When maintaining any outdoor cleaning device, grasping the layout of its essential components is crucial. A clear overview aids in identifying various sections and how they interact, ensuring optimal performance and longevity of the machine.

By examining the structure and arrangement of each element, users can troubleshoot issues effectively. This knowledge is invaluable for both novice and experienced operators alike, facilitating smoother repairs and replacements.

Furthermore, having a visual reference can significantly enhance one’s understanding, making it easier to pinpoint specific areas for attention. This practice not only boosts efficiency but also empowers users to handle their equipment with confidence.

This section provides a comprehensive overview of the various components and features of a high-performance cleaning machine designed for efficient maintenance and upkeep. Understanding the structure and function of each element is essential for proper usage and troubleshooting.

- Introduction to Cleaning Machines

- Key Components and Their Functions

- Importance of Regular Maintenance

- Common Issues and Solutions

- How to Identify Essential Elements

- Upgrading and Replacing Components

- Safety Precautions to Consider

- Choosing the Right Accessories

- Maintenance Tips for Longevity

- Understanding Performance Specifications

- Resource for Finding Replacements

- Conclusion and Final Thoughts

Common Components of Pressure Washers

Understanding the key elements of cleaning devices is essential for effective maintenance and optimal performance. Each component plays a vital role in ensuring the equipment functions smoothly and efficiently, contributing to the overall cleaning experience.

Essential Elements

The fundamental elements found in these machines typically include the motor, pump, hose, and nozzle. Each of these parts works in harmony to deliver powerful cleaning capabilities, making it easier to tackle various cleaning tasks.

Functional Overview

Here is a brief overview of these crucial components:

| Component | Function |

|---|---|

| Motor | Powers the device, generating the necessary force for operation. |

| Pump | Increases the water pressure to enhance cleaning efficiency. |

| Hose | Transports water from the source to the cleaning head. |

| Nozzle | Adjusts the water spray pattern and intensity for different tasks. |

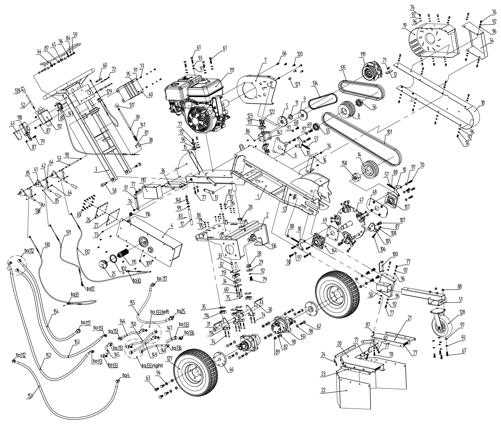

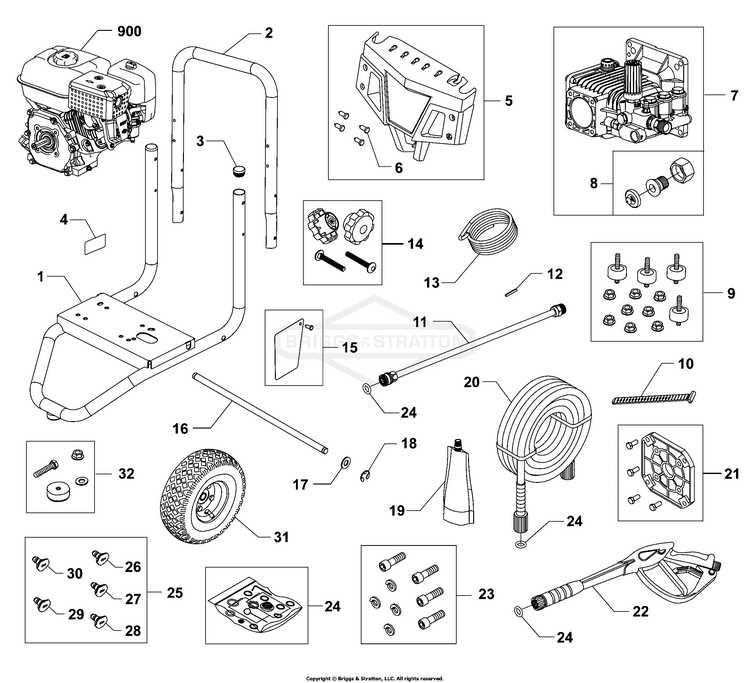

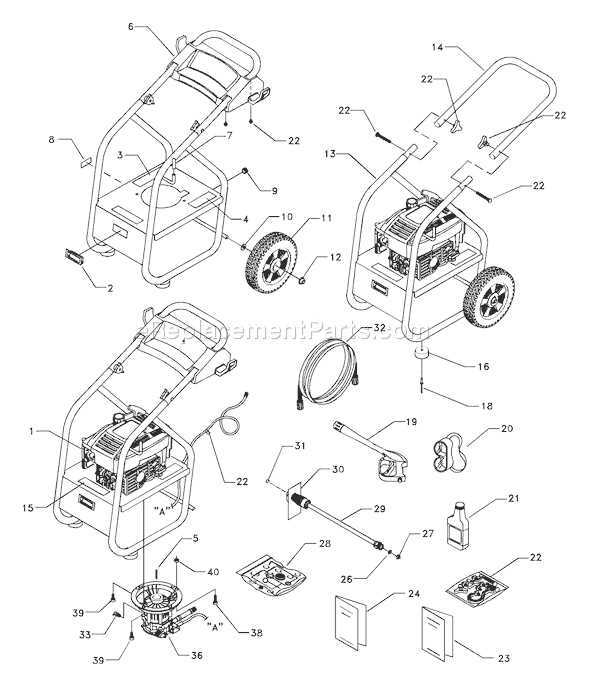

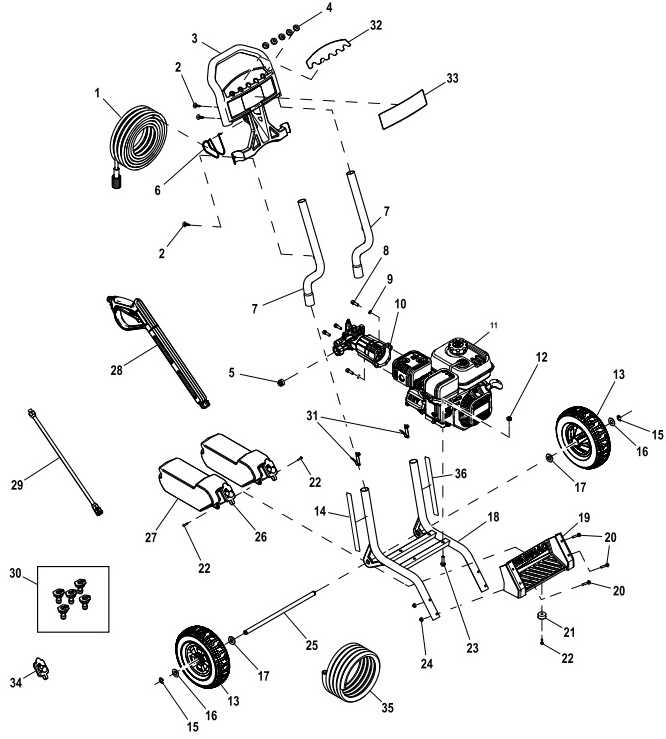

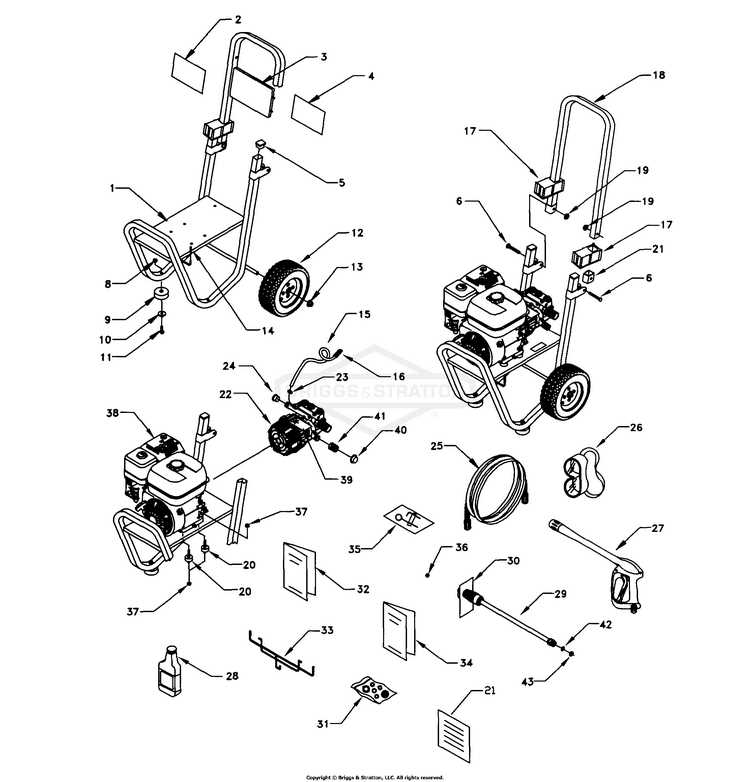

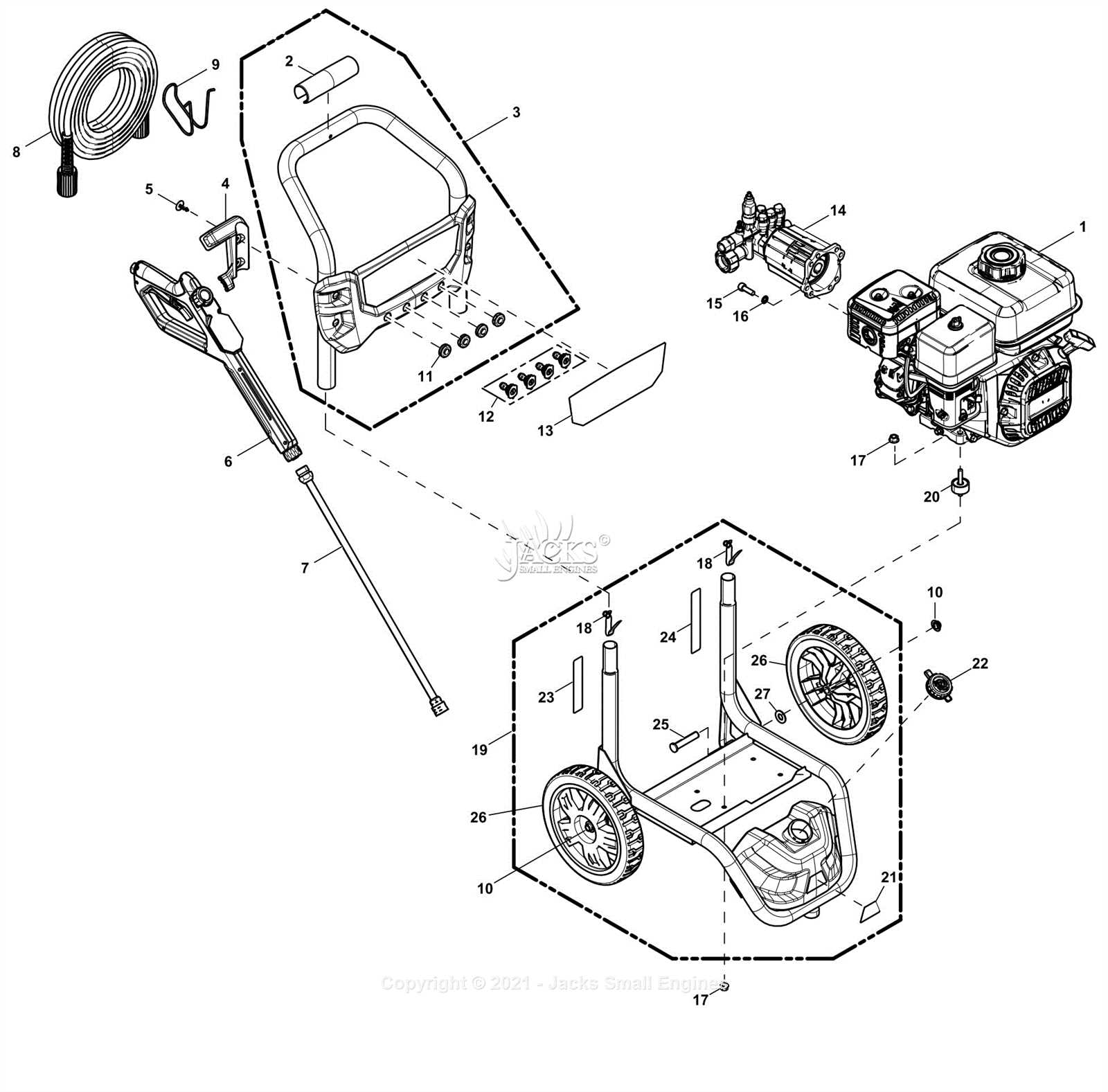

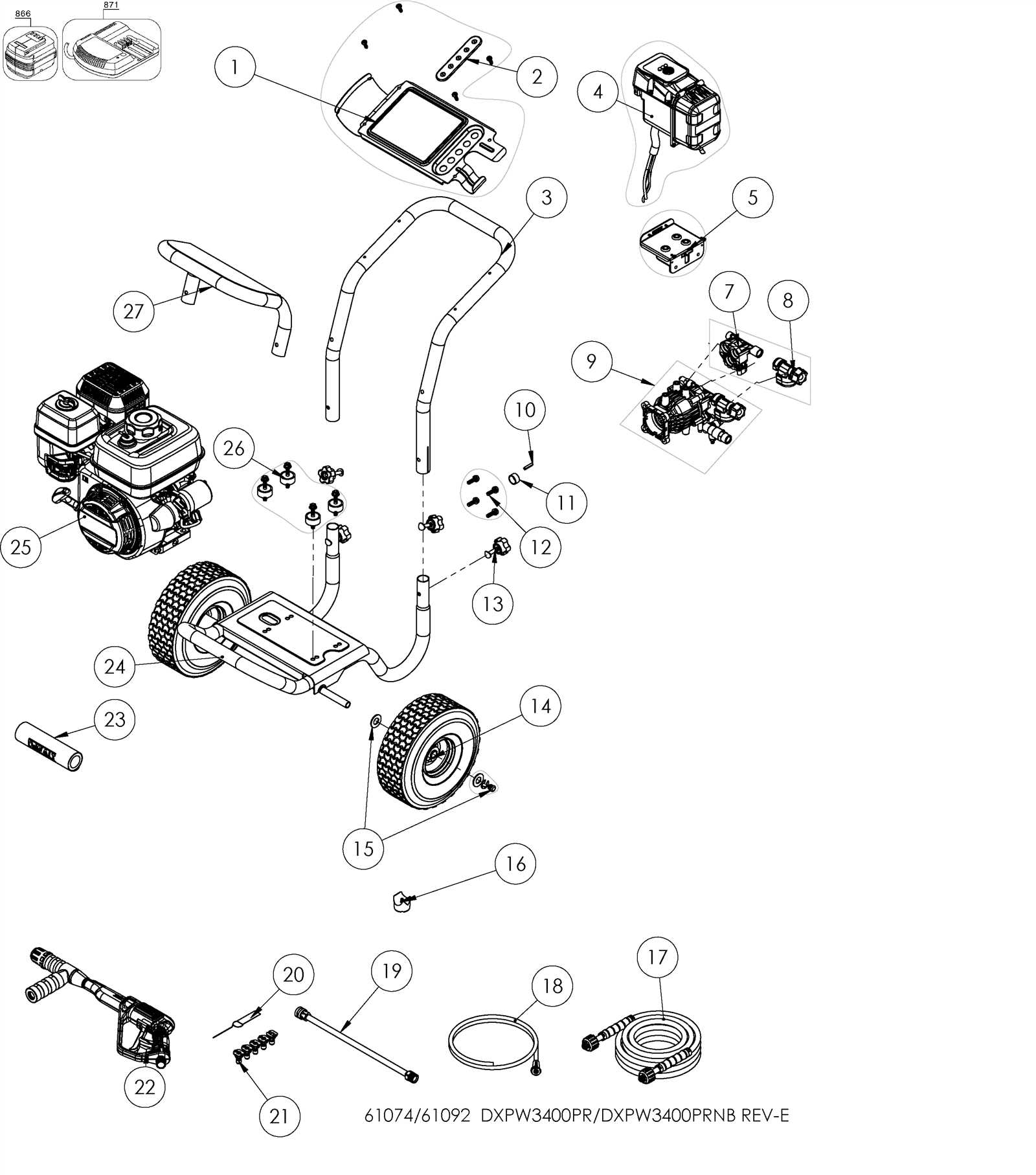

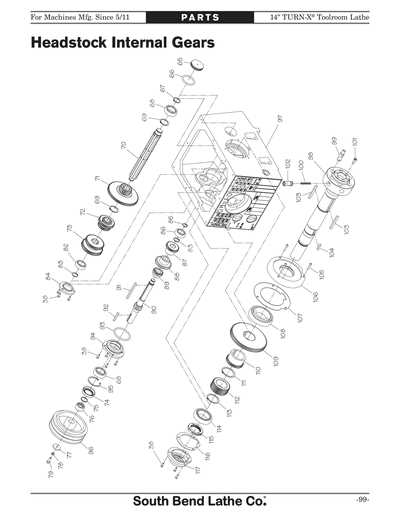

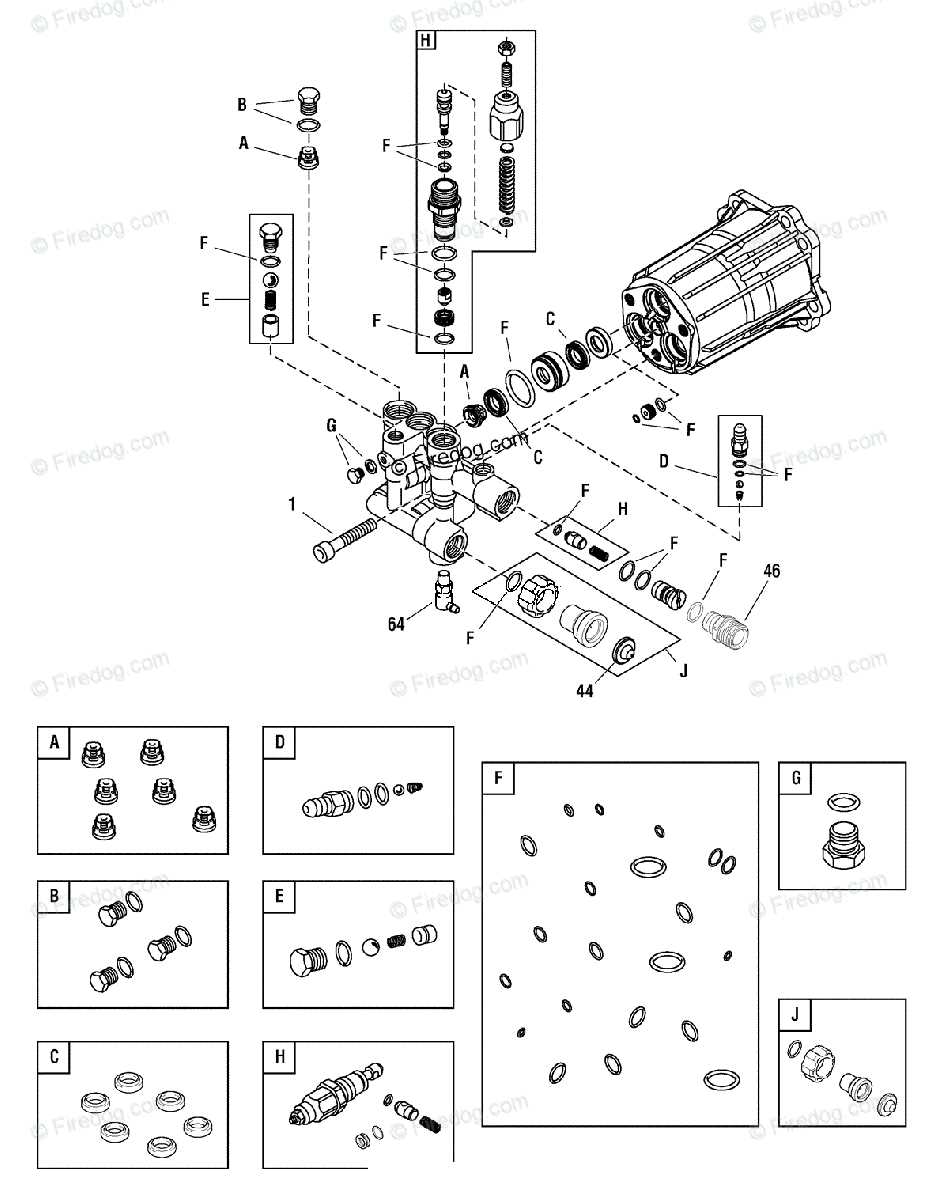

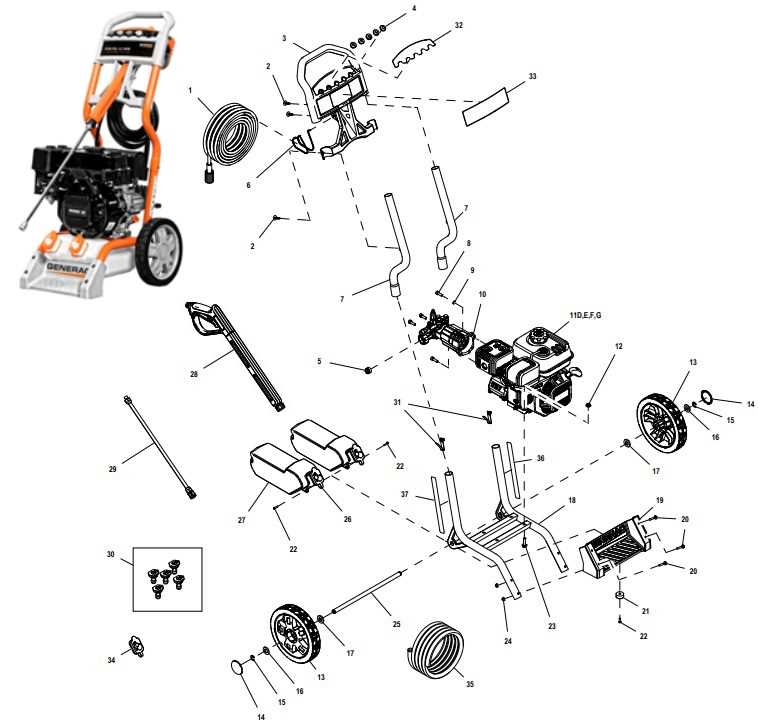

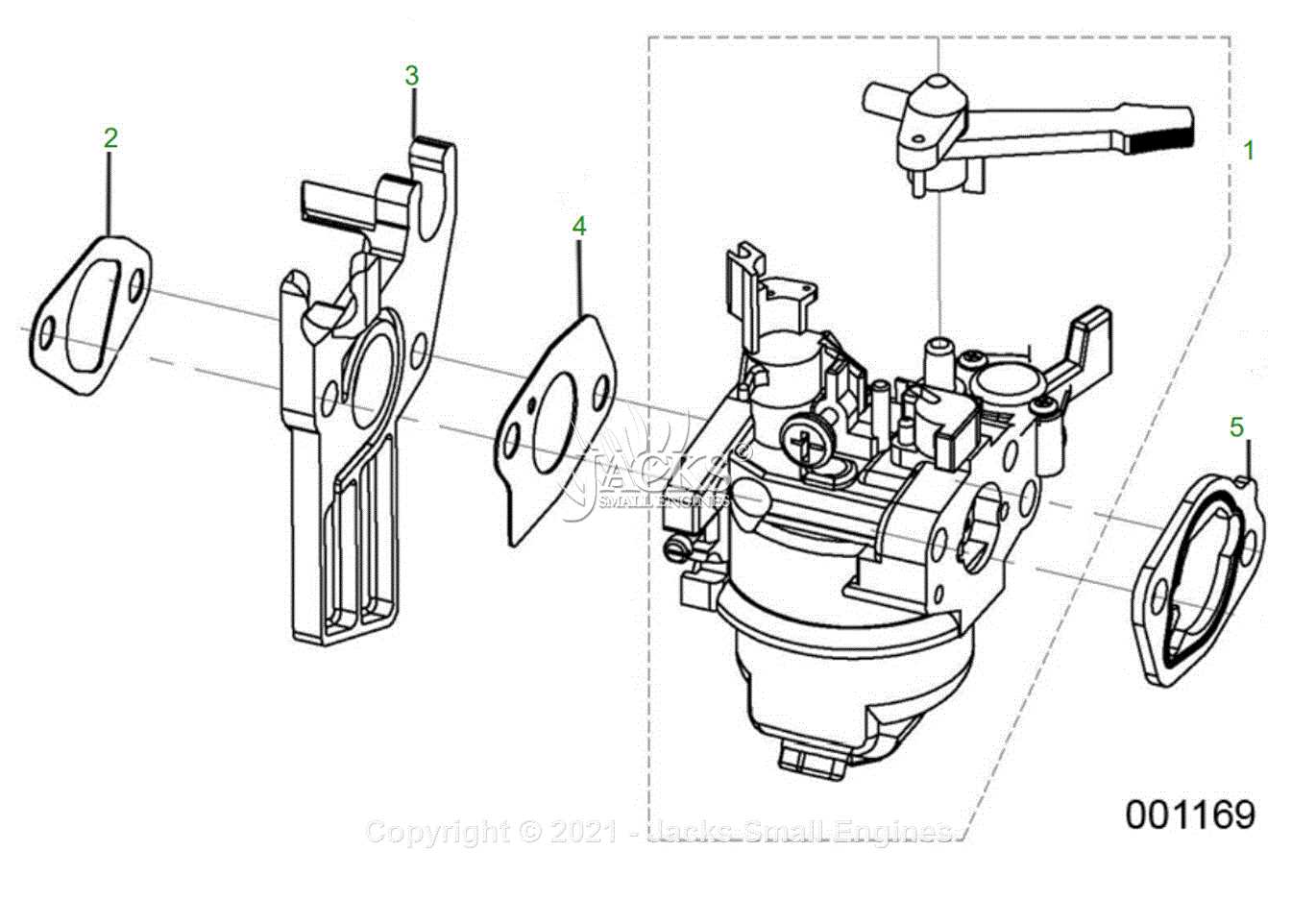

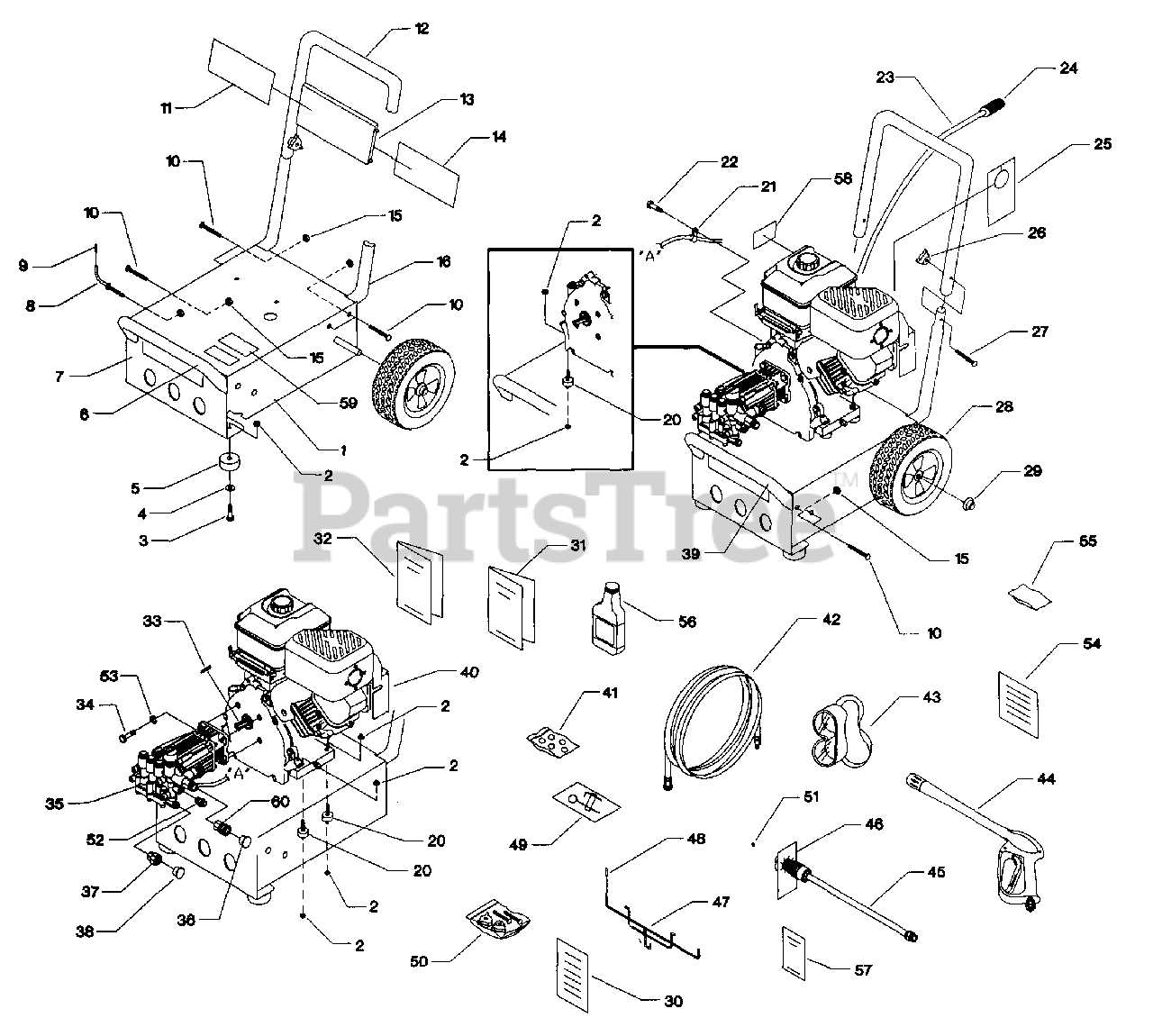

Understanding Pressure Washer Diagrams

Having a clear grasp of the components involved in cleaning machines can greatly enhance your maintenance and troubleshooting skills. These visual representations serve as essential guides, illustrating how each element fits together and functions within the overall system. By studying these illustrations, users can quickly identify areas that may require attention or replacement, ensuring optimal performance.

Components Overview is crucial for effective operation. Each segment has a specific role, contributing to the efficiency and reliability of the equipment. Familiarizing yourself with these sections helps in understanding how they interact during use, leading to more effective problem-solving strategies.

Additionally, recognizing the layout allows for better comprehension of the assembly and disassembly processes. When repairs or upgrades are necessary, knowing the location and function of each part simplifies the task, saving both time and effort.

Identifying Key Parts and Functions

Understanding the essential components and their roles is crucial for effective maintenance and optimal performance of your cleaning equipment. Each element contributes to the overall functionality, ensuring that the device operates smoothly and efficiently.

Major Components

The primary elements of any cleaning apparatus include the motor, pump, and nozzle system. The motor provides the necessary power to initiate operations, while the pump is responsible for generating the pressure needed for effective cleaning. The nozzle system allows for the adjustment of spray patterns, enhancing versatility based on the task at hand.

Additional Elements

In addition to the main components, other critical elements such as hoses, connectors, and filters play significant roles. Hoses transport the fluid from the pump to the nozzle, ensuring a consistent flow. Connectors secure the various parts together, preventing leaks and maintaining pressure. Filters help protect the pump and other internal systems by trapping debris and contaminants, prolonging the life of the equipment.

Maintenance Tips for Pressure Washers

Regular upkeep is essential for ensuring optimal performance and longevity of your cleaning equipment. By following a few straightforward guidelines, you can enhance the efficiency and lifespan of your device, preventing potential issues and costly repairs.

- Clean the Nozzle: Ensure that the nozzle is free from debris. A clogged nozzle can reduce efficiency and create uneven spray patterns.

- Check the Hoses: Inspect the hoses for any signs of wear or damage. Replace any frayed or cracked hoses to prevent leaks and pressure loss.

- Inspect Filters: Clean or replace filters regularly to ensure that the machine operates smoothly. Dirty filters can hinder performance and lead to overheating.

- Change the Oil: If your equipment has an oil reservoir, make sure to check and change the oil periodically to keep the engine running smoothly.

- Store Properly: After use, store the equipment in a dry and protected area. This helps prevent rust and damage from the elements.

By implementing these simple maintenance tips, you can ensure that your cleaning device remains effective and reliable for years to come. Regular attention to these details will save time and money in the long run.

Replacement Parts and Their Uses

When maintaining a cleaning device, understanding the components and their functions is essential for optimal performance. Each element plays a specific role in ensuring the equipment operates efficiently, enhancing its longevity and effectiveness. Familiarizing yourself with these components can help you identify when replacements are necessary, ensuring your device remains in peak condition.

Here is a table detailing some common components along with their uses:

| Component | Description |

|---|---|

| Hose | Delivers water from the source to the nozzle for cleaning tasks. |

| Nozzle | Adjusts the water spray pattern and intensity for different applications. |

| Pump | Pressurizes the water to create an effective cleaning force. |

| Filter | Prevents debris from entering the system, protecting internal components. |

| Trigger | Controls the flow of water, allowing for precise operation during use. |

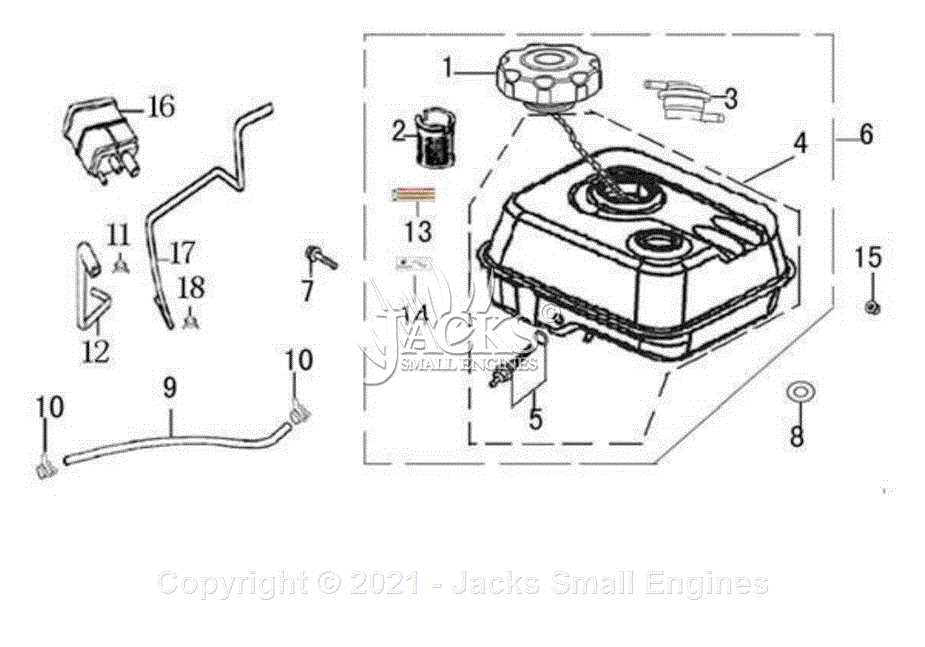

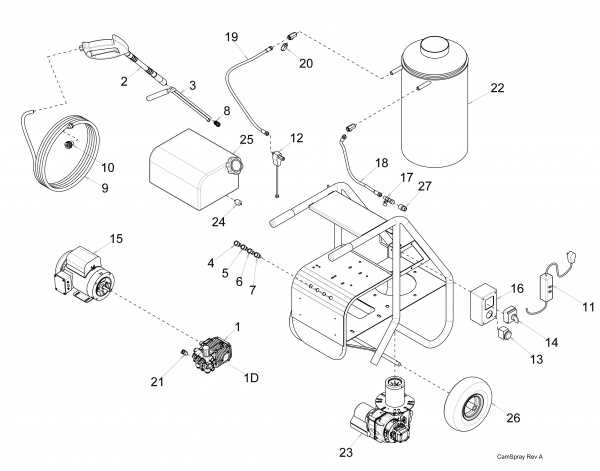

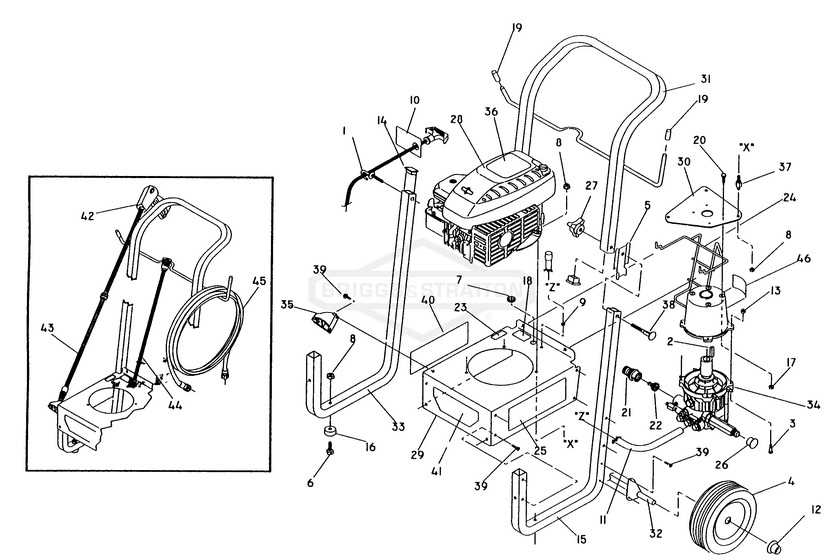

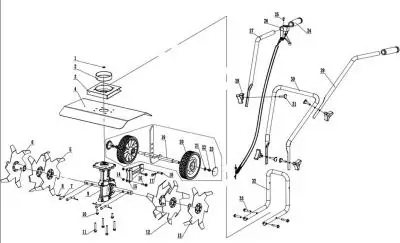

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repairs. These visual representations provide valuable insights into the components of a machine, illustrating how they fit together and interact. By familiarizing yourself with these visuals, you can streamline the process of identifying and sourcing the necessary elements for your equipment.

Begin by examining the layout of the illustration. Each section is typically labeled with corresponding numbers or letters that reference individual components. This labeling system simplifies the identification process and allows for quick cross-referencing with parts lists. Pay close attention to the orientation and arrangement, as these details can highlight how specific components connect and function within the overall assembly.

Next, take note of any annotations or notes accompanying the visuals. These may include information about maintenance tips, installation procedures, or special considerations for certain components. Such insights can significantly enhance your understanding and ability to perform repairs effectively. Additionally, familiarizing yourself with the various symbols used in these illustrations can further aid in deciphering the information presented.

Finally, practice by reviewing multiple illustrations related to your equipment. The more you engage with these resources, the more adept you will become at interpreting them. Over time, this skill will not only save you time but also increase your confidence in managing repairs and maintenance tasks.

Common Issues and Troubleshooting

Addressing frequent problems with cleaning devices can enhance their efficiency and prolong their lifespan. Identifying symptoms early allows for timely interventions, ensuring optimal functionality. Below are some typical challenges users may face and suggestions for resolution.

Identifying Common Problems

- Inconsistent water flow

- Device failing to start

- Unusual noises during operation

- Insufficient cleaning results

- Leaks from connections

Troubleshooting Steps

- Check for clogs in the hose or nozzle, as debris can hinder water flow.

- Ensure that the power source is functioning correctly and that all connections are secure.

- Inspect the unit for any loose components or signs of wear and tear.

- Verify that the correct cleaning solution is being used and properly diluted.

- Look for signs of leaks and tighten any loose fittings or seals.

Ordering Generac Replacement Components

When it comes to maintaining your cleaning device, acquiring suitable components is essential for optimal performance. Understanding the process of obtaining these essential elements ensures that your equipment continues to function efficiently and effectively.

First, identify the specific elements you require for replacement. Consult the user manual or the manufacturer’s online resources to gather details on compatibility and specifications. This will help you avoid potential mismatches and ensure the right fit for your device.

Next, consider where to source these components. Numerous options are available, including authorized dealers, online retailers, and local hardware stores. Comparing prices and availability will allow you to make an informed decision that aligns with your budget.

Once you have chosen a supplier, place your order accurately. Double-check the item numbers and descriptions before finalizing the transaction to avoid any errors. Timely replacement of worn or damaged components can significantly enhance the longevity and efficiency of your equipment.

Finally, after receiving your components, follow the installation instructions carefully. If you encounter any difficulties, seeking professional assistance can help ensure the proper functionality of your cleaning device.

Safety Precautions When Repairing

When undertaking maintenance on any equipment, it is crucial to prioritize safety. Adhering to proper precautions minimizes the risk of accidents and injuries during the repair process. By following essential guidelines, you can ensure a secure working environment and protect yourself from potential hazards.

General Safety Measures

Before starting any repair tasks, familiarize yourself with the equipment and its components. Always wear appropriate personal protective gear, such as gloves and safety goggles, to shield yourself from debris and sharp objects. Ensure that the work area is well-lit and free of clutter to prevent trips and falls.

Handling Tools and Equipment

Using tools safely is fundamental in any repair work. Inspect tools before use to ensure they are in good condition. Utilize the correct tools for each task to avoid damaging components or injuring yourself. Store tools properly after use to maintain a tidy workspace and prevent accidents.

| Safety Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves and safety goggles. |

| Work in a Clean Area | Keep your workspace organized and free from hazards. |

| Inspect Tools | Check tools for damage before use. |

| Use Correct Tools | Employ the right tools for the job. |

Exploring Accessories for Pressure Washers

Accessories play a crucial role in enhancing the efficiency and versatility of cleaning equipment. By incorporating various attachments and tools, users can tailor their devices to tackle different cleaning tasks with ease. From nozzles that adjust spray patterns to specialized brushes, these enhancements can significantly improve the overall experience.

One popular category of accessories includes nozzles. These attachments allow users to modify the spray intensity, making it easier to manage various surfaces. For instance, a narrow nozzle concentrates the water flow for stubborn stains, while a wider one is ideal for rinsing larger areas.

Extension wands are another valuable addition, enabling users to reach high or hard-to-access areas without the need for ladders. This can be especially useful for cleaning gutters or upper walls, making the task safer and more efficient.

Additionally, surface cleaners provide a powerful solution for large, flat surfaces, ensuring an even clean while saving time. These tools are designed to cover more ground quickly, making them perfect for driveways, patios, and decks.

Investing in compatible accessories can elevate the cleaning process, ensuring that equipment meets specific needs while enhancing its functionality. With the right enhancements, users can achieve impressive results with minimal effort.

Benefits of Using Genuine Parts

Utilizing authentic components for your equipment is essential for optimal performance and longevity. These original elements are designed specifically to fit and function perfectly within the system, ensuring reliable operation and reducing the risk of malfunctions.

One of the primary advantages of opting for genuine components is the assurance of quality. Authentic items undergo rigorous testing and adhere to stringent manufacturing standards, which guarantees their durability and effectiveness. In contrast, non-original alternatives may compromise performance and lead to premature wear.

Moreover, using original components often enhances safety. When equipment functions as intended, it minimizes the likelihood of accidents or failures that could arise from inferior substitutes. Genuine components contribute to a safer working environment by providing peace of mind regarding their reliability.

Another significant benefit is the potential for improved efficiency. Equipment fitted with original components tends to operate more smoothly, resulting in better overall functionality. This efficiency can lead to energy savings and increased productivity, making it a wise investment in the long run.

In conclusion, investing in authentic components is a smart choice for those seeking to maintain their equipment’s performance and safety. The advantages of quality, reliability, and efficiency make a compelling case for using original items over imitations.