The effectiveness of a snow management system relies on a range of interconnected elements, each playing a vital role in ensuring smooth and efficient operation. Whether you’re maintaining a residential driveway or tackling larger commercial properties, the precision of the equipment determines the quality of the results. This section will guide you through the key components involved in such systems, offering insight into how they function together.

Durable materials and engineering are essential for long-term performance, especially when facing harsh winter conditions. In this guide, we will explore the mechanisms responsible for controlling the movement and alignment of the system, ensuring it operates as intended during challenging weather conditions.

From the framework to the operational controls, each element is specifically designed to handle heavy-duty tasks. Understanding these components is crucial for anyone looking to maintain or repair such equipment, ensuring its efficiency and reliability throughout the season.

Understanding the Components of the RT3 V Plow

When it comes to heavy-duty snow management equipment, it’s crucial to be familiar with the various mechanical elements that work together to ensure efficient operation. This section focuses on identifying and explaining the essential elements that make up the structure, contributing to the system’s durability and effectiveness in challenging conditions.

| Component | Description |

|---|---|

| Hydraulic System | This mechanism is responsible for controlling the movement and angling of the blade, ensuring smooth and precise operation during use. |

| Blade Sections | The cutting edges are designed to clear snow effectively, with reinforced segments that handle large volumes of snow with ease. |

| Mounting Frame | Provides the necessary support and stability, ensuring the equipment stays securely attached during operation. |

| Lighting System | Ensures visibility during low-light conditions, enhancing safety while operating the equipment in harsh environments. |

Key Features of the V-Shaped Snow Clearing System

The innovative snow removal system offers exceptional functionality and versatility for various weather conditions. Its unique design allows for efficient handling of large volumes of snow, making it ideal for both residential and commercial use. The following section highlights the core components and distinctive advantages of this advanced system, ensuring optimal performance during heavy-duty tasks.

| Feature | Description |

|---|---|

| Hydraulic Efficiency | The system integrates a highly efficient hydraulic mechanism, allowing for smooth and precise control in various angles and configurations. |

| Durable Construction | Crafted from high-strength materials, the framework is designed to withstand harsh environments and prolonged usage without compromising performance. |

| Adaptive Blade Movement | Offers adjustable blade positioning, enabling effective snow removal in different terrains and weather conditions. |

| Quick Attachment System | Features an easy-to-use connection interface, ensuring rapid installation and removal, minimizing downtime. |

How the RT3 Plow Blade Mechanism Works

The blade adjustment system is a crucial part of effective snow clearing equipment. It ensures that the blade can move smoothly and efficiently, adapting to different surfaces and conditions. Understanding how the mechanism functions helps users optimize its performance and maintain its longevity.

The mechanism operates through a combination of pivot points and hydraulics. These components allow for controlled movements and precise angling. Below is an outline of the key functions:

- Hydraulic Lifting: The system raises and lowers the blade, enabling the user to adjust its height as needed for different surface levels.

- Angling Capability: The mechanism provides the ability to angle the blade to the left or right, making it easier to push snow to the desired side.

- Pivoting Motion: The blade can tilt forward or backward, allowing for better ground contact and minimizing wear on the blade’s edges.

- Shock Absorption: Built-in shock absorbers help protect the system from sudden impacts, ensuring a smoother operation even in rough conditions.

Each of these features works in harmony, offering flexibility and control over the blade’s movement, enhancing the overall efficiency of the equipment.

Hydraulic System in Boss RT3 Plows

The hydraulic system plays a critical role in the efficient operation of snow removal equipment, allowing for smooth adjustments and control during work. This system ensures that various components move fluidly, enabling the equipment to perform different tasks seamlessly. Understanding how the hydraulic mechanism functions is essential for maintaining peak performance and avoiding potential issues.

The system is composed of several interconnected parts that work in harmony to manipulate the angle and height of the blade. Below are the primary elements that form this system:

- Pump: Responsible for generating pressure that powers the system.

- Hydraulic hoses: Carry fluid between components, ensuring consistent movement.

- Cylinders: Convert hydraulic pressure into mechanical force to control movement.

- Valves: Manage the direction and flow of hydraulic fluid.

- Reservoir: Stores the hydraulic fluid, which is essential for operation.

Proper maintenance of the hydraulic system includes regularly checking for fluid levels, inspecting hoses for wear or leaks, and ensuring all components are free of debris. By staying proactive with upkeep, you can prevent breakdowns and ensure the machinery operates reliably under tough conditions.

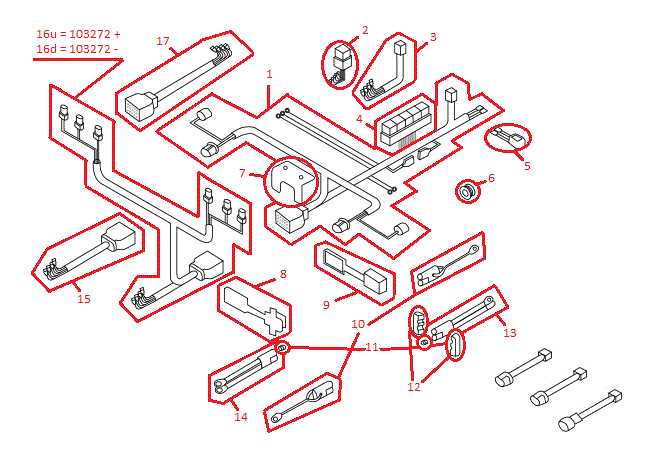

Electrical Wiring in the Boss RT3 V Plow

The electrical system in snow removal equipment involves a series of connections that ensure proper operation of hydraulic mechanisms, lighting, and controls. Understanding these connections is essential for troubleshooting and maintaining the functionality of the machine during operation in harsh winter conditions.

Main Components of the Electrical System

- Control module: Acts as the brain of the system, sending signals to adjust the blade’s position.

- Wiring harness: A set of cables that transfer power between different components.

- Relays and fuses: Protect the system from electrical overload and ensure safe operation.

- Connectors: Provide secure and weatherproof connections between the various elements.

Troubleshooting Common Wiring Issues

- Inspect all connections for signs of corrosion or wear.

- Check fuses and relays to ensure they are functioning properly.

- Test the control module and wiring harness for continuity using a multimeter.

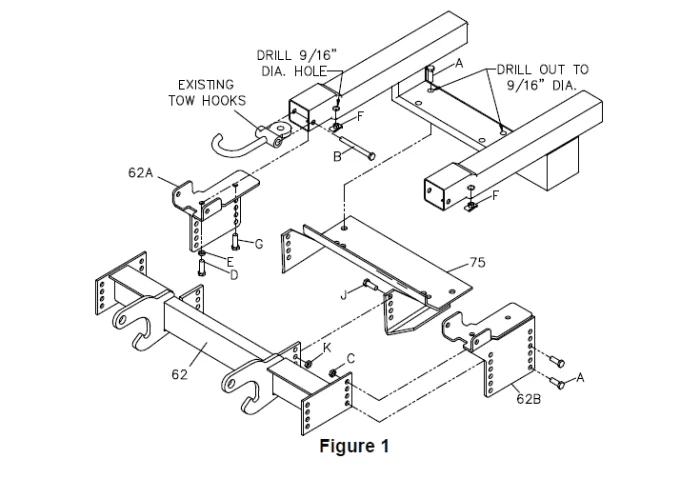

Common Parts in the RT3 Plow Assembly

This section provides an overview of the essential components found in the assembly of this snow removal system. Understanding these elements is crucial for effective maintenance and efficient operation during winter conditions.

Key components typically include:

- Mounting brackets: These secure the system to the vehicle.

- Hydraulic cylinders: Essential for raising and lowering the apparatus.

- Control arms: Allow for precise angle adjustments.

- Pivot pins: Facilitate movement between different sections.

- Blade: The main interface with the snow, designed for durability and effectiveness.

- Wear strips: Protect the blade and enhance longevity.

Each of these elements plays a significant role in ensuring the equipment operates smoothly and withstands harsh conditions. Regular checks and maintenance of these components can lead to enhanced performance and reliability during use.

Additionally, users may consider the following tips for optimal operation:

- Inspect hydraulic connections regularly for leaks.

- Ensure mounting hardware is tight and free from rust.

- Replace wear strips as needed to maintain effectiveness.

- Lubricate moving parts to prevent wear and ensure smooth operation.

Maintenance Tips for Boss RT3 V Plow

Proper upkeep is essential for ensuring optimal performance and longevity of your snow management equipment. Regular maintenance not only enhances functionality but also helps prevent costly repairs in the long run. Below are some key recommendations to keep your system in top shape.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Hydraulic System | Monthly | Check for leaks, fluid levels, and overall condition to ensure smooth operation. |

| Examine Cutting Edge | Before Each Use | Inspect for wear and damage; replace if necessary to maintain efficiency. |

| Lubricate Moving Parts | Every 10 Uses | Apply appropriate lubricant to joints and pivot points to prevent rust and ensure smooth movement. |

| Check Electrical Connections | Seasonally | Inspect wiring and connections for corrosion or wear, ensuring all components function properly. |

| Clean Components | After Each Use | Remove debris and ice build-up from the unit to prevent damage and maintain performance. |

Adhering to these guidelines will significantly enhance the reliability and effectiveness of your snow clearing equipment, allowing for a seamless experience during winter operations.

Identifying Wear Parts in the RT3 Plow

Understanding the components that experience significant wear during operation is crucial for maintaining optimal performance and prolonging the lifespan of your equipment. Regular inspections can help identify these elements, ensuring timely replacements and avoiding costly repairs.

Key components to monitor include:

- Cutting Edge: The forefront element that makes contact with surfaces, often subject to abrasion and wear.

- The stabilizing piece that aids in guiding the unit, which may become damaged or bent over time.

- The connecting mechanisms that facilitate movement, requiring regular checks for wear and alignment.

- Bolts and brackets that secure components together, which can loosen or corrode under stress.

To effectively monitor these components, consider implementing the following maintenance practices:

- Conduct routine visual inspections to assess the condition of each element.

- Use a measuring tool to determine the thickness of the cutting edge and compare it with manufacturer specifications.

- Check for signs of bending or deformation in the ski and linkage.

- Inspect mounting hardware for signs of rust or wear, replacing any compromised pieces promptly.

By focusing on these critical components, operators can ensure their equipment remains in peak condition, ready to tackle any task with efficiency and reliability.

Safety Features of the RT3 V Plow

The design of modern snow removal equipment prioritizes user safety alongside efficiency. This section explores the various protective elements incorporated into this innovative snow-clearing tool, ensuring safe operation in diverse conditions.

Enhanced Visibility

Visibility is crucial during snow removal tasks, especially in low-light conditions. The following features enhance operator awareness:

- Integrated LED lights to illuminate the work area.

- Reflective markings for improved visibility from all angles.

- Wide blade design for better sightlines during operation.

Stability and Control

Stability is vital to ensure safe handling while working on various terrains. Key aspects include:

- Advanced hydraulic system for precise blade positioning.

- Robust frame construction to withstand harsh conditions.

- Weight distribution features that enhance balance and control.

These safety measures collectively contribute to a secure working environment, allowing operators to focus on efficient snow removal without compromising their well-being.

Replacing Critical Components in the Boss Plow

Maintaining the functionality of your snow removal equipment is essential for optimal performance during winter operations. Understanding the process of replacing key elements can significantly enhance the lifespan and effectiveness of your machinery. This section provides insights into how to identify and replace crucial components, ensuring that your system operates smoothly.

Identifying Wear and Tear

Before commencing any replacement, it is important to assess the condition of your machinery. Look for signs of damage such as cracks, excessive wear, or corrosion. Regular inspections will help you spot issues early and determine which elements require immediate attention.

Gathering Necessary Tools

Before starting the replacement process, ensure you have the appropriate tools at your disposal. A standard toolkit, including wrenches, pliers, and a socket set, will typically be required. Additionally, having replacement components ready will streamline the process and minimize downtime.

Step-by-Step Replacement Process

Begin by removing the damaged component carefully. Follow the manufacturer’s guidelines to avoid causing further damage. Once removed, install the new element by aligning it correctly and securing it in place. Double-check all connections to ensure they are tight and secure. Finally, test the machinery to confirm that the replacement was successful.

Regular Maintenance

After replacing essential elements, establish a routine maintenance schedule. Regularly checking and servicing your equipment will prevent future issues and prolong its lifespan. This proactive approach will enhance your overall efficiency and reduce the risk of unexpected breakdowns during critical times.