In the realm of construction and heavy-duty tasks, having a thorough comprehension of the individual elements that make up a robust tool is essential for both efficiency and safety. Each segment plays a vital role, ensuring that the entire system operates seamlessly. Grasping the relationship between these elements can significantly enhance one’s ability to troubleshoot and maintain the equipment effectively.

Exploring the intricate assembly of a specific model reveals not just how it functions, but also highlights the innovative engineering behind its design. With a focus on the layout and functionality of these segments, users can better appreciate the meticulous craftsmanship involved in creating tools that stand the test of time.

By delving into the organization and design of this equipment, one can gain insights into its operation, ultimately leading to improved performance and longevity. Understanding how each piece interacts fosters a deeper connection to the machinery, empowering users to tackle their projects with confidence.

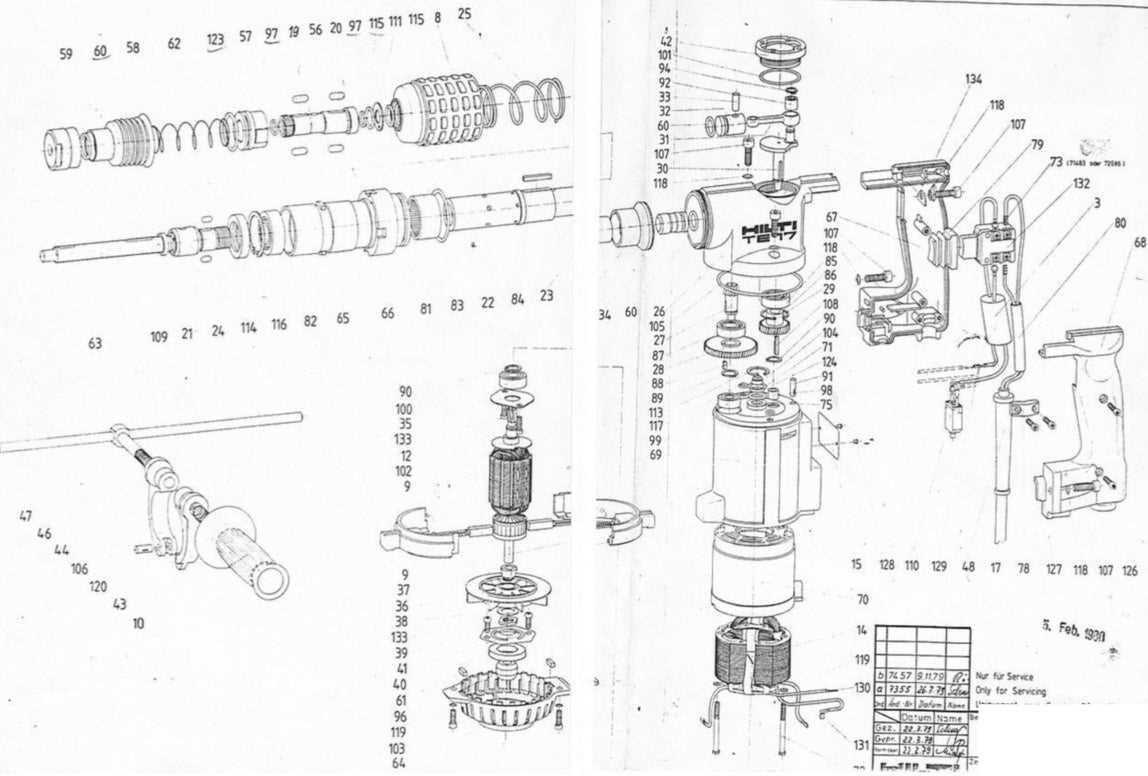

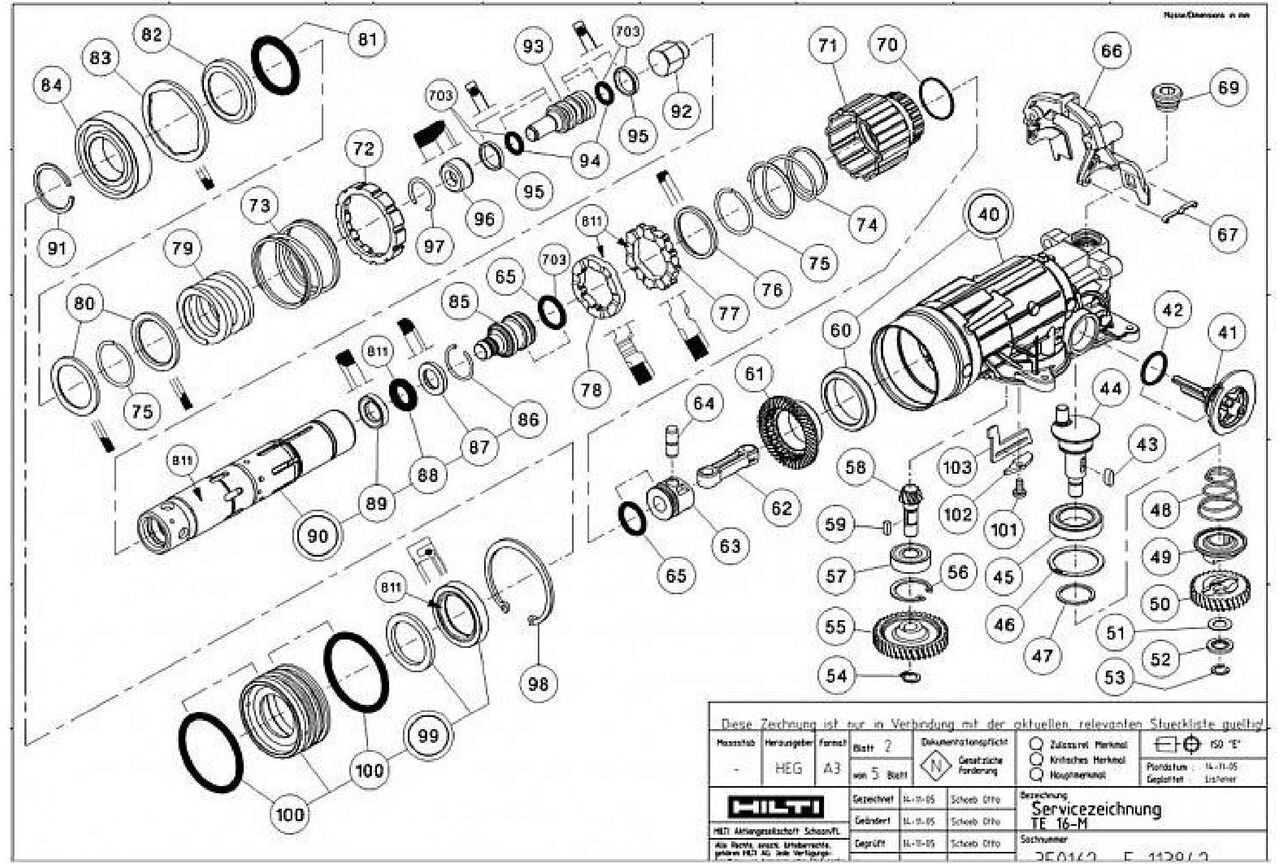

Understanding the Hilti TE 75

This powerful tool is designed for heavy-duty applications, combining advanced technology with robust engineering to tackle the most challenging tasks. Its impressive performance makes it a preferred choice among professionals in construction and demolition. By exploring its components, one can gain insight into how it achieves such efficiency and reliability.

Familiarity with the key elements of this equipment enables users to optimize its functionality and prolong its lifespan. Each section contributes to the overall effectiveness, making it essential to grasp their roles and interactions. This knowledge not only enhances operational proficiency but also facilitates troubleshooting and maintenance.

As one delves deeper into the specifics, understanding the unique features and capabilities of this equipment can ultimately lead to better project outcomes. Mastering its intricacies empowers users to fully harness its potential, ensuring high-quality results in various applications.

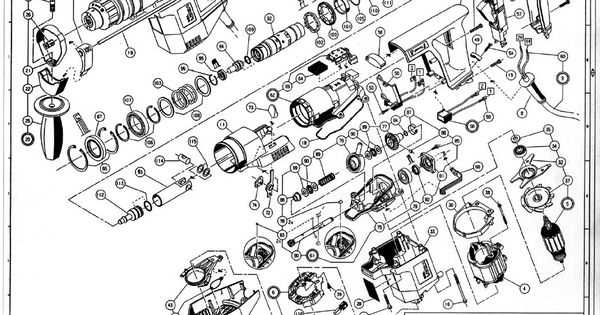

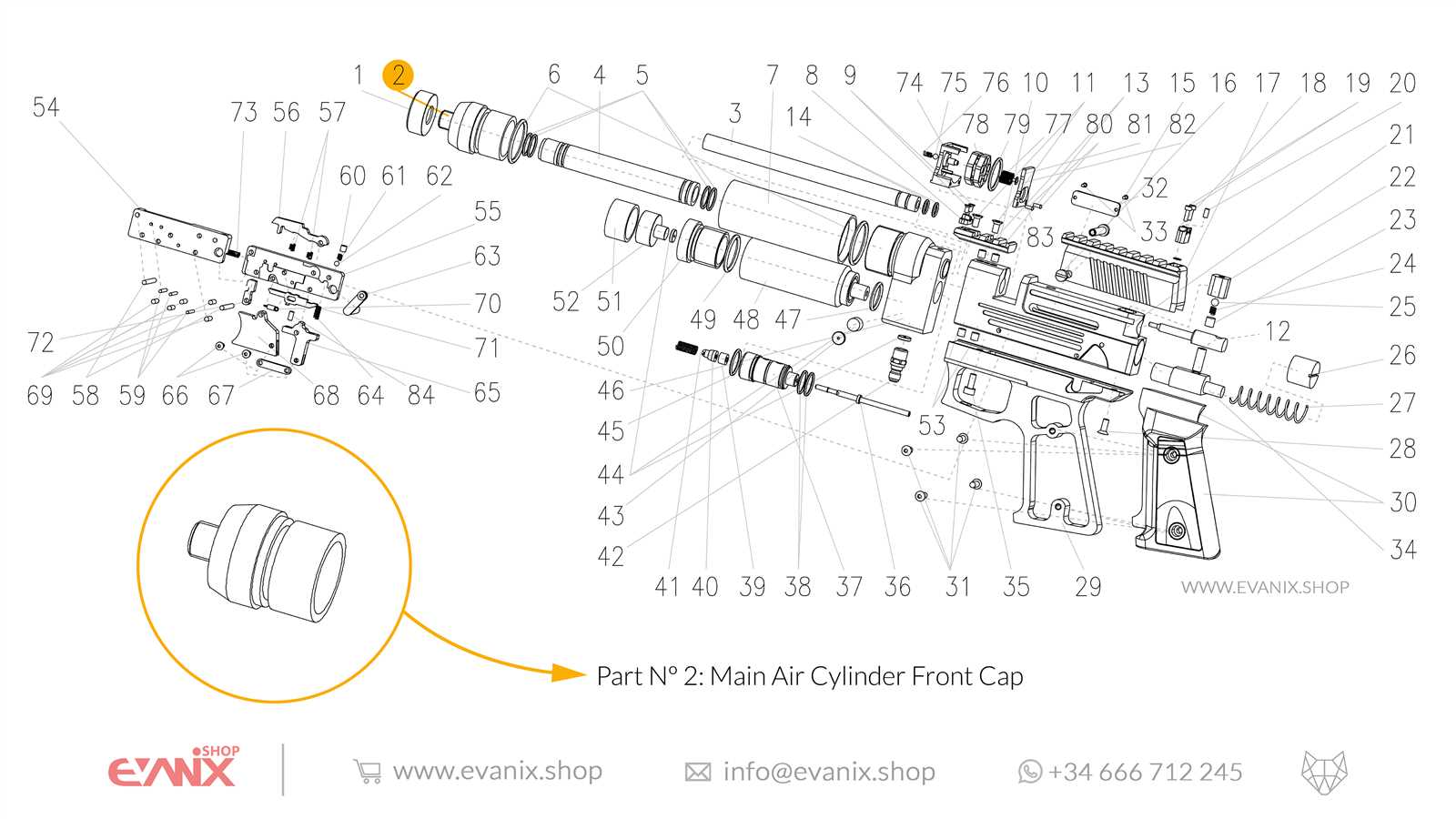

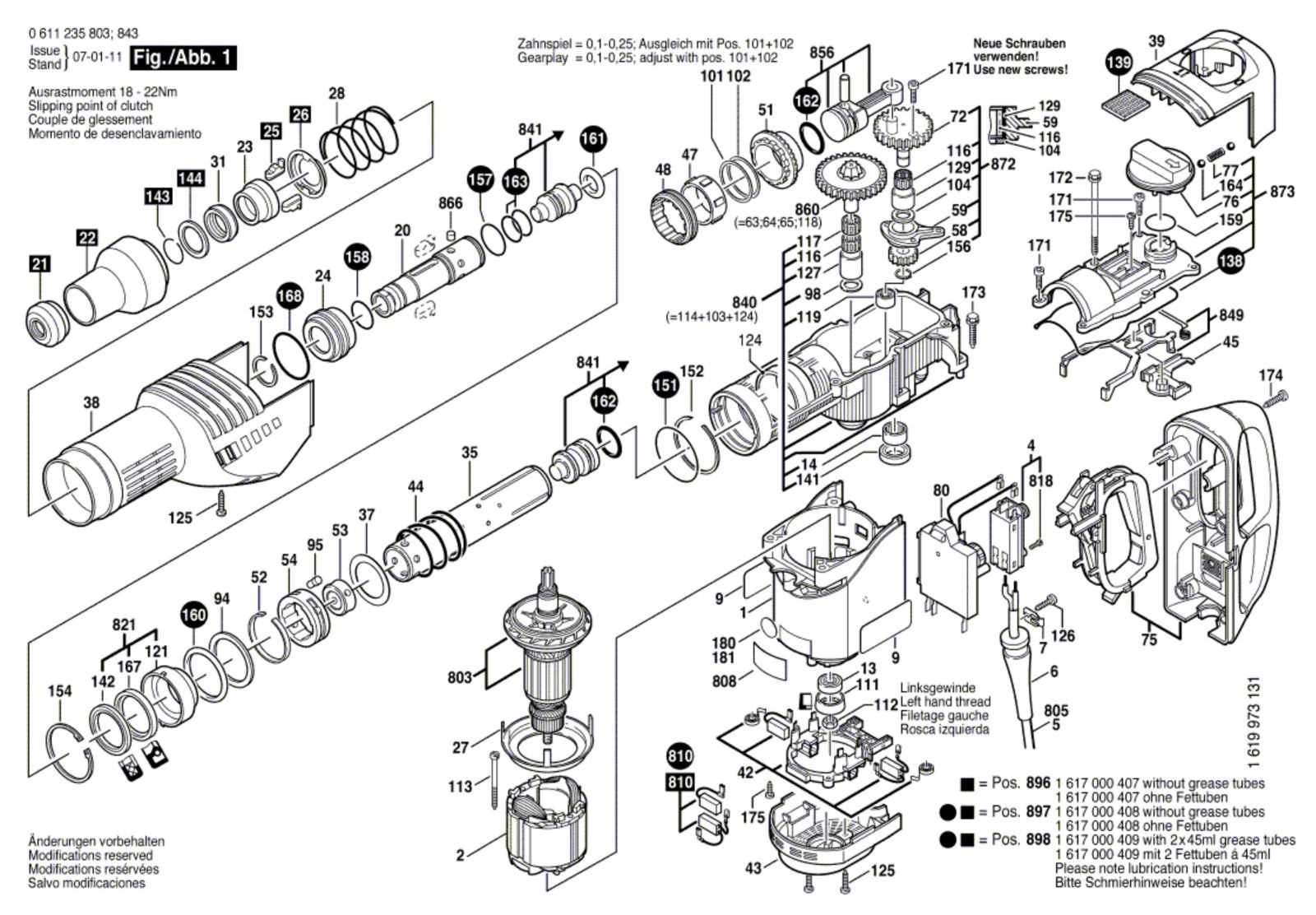

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations of these elements facilitate easier identification, ensuring that users can quickly locate and understand the various sections involved in a device’s operation. This clarity enhances efficiency, reduces errors, and promotes informed decision-making during service tasks.

Enhancing Repair Efficiency

Visual aids serve as essential tools in troubleshooting and repairing equipment. They allow technicians to pinpoint issues swiftly, minimizing downtime and optimizing workflow. When individuals can refer to a clear representation of components, they can execute repairs with greater precision and confidence.

Facilitating Training and Learning

For newcomers in the field, these visual guides provide a foundation for understanding complex systems. They bridge the gap between theory and practice, enabling trainees to grasp the relationships between different elements within machinery. This foundational knowledge is vital for building expertise and fostering safety in operations.

| Benefit | Description |

|---|---|

| Efficiency | Speeds up the identification of components and issues. |

| Accuracy | Reduces mistakes during maintenance and repairs. |

| Training Aid | Assists newcomers in learning about equipment functions. |

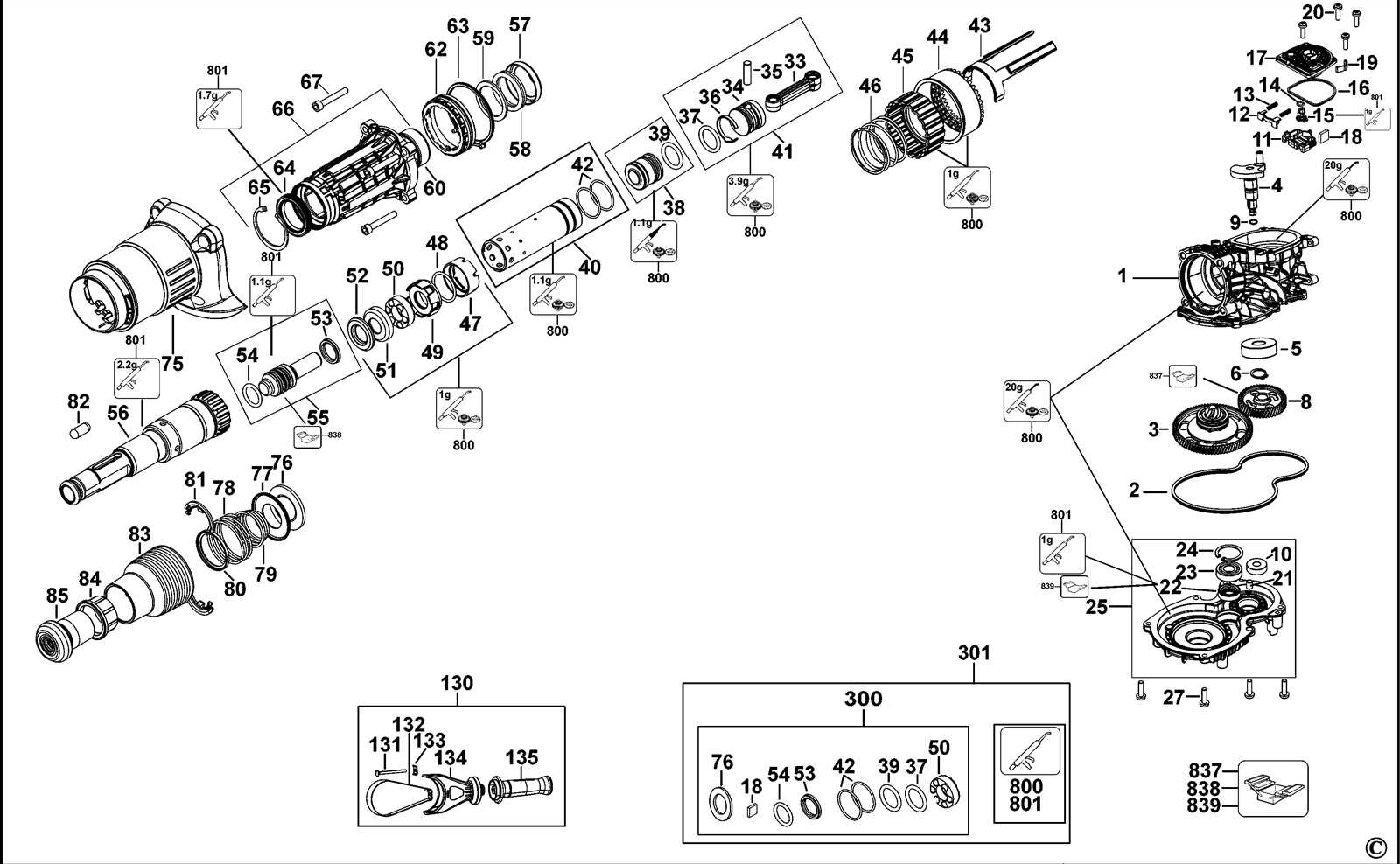

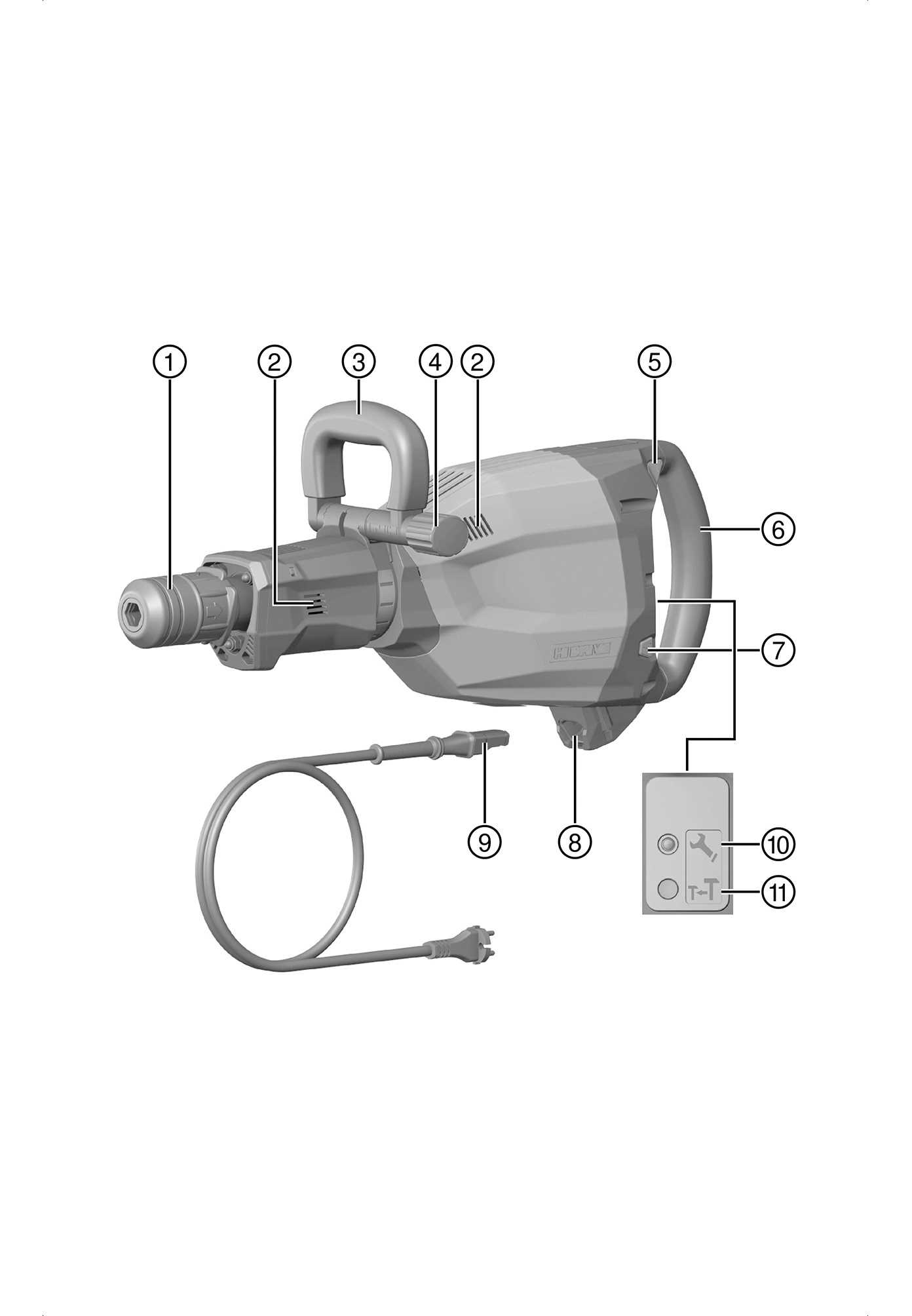

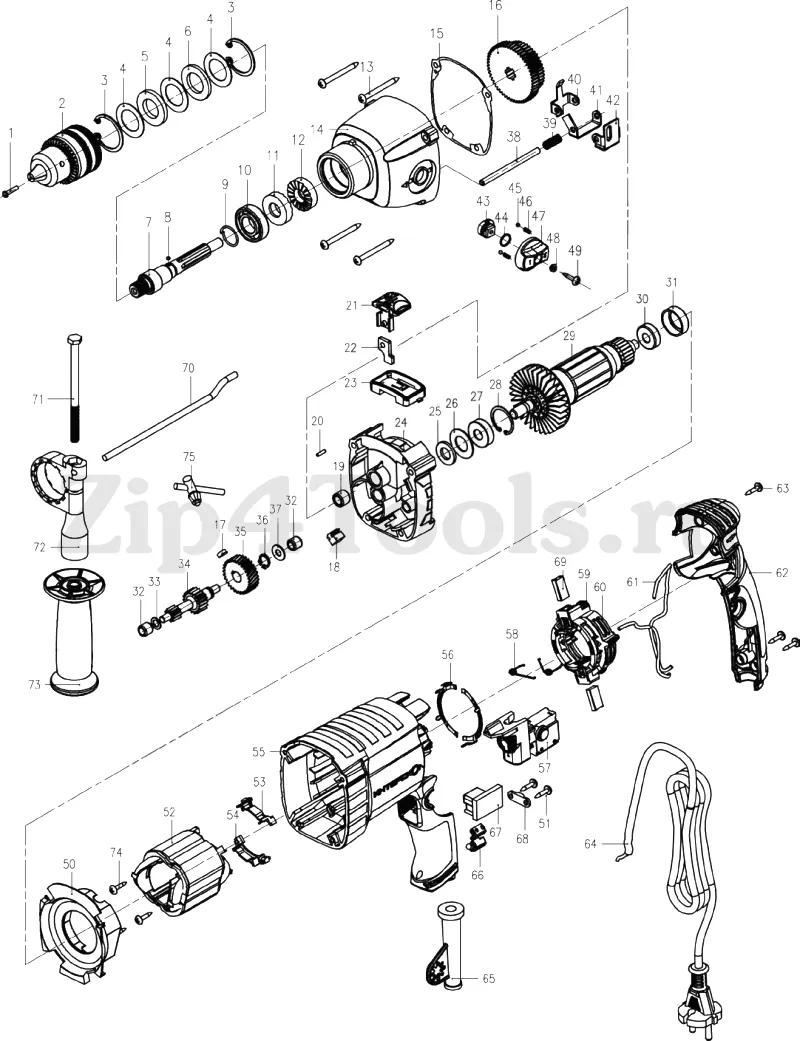

Key Components of the TE 75

The TE 75 is an advanced tool designed for heavy-duty applications, characterized by its robust build and innovative features. Understanding its primary elements is essential for optimal performance and maintenance.

Motor: At the heart of the tool lies a powerful motor, providing exceptional energy efficiency and reliability. This component is crucial for delivering consistent performance during demanding tasks.

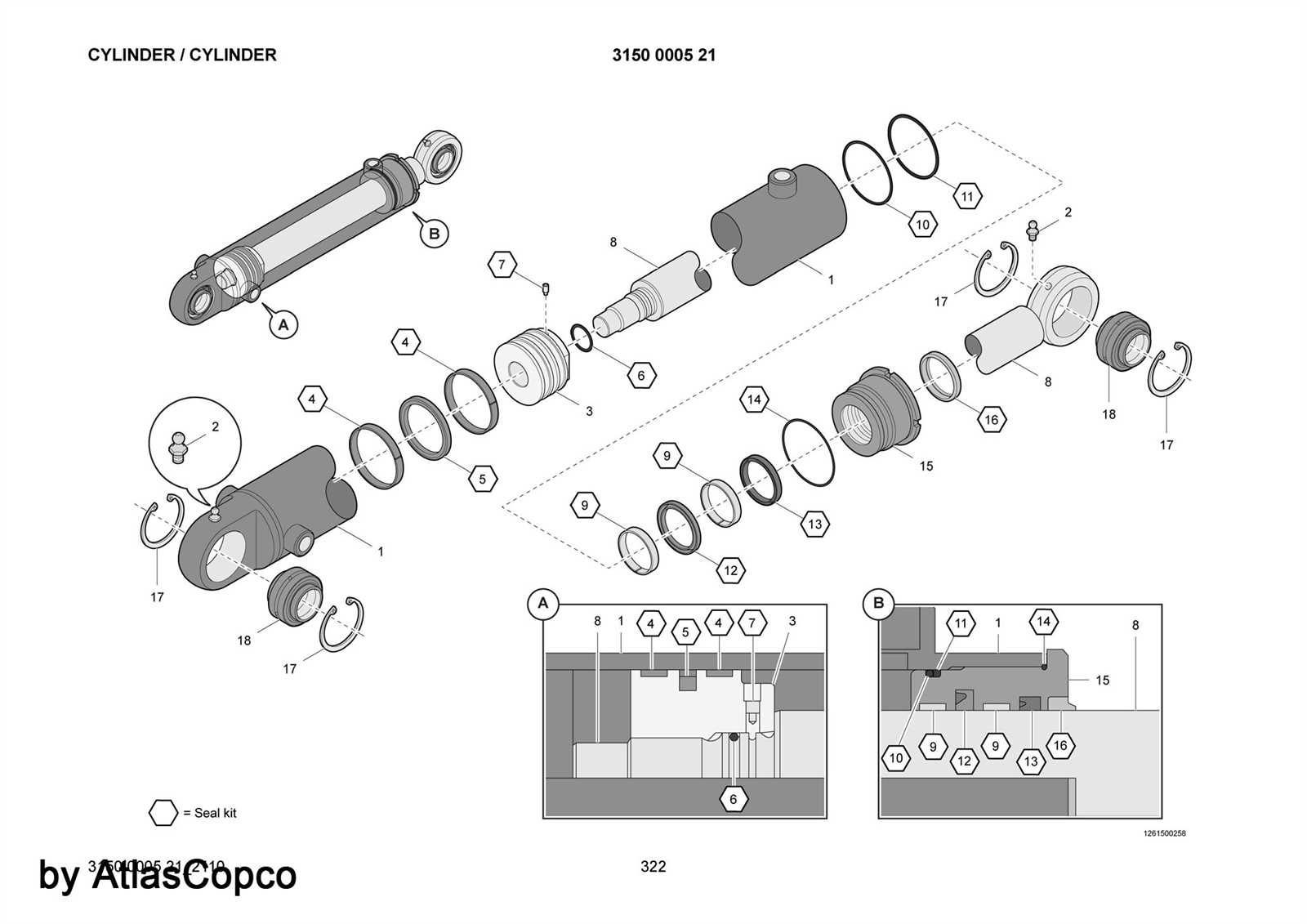

Pneumatic System: The pneumatic mechanism enhances impact efficiency, ensuring effective drilling and chiseling. Its design minimizes air loss, contributing to the overall power of the device.

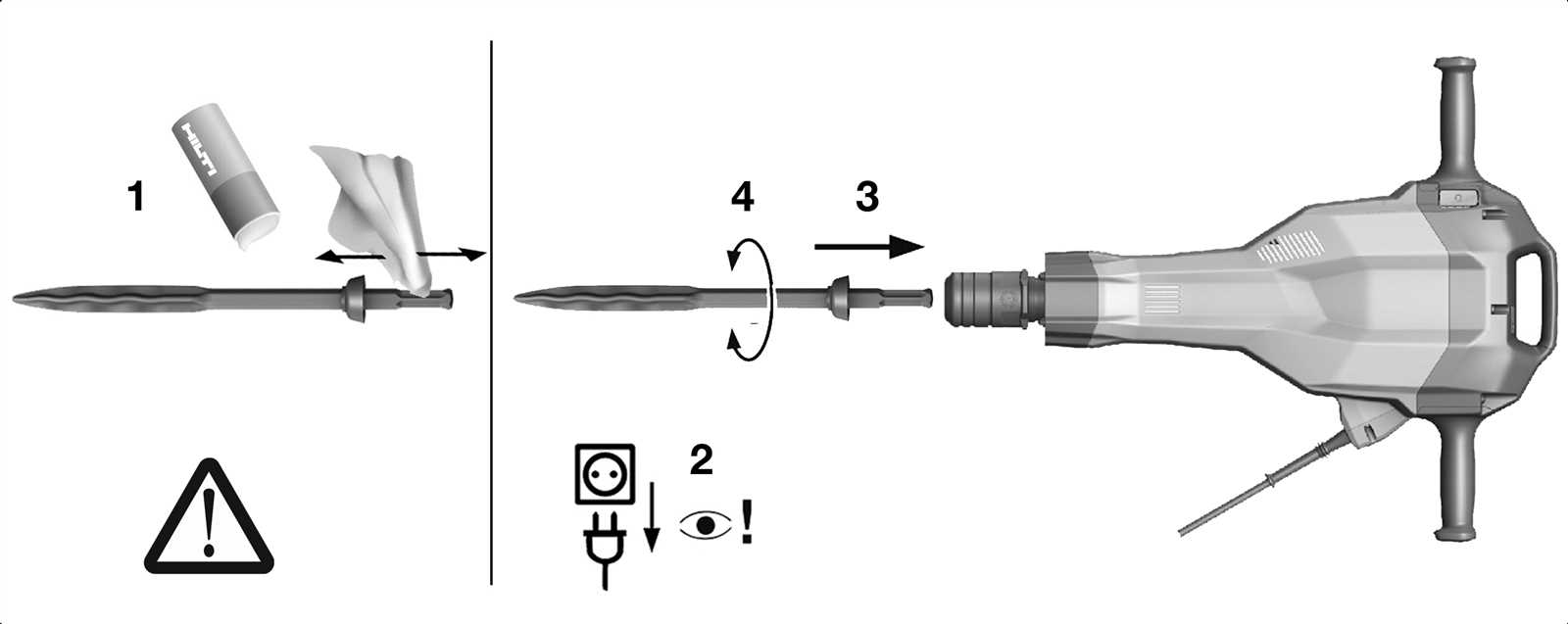

Chisel Tooling: Various chisel attachments are available, allowing users to adapt the tool for different materials and applications. The compatibility with different tool types makes it versatile for construction and renovation projects.

Vibration Control: Advanced vibration dampening technology significantly reduces user fatigue, making prolonged use more comfortable. This feature is vital for maintaining productivity and safety on the job site.

Ergonomic Design: The tool is designed with user comfort in mind, featuring an easy-to-hold handle and balanced weight distribution. This thoughtful design promotes better handling and control during operation.

By familiarizing oneself with these key elements, users can ensure they are utilizing the tool effectively and prolonging its lifespan.

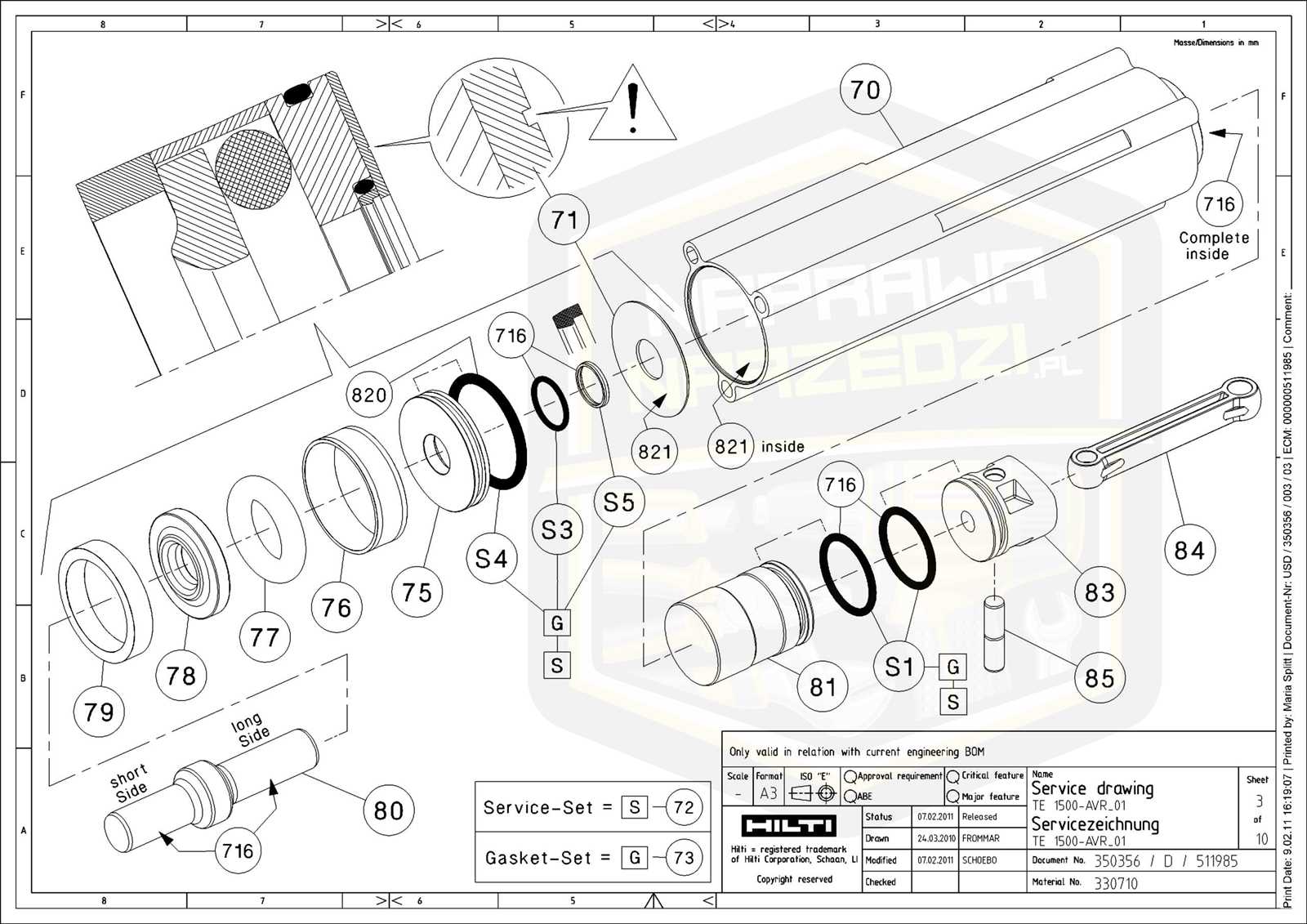

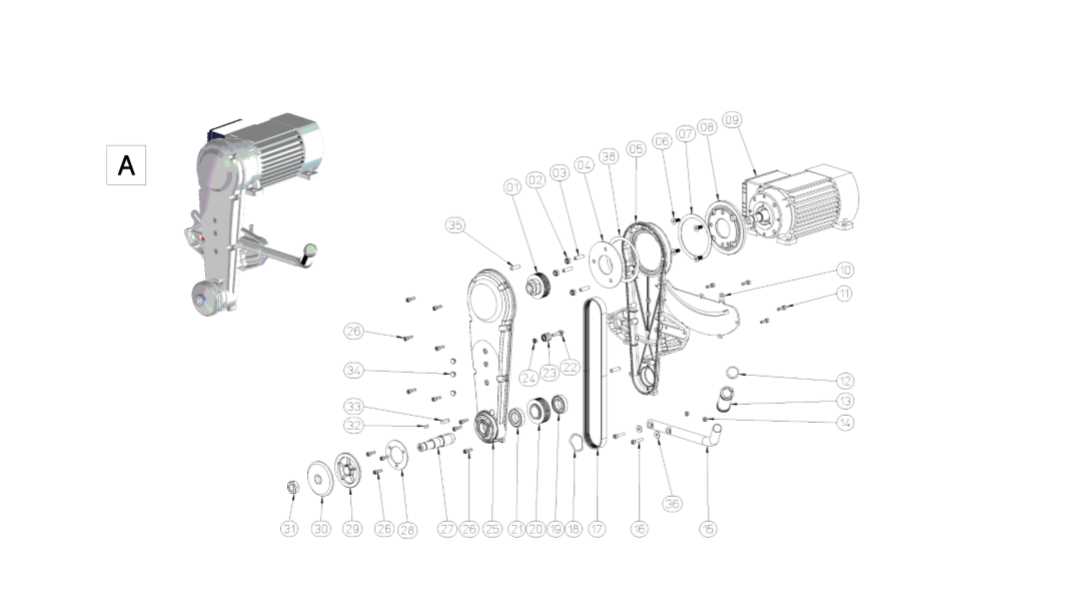

How to Read Parts Diagrams

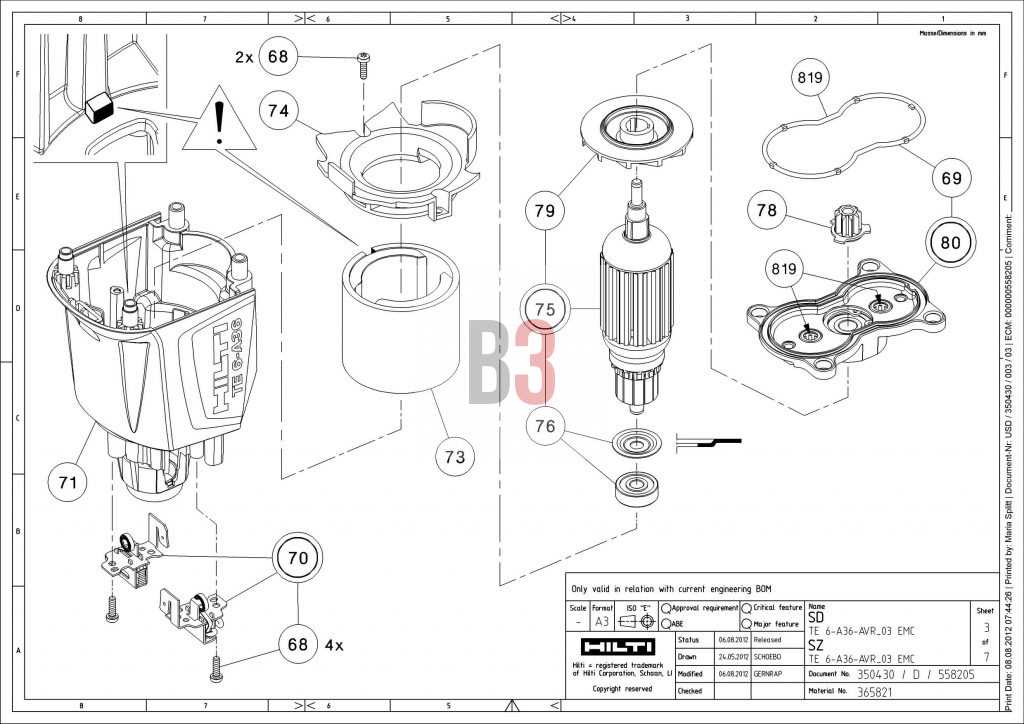

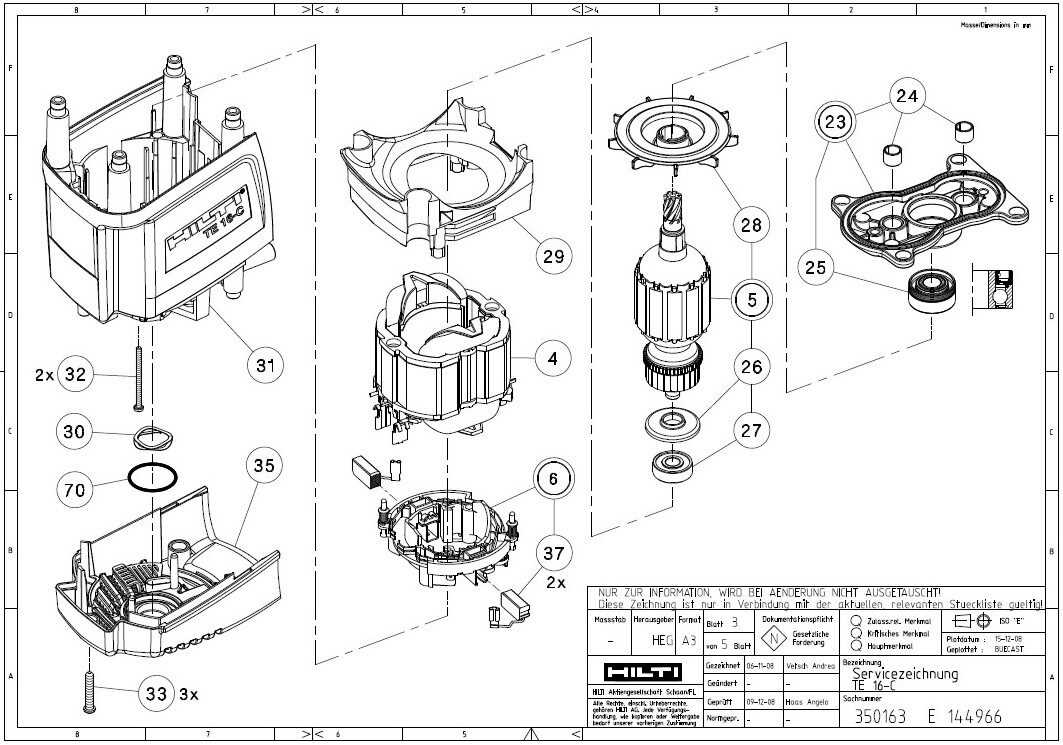

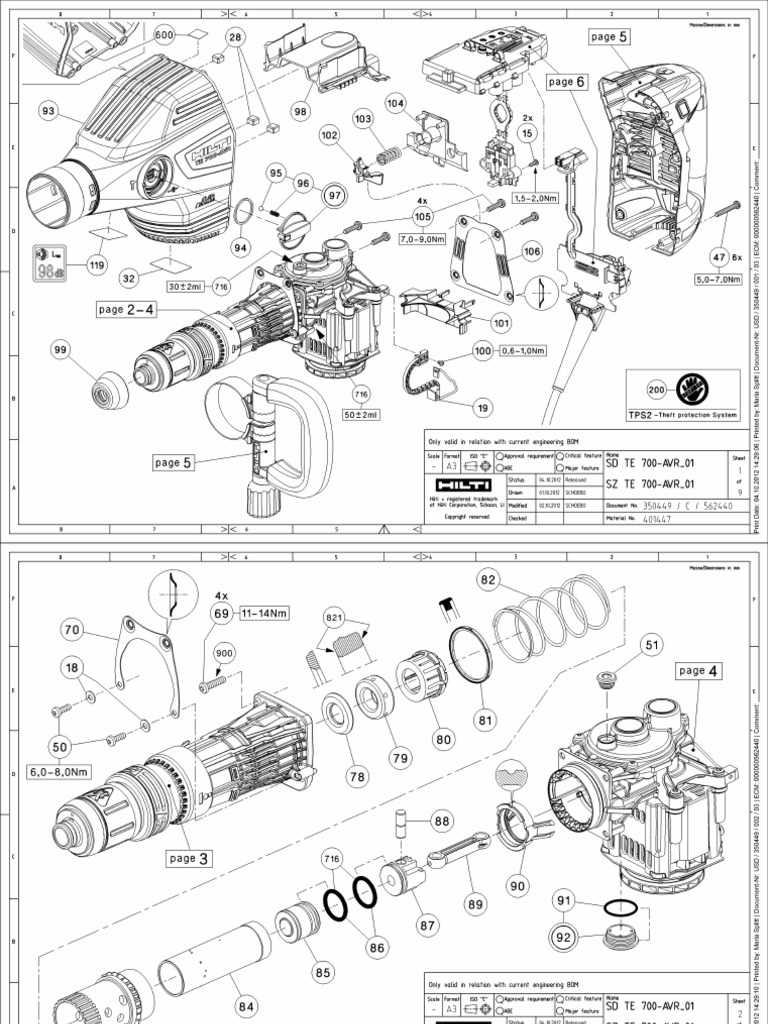

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding users through the assembly and disassembly of equipment. By mastering the ability to interpret these visuals, one can enhance both efficiency and accuracy during the service process.

Key Elements to Identify

When examining a visual layout, focus on the following crucial elements:

- Labels: Each component typically has a corresponding label that indicates its name or number.

- Connections: Look for lines or arrows that illustrate how various elements are connected or interact with one another.

- Groupings: Components may be clustered based on functionality, so pay attention to these arrangements.

Steps for Effective Interpretation

- Familiarize Yourself: Take time to get acquainted with the layout. Identify the overall structure before diving into details.

- Trace Connections: Follow the lines to understand how each element fits into the larger assembly.

- Cross-reference: Use the accompanying documentation to clarify any ambiguities in the illustration.

- Practice: The more you work with these visuals, the easier they will become to interpret.

Common Issues with TE 75 Parts

When operating heavy-duty equipment, various challenges may arise that affect performance and efficiency. Identifying and addressing these concerns is essential for maintaining optimal functionality and prolonging the lifespan of the tool.

Wear and Tear: Frequent use can lead to significant deterioration of components, impacting overall effectiveness. Regular inspections can help identify parts that may need replacement.

Overheating: Extended operation may result in excessive heat buildup, potentially damaging internal mechanisms. Ensuring proper cooling and allowing for rest periods can mitigate this issue.

Misalignment: Components may become misaligned due to regular use, causing uneven performance. Proper calibration and adjustments can resolve these discrepancies.

Loss of Power: A decrease in performance can indicate underlying problems with specific elements. Routine maintenance and prompt repairs are crucial to restore functionality.

Vibration Issues: Excessive vibrations can signify worn or loose parts, which may affect precision. Regular checks and secure fittings can help alleviate this problem.

By proactively addressing these common concerns, users can ensure their equipment operates smoothly and efficiently for years to come.

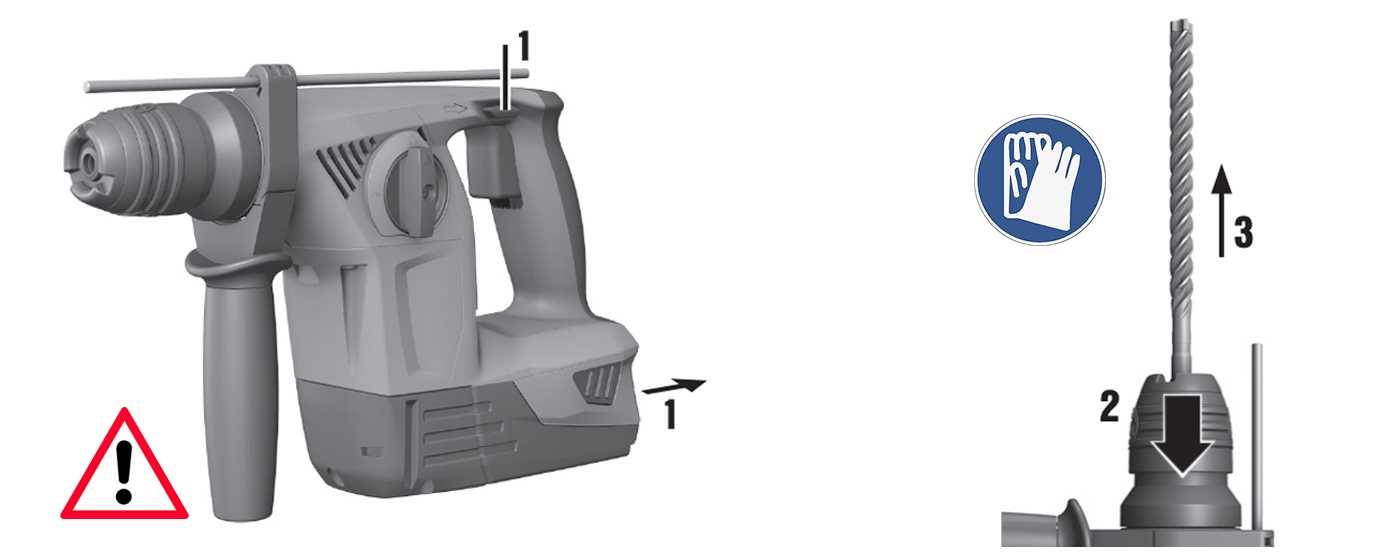

Replacing Worn Components Effectively

Maintaining optimal performance of equipment requires timely replacement of deteriorated elements. Over time, components can wear down, affecting efficiency and safety. Addressing these issues promptly not only prolongs the lifespan of the tools but also ensures they operate at their best. Understanding how to identify, source, and replace these elements can significantly improve functionality.

Identifying Signs of Wear

Recognizing the symptoms of aging parts is crucial for effective maintenance. Look for unusual sounds, decreased efficiency, or physical damage. Regular inspections can help pinpoint which components may need attention. Visual checks combined with performance assessments can guide your decisions on replacements.

Choosing Quality Replacements

When selecting new components, prioritize quality over cost. High-quality replacements often provide better performance and durability. Research reputable suppliers and consider genuine alternatives that meet or exceed original specifications. This investment can save time and money in the long run.

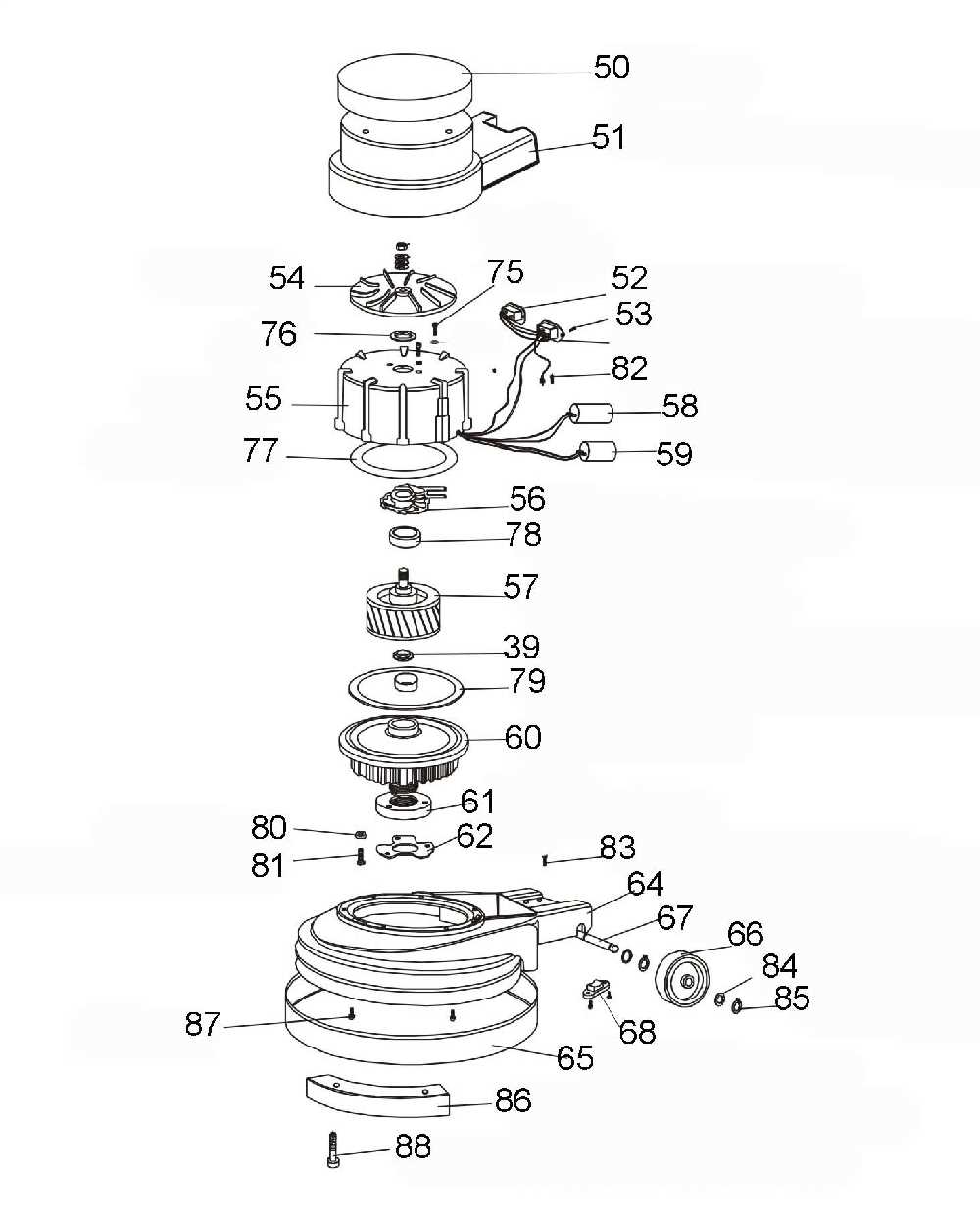

Tools Needed for Maintenance

Regular upkeep of equipment is essential to ensure optimal performance and longevity. To achieve this, a variety of instruments and supplies are required. These tools not only aid in identifying issues but also facilitate the necessary repairs and adjustments, keeping machinery in top condition.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for any maintenance task. They allow for easy access to screws and fasteners, making disassembly and reassembly straightforward. In addition, having a good set of measuring instruments like calipers and micrometers is crucial for precise adjustments.

For more advanced tasks, power tools such as drills and impact drivers can significantly speed up the maintenance process. They provide the necessary torque and efficiency, making it easier to tackle stubborn components. Moreover, cleaning supplies like brushes and lubricants are vital to maintain the functionality and prevent wear over time.

Finally, investing in safety gear is paramount. Items such as gloves, goggles, and ear protection help ensure that maintenance activities are conducted safely, protecting the individual from potential hazards.

Identifying TE 75 Accessories

Understanding the various components that enhance the functionality of your tool is essential for optimizing performance. This section focuses on recognizing the different attachments and add-ons available for the TE 75, enabling users to maximize efficiency and versatility in their projects.

Common Attachments

Among the most sought-after accessories are chisels and drills, each designed for specific applications. Chisels come in various shapes and sizes, tailored for tasks ranging from demolition to detailed work, while drill bits are engineered to penetrate diverse materials.

Choosing the Right Add-Ons

When selecting accessories, consider the intended use and material type. Compatibility with your tool ensures optimal performance and safety. By carefully assessing your needs, you can effectively enhance your tool’s capabilities.

Where to Find Official Diagrams

Locating authentic schematics for equipment can significantly enhance maintenance and repair efforts. Understanding the proper sources ensures that users access reliable and accurate information, enabling them to efficiently manage their tools.

Official Manufacturer Websites

The primary resource for obtaining official schematics is the manufacturer’s website. Most companies provide downloadable resources in their support or product sections, offering comprehensive diagrams and user manuals.

Authorized Distributors and Retailers

Another valuable source includes authorized distributors and retailers. These platforms often have access to official documentation and can provide assistance in finding specific layouts for various models.

| Source Type | Description |

|---|---|

| Manufacturer Websites | Direct access to official schematics and manuals. |

| Authorized Retailers | Support in locating official documentation and parts. |

| Service Centers | Professional guidance and detailed schematics. |

Benefits of Regular Maintenance

Regular upkeep is essential for ensuring the longevity and optimal performance of tools and equipment. By implementing a routine maintenance schedule, users can significantly enhance the reliability and efficiency of their devices.

- Improved Performance: Consistent care helps maintain peak operational efficiency.

- Increased Lifespan: Proper maintenance can extend the life of machinery, delaying the need for replacements.

- Cost Savings: Regular checks can prevent costly repairs and downtime by addressing issues early.

- Enhanced Safety: Well-maintained equipment reduces the risk of accidents and injuries during operation.

- Better Quality Work: Tools in good condition produce superior results, boosting overall productivity.

Ultimately, regular maintenance fosters a more efficient and safe working environment, allowing users to delve into their tasks with confidence.

FAQs About Hilti TE 75

This section addresses common inquiries related to a popular tool known for its robustness and efficiency in construction projects. Here, we provide answers to frequently asked questions, helping users better understand its features and maintenance requirements.

- What is the primary use of this tool?

The device is primarily designed for heavy-duty drilling and chiseling in various materials such as concrete and masonry.

- How often should it be serviced?

Regular maintenance is crucial. It is recommended to service the equipment at least once a year, or after heavy usage, to ensure optimal performance.

- What accessories are compatible?

A wide range of accessories can enhance its functionality, including various drill bits and chisels specifically designed for different applications.

- What safety measures should be taken?

Always wear appropriate personal protective equipment (PPE) such as goggles and gloves. Additionally, ensure a stable work surface and avoid distractions during operation.

- Can it be used for outdoor projects?

Yes, it is suitable for outdoor applications; however, users should take precautions against moisture and dust to prolong the life of the tool.

Comparing TE 75 with Other Models

When evaluating performance tools in the heavy-duty category, understanding the differences between various models is crucial for making informed choices. The TE 75 stands out among its peers, but how does it measure up against similar options? This section delves into the characteristics that set it apart and highlights key features of comparable devices.

One of the primary aspects to consider is the power-to-weight ratio. A well-balanced tool not only improves efficiency but also reduces user fatigue. Here’s how the TE 75 stacks up:

- Weight: The TE 75 maintains a moderate weight, making it manageable for prolonged use.

- Power Output: With robust performance metrics, it delivers exceptional energy, suitable for demanding tasks.

- Vibration Control: Advanced technology minimizes vibrations, enhancing user comfort during operation.

In contrast, other models in the same class may offer varying degrees of performance:

- Model A:

- Heavier design, which may lead to quicker fatigue.

- Higher power output, but increased vibration can be uncomfortable.

- Model B:

- Lighter weight, providing ease of handling.

- Lower power, which may limit efficiency on tougher jobs.

- Model C:

- Similar power levels, but bulkier, affecting maneuverability.

- Effective vibration reduction technology, enhancing overall user experience.

Ultimately, the choice between these options depends on specific job requirements, user preferences, and the environments in which the tools will be utilized. By carefully comparing these features, users can identify which model best meets their needs.