Maintaining your outdoor machinery is essential for optimal performance and longevity. Familiarizing yourself with the various components of your equipment can significantly enhance your ability to troubleshoot and carry out necessary repairs. This section delves into the intricate elements that contribute to the functionality of your grass-cutting equipment.

Recognizing the assembly of your machine is crucial. Each segment plays a vital role in ensuring smooth operation, from the cutting mechanisms to the supporting structures. Understanding how these parts interact will empower you to identify potential issues and make informed decisions regarding maintenance.

In this guide, we will explore the configuration of these essential components, offering a detailed overview to aid in your understanding. Whether you are a seasoned user or a newcomer, grasping the layout of your equipment will enable you to enhance its performance and tackle any challenges effectively.

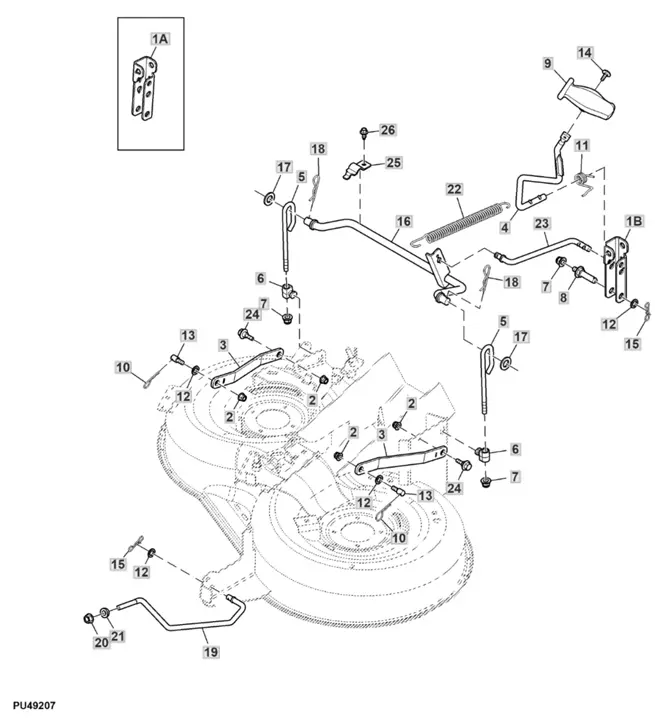

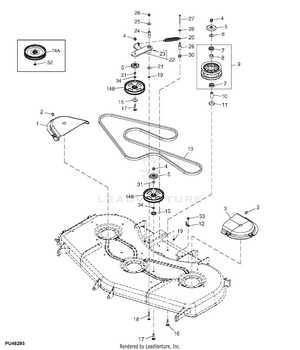

Understanding the Mower Deck Components

This section explores the essential elements that contribute to the overall functionality of a cutting system. Each component plays a significant role in ensuring efficient operation, impacting both performance and maintenance. A comprehensive understanding of these parts enables users to optimize their equipment and enhance longevity.

Key Elements of the Cutting System

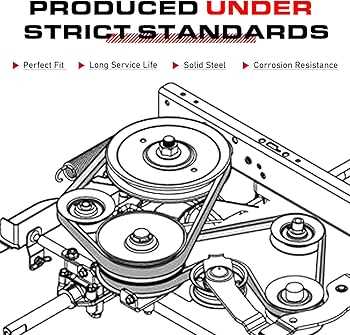

Among the vital components are the blades, which are responsible for achieving a precise cut. The spindle houses the blades and facilitates their rotation, while the belt connects the engine’s power to the blades, allowing them to operate seamlessly. Additional elements, such as the housing and support brackets, provide structural integrity and stability, ensuring that the entire system functions harmoniously.

Maintenance and Care

Regular inspection and maintenance of each part are crucial for optimal performance. Cleaning the blades and checking the tension of the belt can prevent potential issues. Additionally, replacing worn or damaged components promptly will help maintain efficiency and extend the lifespan of the entire system.

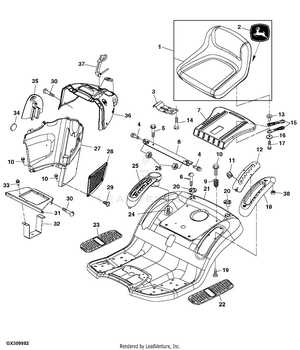

Identifying Key Parts and Functions

Understanding the essential components of a cutting mechanism is crucial for effective maintenance and operation. Each element plays a specific role, contributing to the overall efficiency and functionality of the equipment.

Main Components

- Cutting Blades: Responsible for trimming grass to the desired height, these sharp elements require regular inspection for wear and damage.

- Spindle Assembly: This central unit supports the blades and ensures smooth rotation, influencing the overall cutting performance.

- Lift Mechanism: This system allows for adjusting the height of the cutting elements, enabling users to adapt to different grass conditions.

Supportive Elements

- Drive Belt: Transfers power from the engine to the cutting blades, crucial for operational efficiency.

- Chassis: The frame provides structural support, ensuring stability during operation.

- Guards: Safety features that protect users from debris and enhance overall safety during use.

Common Issues with Mower Decks

When it comes to lawn maintenance equipment, there are several frequent challenges that can affect the cutting mechanism’s performance. Understanding these issues is essential for effective troubleshooting and ensuring optimal functionality. Below are some typical problems encountered in these systems and their potential solutions.

Uneven Cutting

One of the most prevalent concerns is uneven cutting, which can leave patches of grass at varying heights. This often occurs due to improper height adjustments or blade wear. Regular inspection and maintenance of the cutting blades can help mitigate this issue. Ensuring that the blades are sharp and correctly aligned is crucial for achieving a uniform cut.

Clumping and Clogging

Another common problem is clumping of grass clippings, which can lead to clogging in the discharge chute. This issue is typically exacerbated by damp grass or buildup of debris. To prevent this, it is advisable to mow when the grass is dry and to clean the cutting mechanism regularly. Additionally, using the appropriate cutting height can minimize clumping.

Maintenance Tips for Longevity

Proper care and attention are essential for ensuring the extended lifespan of your equipment. By following a few simple practices, you can enhance performance and reduce the likelihood of unexpected issues.

- Regular Cleaning: Keep the machinery free from debris and buildup. Clean after each use to prevent corrosion and damage.

- Routine Inspections: Conduct periodic checks of all components. Look for wear and tear, and replace any worn parts promptly.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction and wear. Refer to the manufacturer’s recommendations for specific intervals.

- Sharp Blades: Ensure cutting tools are sharpened regularly for optimal efficiency. Dull blades can strain the engine and lead to uneven cuts.

- Fluid Levels: Regularly check and maintain oil and coolant levels. Keeping fluids at recommended levels ensures smooth operation.

By implementing these straightforward maintenance practices, you can significantly extend the life and effectiveness of your equipment, ensuring it remains reliable for years to come.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right instruments at hand is crucial for efficiency and effectiveness. Proper tools not only facilitate the process but also ensure safety and precision during work.

| Tool | Description |

|---|---|

| Wrench Set | Essential for loosening or tightening bolts and nuts. |

| Screwdriver Set | Used for driving screws of various types and sizes. |

| Pliers | Handy for gripping, twisting, or cutting wires and other materials. |

| Socket Set | Provides versatility in dealing with different fasteners. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Safety Goggles | Protects eyes from debris and potential hazards. |

Replacement Parts: When to Consider

Understanding the right moments to replace components is essential for maintaining optimal performance. Over time, wear and tear can diminish efficiency, impacting overall functionality. Recognizing the signs that indicate a need for change can prevent further damage and ensure smooth operation.

One key factor is frequency of use. If equipment is utilized regularly, components may degrade faster, necessitating timely replacements. Additionally, visible wear such as cracks, rust, or deformation should prompt an assessment. Routine inspections can help identify these issues before they escalate.

Moreover, performance changes, such as unusual noises or decreased efficiency, often signal the need for new parts. Paying attention to these indicators can enhance longevity and maintain effectiveness. By staying proactive and addressing concerns promptly, you can ensure reliable performance throughout the equipment’s lifespan.

Safety Precautions During Servicing

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines can help create a secure working environment, enabling efficient and effective service. This section outlines essential safety measures to follow during servicing operations.

General Safety Guidelines

Prior to commencing any maintenance, it is vital to familiarize yourself with the equipment and tools involved. Always wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and sturdy footwear. Additionally, ensure the work area is clean and free from hazards to minimize risks.

Proper Tool Usage

Using the correct tools for specific tasks is imperative for safety and efficiency. Inspect tools before use to confirm they are in good working condition. If any tool is damaged or defective, replace it immediately. Below is a summary of essential tools and their recommended usage:

| Tool | Usage |

|---|---|

| Wrenches | Tightening and loosening bolts |

| Screwdrivers | Fastening and removing screws |

| Socket Sets | Efficiently working with nuts and bolts |

| Pliers | Gripping and bending wires |

DIY Repair Techniques Explained

Understanding how to conduct repairs on outdoor machinery can empower enthusiasts and save costs. By employing a systematic approach, individuals can enhance their skills and effectively address common issues that arise with their equipment. This section will explore essential methods and tips that facilitate successful maintenance tasks.

Before starting any repair, it’s crucial to gather the necessary tools and materials. Familiarity with the equipment’s components will streamline the process. Take time to consult available manuals or online resources for guidance on specific repairs, ensuring a clear understanding of each step.

One effective technique is troubleshooting, which involves systematically identifying and resolving issues. Begin by observing the machinery for any visible signs of wear or damage. This initial assessment can often pinpoint areas that require attention.

Furthermore, when disassembling parts, label each component to ensure correct reassembly. Employing a methodical organization can prevent confusion and mistakes. Additionally, using the right tools for each task not only facilitates efficiency but also minimizes the risk of damage.

Finally, consider documenting the repair process. Keeping a record of procedures and outcomes can serve as a valuable reference for future maintenance, allowing for continuous improvement in repair skills.

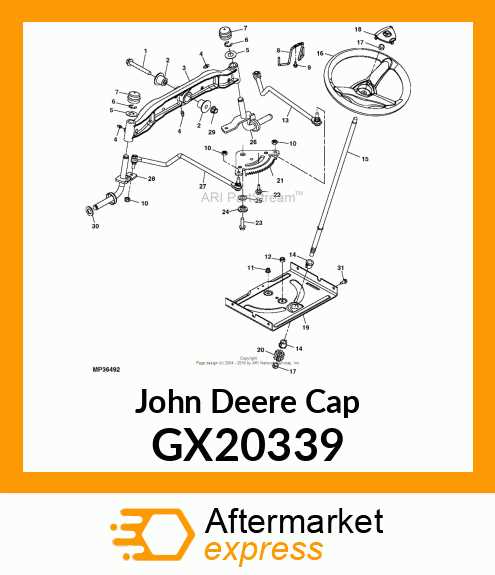

Finding Genuine Replacement Parts

Ensuring your equipment operates efficiently often relies on sourcing authentic components. Using high-quality replacements not only enhances performance but also extends the lifespan of your machinery. Here are key considerations when searching for reliable parts.

Benefits of Genuine Components

- Optimal compatibility with your equipment

- Enhanced durability and performance

- Manufacturer-backed warranties for peace of mind

Where to Look for Authentic Items

- Official manufacturer websites for direct purchases

- Authorized dealers who provide verified components

- Reputable online retailers with positive reviews

Investing time in finding quality replacements ensures that your equipment functions at its best and remains reliable for years to come.

Exploring Aftermarket Options Available

When considering enhancements for your lawn care equipment, exploring alternative components can provide a range of benefits, including improved performance and potential cost savings. Numerous aftermarket solutions cater to various needs and preferences, allowing users to customize their machines to suit specific tasks.

Some popular aftermarket options include:

- High-efficiency blades that offer superior cutting performance.

- Durable belts designed to withstand rigorous use and reduce wear.

- Enhanced spindles for smoother operation and longevity.

- Innovative attachments that expand functionality and versatility.

By researching and selecting quality aftermarket alternatives, users can achieve the ultimate enhancement for their equipment while potentially extending its lifespan.

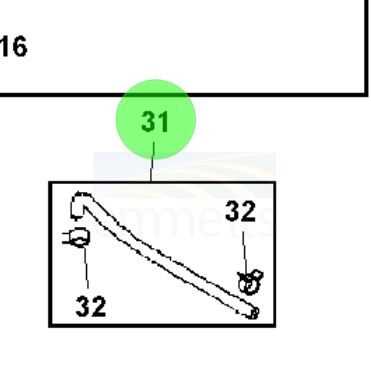

Assembly Instructions for Mower Deck

This section provides essential guidelines for the proper assembly of the cutting apparatus. Following these steps ensures optimal performance and longevity of the equipment.

- Begin by gathering all necessary components and tools required for the assembly process.

- Identify the main structure and lay it out on a flat surface to facilitate access.

- Attach the brackets to the primary framework, ensuring all screws are securely fastened.

Once the frame is set, proceed with the following:

- Install the cutting blades, aligning them correctly to ensure even operation.

- Connect the belt system, making sure it is properly tensioned for effective power transmission.

- Check all connections and tighten any loose fittings.

Finally, review the entire assembly for completeness and adherence to specifications before operational use.

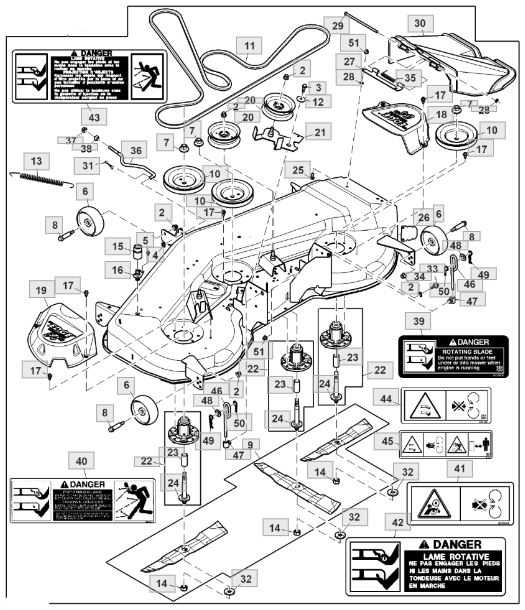

Troubleshooting Mower Deck Problems

When encountering issues with cutting equipment, it’s essential to identify the root cause to ensure optimal performance. Various factors can contribute to malfunctions, including wear and tear, misalignment, or improper settings. Understanding these elements will help in effectively diagnosing and resolving problems.

1. Inspecting Blades: Dull or damaged blades can lead to uneven cutting. Regularly check the sharpness and condition of the blades. If they appear worn, consider sharpening or replacing them to restore efficiency.

2. Checking Height Adjustments: Incorrect height settings may result in inadequate cutting performance. Ensure that the cutting height is adjusted according to the specific requirements of the lawn type being maintained.

3. Examining Belts and Cables: Frayed or broken belts can impede functionality. Regularly inspect belts for signs of wear. Additionally, ensure that all cables are properly connected and functioning to maintain the power transmission to the cutting components.

4. Cleaning Debris: Accumulation of grass clippings and debris can hinder performance. Periodically clean the underside of the unit to prevent blockages that may affect operation.

5. Reviewing Engine Performance: An underperforming engine can also impact cutting effectiveness. Check for fuel flow, air filter cleanliness, and spark plug condition to ensure optimal engine functionality.

By systematically addressing these common issues, operators can enhance the reliability and efficiency of their cutting machinery, ensuring a well-maintained and attractive lawn.