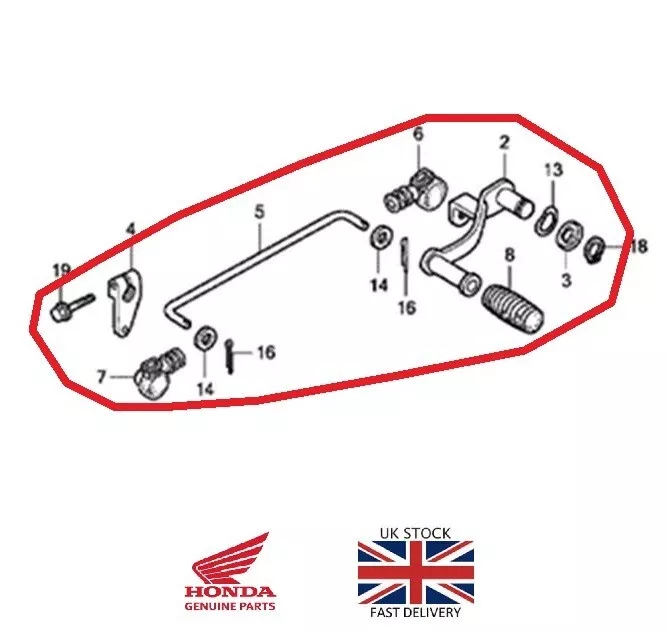

When it comes to maintaining or enhancing a two-wheeler, knowing the precise placement and structure of every element is crucial. Each component works together, forming a seamless system that ensures safety, performance, and durability.

For those seeking to explore how various mechanical and electrical parts are assembled, detailed illustrations provide a clear visual guide. These sketches allow riders and mechanics alike to easily identify what needs attention, whether it’s for routine maintenance or specific adjustments.

Such graphical overviews are invaluable for understanding the complete setup, offering a step-by-step visualization of each section. By following these guides, one can confidently handle everything from simple tasks to more complex repairs.

Comprehensive Guide to Honda CBR 125 Components

This section provides a detailed overview of the essential mechanical and functional elements of a well-known two-wheeled vehicle model. Understanding the different parts and their functions helps ensure proper maintenance, smoother operation, and a longer lifespan of your bike.

Key Engine Elements

- Power Generation Unit: The heart of the vehicle that drives the motion, requiring regular upkeep.

- Cooling Mechanism: Ensures the system remains at optimal temperature during long rides.

- Transmission System: Transfers the generated power to the wheels, enabling acceleration and speed control.

Structural and Functional Parts

- Frame and Chassis: The backbone that holds the entire structure together, providing stability and support.

- Suspension Setup: Absorbs shocks and ensures a smooth ride on various terrains.

- Brake Assembly: Critical for safety, enabling

Understanding the Motorcycle’s Electrical System

The electrical system of a motorcycle plays a critical role in its overall functionality. It ensures the proper operation of various components that rely on electrical power. From starting the engine to providing light, this system is a complex network that requires attention and understanding to maintain optimal performance.

Main Components of the Electrical System

The key components within the electrical system include the battery, wiring, and the generator. These elements work together to deliver power where it’s needed, ensuring smooth operation of systems such as lighting, ignition, and communication between parts.

Common Electrical Issues and Their Solutions

Understanding how to diagnose and fix common electrical problems can prevent larger issues down the road. Common signs of electrical issues include dim lights, weak starting, or complete power loss. Addressing these symptoms promptly helps maintain the bike’s reliability.

Component Function Potential Issues Battery How to Identify Engine Parts

Understanding the components of an engine is essential for proper maintenance and repairs. By recognizing the key sections and individual elements, one can ensure that the engine functions efficiently and remains in good condition over time. This knowledge allows for better problem detection and replacement of worn or damaged elements.

Main Sections of the Engine

The engine consists of several main sections, each playing a vital role in its operation. These include the core structure that houses the combustion process, the system responsible for fuel delivery, and the mechanisms that manage airflow. Recognizing these sections helps in identifying specific elements during inspection or repair.

Recognizing Key Components

When inspecting an engine, focus on identifying critical components such as the cylinder block, pistons, and connecting rods. Each element works in conjunction with others to produce power. By familiarizing yourself with the layout and function of these parts, you can quickly identify any issues or areas that need attention. It’s important to regularly check for wear and ensure that all moving parts are well-lubricated and functioning as intended.

Breaking Down the CBR 125 Transmission

The transmission system plays a crucial role in ensuring smooth power delivery from the engine to the wheels, allowing efficient control and speed adjustments. By understanding its structure and key components, riders and mechanics can maintain its optimal performance and address any mechanical issues effectively.

Main Components of the Transmission

- Gears: Different gear ratios help manage speed and torque, offering flexibility for various riding conditions.

- Clutch: Engages and disengages the engine’s power, allowing for smooth gear transitions without stalling the engine.

- Shift Mechanism: The lever and linkage system that enables the rider to change gears with precision.

How the Transmission Operates

- Power is generated by the engine and directed toward the transmission.

- The clutch is engaged to allow the rider to shift gears based on speed and terrain.

- Selected gear ratios adjust the balance between speed and torque, optimizing performance.

Understanding the inner workings of the transmission helps in both routine maintenance and troubleshooting, ensuring the bike continues to perform at its best.

Exhaust System: Key Components and Layout

The exhaust system plays a crucial role in ensuring that gases produced during combustion are safely directed away from the engine. Its design impacts the overall performance and efficiency of the vehicle, as well as the noise levels it produces. Understanding the key components and their arrangement is essential for maintaining and optimizing the exhaust system.

Main Elements of the Exhaust System

The exhaust system is composed of several interconnected parts that work together to expel gases. Each component has a specific function and is strategically placed to maximize efficiency. The primary parts include the manifold, piping, muffler, and catalytic converter, each contributing to different stages of gas processing and noise reduction.

General Layout and Connections

The components of the exhaust system are arranged in a linear path, starting from the manifold and leading to the exit point at the rear of the vehicle. The manifold collects exhaust gases from the engine and channels them into the piping. The catalytic converter, typically located after the manifold, treats the gases to reduce harmful emissions. Finally, the muffler reduces noise before the gases are expelled.

Component Function Fuel System: An In-Depth Look

The fuel system plays a crucial role in the efficient operation of any two-wheeled vehicle. It is responsible for delivering the appropriate amount of fuel to the engine, ensuring optimal performance and fuel efficiency. Understanding the components and functioning of this system can enhance maintenance and troubleshooting efforts.

Key Components

- Fuel Tank: Stores the fuel, providing a reservoir for the system.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Fuel Injector: Delivers fuel into the combustion chamber in a precise manner.

- Throttle Body: Controls the airflow into the engine, working in conjunction with the fuel injector.

How It Works

The process begins with the fuel being stored in the tank. When the ignition is turned on, the pump activates and draws fuel from the tank. This fuel then passes through the filter to eliminate any contaminants. Next, it travels to the injector, which atomizes the fuel and injects it into the combustion chamber at the right moment. The throttle body regulates the air intake, allowing for the ideal air-fuel mixture needed for efficient combustion.

Regular maintenance of the fuel system is vital for longevity and performance. Checking fuel filters, inspecting hoses for leaks, and ensuring the pump operates smoothly can prevent costly repairs and enhance the overall riding experience.

Exploring the Cooling System of CBR 125

The cooling mechanism in a motorcycle is essential for maintaining optimal engine temperature, ensuring smooth operation and longevity. This intricate system is designed to dissipate heat generated during the combustion process, preventing overheating and potential damage. Understanding the various components and their functions can enhance performance and reliability.

Key Components of the Cooling Mechanism

Central to the cooling system is the radiator, which plays a crucial role in heat exchange. Coolant circulates through the engine, absorbing heat before flowing into the radiator, where it releases heat into the atmosphere. Additionally, a water pump ensures efficient coolant circulation, while hoses facilitate the movement between different components.

Maintenance Tips for Optimal Performance

Regular maintenance is vital to keep the cooling system functioning effectively. Checking the coolant level and condition, inspecting hoses for wear, and ensuring the radiator is free from obstructions are essential practices. Additionally, flushing the cooling system periodically can prevent buildup and maintain efficiency.

Detailed Overview of the Suspension Assembly

The suspension system plays a crucial role in ensuring a smooth and controlled ride. It comprises various components that work together to absorb shocks and maintain stability during operation. Understanding the intricacies of this assembly can enhance both performance and safety.

Key Components of the Suspension System

This assembly consists of several vital elements that contribute to its overall functionality. Each part is designed to work in harmony with the others, providing optimal support and comfort. The main components include:

Component Description Forks These provide initial shock absorption and maintain wheel alignment. Shock Absorber This element dampens oscillations and enhances ride stability. Springs They support the weight of the vehicle and manage compression and rebound. Mounting Hardware This includes bolts and brackets that secure the assembly to the frame. Importance of Maintenance

Regular inspection and maintenance of the suspension components are essential for optimal performance. Worn or damaged parts can lead to decreased handling capabilities and increased wear on other systems. Timely replacements and adjustments ensure a safe and enjoyable riding experience.

Braking System Components and Their Functions

The braking mechanism of a two-wheeled vehicle is essential for ensuring safe operation and control. This system consists of various elements that work in unison to facilitate effective deceleration and stopping. Understanding these components and their roles is crucial for maintaining optimal performance and safety.

Main Components of the Braking System

The braking system comprises several key parts, each serving a distinct function:

Component Function Brake Lever Acts as the control mechanism for the braking action, allowing the rider to apply force. Brake Caliper Houses the brake pads and applies pressure to them against the disc, generating friction. Brake Pads Press against the rotor to create the necessary friction to slow down or stop the vehicle. Brake Rotor Rotating component that interacts with the pads to produce braking force. Brake Fluid Transmits force from the lever to the caliper, enabling effective braking action. Regular checks and maintenance of the braking system components are vital to ensure safety and performance. Worn or damaged parts can significantly affect the overall functionality, leading to potential hazards while riding.

Frame Structure and Key Parts Explained

The framework of a two-wheeled vehicle serves as its foundational component, providing the necessary support and stability for various assemblies. Understanding the design and essential elements of this structure is crucial for both performance and safety.

Primary Components: The main elements of the frame include the main body, subframe, and suspension mounts. Each section plays a distinct role in ensuring that the vehicle remains sturdy while accommodating the rider’s movements.

Design Considerations: An efficient frame design optimizes weight distribution and enhances handling characteristics. Factors such as material choice and geometry significantly impact the overall dynamics of the machine.

By comprehensively examining these aspects, enthusiasts can appreciate the intricate relationship between the frame and the vehicle’s performance, leading to informed decisions when considering modifications or repairs.

Handlebar and Control Layout Overview

This section provides a comprehensive understanding of the arrangement of the steering mechanism and its associated controls. The setup is designed to enhance rider comfort and ensure efficient operation of various functions.

Positioning of the handlebars plays a crucial role in achieving an optimal riding posture. Riders can expect a balance between control and comfort, allowing for extended periods of use without fatigue.

The layout incorporates essential components, such as brake levers and throttle controls, strategically placed for easy accessibility. This ensures that riders can maintain focus on the road while managing the vehicle’s speed and stopping power effectively.

Additionally, the arrangement often includes various switches for activating lights and indicators, enhancing safety during rides. Understanding this configuration is vital for any rider aiming to maximize their experience and performance on the road.

Understanding Wheel and Tire Diagrams

Comprehending the illustrations associated with wheels and tires is essential for anyone involved in vehicle maintenance and repairs. These visuals provide a detailed representation of various components, highlighting their relationships and functions. By familiarizing oneself with these illustrations, one can gain insights into the assembly and disassembly processes, as well as the correct positioning of parts.

Key Components Illustrated

These illustrations typically depict crucial elements such as the rim, tire, valves, and other associated fittings. Each component plays a vital role in the overall performance and safety of the vehicle. Recognizing the purpose of each part can facilitate better understanding and maintenance practices.

Benefits of Understanding the Visuals

Grasping the details presented in these visuals can significantly enhance the repair and maintenance experience. It enables users to identify issues promptly, select appropriate replacement parts, and ensure proper installation. Ultimately, this knowledge contributes to improved vehicle reliability and longevity.

Maintenance Tips for Key Mechanical Parts

Proper upkeep of essential components is crucial for the longevity and optimal performance of any vehicle. Regular maintenance not only enhances efficiency but also prevents unforeseen breakdowns. Here are some vital suggestions to ensure that key mechanical elements remain in excellent condition.

1. Regular Inspections: Conduct thorough examinations of critical systems, including the braking and transmission units. Look for signs of wear, leaks, or unusual noises that may indicate potential issues.

2. Lubrication: Ensure that moving parts receive appropriate lubrication to minimize friction. This can significantly extend their lifespan and improve overall functionality. Use high-quality lubricants designed for specific components.

3. Cleaning: Keep all mechanical parts clean and free of debris. Accumulated dirt can lead to corrosion and hinder performance. Utilize suitable cleaning agents to maintain cleanliness without damaging sensitive surfaces.

4. Replacement of Worn Components: Identify and replace any parts that show signs of fatigue or damage promptly. Delaying this can lead to more severe complications and costly repairs.

5. Adhere to Service Intervals: Follow the recommended maintenance schedule to ensure all mechanical systems receive the care they require at appropriate times. This proactive approach helps to avoid major issues down the line.

By implementing these tips, you can enhance the durability and reliability of vital mechanical systems, ensuring a smoother and more enjoyable riding experience.