In the realm of heavy equipment, comprehending the intricate structure and functionality of essential machinery is crucial for efficient operation and maintenance. This segment delves into the various elements that contribute to the seamless performance of such vehicles. By gaining insight into the arrangement and purpose of these components, operators can ensure longevity and reliability in their equipment.

Each section of the machinery serves a unique function, playing a pivotal role in the overall efficiency of operations. Analyzing these elements not only aids in troubleshooting issues but also enhances the ability to conduct effective repairs. Understanding how different pieces interact within the system fosters a comprehensive approach to equipment management, allowing for improved performance and productivity.

Moreover, being familiar with the specific characteristics and configurations of these components empowers users to make informed decisions regarding upgrades and replacements. As advancements in technology continue to evolve, staying abreast of the latest innovations in machinery design becomes increasingly important for maximizing operational effectiveness. The insights gained from exploring the intricacies of these essential elements can significantly contribute to the mastery of heavy machinery management.

Engine specifications are critical for comprehending the performance and efficiency of machinery. These details encompass various aspects that dictate how well the engine operates, including its power output, displacement, and design features. A thorough understanding of these specifications can aid in selecting the right components and ensuring optimal functionality.

Key specifications typically include the engine type, number of cylinders, and maximum horsepower. Additionally, the torque ratings and fuel consumption figures provide valuable insights into the engine’s capabilities and operational costs.

| Specification | Details |

|---|---|

| Engine Type | Diesel or Gasoline |

| Cylinders | Number and Configuration |

| Horsepower | Maximum Power Output |

| Torque | Peak Torque Rating |

| Displacement | Engine Capacity Measurement |

By examining these factors, operators can better understand the engine’s suitability for specific tasks and its overall impact on performance. This knowledge is essential for maintaining equipment and achieving optimal results in various applications.

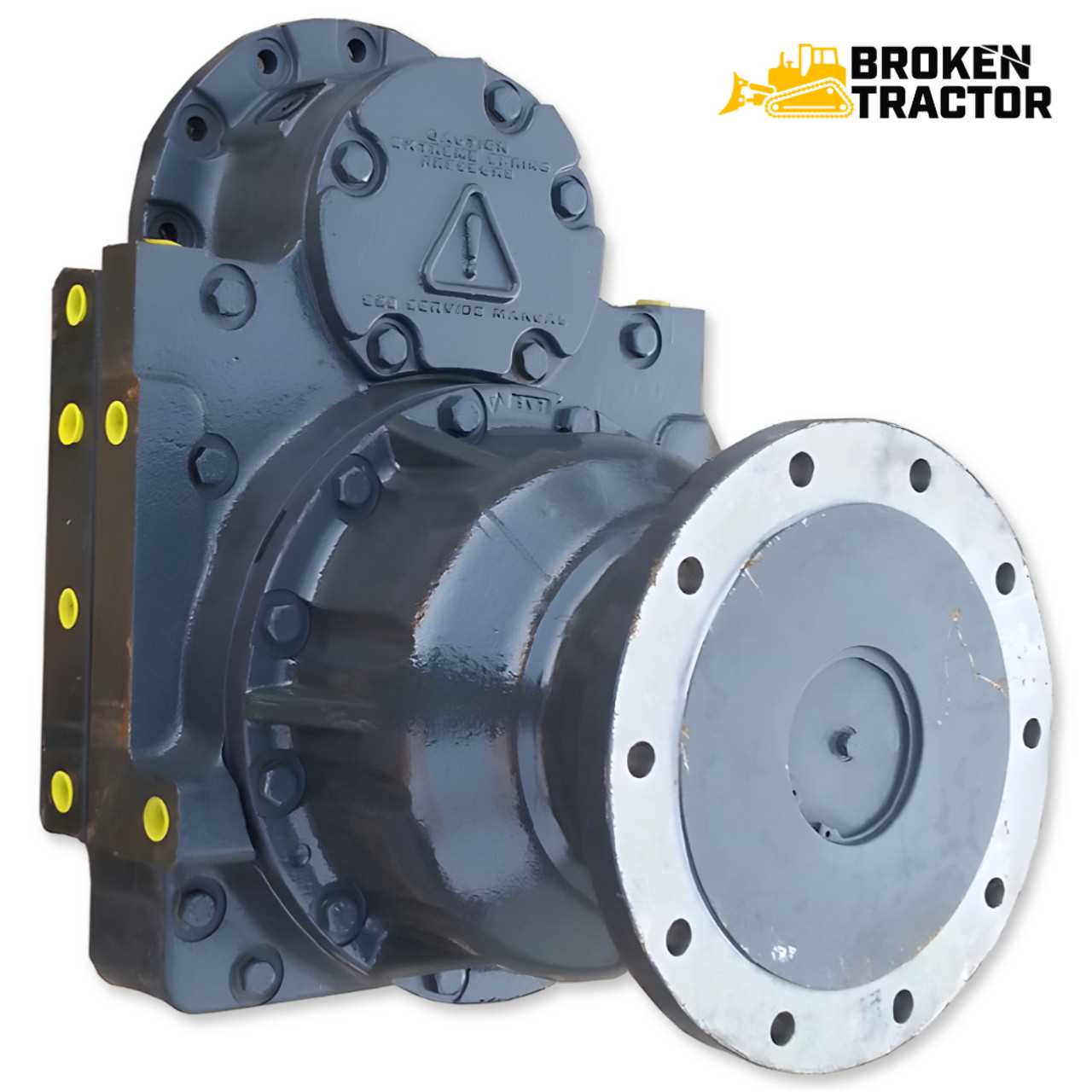

Transmission and Powertrain Details

This section provides an overview of the components responsible for transferring power from the engine to the operational mechanisms of the machinery. Understanding these systems is crucial for ensuring optimal performance and efficiency in various applications.

Key Components of the Transmission

The transmission system consists of several critical elements that work together to facilitate smooth gear changes and control vehicle speed. These include gear sets, clutches, and hydraulic systems that manage power distribution. Regular maintenance of these components is essential for preventing mechanical failures and extending the lifespan of the machinery.

Powertrain Efficiency

Efficiency in the powertrain is achieved through precise engineering and design, which minimizes energy loss during operation. Factors such as gear ratios and torque converter performance play a significant role in optimizing fuel consumption and enhancing overall productivity. Regular assessments can help identify areas for improvement, ensuring that the machinery operates at peak performance.

Hydraulic System Insights

The hydraulic mechanism plays a pivotal role in the operation of heavy machinery, facilitating efficient movement and power transmission. This intricate network of components ensures that the machine can perform various tasks effectively by harnessing the power of fluid dynamics. Understanding the essential elements and their interactions is crucial for maintaining optimal performance and longevity of the equipment.

Key components of the hydraulic setup include pumps, valves, and cylinders, each contributing to the overall functionality. The system operates on principles that allow for the transfer of force through pressurized fluid, enabling the machinery to perform heavy lifting and precise maneuvers.

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure to facilitate fluid movement. |

| Valves | Control the flow and direction of hydraulic fluid. |

| Cylinders | Convert hydraulic pressure into mechanical force for movement. |

| Hoses | Transport hydraulic fluid between components. |

Regular inspection and maintenance of these components are vital to prevent breakdowns and ensure the reliability of the equipment. A thorough understanding of the hydraulic system contributes significantly to the efficiency and productivity of heavy machinery operations.

Blade Mechanism Explained

The blade system is a critical component of heavy machinery, designed to facilitate efficient earthmoving and material handling. Understanding the mechanics behind this system reveals how it optimizes performance, allowing operators to execute various tasks with precision and ease. This section delves into the intricate workings of the blade mechanism, highlighting its essential features and functions.

Key Components of the Blade System

Several vital elements contribute to the functionality of the blade system. These components work in tandem to ensure smooth operation and effective control during use. Below is a summary of the primary parts involved:

| Component | Function |

|---|---|

| Blade | Primary tool for cutting and moving material. |

| Lift Cylinder | Controls the vertical movement of the blade. |

| Angle Cylinder | Adjusts the blade angle for better material control. |

| Frame | Supports the blade and provides structural integrity. |

Operational Mechanics

The operation of the blade mechanism is facilitated by hydraulic systems that provide the necessary force for movement and adjustments. These systems allow for fine-tuning of the blade’s position, enabling operators to achieve the desired grade or angle for effective material distribution. Proper understanding of these mechanics enhances operational efficiency and overall productivity.

Track and Undercarriage Features

The track and undercarriage system plays a vital role in the overall performance and stability of heavy machinery. This assembly is designed to provide optimal traction and support while navigating various terrains, ensuring that the machine operates effectively in demanding conditions.

Key characteristics of this system include:

- Durable Construction: Components are built to withstand harsh environments and heavy loads.

- Adjustable Tension: Allows for fine-tuning to maintain optimal track performance and prolong lifespan.

- Robust Idler Wheels: Enhance maneuverability and contribute to smoother operation.

- Track Link Design: Facilitates better grip and traction, reducing slippage on uneven surfaces.

- Shock Absorption: Features that minimize vibrations, improving operator comfort and reducing wear on components.

Understanding these attributes is essential for proper maintenance and operation, ensuring that the machinery remains efficient and reliable throughout its lifecycle.

Electrical System Overview

The electrical framework of heavy machinery plays a crucial role in ensuring smooth operation and functionality. It encompasses various components that work in harmony to deliver power, manage control signals, and enhance overall efficiency. Understanding this system is essential for maintaining optimal performance and diagnosing potential issues.

Key Components

Central to the electrical architecture are the power supply elements, wiring harnesses, and control units. These components facilitate the flow of electricity throughout the machine, allowing it to execute various tasks effectively. Additionally, sensors and relays contribute to monitoring and regulating performance, ensuring that every function operates seamlessly.

Importance of Maintenance

Regular inspection and maintenance of the electrical system are vital for preventing unexpected failures. Proper care can extend the lifespan of the components and enhance the reliability of the equipment. Technicians should prioritize checking connections, testing circuits, and replacing worn parts to keep the system in excellent working condition.

Maintenance and Service Parts

Ensuring optimal functionality of heavy machinery involves a thorough understanding of the components essential for upkeep and repair. Proper maintenance practices not only enhance performance but also extend the lifespan of equipment. Familiarity with various elements involved in service processes is crucial for operators and technicians alike.

Regular servicing is vital for preventing unexpected breakdowns. The following aspects should be prioritized:

- Routine inspections of vital components to identify wear and tear.

- Replacement of worn-out elements to maintain efficiency.

- Use of quality supplies to ensure reliability and durability.

- Adherence to recommended maintenance schedules to prevent potential issues.

Specific components play a significant role in maintaining the functionality of machinery. Key items include:

- Hydraulic filters to ensure fluid cleanliness.

- Belts that drive essential systems.

- Seals that prevent leaks and protect internal mechanisms.

- Lubricants that minimize friction and enhance performance.

Incorporating these practices into a routine will lead to improved operational efficiency and reduced downtime. Always consult equipment manuals for specific guidelines and recommended replacement intervals.

Common Repairs and Replacements

Maintenance and upkeep of heavy machinery are essential for optimal performance and longevity. Understanding typical repairs and component substitutions can help operators ensure their equipment remains functional and reliable.

Key areas often requiring attention include:

- Hydraulic systems

- Transmission components

- Engine elements

- Track and undercarriage parts

Frequent issues involve:

- Hydraulic leaks: Over time, seals and hoses can wear out, leading to fluid loss and diminished efficiency.

- Worn tracks: Regular inspections are vital, as track components can deteriorate, impacting mobility and traction.

- Engine overheating: This can result from coolant system failures or blocked airflow, necessitating immediate repairs.

- Transmission problems: Gears may become damaged or worn, requiring replacement to ensure smooth operation.

By addressing these common repairs proactively, operators can enhance the reliability and performance of their machinery.

Parts Availability and Sourcing

When it comes to maintaining heavy machinery, securing the right components is crucial for ensuring optimal performance. Access to quality replacements can significantly affect operational efficiency. This section explores various avenues for obtaining essential components, emphasizing reliable sources and availability options.

Trusted Suppliers and Manufacturers

Identifying reputable suppliers is key to acquiring high-quality replacements. Many manufacturers offer official distribution channels that guarantee authenticity and compatibility. Additionally, third-party vendors can provide alternative options, often at competitive prices. It’s advisable to assess the credibility of these sources through customer reviews and warranty offers.

Online Marketplaces and Resources

The digital landscape has transformed sourcing practices, providing a wealth of online platforms dedicated to heavy equipment components. Websites specializing in machinery parts often feature extensive catalogs, enabling users to compare prices and specifications conveniently. Furthermore, forums and discussion boards can be valuable resources for recommendations on sourcing reliable suppliers.

| Supplier Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine components, warranties | Higher cost |

| Aftermarket Providers | Cost-effective alternatives | Variable quality |

| Online Marketplaces | Wide selection, price comparisons | Authenticity concerns |

Diagram Interpretation Techniques

Understanding visual representations of mechanical components is essential for effective maintenance and repair. Employing various strategies can enhance one’s ability to decipher these intricate illustrations. Such methods involve recognizing symbols, grasping connections between elements, and identifying key features that guide the troubleshooting process.

One effective approach is to familiarize oneself with the standard symbols and notations commonly used in these representations. This knowledge allows for quicker identification of specific parts and functions, enabling a more efficient analysis of the overall system. Additionally, paying attention to the layout and organization of the illustration can provide valuable insights into the operational flow of the machinery.

Utilizing a systematic method for examining each segment of the representation can further facilitate comprehension. Breaking down complex assemblies into smaller, manageable parts makes it easier to analyze their roles and interactions. Cross-referencing with technical manuals or service guides can also reinforce understanding and offer practical applications of the information presented.