The intricacies of a ten-speed transmission system can be both fascinating and complex. This essential mechanism plays a crucial role in ensuring optimal performance and efficiency in various vehicles. Understanding how these systems operate requires a closer look at their individual components and how they interact with one another.

In this section, we will explore the various elements that contribute to the functionality of a ten-speed transmission. Each component, from gears to synchronizers, serves a specific purpose, enhancing the overall driving experience. By examining these parts, one can gain insights into the mechanics that allow for smooth gear shifts and reliable operation.

Moreover, a comprehensive overview of these components not only aids in the understanding of their roles but also highlights the importance of regular maintenance and potential upgrades. By familiarizing oneself with the design and arrangement of these elements, vehicle owners and enthusiasts can make informed decisions regarding repairs and enhancements.

Eaton Fuller 10-Speed Transmission Overview

The ten-gear transmission is a crucial component in heavy-duty vehicles, providing enhanced efficiency and control over power delivery. This type of system is designed to optimize performance across various driving conditions, allowing operators to adapt to different loads and terrains.

Constructed with durability in mind, this transmission features a robust design that can withstand the rigors of demanding applications. Its configuration allows for smooth shifting between gears, ensuring seamless transitions that improve overall driving experience. Operators benefit from the increased torque capacity and enhanced fuel efficiency, making it a preferred choice in commercial transport.

Moreover, the system includes a variety of internal components that work in harmony to facilitate operation. Key elements such as gear sets, synchronizers, and bearings are engineered to provide reliability and longevity, minimizing maintenance needs. As a result, vehicle operators can focus on their tasks with confidence, knowing they have a dependable transmission system at their disposal.

Key Components of the Transmission

The effective operation of a vehicle’s transmission relies on several essential elements working in harmony. These components play critical roles in ensuring smooth gear shifts and optimal power delivery from the engine to the wheels. Understanding these parts is crucial for anyone involved in maintenance or repair, as they contribute significantly to the overall functionality and performance of the drivetrain.

Gear Sets

Gear sets are fundamental to the transmission’s functionality. They are responsible for changing the torque and speed characteristics, allowing the vehicle to accelerate smoothly and efficiently. Each gear ratio is meticulously designed to provide the right balance between power and speed, catering to various driving conditions and requirements.

Shifting Mechanism

The shifting mechanism is vital for transitioning between different gear ratios. This system can be manual or automated, with each type offering distinct advantages. A well-designed shifting mechanism enables the driver to select gears intuitively, enhancing the driving experience while maintaining control over the vehicle’s power delivery.

Understanding Gear Ratios

Gear ratios play a crucial role in the performance and efficiency of mechanical systems. They define the relationship between the rotation of a driving gear and the rotation of a driven gear. By adjusting these ratios, engineers can influence factors such as torque, speed, and overall functionality of the machinery. A proper grasp of these concepts is essential for optimizing performance in various applications.

In essence, the gear ratio can be described as a mathematical expression that compares the number of teeth on two interlocking gears. This ratio impacts how power is transmitted through the system, making it a fundamental element in design considerations.

Below is a table illustrating common gear ratios and their implications:

| Gear Ratio | Torque Multiplication | Speed Reduction |

|---|---|---|

| 1:1 | No change | No change |

| 3:1 | 3 times | 1/3 of input |

| 4:1 | 4 times | 1/4 of input |

| 5:1 | 5 times | 1/5 of input |

| 1:3 | 1/3 of input | 3 times |

Understanding these ratios allows for better control over machinery and can lead to enhanced efficiency and performance in various operations. Adjusting the gear ratio provides a strategic approach to managing speed and power, making it an integral aspect of mechanical design.

Common Issues with Eaton Fuller

Many users experience a range of challenges with their heavy-duty transmission systems. Understanding these common problems can aid in timely maintenance and repairs, ensuring optimal performance and longevity.

1. Gear Slippage: One prevalent issue is the unexpected slipping of gears during operation. This can occur due to worn synchronizers or insufficient lubrication, resulting in difficulty maintaining speed and power.

2. Fluid Leaks: Another frequent concern involves leaks in the transmission fluid. This can lead to a significant drop in fluid levels, which affects the entire system’s functionality and can cause severe damage if not addressed promptly.

3. Difficulty Shifting: Many operators report challenges when shifting gears. This problem can stem from misaligned components or worn-out shifter forks, leading to delays and complications while changing gears.

4. Overheating: Overheating is a critical issue that can result from excessive load or insufficient cooling. High temperatures can degrade the transmission fluid and harm internal components, making it essential to monitor operating conditions.

5. Noise and Vibration: Unusual sounds or vibrations during operation often indicate underlying mechanical problems. These symptoms can result from worn bearings, damaged gears, or other internal failures that require immediate attention.

By recognizing these common issues, operators can take proactive measures to maintain their transmission systems effectively. Regular inspections and prompt repairs will enhance performance and extend the lifespan of the equipment.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your vehicle’s transmission system requires regular care and attention. Implementing a few best practices can significantly enhance durability and efficiency, preventing costly repairs and downtime. Below are essential maintenance tips to keep your transmission in optimal condition.

Regular Inspections

Conducting frequent checks is crucial for early detection of potential issues. Pay attention to the following:

- Inspect fluid levels and conditions regularly.

- Look for any signs of leakage around seals and gaskets.

- Monitor performance changes during operation.

Fluid Maintenance

The transmission fluid plays a vital role in ensuring smooth operation. Proper fluid management includes:

- Regularly changing the fluid according to the manufacturer’s guidelines.

- Using the recommended type of fluid to ensure compatibility.

- Checking for contaminants and debris that may affect functionality.

By following these maintenance strategies, you can promote the longevity and reliability of your transmission system, ensuring it remains a dependable component of your vehicle.

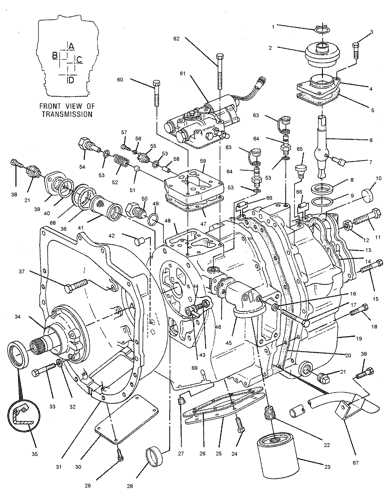

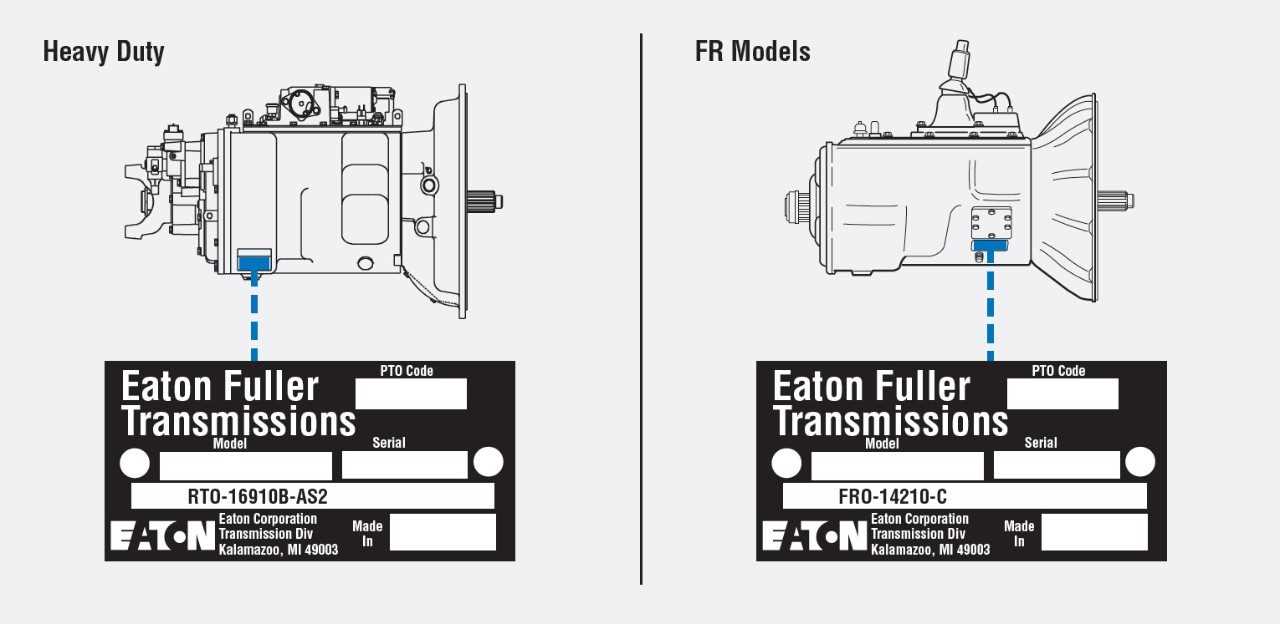

Identifying Replacement Parts

Understanding the components of a transmission system is essential for ensuring optimal performance and longevity. When maintenance or replacement is necessary, recognizing the various elements involved can significantly aid in the selection of suitable substitutes. This section provides guidance on how to effectively identify these crucial components.

Start by examining the transmission assembly, taking note of each component’s appearance and functionality. Using visual references or schematics can facilitate the identification process. Key elements to focus on include gears, shafts, bearings, and seals. Ensure you are familiar with the specific specifications and measurements of these components to ensure compatibility when sourcing replacements.

Additionally, consult the manufacturer’s documentation for part numbers and detailed descriptions. This information can be invaluable when seeking equivalent items from suppliers or retailers. Utilizing online resources, forums, or communities dedicated to transmission maintenance can also enhance your understanding and provide insights from experienced users.

Finally, always verify that the components you intend to purchase align with the original specifications. Accurate identification is crucial to maintaining the reliability and efficiency of your transmission system.

Tools Required for Repairs

Undertaking repairs on complex machinery necessitates a specific set of instruments to ensure precision and efficiency. Proper tools not only facilitate the repair process but also help maintain the integrity of the components being serviced. Familiarizing oneself with the essential equipment before beginning the repair task can significantly enhance the overall outcome.

Essential Hand Tools

Having the right hand tools is crucial for any maintenance job. Commonly required instruments include wrenches, screwdrivers, and pliers. These tools allow for effective manipulation of various fasteners and components. Additionally, a ratchet set can provide added versatility in tight spaces.

Specialized Equipment

Beyond standard tools, certain specialized equipment may be necessary. A torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening. A gear puller may also be needed to safely remove gears without causing harm to the surrounding assembly. Investing in quality tools will ultimately result in a more successful repair process.

Wiring Diagrams Explained

Wiring schematics serve as essential tools for understanding the intricate connections within complex systems. They visually represent the electrical pathways and components, enabling technicians to troubleshoot and repair issues effectively. These illustrations highlight how various elements interact, providing clarity on the flow of current and the functionality of each part.

Typically, these illustrations include symbols representing different components such as switches, connectors, and power sources. By following the pathways depicted, one can easily trace circuits and pinpoint areas requiring attention. Additionally, they often indicate wire colors, gauge sizes, and other specifications, ensuring that replacements or modifications are made correctly.

In practice, familiarity with these schematics is crucial for anyone involved in maintenance or repair work. Understanding the layout not only facilitates efficient repairs but also enhances overall safety by preventing incorrect connections that could lead to malfunctions or hazards. Therefore, mastering the interpretation of these visual guides is vital for successful operations in electrical systems.

Installation Procedures for Parts

This section provides a comprehensive overview of the steps necessary for the correct installation of components within a specific transmission system. Proper adherence to these procedures ensures optimal functionality and longevity of the mechanism. Careful attention to detail is crucial during the installation process to prevent potential issues that could arise from improper assembly.

Preparation Steps

Before beginning the installation process, it is essential to gather all required tools and components. Ensure the workspace is clean and organized to facilitate an efficient workflow. The following table outlines the necessary tools and materials:

| Tool/Material | Description |

|---|---|

| Socket Wrench Set | For loosening and tightening bolts and nuts. |

| Torque Wrench | To ensure bolts are tightened to the specified torque. |

| Replacement Components | All necessary elements that need to be installed. |

| Clean Cloth | For cleaning surfaces prior to assembly. |

Installation Steps

Follow the outlined procedures for a successful installation:

- Begin by removing any existing components that require replacement. Make sure to note the configuration for reassembly.

- Clean the surfaces where new components will be installed, removing any dirt or old sealant.

- Carefully position the new component in place, ensuring proper alignment with existing fixtures.

- Using a socket wrench, secure the component by tightening the bolts, following the manufacturer’s specifications.

- After installation, perform a thorough inspection to ensure everything is securely fastened and aligned correctly.

Performance Upgrades Available

Enhancing the efficiency and power delivery of heavy-duty transmission systems can significantly improve vehicle performance and drivability. A range of modifications and enhancements are accessible to optimize gear shifting, increase durability, and maximize overall effectiveness.

One of the primary areas for enhancement involves upgrading internal components such as gears and synchronizers. High-performance alternatives can offer smoother engagement and better load handling capabilities, ultimately leading to a more responsive driving experience. Additionally, reinforced materials can help withstand greater torque and extend the lifespan of the system.

Another avenue for improvement is the integration of advanced electronic control units (ECUs). These sophisticated systems can fine-tune shifting patterns, adapt to driving conditions, and improve fuel efficiency. The installation of aftermarket ECUs often allows for customized settings that cater to specific driving styles or requirements.

Moreover, optimizing the fluid used in the transmission can also contribute to better performance. Specialized lubricants can reduce friction, enhance cooling, and promote efficient operation, resulting in smoother shifts and lower operating temperatures.

Lastly, regular maintenance and inspection play a crucial role in sustaining optimal performance. Ensuring that all components are in good condition and free of wear can prevent potential issues and maintain the efficiency of the entire system. By investing in these upgrades and regular upkeep, vehicle owners can enjoy improved reliability and performance on the road.

Resources for Further Learning

To deepen your understanding of heavy-duty transmission systems, a variety of resources are available that cover various aspects of their operation, maintenance, and components. Engaging with these materials can enhance your knowledge and practical skills, making it easier to work with complex machinery.

Below is a table highlighting some valuable resources, including books, online courses, and websites that offer in-depth information on the subject.

| Resource Type | Title/Link | Description |

|---|---|---|

| Book | Heavy-Duty Truck Systems | A comprehensive manual covering truck drivetrain and transmission systems. |

| Online Course | Advanced Truck Transmission Repair | An in-depth course focusing on the repair and maintenance of transmission systems. |

| Website | TruckInfo | A resourceful site offering technical articles and guides related to truck systems. |

| Forum | Truckers Forum | An online community where professionals discuss challenges and solutions related to truck mechanics. |