When dealing with the maintenance or repair of a small engine, one of the most important aspects is understanding its internal structure. Knowing how each element interacts and functions within the engine is crucial for ensuring its efficiency and longevity. This knowledge not only helps with troubleshooting but also assists in preventing future issues.

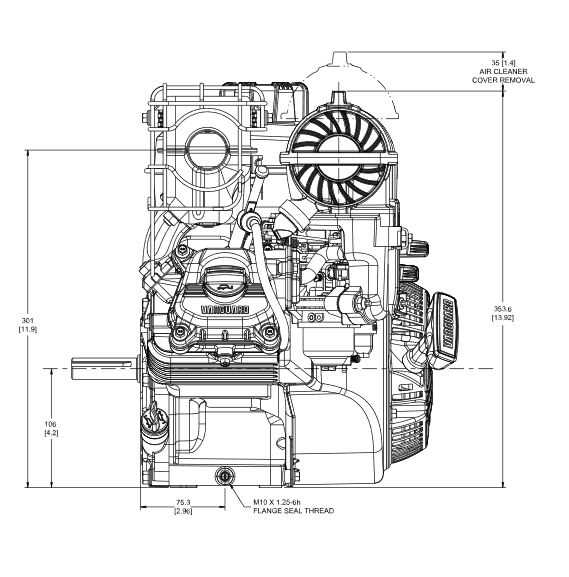

In the case of a 16 horsepower engine, recognizing the individual elements and how they fit together is key to effective upkeep. Each part plays a significant role in the overall performance, from the fuel system to the mechanical components. Having a clear visual representation of the setup can make the process much more straightforward, whether for professionals or hobbyists alike.

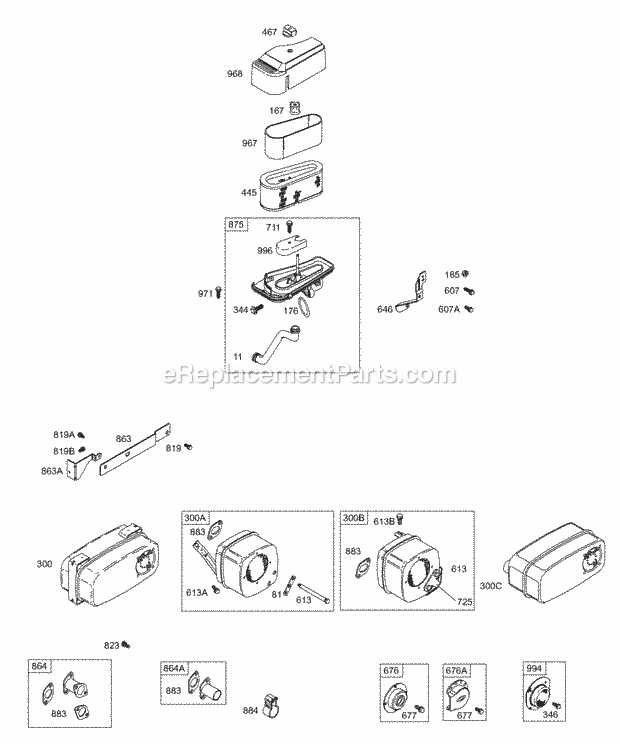

A well-organized schematic can provide insights into the detailed arrangement of every section. It simplifies the identification of specific components and offers clarity when it comes to assembling or replacing certain elements. By familiarizing yourself with this layout, you ensure that any mechanical work on the engine is executed with precision and accuracy.

Overview of Vanguard 16 HP Engine Components

This section provides a comprehensive look at the essential elements that make up the functionality of the 16-horsepower engine. Each component plays a vital role in ensuring smooth operation, contributing to the machine’s reliability and performance.

Main Structural Components

- Cylinder Block: The foundation of the engine, housing crucial internal systems like the pistons and crankshaft.

- Crankshaft: Converts the reciprocating motion of the pistons into rotational energy, which powers the equipment.

- Cylinder Head: Contains the intake and exhaust valves, ensuring proper airflow and combustion processes.

Key Systems

- Fuel System: Regulates the intake of fuel and air mixture, crucial for combustion efficiency.

- Ignition System: Ensures precise timing to ignite the fuel mixture, driving engine power.

- Cooling System: Keeps the temperature under control, preventi

Common Issues with Vanguard 16 HP Engines

Engines of this model are known for their durability, but like any mechanical device, they can encounter certain challenges over time. Identifying these problems early can help ensure longevity and smooth performance. Below are some frequent complications users may face and ways to address them effectively.

Starting Problems

One of the more typical issues is difficulty with ignition. This can stem from a variety of causes, including fuel delivery issues or problems with the electrical system. Ensuring that fuel is reaching the engine properly and that the spark plug is in good condition can often resolve this complication.

Overheating

Another recurring problem is excessive heat during operation. This can be caused by blockages in the cooling system or a buildup of debris. Regular maintenance of cooling fins and air filters can prevent overheating, keeping the engine running efficiently.

How to Identify Worn-Out Engine Parts

Regular maintenance is crucial for keeping any mechanical system running smoothly. Over time, various components may experience wear and tear, leading to performance issues. Recognizing the early signs of damage can help prevent costly repairs and extend the life of the machine.

One of the first indicators of deterioration is unusual noise coming from the machinery. This could be knocking, grinding, or rattling, signaling that certain elements are no longer functioning as they should. Paying attention to these sounds can provide early warnings of potential issues.

Another key sign is a drop in efficiency. If the engine requires more effort to perform routine tasks, this could indicate that some components are struggling to operate at their optimal level. This reduction in output can often be linked to worn-out elements that are no longer working as intended.

Visual inspection is another effective method. Look for visible damage such as cracks, rust, or excessive wear on specific elements. Components that appear degraded may need to be replaced to avoid further damage to the overall system.

Lastly, frequent overheating or sudden loss of power are clear signs that something within the engine is not functioning properly. These symptoms often point to a critical issue that requires immediate attention.

Essential Maintenance Tips for Longevity

Regular upkeep is crucial to ensure your machine runs smoothly for years to come. By following some basic maintenance routines, you can prevent potential breakdowns and prolong the lifespan of your equipment, saving both time and money in the long run.

Routine Inspections

- Inspect key components regularly to identify wear and tear early. This can help you avoid more significant issues down the line.

- Check all connections and fasteners to ensure they are secure and properly aligned.

- Look for any leaks, rust, or signs of deterioration, and address these issues immediately.

Fluid and Filter Maintenance

Maintaining proper fluid levels and replacing filters at regular intervals is essential to keep the system running efficiently.

- Check oil levels before each use and replace as needed, following the manufacturer’s guidelines.

- Replace air filters regularly to ensure optimal air flow and engine performance.

- Examine the fuel system for

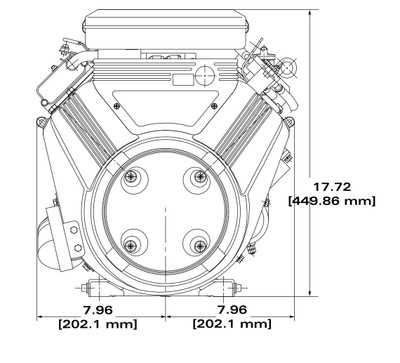

Key Differences Between Various Vanguard Models

When exploring a range of engine types, understanding the distinctions between different versions is essential for making informed choices. These differences often lie in the engine’s power output, design specifications, and additional features, which can influence performance across various applications.

Engine Specifications

Different models are equipped with varying horsepower levels, which affect their suitability for specific tasks. Some versions are designed for high-demand applications, while others focus on efficiency and longevity in less intensive use cases. Additionally, factors such as cylinder arrangement, fuel consumption, and cooling methods can differ significantly.

Additional Features and Accessories

Beyond core specifications, certain versions come with optional enhancements or built-in features, such as advanced air filtration systems, improved mufflers, or enhanced starting mechanisms. These enhancements can greatly impact ease of use, noise reduction, and overall performance.

Feature Model A Model B Model C Horsepower 16 hp 18 hp 20 hp Signs You Need to Replace Engine Parts

Recognizing when to swap out components of your engine is crucial for maintaining optimal performance and avoiding more severe issues. Certain indicators can help you determine whether it’s time to invest in new elements to ensure the smooth functioning of your machinery.

- Unusual Noises: If you hear knocking, rattling, or grinding sounds, it may signal internal damage or wear.

- Decreased Performance: A noticeable drop in power, acceleration, or responsiveness could indicate failing elements.

- Excessive Vibration: If your engine shakes more than usual, it may be a sign of misaligned or damaged components.

- Warning Lights: Dashboard indicators can alert you to issues needing immediate attention.

- Fluid Leaks: Puddles or stains under your vehicle can indicate leaking fluids, suggesting worn seals or gaskets.

- Increased Emissions: A rise in exhaust smoke or smell could indicate inefficient combustion, pointing to the need for replacements.

- Frequent Breakdowns: If your engine frequently stalls or has starting issues, it may require new parts.

Paying attention to these signs can help you maintain your equipment efficiently and extend its lifespan. Regular inspections and timely replacements can prevent costly repairs down the line.

Where to Find Genuine Parts for Vanguard 16 HP

When it comes to maintaining the performance and longevity of your engine, sourcing authentic components is essential. Reliable suppliers offer a variety of options that ensure compatibility and quality. This guide provides insights into the best avenues for acquiring these critical elements.

Authorized Dealers

One of the most reliable sources for authentic components is authorized dealers. These outlets typically carry a wide selection of original equipment, guaranteeing that what you purchase will meet the manufacturer’s specifications. Additionally, purchasing from an authorized dealer often provides access to knowledgeable staff who can assist with any inquiries or recommendations.

Online Marketplaces

The internet offers numerous platforms where you can find genuine components. Reputable online marketplaces feature sellers who specialize in engine supplies, often with user reviews to help ensure quality. When shopping online, it’s important to verify the seller’s credibility and check for return policies to protect your purchase.

Step-by-Step Guide to Engine Disassembly

Disassembling an engine can seem like a daunting task, but with the right approach, it becomes manageable. This guide provides a structured method for taking apart your engine, ensuring that each component is carefully handled and documented. By following these steps, you can gain a deeper understanding of your machine’s mechanics and facilitate smoother repairs or upgrades.

Preparation and Safety

Before you begin, ensure that you have the necessary tools and a clean, organized workspace. Wear safety gear such as gloves and goggles to protect yourself from debris and sharp edges. It’s also beneficial to have a camera or notepad handy to document the assembly process, making it easier to reassemble later.

Disassembly Process

Start by removing any external components such as the air filter and exhaust system. Next, drain all fluids, including oil and fuel, to prevent spills. Carefully detach the electrical connections and label them for easy reconnection. Continue by unscrewing the main bolts holding the engine casing together, taking care to keep track of each part’s location. Once the casing is open, you can proceed to extract the internal components, like the pistons and crankshaft, following a systematic order to maintain organization.

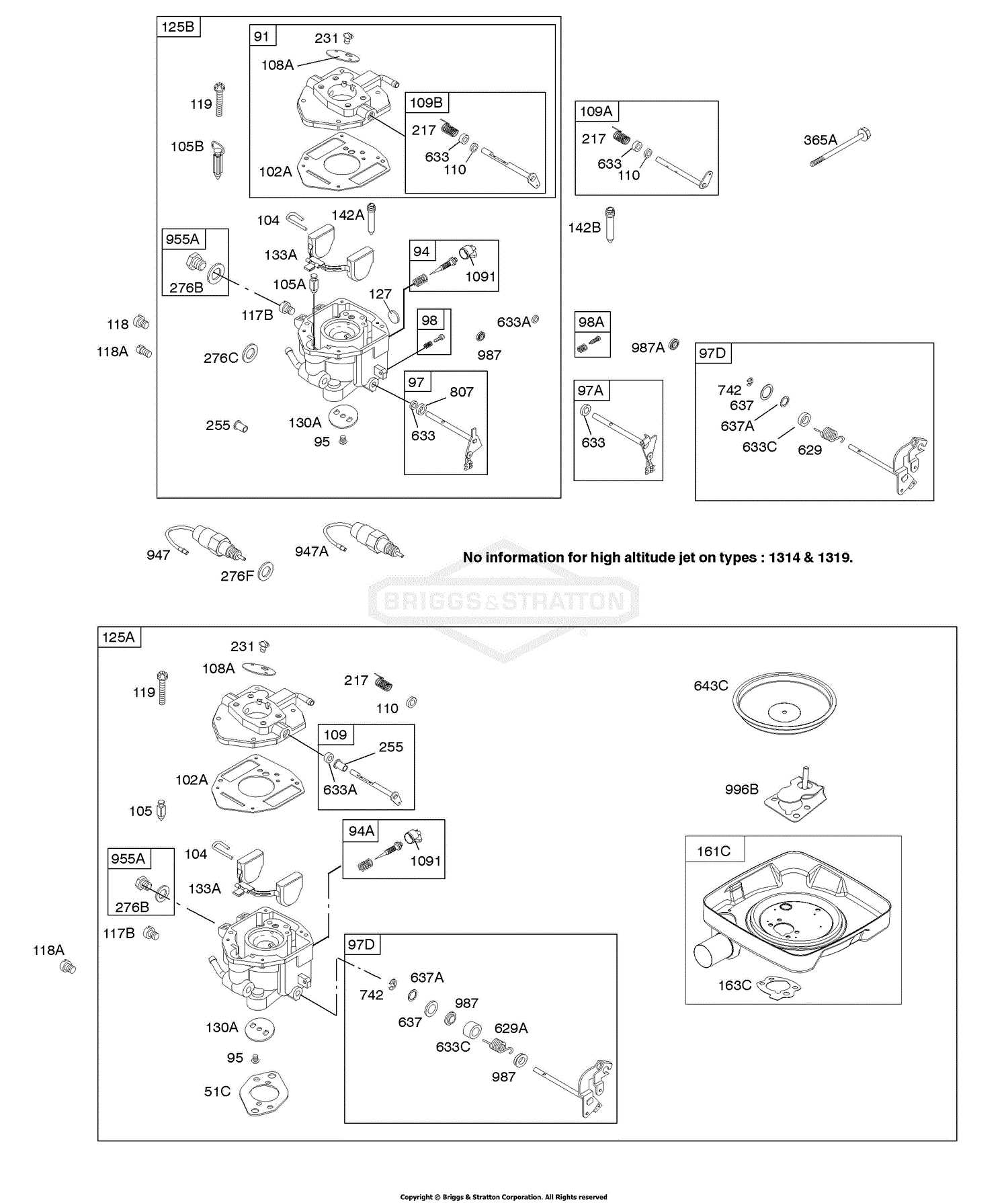

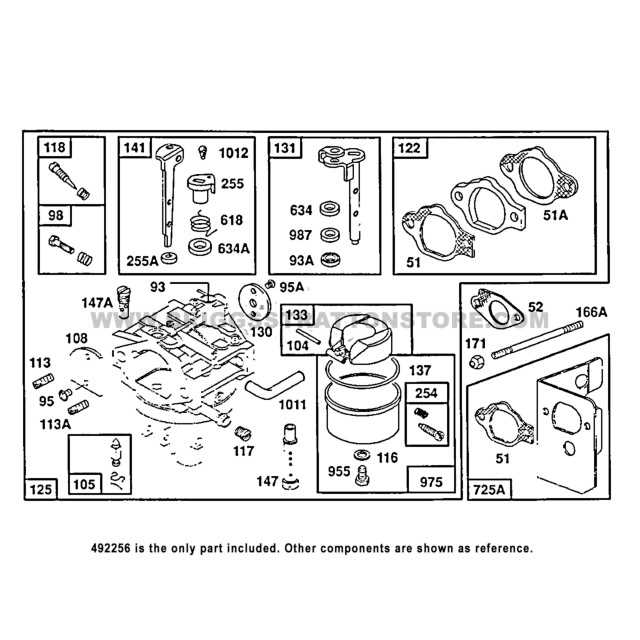

Understanding the Vanguard 16 HP Fuel System

The fuel system of small engines is crucial for their performance and efficiency. It involves various components that work together to ensure the proper delivery of fuel to the engine. A comprehensive understanding of this system helps in diagnosing issues and performing effective maintenance.

Key Components

- Fuel Tank: Stores the fuel required for operation.

- Fuel Pump: Delivers fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Carburetor: Mixes fuel with air for combustion.

- Fuel Lines: Transport fuel between components.

Operating Principles

The process begins with the fuel being drawn from the tank by the pump. It then travels through the filter, where any contaminants are removed. Once filtered, the clean fuel enters the carburetor, where it is mixed with air to form a combustible mixture. This mixture is then directed into the combustion chamber, where it ignites and powers the engine.

Understanding these components and their interactions is essential for troubleshooting issues such as poor performance, stalling, or starting difficulties. Regular maintenance of the fuel system components is vital for ensuring long-term reliability and optimal engine function.

Cooling Mechanism in Vanguard 16 HP Engines

The cooling system in small engines plays a crucial role in maintaining optimal operating temperatures, preventing overheating, and ensuring longevity. This system employs a combination of air and liquid cooling techniques to effectively dissipate heat generated during engine operation. Understanding how this mechanism functions can provide insights into its efficiency and performance in various applications.

Air Cooling System

Air cooling is achieved through the natural flow of air over the engine components. As the engine runs, a fan draws in ambient air, which circulates around the engine block and cylinder head. This process helps to cool the engine by transferring heat away from critical areas. The design of the engine includes fins and channels that enhance airflow, maximizing heat dissipation. This method is particularly effective in environments where ambient temperatures are moderate, ensuring the engine operates within safe temperature limits.

Liquid Cooling System

In some configurations, a liquid cooling system is utilized to maintain optimal temperatures more effectively. This system involves a coolant that circulates through the engine block, absorbing heat and carrying it to a radiator. The radiator then dissipates the heat into the surrounding air. This method provides superior thermal regulation, making it suitable for heavier loads and extended operation. Regular maintenance of the cooling system, including checking coolant levels and inspecting for leaks, is essential to ensure consistent performance.

Tips for Installing New Engine Parts

When it comes to enhancing engine performance, the installation of new components can make a significant difference. Proper fitting of these elements not only ensures optimal functioning but also extends the longevity of the entire system. Here are some valuable suggestions to consider during the installation process.

Preparation and Organization

Before starting the installation, gather all necessary tools and materials. Organize your workspace to minimize distractions and ensure that you can easily access what you need. Having a clear plan will help streamline the process and reduce the likelihood of mistakes.

Follow Manufacturer Guidelines

Always consult the manufacturer’s instructions when fitting new components. These guidelines provide crucial information about torque specifications and installation sequences that are essential for optimal performance. Adhering to these recommendations will help you avoid potential issues that may arise from improper installation.