Understanding the components and how they fit together in a leaf blower is essential for anyone looking to maintain or repair their equipment. This section provides an in-depth look into the various elements that make up this powerful outdoor tool, ensuring you can identify and work with each part effectively. Whether you’re a seasoned professional or a homeowner, gaining a clear picture of the machine’s internal structure will aid in optimizing its performance.

From the engine assembly to the smaller connections and fittings, every element plays a crucial role in the tool’s functionality. Learning about each component helps users not only troubleshoot potential issues but also make informed decisions when it comes to replacing worn-out elements. By familiarizing yourself with these details, you can extend the lifespan of your equipment and maintain its efficiency.

Our guide provides a step-by-step exploration of these elements, highlighting their purpose and positioning within the machinery. This information serves as a valuable resource, allowing users to become more proficient and confident in handling their tools, ensuring they operate smoothly and efficiently throughout their usage period.

Comprehensive Guide to Stihl BR 420 Components

This section provides an overview of the key elements and functional components of this specific model, focusing on their roles and how they contribute to the overall performance. Understanding the assembly and structure of these elements is crucial for maintaining and ensuring optimal operation.

Core Elements Overview

The equipment is composed of various integral units that work together to deliver its functionality. Below is a breakdown of the main components:

- Engine Unit – Powers the entire system, ensuring efficient energy output and operation.

- Air Filter – Keeps the airflow clean, preventing dust and debris from entering the internal mechanisms.

- Fuel Tank – Stores the necessary fuel, designed for safety and easy access during refueling.

- Nozzle and Tube Assembly – Directs the flow effectively, providing control over the output.

Maintenance and Replacement Tips

For optimal longevity, it is important to check and service the essential elements regularly. Follow these basic steps to keep the equipment in top condition:

- Inspect the engine frequently for any signs of wear or leakage.

- Replace the air filter when it appears clogged or dirty to maintain proper airflow.

Understanding the Stihl BR 420 Model

This model is a powerful and efficient solution for outdoor maintenance, designed to tackle demanding tasks with ease. Known for its reliability and robust performance, it offers a combination of high airflow and durability, making it suitable for both professional and personal use. In this section, we will explore its main features, capabilities, and operational efficiency.

To provide a clearer overview of its specifications, the following table summarizes the key aspects:

| Feature | Description |

|---|---|

| Engine Type | Air-cooled, two-stroke engine |

| Fuel Capacity | 1.5 liters |

| Air Velocity | Up to 180 mph |

| Weight | Approximately 9.5 kg |

This equipment is designed for optimal comfort and efficiency, featuring ergonomic straps and a user-friendly control system. It ensures maximum performance with minimal effort, making it an essential tool for various ou

Key Components of the Stihl BR 420

The equipment is composed of several essential elements that work together to provide reliable and efficient operation. Understanding these elements and their functions is crucial for maintaining performance and ensuring the longevity of the machine.

Engine Unit: The core power source that drives the entire system, providing the necessary force for effective operation. It is designed to offer maximum efficiency and durability.

Air Filter System: A vital part that prevents debris and dust from entering the main unit, maintaining optimal performance and preventing damage. It requires regular maintenance to ensure it functions properly.

Fuel Tank: The container that holds the fuel, ensuring the power source is consistently supplied. It is designed to be both durable and easy to access for refueling.

Throttle Control: This component allows precise adjustment of the power level, giving the user full control over the operation speed and efficiency. Proper use of the throttle is essential for effective control.

Blower Tube: The extension through which air is directed, designed to maximize airflow and reach. It is adjustable to suit various working conditions, ensuring flexibility in usage.

These key components play an integral role in the overall function of the device, working together to provide an efficient and dependable solution for outdoor tasks.

Air Filter Assembly Overview

The air filter system is essential for maintaining efficient performance and longevity of the equipment. It prevents unwanted particles from entering the engine, ensuring smooth operation and reducing the risk of damage. Understanding the components of this system is crucial for proper maintenance and effective operation.

The assembly typically includes several interconnected parts that work together to filter the incoming air before it reaches the engine. Each component has a specific function, contributing to the overall filtration process.

| Component | Description |

|---|---|

| Filter Cover | Protects the internal filter and provides easy access for maintenance. |

| Filter Element | Captures dust, debris, and other particles, ensuring clean airflow. |

| Housing | Encases the filter element and channels air through the system efficiently. |

| Mounting Bracket | Secures the entire assembly to the equipment, ensuring stability and proper alignment. |

Regular inspection and cleaning of the air filter are vital to keep the equipment functioning at its best. Replacing damaged components promptly ensures the longevity and reliability of the entire system.

Fuel System Parts and Functionality

The fuel system is an essential component of any blower, ensuring the efficient delivery of energy required for operation. It consists of various interconnected elements designed to supply and regulate the flow of liquid energy, allowing the engine to perform optimally. Understanding how these elements work together can help in maintaining and troubleshooting any issues related to this system.

Main Components of the System

- Fuel Tank: Serves as the reservoir for storing the liquid that powers the engine.

- Carburetor: This part mixes the stored liquid with air, creating a combustible mixture that is essential for engine function.

- Fuel Lines: Flexible tubes that transport the liquid from the tank to the carburetor and other essential components.

- Primer Bulb: A small pump that helps to circulate the liquid through the system, making it easier to start the engine.

- Fuel Filter: Located within the tank, it ensures that only clean, filtered liquid reaches the engine.

How the System Operates

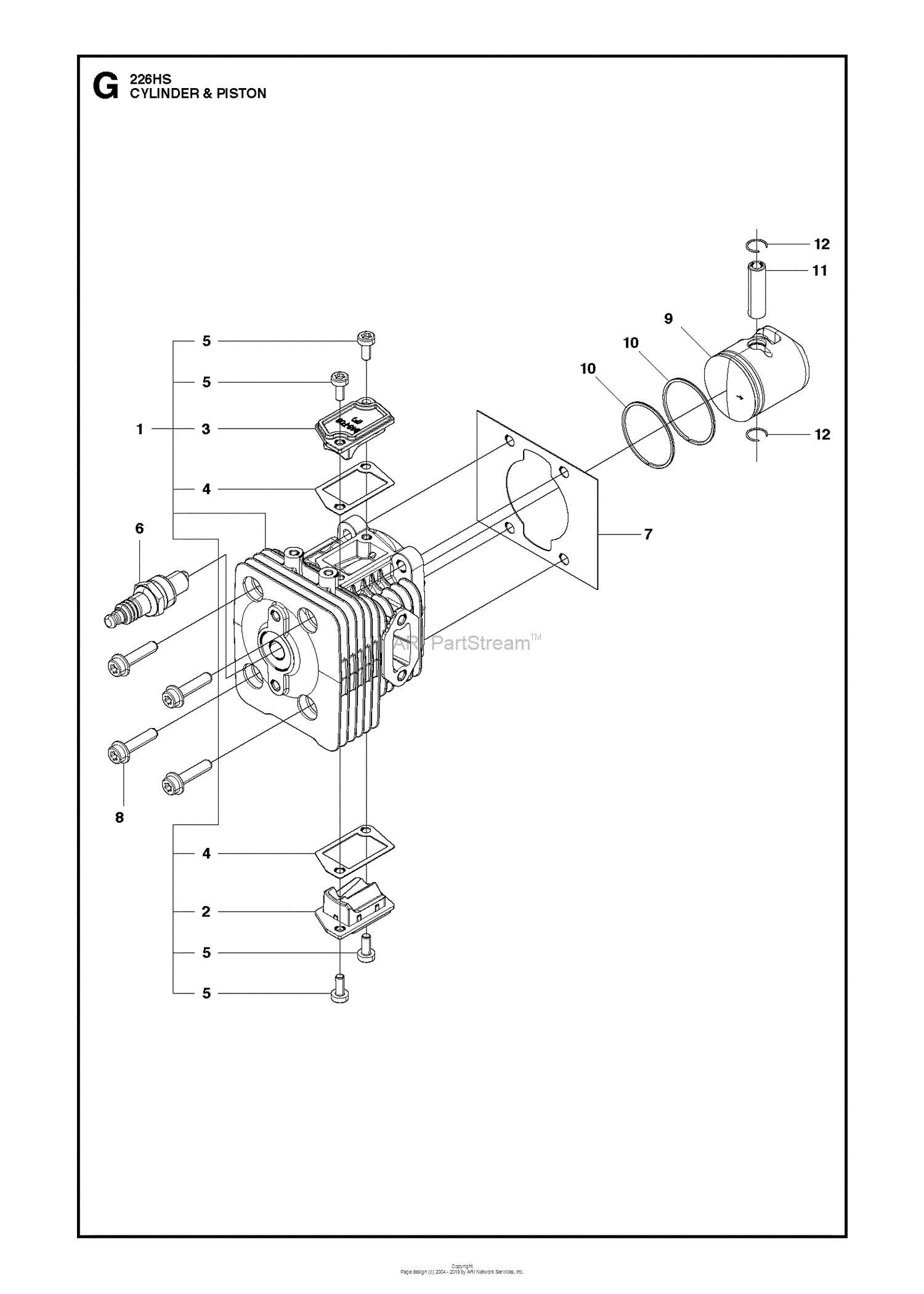

Ignition System Components Explained

The ignition system plays a crucial role in the overall functionality of small engines, ensuring reliable starting and efficient operation. This system comprises several key components that work together to create the necessary spark for combustion. Understanding these elements is essential for effective maintenance and troubleshooting.

The primary component is the ignition coil, which transforms battery voltage into a much higher voltage required to create a spark at the spark plug. The spark plug itself ignites the air-fuel mixture in the combustion chamber, initiating the power cycle. Additionally, the ignition module regulates the timing of the spark, ensuring it occurs at the optimal moment for maximum efficiency.

Another vital part is the flywheel, which often houses the ignition magnets that generate electrical energy for the coil. Some systems may also include a trigger mechanism, such as a pickup coil, that senses the position of the flywheel to synchronize the ignition timing. Understanding the interplay of these components can greatly enhance the performance and reliability of the engine.

Carburetor Assembly Breakdown

The carburetor is a crucial component in the engine’s performance, as it plays a significant role in mixing air and fuel for combustion. Understanding its assembly is essential for effective maintenance and repair. This section will provide a detailed overview of the various parts that make up the carburetor, helping users identify and address any issues that may arise.

| Component | Description |

|---|---|

| Float Chamber | Holds fuel and regulates the fuel level within the carburetor. |

| Needle Valve | Controls the flow of fuel into the float chamber. |

| Jet | Regulates the amount of fuel mixed with air for optimal combustion. |

| Throttle Valve | Controls the engine’s power output by regulating air intake. |

| Choke Valve | Helps enrich the fuel-air mixture for easier starting in cold conditions. |

Each of these components plays a vital role in ensuring the efficient operation of the engine. Familiarity with their functions can aid in troubleshooting and optimizing performance.

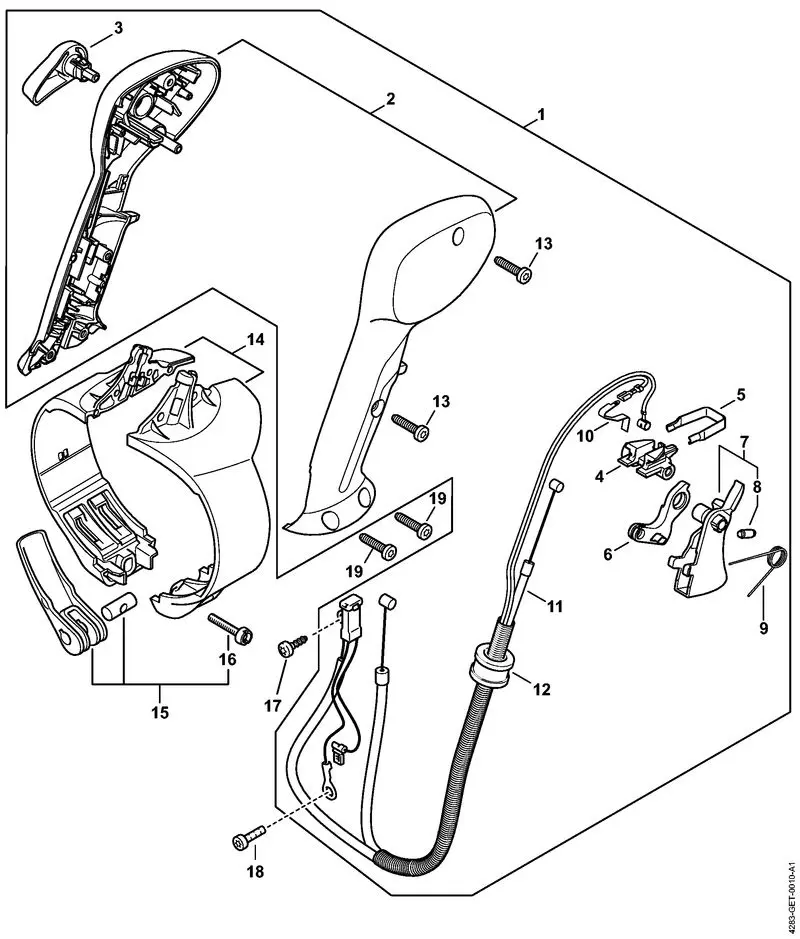

Throttle Control and Linkage Mechanism

The throttle control and linkage mechanism is a vital component in ensuring optimal performance and responsiveness in outdoor power equipment. This system regulates the flow of fuel and air, enabling the operator to adjust engine speed and power output efficiently. Understanding its structure and functionality is crucial for maintaining the equipment’s operational efficiency and longevity.

The throttle control is typically operated through a lever or trigger, which the user manipulates to increase or decrease engine RPM. This action is transmitted through a series of linkages that connect the control mechanism to the carburetor or fuel injection system, allowing precise control over the engine’s power delivery.

| Component | Description |

|---|---|

| Throttle Lever | The primary control used by the operator to adjust engine speed. |

| Linkage Rod | A connecting rod that transmits the movement from the throttle lever to the throttle plate. |

| Throttle Plate | The component within the carburetor that regulates airflow and fuel mixture into the engine. |

| Return Spring | A spring that ensures the throttle lever returns to its default position when released. |

Regular inspection and maintenance of the throttle control and linkage mechanism are essential for optimal performance. Ensuring that all components are free from debris and wear will contribute to the overall efficiency and reliability of the equipment.

Blower Tube and Nozzle Specifications

The blower tube and nozzle are essential components that significantly influence the performance and efficiency of the equipment. These parts are designed to direct airflow and enhance the user’s ability to manage debris and leaves effectively. Understanding their specifications can aid in selecting the right attachments for specific tasks.

Tube Length and Diameter

The length and diameter of the blower tube are critical factors affecting the airflow speed and reach. A longer tube can help in reaching distant areas, while a wider diameter allows for greater volume of air to be moved. It is important to choose a tube that balances these attributes to meet the specific needs of various tasks.

Nozzle Design and Functionality

The nozzle is designed to focus the airflow, allowing for precise control when directing debris. Different nozzle shapes, such as tapered or flat, can be used for various applications. A tapered nozzle provides a concentrated stream, ideal for moving heavier debris, whereas a flat nozzle is better suited for spreading out airflow over a larger area.

Maintenance Tips for Engine Parts

Proper upkeep of engine components is essential for ensuring optimal performance and longevity. Regular maintenance not only helps in identifying potential issues early but also enhances the efficiency of the entire system. Following a systematic approach can prevent unnecessary breakdowns and costly repairs.

Here are some essential maintenance tips:

- Regular Cleaning: Keep the engine area clean from dirt, debris, and grime. Use a soft brush or cloth to remove buildup.

- Inspection: Periodically inspect all components for wear and damage. Look for signs of corrosion, cracks, or loose fittings.

- Lubrication: Ensure that moving parts are properly lubricated to reduce friction. Use the recommended lubricant as specified in the manual.

- Air Filter Maintenance: Check and clean or replace the air filter as needed. A clean filter improves airflow and engine efficiency.

- Fuel System Care: Keep the fuel system clean by using high-quality fuel. Regularly check for clogs in the lines and replace old fuel.

- Check Belts and Cables: Inspect belts and cables for signs of wear. Replace any frayed or damaged components immediately.

Implementing these maintenance practices will help in maintaining the reliability and efficiency of engine parts, ultimately extending their lifespan and performance.

Replacement Guide for Stihl BR 420 Parts

This section provides essential information on how to effectively replace components of your outdoor power equipment. Understanding the various elements and their functions will help ensure proper maintenance and longevity of your device. With the right approach, you can easily identify when parts need to be changed and how to proceed with the replacement process.

Identifying Components for Replacement

Before initiating any replacements, it’s crucial to familiarize yourself with the key components of your machine. Regular inspection will allow you to spot any signs of wear or damage. Common parts that may require attention include:

- Filters

- Blades

- Fuel lines

- Seals and gaskets

Replacement Process

Once you have identified the necessary components, follow these steps for a smooth replacement:

- Turn off the device and disconnect any power sources.

- Carefully remove the worn or damaged component.

- Install the new part, ensuring a secure fit.

- Reconnect the device and test its functionality.

Proper replacement not only enhances performance but also promotes safety during operation. Regular maintenance checks and timely replacements are essential for optimal performance.

Where to Find Authentic Stihl Parts

When it comes to maintaining outdoor power equipment, sourcing genuine components is essential for optimal performance and longevity. Authentic replacements ensure compatibility and reliability, which are crucial for efficient operation. Whether you’re a professional or a DIY enthusiast, knowing where to acquire these original elements can make a significant difference in your machinery’s upkeep.

Authorized Dealers

One of the best places to locate genuine components is through authorized dealers. These retailers are certified to sell original replacements and often provide expert advice on installation and maintenance. Visiting a nearby dealership can also allow you to ask questions and receive guidance tailored to your specific equipment needs.

Official Online Retailers

In addition to physical stores, official online platforms offer a convenient way to browse and purchase authentic components. These websites usually have extensive catalogs, complete with descriptions and compatibility information. Make sure to verify that the website is legitimate to avoid counterfeit products. Look for customer reviews and ratings to ensure you’re purchasing from a trusted source.