Exploring the intricacies of heavy machinery reveals the essential elements that contribute to their functionality and efficiency. Each component plays a pivotal role in ensuring optimal performance, allowing operators to navigate various terrains and complete tasks effectively. A comprehensive overview of these elements provides valuable insights into maintenance and repair processes.

In this section, we delve into the specific configurations and functionalities of a well-known model within the construction industry. By examining its construction and arrangement, one can appreciate how different components work together harmoniously. This knowledge not only aids in troubleshooting but also enhances overall operational awareness.

Understanding the layout of these crucial elements fosters a deeper appreciation for the engineering behind powerful machinery. With the right information at hand, operators and technicians can ensure longevity and reliability in their equipment, making informed decisions regarding upkeep and enhancements.

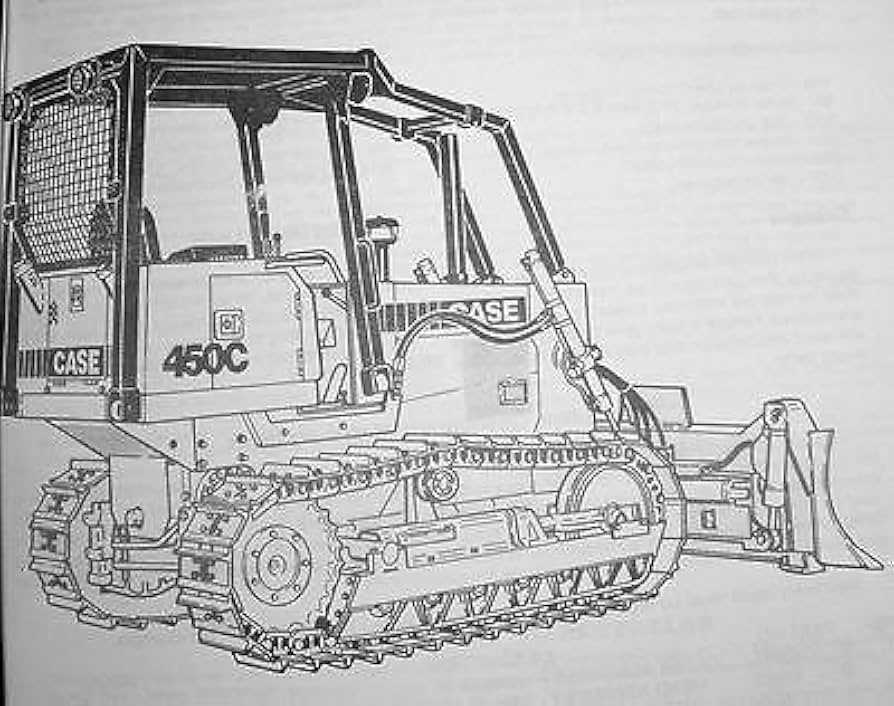

Overview of Case 450 Dozer

This section provides a comprehensive look at a specific heavy machinery model, focusing on its design, capabilities, and applications in various industries. This equipment is renowned for its durability and efficiency, making it a popular choice for construction and earth-moving tasks.

Key Features and Specifications

The machinery is equipped with advanced engineering elements that enhance performance and reliability. Its powerful engine and robust frame ensure optimal functionality even in challenging environments. Additionally, its versatility allows for a wide range of attachments, further increasing its utility on job sites.

Applications in Various Industries

This type of equipment plays a vital role in numerous sectors, including construction, mining, and agriculture. Its ability to move large quantities of earth and materials expedites projects, making it an essential tool for professionals. Moreover, its adaptability to different attachments makes it suitable for tasks ranging from grading to land clearing.

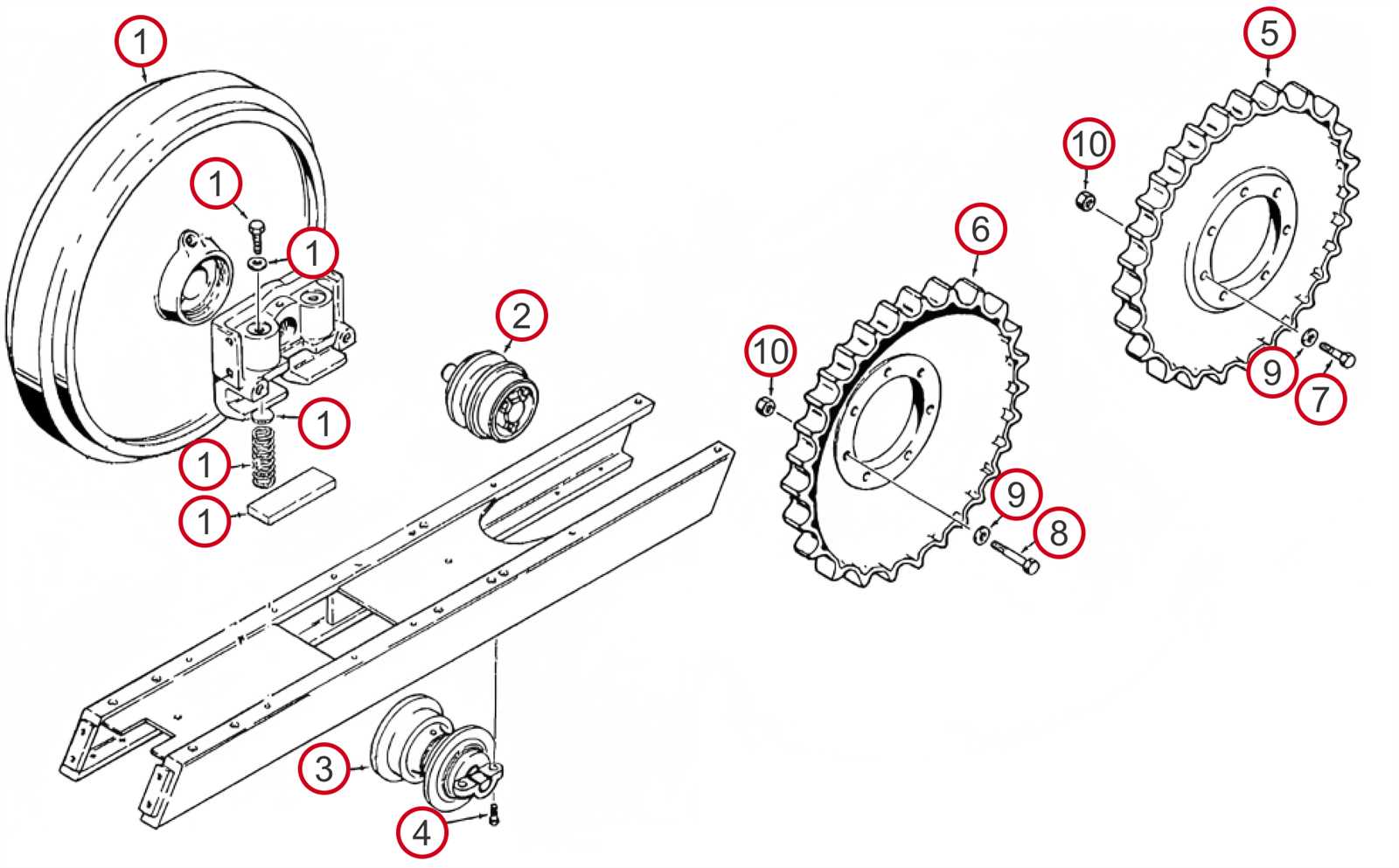

Essential Components and Their Functions

Understanding the key elements of heavy machinery is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity, contributing to the overall efficiency of the machine.

Key Elements

- Engine: Powers the machine and provides the necessary energy for operation.

- Transmission: Transmits power from the engine to the tracks, allowing for movement.

- Hydraulic System: Enables lifting and maneuvering, essential for various tasks.

- Track Assembly: Provides traction and stability on different terrains.

Supporting Components

- Cab: The operator’s area, designed for comfort and visibility.

- Fuel System: Stores and supplies fuel to the engine, vital for operation.

- Cooling System: Regulates temperature to prevent overheating of critical parts.

- Electrical System: Powers lights, gauges, and other electronic components.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of heavy machinery requires consistent upkeep and attention to detail. Regular maintenance not only enhances performance but also minimizes the risk of costly repairs and downtime. Implementing a systematic approach to care can significantly improve operational capabilities.

Regular Inspections

Conducting frequent assessments is crucial for identifying wear and tear before it leads to major issues. Check hydraulic systems, tracks, and engine components to ensure everything is functioning as intended. Look for leaks, unusual noises, and signs of fatigue.

Fluid Changes and Filter Replacements

Maintaining proper fluid levels and replacing filters according to the manufacturer’s recommendations is essential. Clean fluids facilitate smooth operation and protect critical parts from damage. Regular changes contribute to the overall health of the equipment.

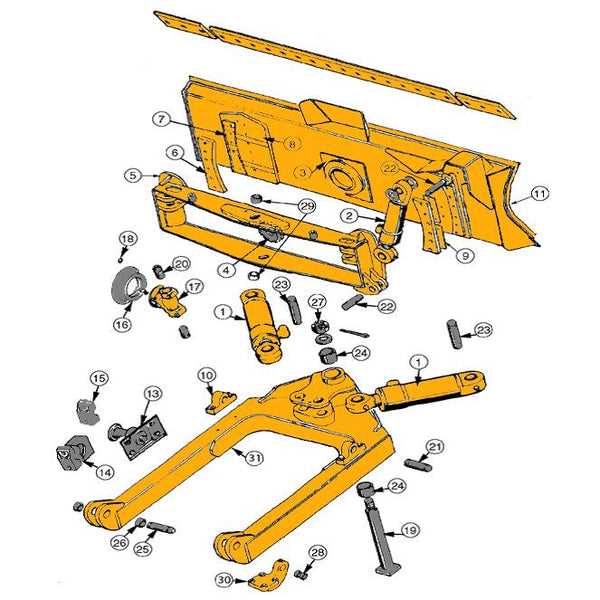

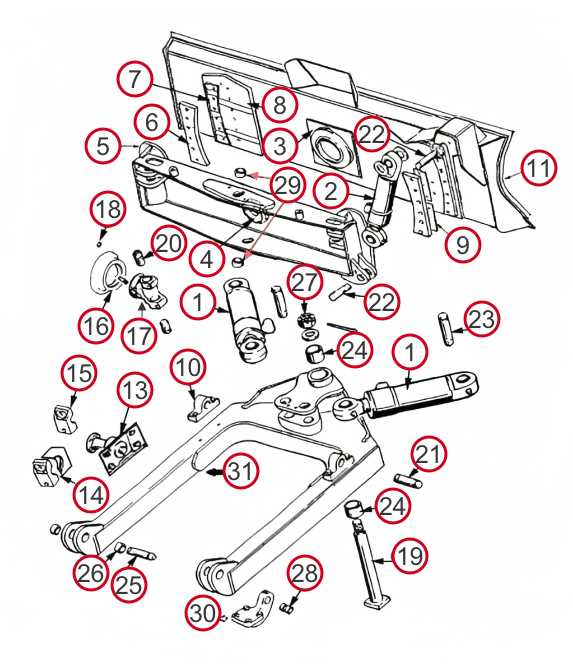

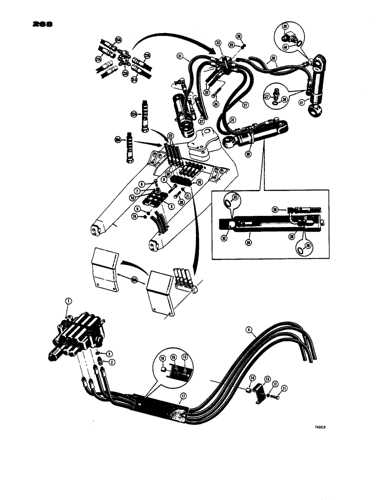

Understanding Hydraulic Systems in Dozers

Hydraulic mechanisms play a crucial role in the operation of heavy machinery, enabling powerful movements and precise control. These systems leverage fluid pressure to facilitate various functions, enhancing efficiency and performance in challenging environments.

At the core of hydraulic functionality are several key components that work together seamlessly. Below is an overview of these essential elements:

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure by moving fluid from the reservoir. |

| Valve | Regulates fluid flow and directs it to the appropriate actuators. |

| Cylinders | Convert hydraulic energy into mechanical force, enabling movement. |

| Reservoir | Stores hydraulic fluid, ensuring a constant supply for the system. |

Understanding these components and their interactions is vital for troubleshooting and optimizing the performance of hydraulic systems in heavy machinery.

Identifying Common Replacement Parts

Understanding the essential components of heavy machinery is crucial for maintaining optimal performance and longevity. Familiarity with frequently replaced items can streamline repairs and enhance efficiency in operations. This section delves into the typical elements that may require replacement over time.

One of the primary components often needing attention is the hydraulic system. It plays a vital role in ensuring smooth operation, and parts such as hoses, filters, and pumps may wear out or become damaged, necessitating timely replacements. Additionally, track assemblies and undercarriage elements frequently require inspection and, when necessary, replacement to sustain traction and mobility.

Another area to consider is the engine assembly, where various components, including gaskets, belts, and filters, are essential for optimal functionality. Regular checks and replacements of these items can prevent more significant issues and downtime. Lastly, electrical systems, which include batteries and wiring, should not be overlooked, as they are integral to the overall operation of the machinery.

Operating Principles of Case 450

The operational mechanisms of this construction equipment revolve around the synergy of various components designed to enhance performance and efficiency. The integration of hydraulic systems, power transmission, and control mechanisms ensures that the machine performs effectively in challenging environments.

Hydraulic Systems: At the core of the machine’s functionality lies its hydraulic system, which facilitates the movement of heavy loads with precision. This system uses fluid power to transmit force, enabling the blade to lift and lower smoothly.

Power Transmission: The power generated by the engine is transmitted through a series of gears and belts, allowing the operator to maintain optimal control over speed and torque. This design allows for efficient energy use while minimizing wear on components.

Control Mechanisms: Operators interact with various controls that allow for nuanced adjustments to movement and operation. The intuitive layout of these controls enhances user experience, ensuring that tasks can be completed with accuracy and speed.

Ultimately, understanding these operational principles is crucial for maximizing the effectiveness and longevity of the machinery in demanding applications.

Diagnostic Techniques for Component Issues

Identifying problems within machinery requires a systematic approach to ensure accurate assessments. By employing effective diagnostic methods, one can uncover underlying issues that affect performance and reliability.

Common techniques include:

- Visual Inspection: Regularly check for visible signs of wear, leaks, or damage.

- Sound Analysis: Listen for unusual noises during operation, which can indicate malfunctioning parts.

- Performance Testing: Measure operational parameters against specifications to identify deviations.

For a more thorough investigation, consider the following:

- Vibration Analysis: Use sensors to detect abnormal vibration patterns that could signal imbalances or misalignments.

- Thermal Imaging: Employ infrared cameras to detect overheating components that might be failing.

- Fluid Analysis: Analyze oil or coolant samples to identify contaminants or wear particles.

These techniques, when combined, provide a comprehensive overview of machinery health, enabling timely maintenance and reducing downtime.

Exploring Aftermarket Parts Availability

The landscape of replacement components for heavy machinery has evolved significantly, providing operators with a plethora of options beyond original manufacturer offerings. This shift has opened up avenues for enhanced performance and cost-effectiveness, allowing users to maintain their equipment efficiently.

Benefits of Aftermarket Options

- Cost Efficiency: Aftermarket alternatives often come at a lower price point compared to OEM options, making repairs and upgrades more affordable.

- Diverse Selection: The market is flooded with various manufacturers, ensuring a wide array of components to suit different needs.

- Performance Enhancements: Some aftermarket products are designed to improve functionality, offering superior durability or enhanced features.

Considerations When Choosing Aftermarket Components

- Quality Assurance: Verify the reputation of the manufacturer and ensure that components meet industry standards.

- Compatibility: Always check that the replacement items are suitable for your specific machinery model to avoid issues during installation.

- Warranty Options: Look for products that come with a warranty, providing peace of mind in case of defects or failures.

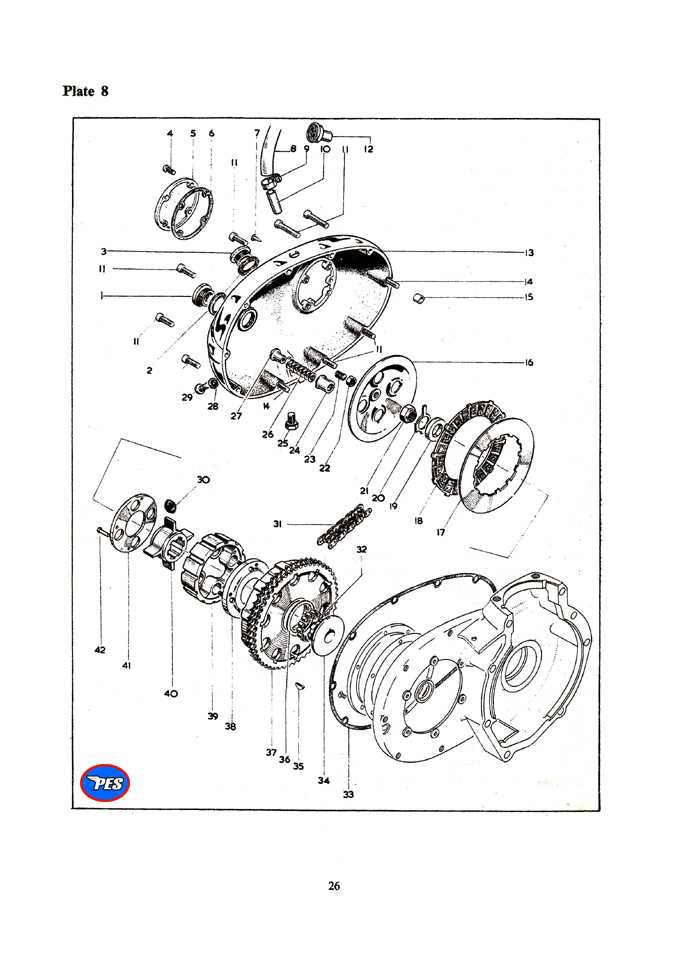

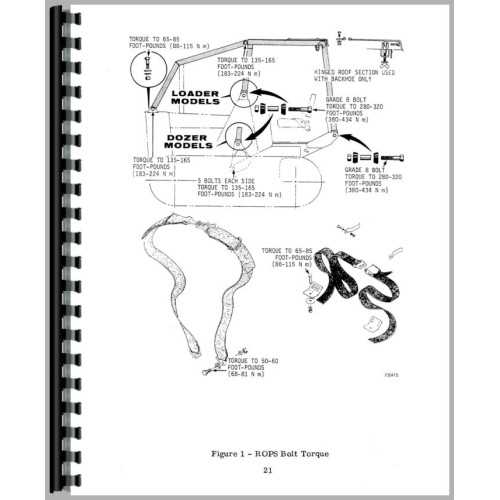

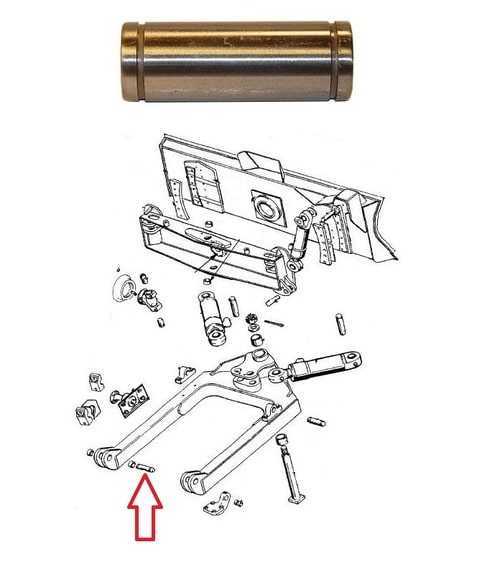

Assembly and Disassembly Guidelines

Understanding the proper methods for assembling and disassembling heavy machinery components is essential for maintaining efficiency and safety. These processes require careful attention to detail and adherence to established procedures to ensure optimal performance.

Preparation is key before beginning any assembly or disassembly task. Ensure that you have all necessary tools and safety equipment at hand. Familiarize yourself with the various components and their configurations to avoid confusion during the process.

When dismantling, follow a systematic approach. Start from the outer sections and work your way inward, labeling each component as you remove it. This practice will facilitate easier reassembly. Keep all fasteners organized and refer to any relevant documentation for guidance.

During the assembly phase, reverse the disassembly steps. Ensure that all components are clean and free from debris. Utilize appropriate torque specifications for fasteners to guarantee a secure fit. Regularly check your work against the provided schematics to ensure accuracy.

Following these guidelines will not only enhance the longevity of your equipment but also improve safety and functionality during operation.

Safety Considerations During Repairs

Ensuring a secure work environment is paramount when conducting maintenance on heavy machinery. Proper precautions not only protect the technician but also enhance the efficiency of the repair process.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Inspect the work area for hazards such as oil spills, loose tools, or unstable surfaces.

- Utilize proper lifting techniques and equipment when handling heavy components.

- Disconnect the power source to prevent accidental start-up during maintenance.

Moreover, being aware of the machinery’s operational manual can provide valuable insights into safe practices and recommended procedures.

- Ensure that all safety guards and shields are in place before operating the equipment.

- Keep a first-aid kit readily available for emergencies.

- Communicate clearly with team members to avoid misunderstandings during repairs.

By following these guidelines, technicians can mitigate risks and promote a safer repair environment.

Performance Upgrades for Enhanced Efficiency

Improving operational capabilities can significantly elevate the performance of heavy machinery. By integrating advanced components and optimizing existing systems, operators can achieve better productivity and reduced downtime. These enhancements often focus on maximizing power output, enhancing fuel efficiency, and ensuring smoother operation in challenging conditions.

One effective approach is upgrading the engine with high-performance filters and tuning kits. These modifications can increase air intake and improve combustion efficiency, leading to greater power and reduced emissions. Additionally, implementing better hydraulic systems can enhance lifting and digging capabilities, providing faster cycle times and improved responsiveness.

Another key area for enhancement involves the use of advanced track systems and undercarriage components. Upgrading to more durable materials and innovative designs can result in improved traction and stability, especially in rough terrains. This not only boosts performance but also extends the lifespan of the equipment, ensuring long-term reliability.

Regular maintenance, coupled with these upgrades, ensures that machinery operates at its peak. Investing in technology and superior components ultimately leads to greater efficiency and productivity, making a noticeable difference in operational success.

Connecting with Case Dozer Community

Engaging with fellow enthusiasts can enhance your understanding and experience with heavy machinery. Joining online forums and social media groups dedicated to these machines provides opportunities to exchange knowledge, share insights, and seek advice. These platforms serve as valuable resources for troubleshooting and exploring modifications.

Participating in local meetups or community events can further strengthen connections. Such gatherings allow for hands-on demonstrations, sharing of best practices, and fostering friendships among individuals with a shared passion. Whether discussing maintenance techniques or sharing stories about projects, these interactions can be both informative and enjoyable.

Additionally, subscribing to specialized publications or following blogs focused on equipment can keep you informed about the latest trends and innovations in the industry. This ongoing learning process will not only benefit your own projects but also contribute to the collective knowledge within the community.