In the realm of modern agriculture, the efficiency of soil management tools plays a pivotal role in ensuring optimal crop yields. A comprehensive grasp of the various elements that make up these implements can greatly enhance their functionality and longevity.

Each component serves a unique purpose, contributing to the overall effectiveness of the machinery. By familiarizing oneself with these individual sections, users can make informed decisions regarding maintenance and upgrades.

Moreover, having access to visual representations of these elements allows for a deeper understanding of how they interact within the larger system. This knowledge is essential for anyone looking to improve their farming practices or troubleshoot issues effectively.

Understanding Ford Disc Harrow Components

Familiarity with the various elements of agricultural implements is essential for effective operation and maintenance. Each component plays a crucial role in the overall functionality, contributing to optimal performance during tilling and soil preparation tasks. Recognizing these elements can help users ensure that their equipment runs smoothly and efficiently.

Key Components and Their Functions

The primary segments of these implements include the cutting edges, frames, and adjustments mechanisms. Cutting edges are designed to penetrate the soil, breaking it up and turning it over. The frame serves as the backbone, providing stability and support for the entire assembly. Additionally, adjustment mechanisms allow operators to modify the depth and angle of the cutting edges, tailoring the equipment to different soil conditions and farming needs.

Maintenance Considerations

Regular inspection of these elements is vital to prevent wear and ensure longevity. Checking the integrity of the cutting edges and frame for any signs of damage can help avoid costly repairs. Furthermore, keeping the adjustment systems well-lubricated and free from debris enhances operational efficiency and extends the life of the implement.

Importance of Maintenance for Discs

Regular upkeep of agricultural implements is crucial for ensuring optimal performance and longevity. Proper care not only enhances functionality but also minimizes the risk of breakdowns, which can lead to costly repairs and downtime.

When it comes to circular tools used in soil preparation, maintaining their condition is vital for achieving the best results. Here are some key reasons why regular maintenance should not be overlooked:

- Enhanced Efficiency: Well-maintained tools operate smoothly, allowing for quicker and more effective soil processing.

- Longevity: Consistent care extends the lifespan of the equipment, providing better returns on investment over time.

- Consistent Results: Regular inspections and repairs ensure uniformity in soil cultivation, leading to improved crop yields.

- Safety: Routine checks can prevent accidents caused by faulty equipment, safeguarding the operator and other workers.

- Cost Savings: Preventive maintenance can reduce the likelihood of expensive repairs and replacements down the line.

In conclusion, prioritizing the upkeep of circular implements is essential for farmers and land cultivators. By adopting a proactive maintenance approach, one can ensure reliable performance and maximize productivity on the field.

Common Issues with Harrow Parts

Various components used in soil preparation equipment often face specific challenges that can hinder their performance and longevity. Understanding these issues is essential for maintaining efficiency and ensuring optimal results during agricultural operations.

- Wear and Tear: Frequent usage can lead to significant deterioration. Key indicators include:

- Cracks or fractures in the structure.

- Loss of sharpness on blades.

lessCopy code

- Inconsistent depth of tillage.

- Increased fuel consumption due to inefficiency.

- Visible rust spots on metal components.

- Weakened structures leading to potential failure.

- Vibration during operation.

- Parts detaching while in use, posing safety risks.

Addressing these common challenges promptly can enhance the overall effectiveness and safety of your agricultural equipment, ensuring that it operates smoothly for years to come.

How to Identify Replacement Parts

When maintaining agricultural equipment, understanding how to pinpoint essential components is crucial for effective repairs. Accurate identification ensures that the right items are acquired, minimizing downtime and enhancing performance.

Start with Documentation: Begin by consulting the equipment’s manual or service guide. These documents often include valuable information about the specifications and numbers of various components.

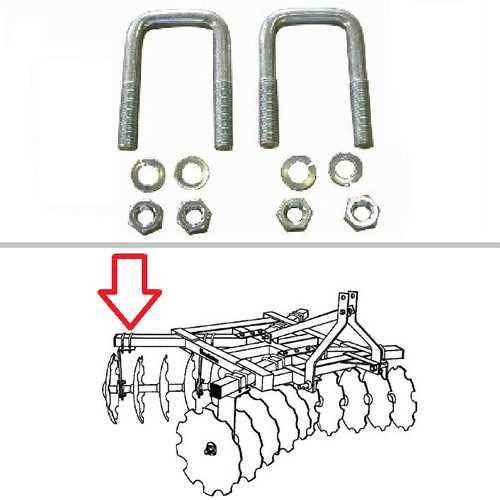

Visual Inspection: Conduct a thorough examination of the machinery. Look for identifying marks, serial numbers, or any labels on the elements you intend to replace. This can provide essential clues for finding compatible replacements.

Consult Experts: If uncertainty persists, consider reaching out to specialists or visiting forums dedicated to agricultural machinery. These resources can offer insights and recommendations based on firsthand experiences.

Use Online Resources: Leverage the power of the internet. Numerous websites feature databases and catalogs that can help identify items by inputting the model number or other relevant details.

Compare Components: When you have a potential match, compare the old and new items side by side. Ensure that dimensions, shapes, and connection types align perfectly to guarantee compatibility.

By following these strategies, you can efficiently identify and procure the necessary components for your agricultural machinery, ensuring optimal functionality and longevity.

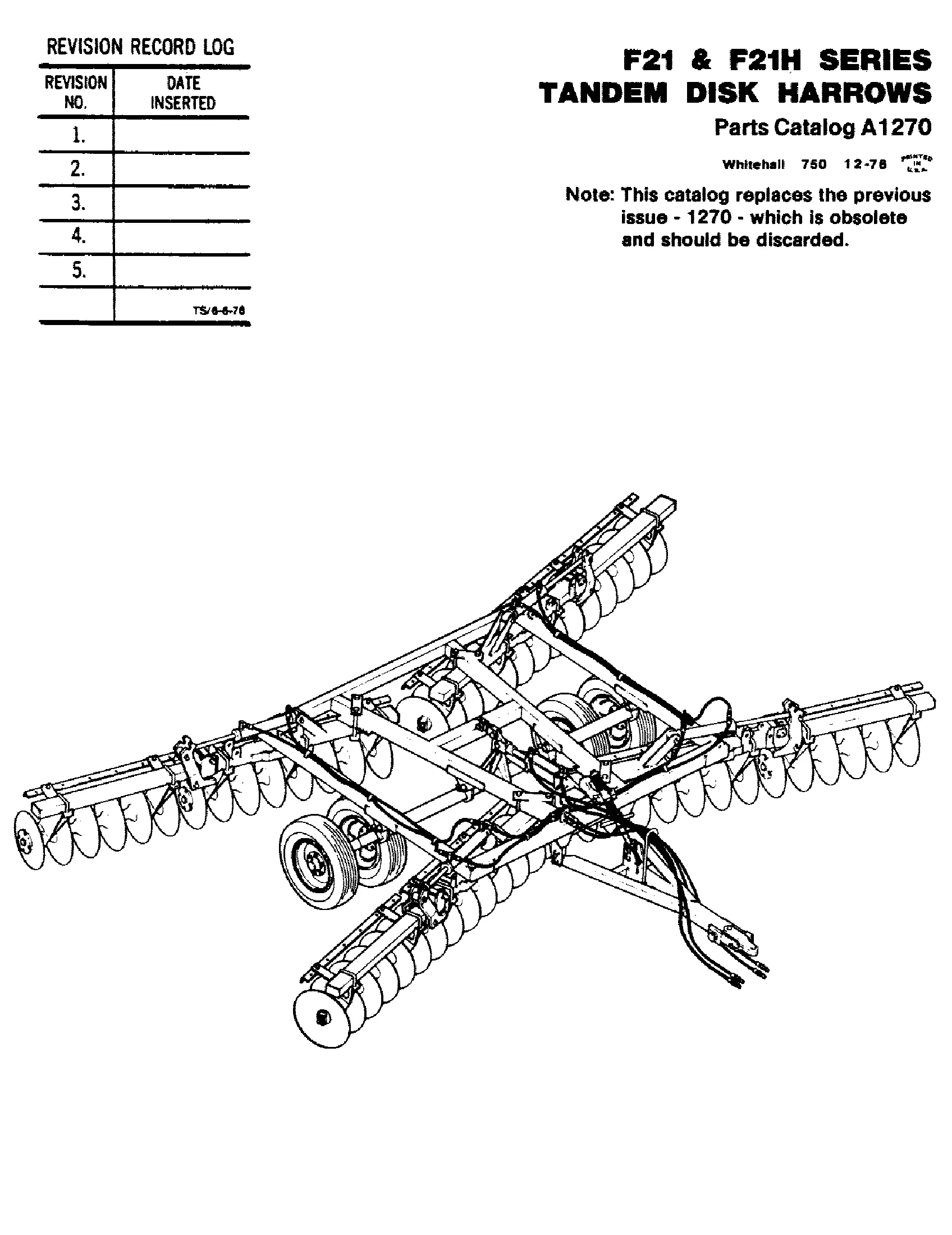

Visual Guide to Parts Diagram

This section offers a comprehensive overview of the essential components involved in agricultural equipment. By breaking down the elements visually, users can better understand the structure and function of each part, enhancing maintenance and repair efforts.

Understanding Key Elements

Each component plays a vital role in ensuring optimal performance. Familiarizing yourself with these elements will ultimately lead to improved efficiency and longevity of the machinery.

Benefits of a Visual Representation

Utilizing a graphical representation allows for quick identification and troubleshooting. This approach simplifies complex assemblies, making it easier for users to grasp the intricacies involved in their equipment.

Types of Ford Disc Harrows

In the world of agricultural implements, various models cater to different soil cultivation needs. These tools are designed to effectively manage soil conditions, improving seedbed preparation and enhancing crop yields. Understanding the various classifications available can help farmers select the right equipment for their specific requirements.

Standard Models

Standard variants are typically suited for general tillage tasks. They feature a balanced design that allows for efficient soil disruption and incorporation of organic material.

Heavy-Duty Models

Heavy-duty versions are built to handle tougher soil conditions. Their robust construction and larger blades ensure they can penetrate hard ground and effectively mix soil layers.

| Type | Features | Best For |

|---|---|---|

| Standard | Balanced design, versatile | General cultivation |

| Heavy-Duty | Robust construction, larger blades | Tough soil conditions |

Tools Needed for Repairs

Effective maintenance requires a specific set of instruments to ensure proper functionality and longevity of agricultural equipment. Understanding what is essential can make the repair process more efficient and less time-consuming.

Essential Tools

- Wrenches and Sockets

- Hammers

- Pliers

- Screwdrivers

- Torque Wrench

Safety Equipment

- Gloves

- Safety Glasses

- Steel-Toed Boots

Having these tools readily available will facilitate a smoother repair process and help you delve into any necessary fixes with confidence.

Where to Source Genuine Parts

Finding authentic components for your agricultural machinery is crucial for maintaining performance and longevity. Reliable sources not only provide high-quality replacements but also ensure compatibility and durability. Here are some recommended avenues for acquiring these essential items.

Authorized Dealers

One of the most reliable options is to visit authorized dealerships. These locations typically stock genuine replacements and have trained staff who can assist with your specific requirements. Purchasing from them guarantees you receive the correct items suited for your equipment.

Online Retailers

Many online platforms specialize in agricultural machinery components. Look for reputable websites that offer original items and have customer reviews to ensure credibility. Always check return policies and warranty information to safeguard your investment.

Tips for Efficient Operation

To achieve optimal performance during soil cultivation, understanding key techniques and strategies is essential. Implementing effective practices can significantly enhance productivity and equipment longevity while minimizing downtime.

Regular Maintenance

Consistent upkeep is crucial for ensuring that your machinery operates smoothly. Regularly check for wear and tear on components, lubricate moving parts, and replace any damaged elements promptly to prevent more extensive issues.

Proper Adjustment

Making the correct adjustments based on soil conditions and desired depth can lead to improved results. Take the time to fine-tune settings for varying terrains to achieve the best possible outcomes.

Upgrading Your Disc Harrow

Enhancing your tillage equipment can significantly improve its efficiency and performance in the field. By incorporating modern components and innovative technologies, you can achieve better soil preparation and crop yields. This section explores various upgrades that can elevate your agricultural implement to meet contemporary demands.

Consider investing in high-quality blades that offer increased durability and optimal cutting ability. Additionally, adjusting the frame for improved stability and strength can enhance overall functionality. Implementing advanced hydraulic systems can also streamline operation, allowing for precise adjustments on-the-go.

Moreover, integrating precision farming technologies can help monitor performance and ensure effective use of resources. With these enhancements, you can not only boost productivity but also extend the lifespan of your equipment, ultimately resulting in a more sustainable agricultural practice.