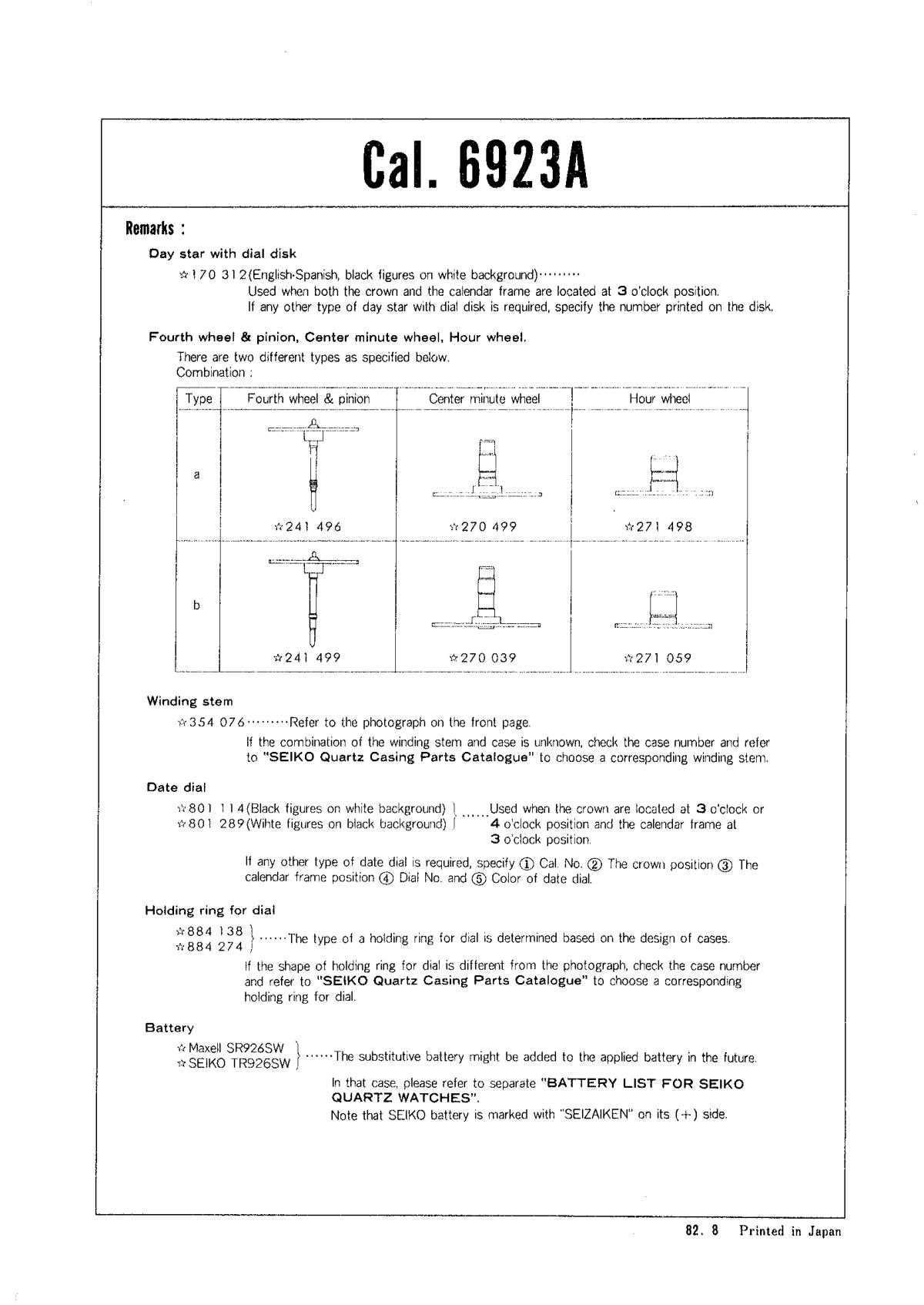

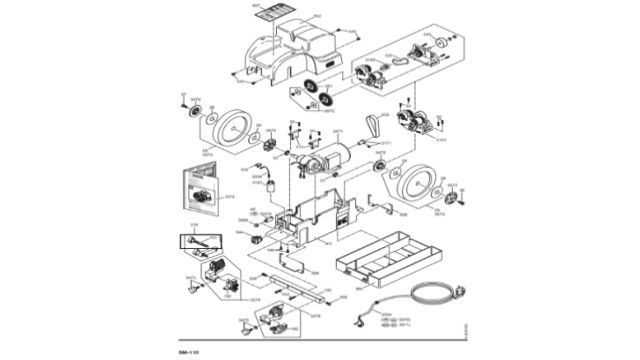

Visual representations of mechanical structures serve as essential tools for anyone involved in repair and assembly processes. These illustrations provide insights into the positioning and relationship between different elements, making it easier to grasp their roles. Additionally, such resources can guide users in troubleshooting and identifying potential areas for improvement.

By studying these schematic representations, individuals can develop a deeper appreciation for the intricacies of the equipment they work with. This understanding fosters a proactive approach to care and enhances the longevity of the machinery. Whether for educational purposes or practical applications, comprehending the arrangement of each element is invaluable for success in any technical endeavor.

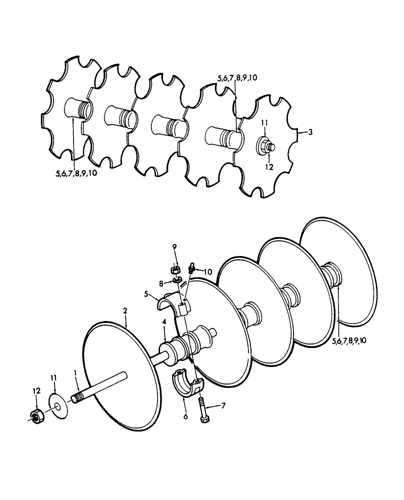

This section explores the versatile applications of a specific agricultural implement widely used in various farming practices. Its design and functionality enable it to perform multiple tasks, enhancing productivity and efficiency in different environments.

Agricultural Applications

- Tilling soil for planting

- Preparing seedbeds for optimal growth

- Mixing soil with fertilizers or organic matter

Horticultural Benefits

- Enhancing aeration for better root development

- Facilitating weed control through soil disruption

- Improving moisture retention in soil

Essential Components of the Disc

The intricate design of a circular implement comprises several critical elements that work in harmony to ensure optimal performance. Each component plays a significant role in the functionality and efficiency of the system, contributing to its overall effectiveness in various applications.

| Component | Description |

|---|---|

| Center Hub | The central part that connects the implement to the axle, providing stability and rotation. |

| Blades | Sharp edges designed for cutting through soil or materials, crucial for effective operation. |

| Spindle | A rotating shaft that transfers power from the engine to the implement, allowing for movement. |

| Bearing | A supportive structure that enables smooth rotation of moving parts, reducing friction. |

| Mounting Frame | The framework that holds all components together and connects the implement to the machinery. |

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By implementing a few simple practices, you can significantly extend the lifespan of your machinery, keeping it functioning at peak performance. Proper upkeep not only enhances efficiency but also minimizes costly repairs.

Regular Inspections

Frequent examinations are crucial in identifying potential issues before they escalate. Look for signs of wear, corrosion, or other damage that may affect operation. Establish a routine schedule to check all components, ensuring that everything is in optimal condition.

Proper Cleaning

Maintaining cleanliness is essential for preventing debris buildup that can hinder functionality. Regularly clean the equipment using appropriate tools and methods. Avoid harsh chemicals that may damage surfaces. Instead, opt for gentle cleaners and soft brushes to keep all areas free from contaminants.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for signs of wear and damage. |

| Deep Cleaning | Monthly | Use non-abrasive cleaners. |

| Lubrication | Every 3 Months | Ensure moving parts are well-lubricated. |

| Calibration Check | Annually | Verify accuracy of settings. |

Understanding the Parts Diagram

This section aims to provide insight into the visual representation of components, facilitating a deeper comprehension of how each element interacts within a larger system. An accurate illustration serves as a valuable tool for users, allowing them to identify and understand the individual elements that comprise the overall mechanism.

To effectively utilize such representations, consider the following key aspects:

- Identification: Recognizing the various elements within the image helps in troubleshooting and maintenance tasks.

- Functionality: Understanding how each component operates within the system enhances overall efficiency.

- Compatibility: Knowing which parts are interchangeable or specific to certain models ensures proper replacements are used.

When analyzing the visual guide, pay attention to the labeled sections that indicate the function and placement of each component. This structured approach will aid in grasping the complexities involved in the assembly and operation of the equipment.

Step-by-Step Assembly Guide

This section provides a detailed procedure for putting together the components of the specified device. Following these instructions will ensure that each piece is fitted correctly, leading to optimal performance and longevity of the equipment.

Preparation of Components

Before starting the assembly, gather all necessary components and tools. Ensure that each item is clean and free from any damage. Familiarize yourself with the shape and function of each component to facilitate a smoother assembly process.

Assembly Process

Begin by aligning the first element with the corresponding attachment point. Gently insert the fasteners, ensuring a secure fit without overtightening. Progressively attach subsequent pieces, checking that all alignments are correct. Double-check each connection before moving to the next step to avoid complications later on.

Once all elements are assembled, conduct a thorough inspection. Ensure that all fasteners are tight and that the assembly functions as intended. If any issues arise, disassemble the necessary parts and repeat the previous steps for correction.

Troubleshooting Common Issues

Addressing frequent problems is essential for maintaining optimal performance and ensuring longevity. This section provides guidance on identifying and resolving typical complications that may arise during operation. By following these steps, users can enhance their experience and minimize downtime.

Identifying Symptoms

Recognizing the signs of potential issues can help in early detection and resolution. Here are some common indicators:

- Unusual noises during operation

- Inconsistent performance or power loss

- Visible wear or damage on components

- Overheating or excessive vibrations

Resolution Steps

Once symptoms are identified, follow these troubleshooting steps:

- Inspect all components for wear or damage.

- Ensure proper alignment and secure connections.

- Check fluid levels and refill if necessary.

- Consult the user manual for specific guidance on adjustments.

- If issues persist, seek professional assistance.

By taking proactive measures and understanding common problems, users can maintain efficiency and avoid extensive repairs.

Comparing White 271 to Other Models

This section explores the key differences and similarities among various models in the same category. By analyzing their features, performance, and design, we can gain insights into how each unit stands out or falls short in comparison to others.

One notable distinction lies in the operational efficiency, where certain models demonstrate superior functionality in specific tasks. Additionally, the design elements and build quality can vary significantly, impacting durability and user experience. For instance, some alternatives may offer enhanced ergonomics or improved maintenance access, which can be crucial for users seeking ease of use.

Moreover, the technological advancements incorporated in newer designs often lead to better performance metrics. Comparing the specifications, such as horsepower, torque, and operational speed, provides a clearer picture of how each model fulfills user needs. Ultimately, understanding these comparisons allows users to make informed decisions based on their unique requirements and preferences.

Recommended Tools for Repairs

Having the right instruments is essential for efficient maintenance and restoration tasks. This section outlines the tools that will facilitate the repair process, ensuring that you can address any issues effectively.

When undertaking repairs, consider equipping yourself with the following essential items:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws |

| Wrench Set | To grip and turn nuts and bolts |

| Pliers | For gripping, twisting, and cutting |

| Utility Knife | For cutting materials or components |

| Measuring Tape | To ensure precise measurements |

| Work Gloves | To protect your hands during repairs |

Using these tools will not only make the repair process smoother but also enhance safety and accuracy throughout your project.

Where to Purchase Replacement Parts

Finding the right components for your equipment is essential to ensure optimal performance and longevity. Various sources offer a wide selection of alternatives to meet your needs, making it easy to find the right match for your specific model.

Here are some recommended places to consider when looking for quality replacements:

- Authorized Dealers: Check with authorized retailers who specialize in your specific machinery. They often have access to genuine replacements and can provide expert advice.

- Online Marketplaces: Websites like Amazon and eBay offer a vast array of options. Always verify the seller’s reputation and read customer reviews before making a purchase.

- Specialty Stores: Local shops that focus on machinery may have the necessary items in stock or can order them for you. Supporting local businesses can also be beneficial.

- Manufacturer’s Website: The official website of the manufacturer may provide a dedicated section for accessories and replacements, ensuring you find the exact component needed.

When purchasing, consider factors such as warranty, return policy, and shipping costs. Taking the time to research can lead to a successful replacement that enhances the functionality of your equipment.

Frequently Asked Questions

This section addresses common inquiries related to the components and functionalities of the equipment. Below are some frequently asked questions that provide clarity and assist users in understanding key aspects.

-

What are the main elements of the system?

The primary elements typically include various mechanical and electronic components that work together to ensure optimal performance.

-

How can I identify a malfunctioning component?

Signs of a malfunction may include unusual noises, decreased efficiency, or visible damage. Regular inspections are recommended.

-

Where can I find replacement items?

Replacement components can often be sourced from authorized dealers or online retailers specializing in similar equipment.

-

Is there a maintenance schedule to follow?

Yes, adhering to a routine maintenance schedule is crucial for ensuring longevity and reliable operation. Check the manufacturer’s guidelines for specific recommendations.

-

Can I perform repairs myself?

While some minor repairs can be carried out by users, complex issues should be handled by a qualified technician to prevent further damage.