In the world of mechanical devices, recognizing the individual elements and how they fit together is crucial for both maintenance and efficient operation. Each mechanism consists of multiple segments that work in harmony to ensure optimal performance. Identifying these pieces helps users to better comprehend the overall functionality and troubleshooting process.

Whether you are working on routine upkeep or need to replace specific elements, knowing how to spot the right components can save both time and effort. This guide aims to simplify the process by providing a clear breakdown of the essential elements, helping you navigate the system with confidence.

By understanding the layout and purpose of each piece, you can ensure that your equipment operates smoothly. This knowledge not only enhances performance but also extends the lifespan of the machinery, reducing the need for frequent repairs.

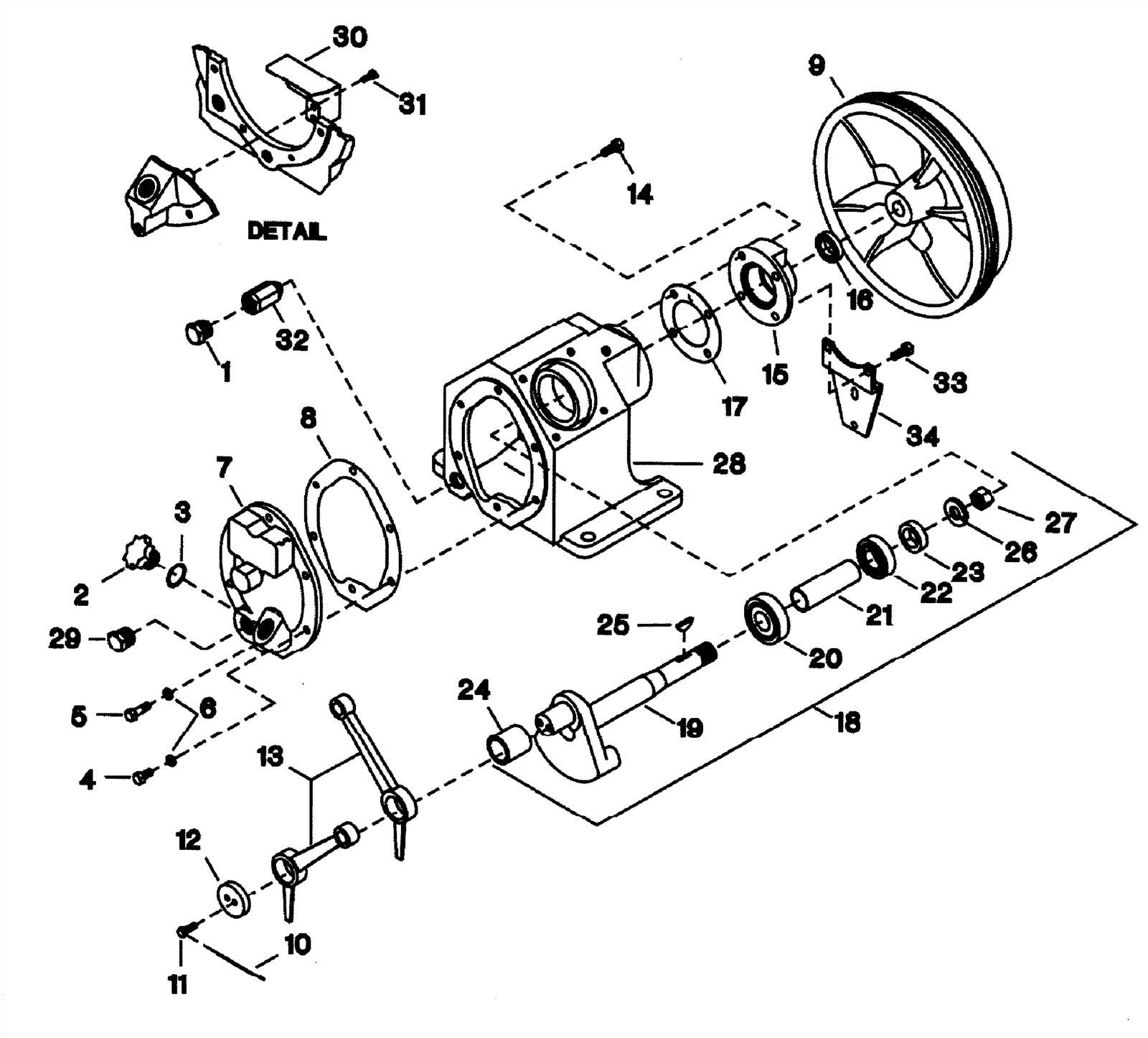

Understanding the Rb24eap Structure

The design of this equipment revolves around a carefully arranged system, ensuring maximum functionality and durability. Each component is strategically placed, contributing to the overall performance, which emphasizes efficiency and ease of use. By examining its framework, we can better understand how these individual elements work together, creating a seamless operational experience.

Key Elements of the Design

At the core of its structure are several critical elements that support its functionality. These include mechanisms that help regulate the device’s operation, as well as parts that ensure it remains reliable during long-term use. Understanding the role of these components allows users to maintain and operate the machine more effectively.

Importance of Proper Arrangement

The proper arrangement of every element is essential for the system’s overall success. Each piece plays a unique role in the operation, making their organization crucial for achieving optimal performance. Paying attention to the placement of these components can extend the lifespan and enhance the efficiency of the entire system.

Key Components Breakdown

Understanding the individual elements that make up a tool or machine is crucial for effective maintenance and repairs. Each section plays a specific role, contributing to the overall function and performance. By breaking down these sections, you gain better insight into how everything works together to create a seamless operation.

Primary Elements

One of the most important areas to focus on is the core mechanism. This essential part is responsible for the main operation and is designed to handle the tool’s toughest tasks. It ensures that the device can operate under various conditions, providing consistent performance.

Supporting Structures

Another vital aspect is the support structure, which keeps everything in place and stable. These elements provide a strong foundation, ensuring the tool remains balanced and durable during use. Without this, other sections wouldn’t function as effectively.

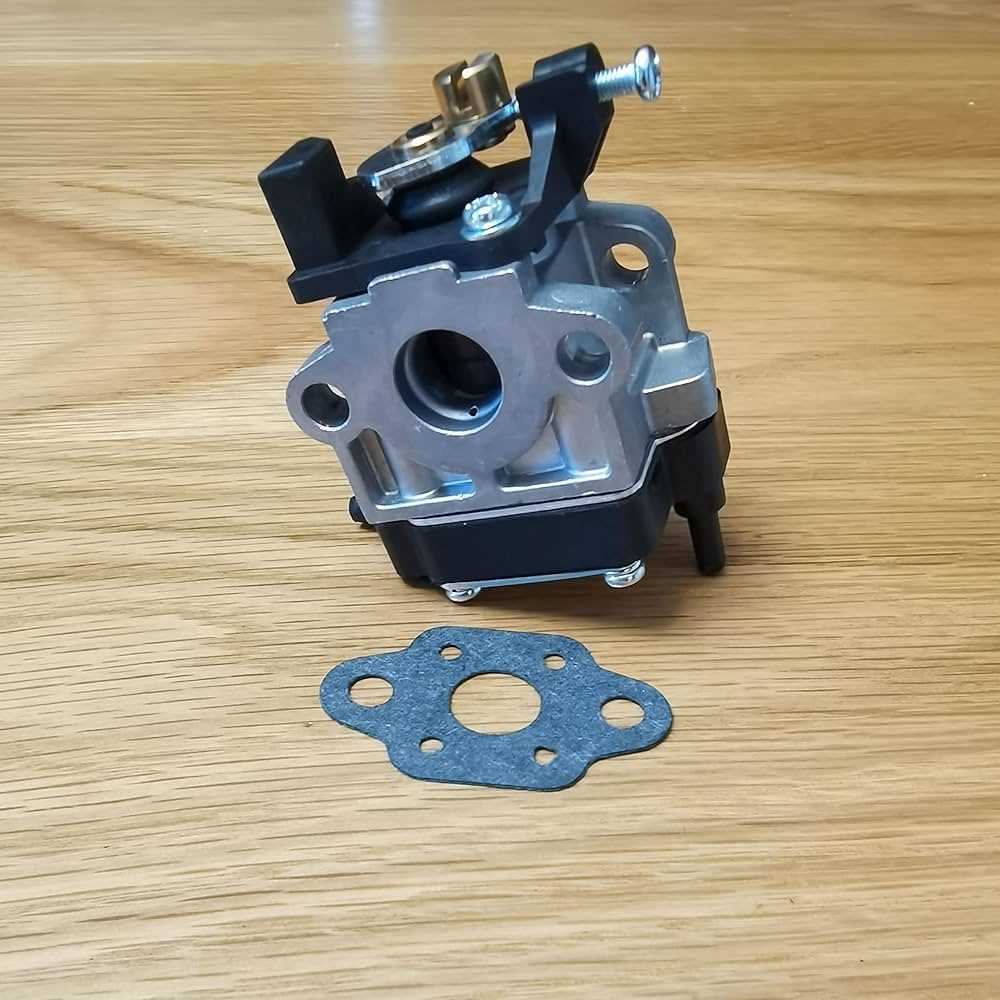

How the Rb24eap Engine Works

The internal mechanism operates through a finely tuned system that converts energy into motion. This process is fundamental to the overall functioning of the machinery, relying on the interaction of multiple components working together to achieve optimal performance.

Energy Conversion Process

The system begins by utilizing a specific form of energy, which is then transformed through a series of movements. These actions produce the power necessary to drive the equipment, allowing it to perform its intended tasks with precision and efficiency.

Key Components Involved

A set of critical parts plays a pivotal role in ensuring smooth operation. Each component is designed to perform a specific function, contributing to the overall efficiency of the engine. The collaboration between these elements ensures that the system runs reliably over time.

| Component | Function |

|---|---|

| Energy Source | Supplies power for the system to operate. |

| Mechanical Converter | Transforms energy into usable mechanical motion. |

| Control Unit | Regulates the engine’s performance and maintains stability. |

Internal Mechanisms of Rb24eap

Understanding the inner workings of this equipment helps in maintaining and troubleshooting it effectively. The internal components are designed to interact with each other, ensuring smooth functionality and optimal performance. A closer look at the core elements reveals how each part plays a crucial role in the system’s overall operation.

Main Drive Components

The primary driving mechanism consists of several key elements that work together to provide the required motion. These include gears, shafts, and other essential parts that transfer energy and movement efficiently.

Supporting Structures

Alongside the main drive, there are supportive systems that stabilize and guide the entire process. These structures ensure that everything functions with precision and minimize wear over time, contributing to the longevity of the device.

External Features Overview

When exploring the design and structure, it’s important to focus on the visible components that directly influence functionality. These elements often provide both aesthetic appeal and practical utility, contributing to the overall user experience.

Key attributes of the exterior include areas designed for easy handling, access points for maintenance, and strategic placement of controls. Each aspect is carefully engineered to enhance ease of use, ensuring that the device operates efficiently and intuitively.

Durability and ergonomics are also critical factors in the design, providing comfort and reliability during operation. The overall exterior reflects a balance between form and function, supporting long-term performance and user satisfaction.

Maintenance Tips for Rb24eap Parts

Proper upkeep is essential for ensuring the longevity and optimal performance of automotive components. Regular attention to these elements can prevent wear and tear, enhance efficiency, and reduce the likelihood of unexpected failures. Below are some valuable suggestions to help maintain these crucial items.

| Tip | Description |

|---|---|

| Regular Inspections | Consistently check for any signs of damage, leaks, or wear. Early detection can save time and expenses later on. |

| Cleanliness | Keep components clean to prevent debris accumulation. Regular cleaning helps maintain functionality and efficiency. |

| Lubrication | Apply appropriate lubricants as needed to reduce friction and wear. Refer to manufacturer guidelines for specific products. |

| Follow Manufacturer Guidelines | Adhere to the recommended maintenance schedule provided by the manufacturer to ensure reliability and performance. |

| Use Quality Replacements | When replacements are necessary, choose high-quality components to guarantee compatibility and durability. |

Common Issues and Solutions

This section addresses frequent challenges encountered with a specific model and provides practical solutions. Users often face problems that can hinder performance, and understanding these issues is crucial for effective troubleshooting.

One common challenge is the occurrence of unusual noises during operation. This can be caused by loose components or insufficient lubrication. Regular maintenance and checks can help identify and rectify these issues, ensuring smooth functionality.

Another issue that might arise is overheating. This can stem from clogged air filters or malfunctioning cooling systems. To prevent this, it is important to regularly inspect and clean filters, as well as ensure that the cooling mechanisms are operating effectively.

Leakage problems can also surface, leading to decreased efficiency. This may be a result of worn seals or improper assembly. Regular inspections and timely replacements of faulty parts are essential to maintain optimal performance.

Lastly, electrical failures can occur, often due to damaged wiring or connections. Routine checks and proper handling during installation can mitigate these risks, ensuring reliable operation.

How to Replace Worn-Out Components

Over time, certain elements within a system may become less effective due to wear and tear. Recognizing when these parts need to be changed is crucial for maintaining overall functionality. This guide will help you understand the steps necessary to replace these fatigued components effectively.

Before starting the replacement process, gather all the required tools and new elements. This preparation will ensure a smooth and efficient operation.

- Identify the Components: Inspect the system carefully to locate the parts that need attention. Signs of damage or degradation include unusual noises, leaks, or reduced performance.

- Disconnect Power: Always ensure that the system is powered down before beginning any work to avoid accidents and ensure safety.

- Remove the Old Components: Carefully detach the worn-out parts using appropriate tools. Take note of how they are installed for easier reassembly later.

- Install New Elements: Position the new components in place, following the original configuration. Make sure they fit snugly and securely.

- Reconnect Power: Once everything is in place, restore power to the system and conduct a test to confirm that the replacements are functioning correctly.

Regular maintenance and timely replacements of worn components will enhance the longevity and efficiency of the entire system. Stay attentive to performance changes to address issues promptly.

Rb24eap Compatibility with Other Models

This section explores how a specific engine variant interacts with various other models within the same category. Understanding compatibility is crucial for ensuring optimal performance and seamless integration during repairs or modifications.

Key Compatible Models

- Model A: Known for similar specifications.

- Model B: Shares a comparable framework.

- Model C: Often utilized in conjunction with similar components.

Considerations for Compatibility

When assessing compatibility, it’s essential to consider several factors:

- Engine specifications: Ensure dimensions and configurations match.

- Mounting points: Verify alignment for secure installation.

- Wiring harness: Check for electrical compatibility to prevent issues.

Choosing the Right Replacement Parts

Selecting appropriate components for your vehicle is crucial for optimal performance and longevity. Ensuring compatibility and quality can significantly impact the overall functionality of your engine. This section will guide you through the essential considerations when making your choice.

- Understand Your Requirements: Evaluate what specific needs your vehicle has. Are you looking for enhanced efficiency, improved performance, or merely restoring original functionality?

- Research Options: Investigate various brands and their reputations. Look for reviews or feedback from other users to gauge reliability.

- Consult Manuals: Reference any technical documents available for your vehicle model. These often provide valuable insights into compatible components.

- Consider Aftermarket Alternatives: Sometimes, aftermarket options can offer better performance or pricing than original components. Make sure to verify their quality.

Taking the time to thoroughly assess your options will lead to better outcomes in vehicle maintenance and performance enhancement. Prioritize reliability and compatibility to ensure a smooth experience.

How to Extend the Life of Rb24eap

Maintaining the longevity of any mechanical system involves regular care and attention. Implementing effective strategies can significantly enhance performance and durability. This section explores various methods to ensure your equipment remains in optimal condition for an extended period.

Regular Maintenance Checks

Consistent evaluations are essential for identifying potential issues before they escalate. Follow these tips:

- Schedule routine inspections to detect wear and tear.

- Clean components regularly to prevent dust and debris buildup.

- Lubricate moving parts as recommended to reduce friction.

Proper Usage and Handling

Adhering to best practices during operation can prevent unnecessary strain. Consider these guidelines:

- Follow the manufacturer’s instructions for optimal operation.

- Avoid overloading the system to reduce stress on components.

- Store the equipment in a dry, cool environment to protect against corrosion.