This section provides a comprehensive overview of the various components involved in the operation of specialized gardening equipment. By familiarizing oneself with these elements, users can enhance their maintenance practices and ensure optimal performance.

Recognizing the structure and function of each component is crucial for efficient troubleshooting and repairs. Detailed illustrations and descriptions will assist users in identifying individual parts, facilitating a deeper understanding of how they contribute to the overall functionality of the device.

Moreover, understanding the relationships between these components can lead to improved safety and enhanced usability. This knowledge empowers users to perform basic maintenance tasks, ensuring their equipment remains in top condition for longer periods.

This section explores the essential characteristics of specialized cutting tools designed for high-reaching tasks. These devices are known for their efficiency and user-friendly designs, making them suitable for various outdoor maintenance projects.

- Extended Reach: These tools typically feature a long reach, allowing users to access branches and foliage that are high off the ground without the need for ladders.

- Lightweight Construction: Many models are constructed from lightweight materials, ensuring ease of maneuverability and reducing user fatigue during prolonged use.

- Powerful Performance: Equipped with robust engines, these tools deliver consistent power, enabling efficient cutting through thick branches and limbs.

- User-Friendly Controls: Designed with intuitive controls, these devices provide a comfortable grip and simple operation, enhancing user experience.

- Versatile Attachments: Some models come with interchangeable attachments, allowing for versatility in tackling various tasks, from trimming to pruning.

Overall, the combination of these features ensures that these specialized tools meet the demands of both professional landscapers and homeowners, providing reliable solutions for maintaining trees and shrubs.

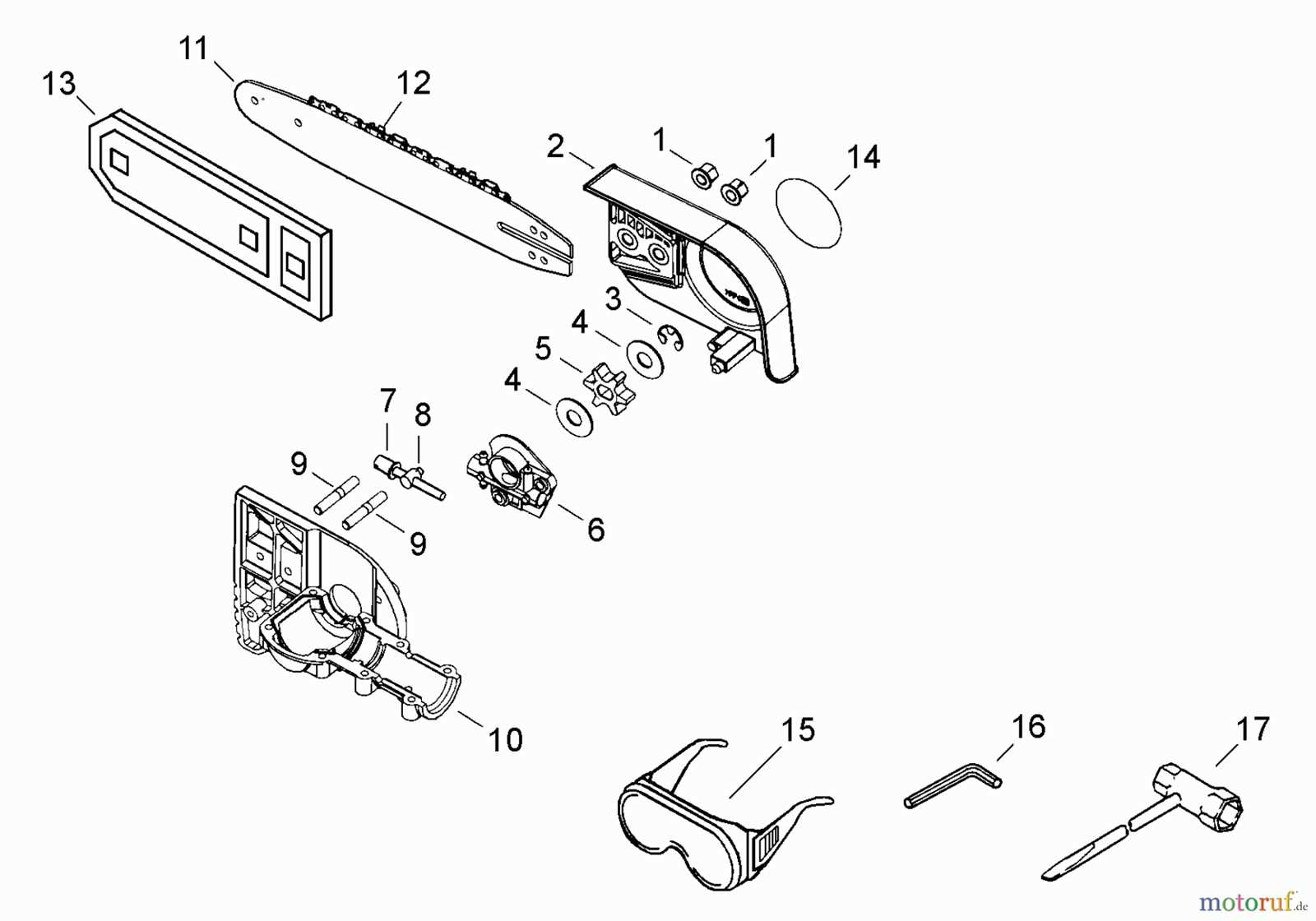

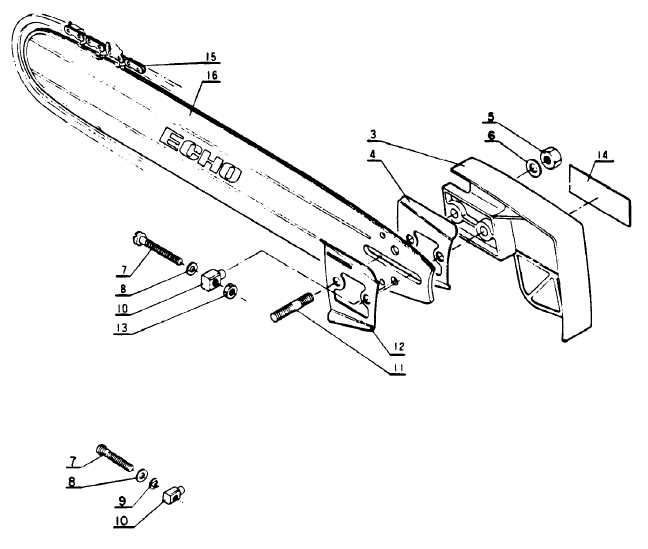

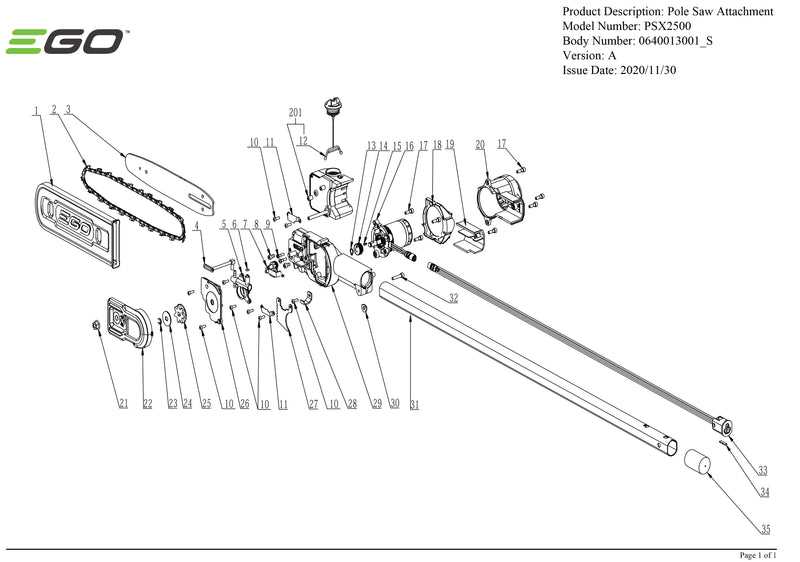

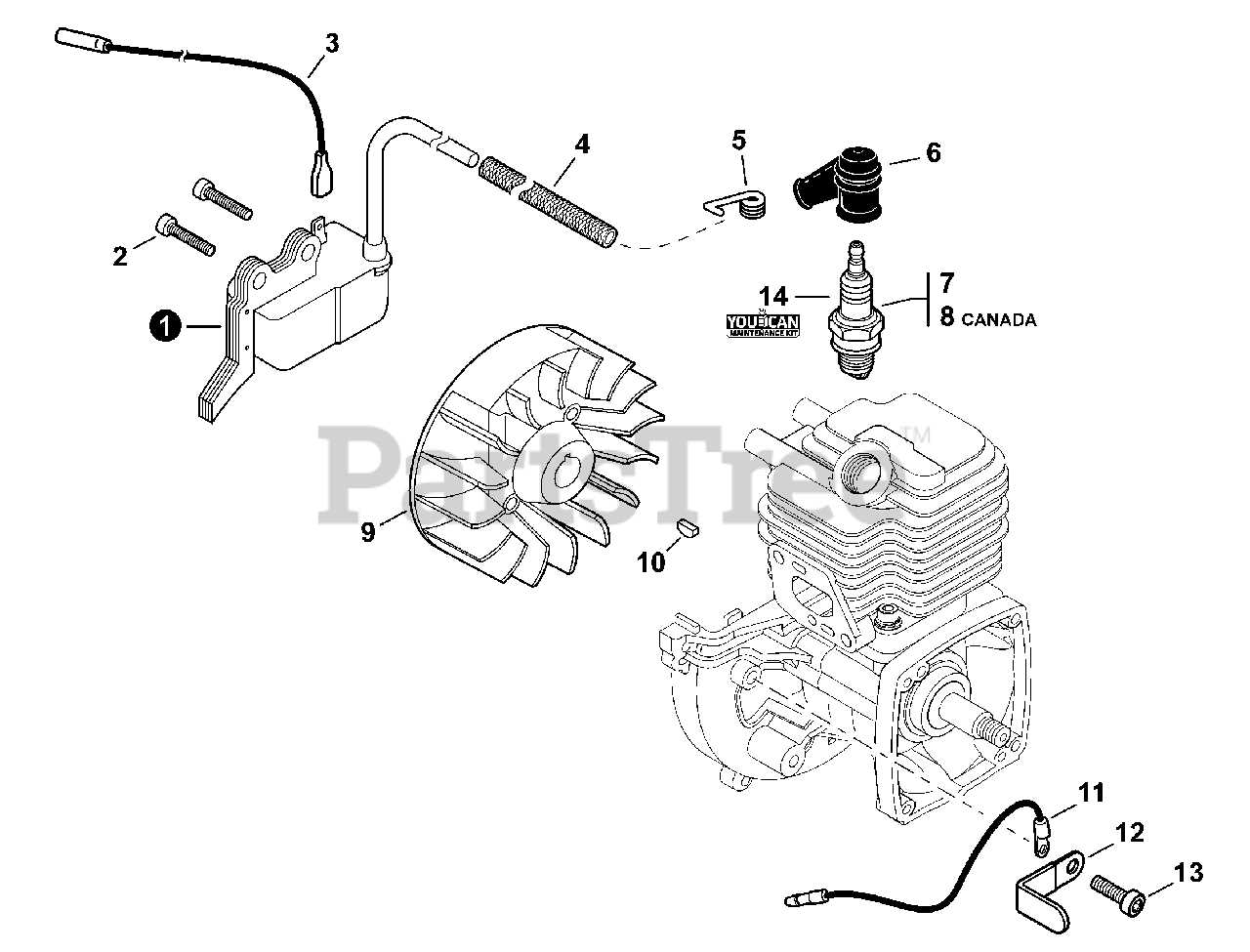

Identifying Main Parts in Diagrams

Understanding the essential components represented in schematic illustrations is crucial for effective maintenance and troubleshooting. These visuals serve as a guide, allowing users to locate and comprehend each element’s function. Recognizing the key segments enhances operational efficiency and aids in the identification of potential issues.

Key Components Overview

Every schematic typically highlights the main segments, each serving a specific role in the overall mechanism. Familiarity with these elements enables users to navigate the illustration easily and grasp how each component interacts within the system. Common components include the motor assembly, drive system, and control mechanisms.

Interpreting Visual Symbols

In many cases, various symbols and notations are used to represent different elements. Understanding these visual cues is essential for accurate identification. For instance, circles may indicate connection points, while arrows often denote movement or direction. Paying attention to these symbols ensures a comprehensive understanding of the entire assembly.

Maintenance Tips for Your Equipment

Regular upkeep is essential for ensuring the longevity and optimal performance of your tools. By following some basic maintenance practices, you can enhance the efficiency of your equipment and reduce the risk of breakdowns.

Here are some key tips to consider:

- Cleaning: After each use, clean your tools thoroughly to remove debris and dirt. This prevents rust and prolongs the lifespan of various components.

- Inspection: Regularly check all parts for signs of wear and tear. Pay attention to moving parts and replace any damaged components promptly.

- Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. This minimizes friction and keeps your equipment running smoothly.

- Storage: Store your tools in a dry, safe place to protect them from environmental factors. Using protective cases can further safeguard against damage.

- Sharpening: Keep blades sharp for improved performance. Regular sharpening reduces the strain on the motor and ensures efficient cutting.

By adhering to these maintenance practices, you can maintain the functionality of your tools and extend their operational life.

Common Issues and Solutions

Maintaining a tool often involves addressing various challenges that may arise during its operation. Users frequently encounter specific malfunctions or inefficiencies that can hinder performance. Understanding these common problems and their corresponding remedies is essential for effective use and longevity.

1. Engine Won’t Start: This is a prevalent issue that can stem from several factors, including fuel blockage, spark plug failure, or a dirty air filter. To resolve this, check the fuel supply and ensure it’s fresh. Inspect the spark plug for wear and replace it if necessary. Additionally, clean or replace the air filter to ensure proper airflow.

2. Excessive Vibration: Unusual vibrations during operation may indicate loose components or unbalanced cutting attachments. Inspect all screws and bolts for tightness, and ensure that attachments are properly aligned. If the problem persists, consider replacing worn or damaged parts.

3. Poor Cutting Performance: If the tool struggles to cut effectively, it could be due to dull blades or incorrect chain tension. Regularly sharpen the blades and adjust the tension according to the manufacturer’s specifications to maintain optimal cutting efficiency.

4. Fuel Leaks: Fuel leaks can occur due to damaged fuel lines or connectors. Regularly inspect these components for signs of wear. If a leak is detected, replace the damaged parts immediately to prevent further issues and ensure safety.

5. Overheating: Overheating can result from prolonged use without adequate breaks or poor ventilation. To prevent this, take regular breaks during operation and ensure that the tool is not obstructed by debris that may hinder airflow.

By identifying these common issues and applying the suggested solutions, users can enhance the functionality and lifespan of their equipment.

How to Replace Damaged Parts

Over time, wear and tear can lead to the need for replacing certain components in your equipment. Identifying and addressing damaged elements promptly helps maintain performance and extend the lifespan of the machine. Below is a step-by-step guide for replacing worn-out components efficiently.

Step 1: Begin by disconnecting the power source to ensure safety during the replacement process. This step is essential to avoid accidental starts or injuries.

Step 2: Locate the damaged section that requires replacement. Carefully inspect the surrounding areas to make sure no other components are affected. Taking time to do this will help prevent further malfunctions in the future.

Step 3: Remove the worn-out component using the appropriate tools. Make sure to follow any manufacturer instructions for disassembly, paying attention to how the parts are fitted together.

Step 4: Install the new piece, ensuring that it is correctly aligned and securely fastened. Double-check that everything is properly in place before proceeding to reassemble the rest of the device.

Step 5: Reconnect the power source and test the functionality of the equipment. Ensure that the new component operates smoothly without any issues.

Safety Precautions When Using

When operating any type of cutting equipment, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the basic principles of safe operation can help avoid common risks and ensure a more efficient use of the tool.

Wear Protective Gear

Always wear appropriate protective equipment, including gloves, safety goggles, and hearing protection. Suitable clothing can minimize the risk of injury, and sturdy footwear will provide better stability while working.

Check the Area Before Use

Before starting the equipment, inspect the surrounding area to make sure it’s free of obstacles. Ensure no bystanders or animals are nearby, and remove any debris that could interfere with your task or cause the tool to malfunction.

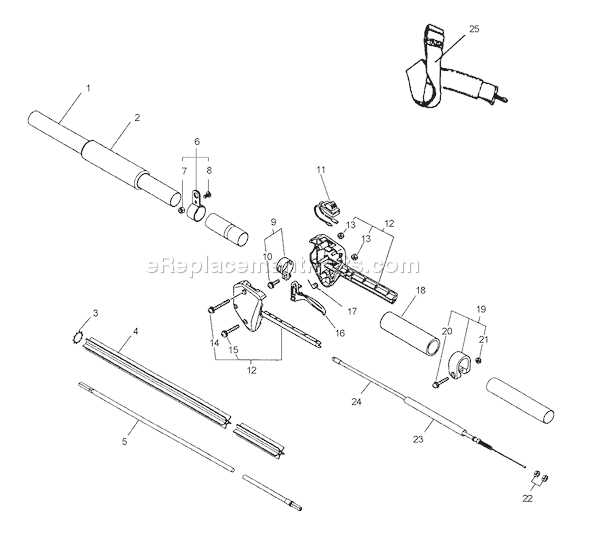

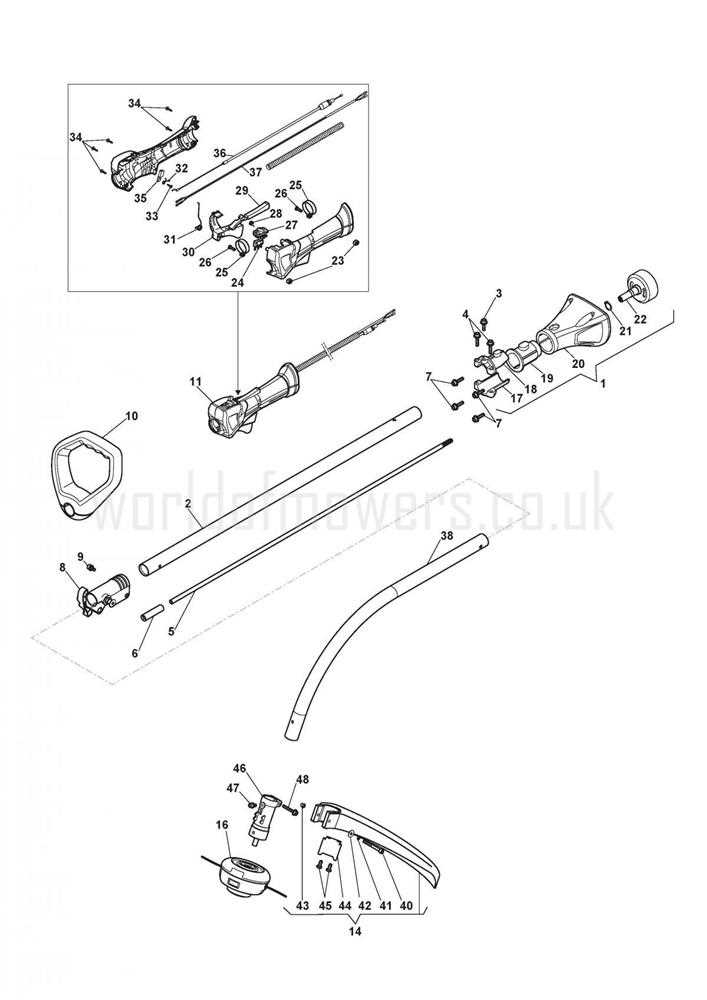

Assembly Instructions for Echo Models

When putting together these models, it’s important to follow the provided guidelines carefully to ensure proper functioning. Each component is designed to fit precisely, and all connections must be securely fastened. By adhering to the steps outlined in the instruction manual, users can efficiently complete the setup.

Step-by-step Process:

Start by gathering all the necessary tools. Make sure every part is available before beginning the assembly. Begin with the main structure, attaching the smaller sections in the order specified by the manual. For optimal performance, tighten each connection properly but avoid over-tightening to prevent damage.

Final Adjustments: After assembly, verify that all moving parts function smoothly. Conduct a thorough check of the assembled product to confirm that everything is secure and ready for use. Regular maintenance will ensure long-lasting operation.

Choosing Compatible Replacement Parts

When it comes to maintaining your equipment, selecting the correct replacement components is crucial to ensuring optimal performance and longevity. Using items that do not match your machine’s specifications can lead to inefficiencies and potential damage. It’s important to know how to identify the right fit to keep your tool functioning smoothly.

Understanding Component Specifications

Before purchasing any replacements, always verify the specific details of your equipment, such as dimensions and material types. Cross-referencing these characteristics with available products will help in finding suitable alternatives. Make sure the items meet the necessary technical requirements.

Where to Find Compatible Options

Specialized retailers and authorized dealers often provide a range of options designed to match your tool’s structure. It’s best to source replacements from trusted suppliers to ensure both quality and compatibility, preventing unnecessary repairs or replacements in the future.

Benefits of Using Original Parts

Choosing authentic components ensures the longevity and reliability of your equipment. Genuine replacements are specifically designed to match the original specifications, offering superior performance and reducing the risk of malfunctions.

Extended Durability

Original replacements are crafted with high-quality materials that withstand wear and tear more effectively. This contributes to a longer lifespan of the device, minimizing the need for frequent repairs.

Optimal Performance

Using authentic components guarantees that the machinery will function at its peak efficiency. The precise fit and compatibility of original replacements result in smoother operation and increased output.

| Advantages | Description |

|---|---|

| Reliability | Original components are designed for perfect compatibility, ensuring consistent and stable performance. |

| Longevity | Genuine replacements reduce the risk of premature wear, extending the lifespan of the equipment. |

Frequently Asked Questions About Saws

In this section, we address the most common queries related to cutting tools used in forestry and garden maintenance. Here, we clarify various technical aspects, offer advice on proper usage, and provide insights into ensuring optimal performance and longevity of these tools.

| Question | Answer |

|---|---|

| What is the best way to maintain a cutting tool? | Regular cleaning and sharpening of the blade are essential for maintaining cutting efficiency. Lubricating moving parts and checking for any wear and tear will also help prolong the life of the equipment. |

| How can I ensure safety while using cutting tools? | Always wear protective gear such as gloves and safety glasses. Follow the manufacturer’s instructions and avoid operating the tool in hazardous conditions. |

| What are the signs that my tool needs repair? | Signs like difficulty in cutting, unusual noises, or reduced efficiency indicate that the tool might need repairs. |