In the world of engineering and mechanics, a thorough grasp of individual elements is essential for effective assembly and maintenance. This segment delves into the intricate arrangement and functionality of each segment related to a particular small aquatic mammal, offering insights into their design and operation. By dissecting these elements, we can enhance our knowledge and ensure optimal performance.

Each component plays a vital role in the overall mechanism, contributing to the efficiency and durability of the system. Recognizing the significance of each section not only aids in troubleshooting but also facilitates informed decisions during upgrades or repairs. Emphasizing clarity and detail, this exploration will equip enthusiasts and professionals alike with the ultimate understanding of the assembly.

Whether you are a hobbyist or an expert, understanding these integral segments will enrich your experience and broaden your appreciation for the engineering marvels inspired by nature. Join us as we embark on a detailed examination of these fascinating components.

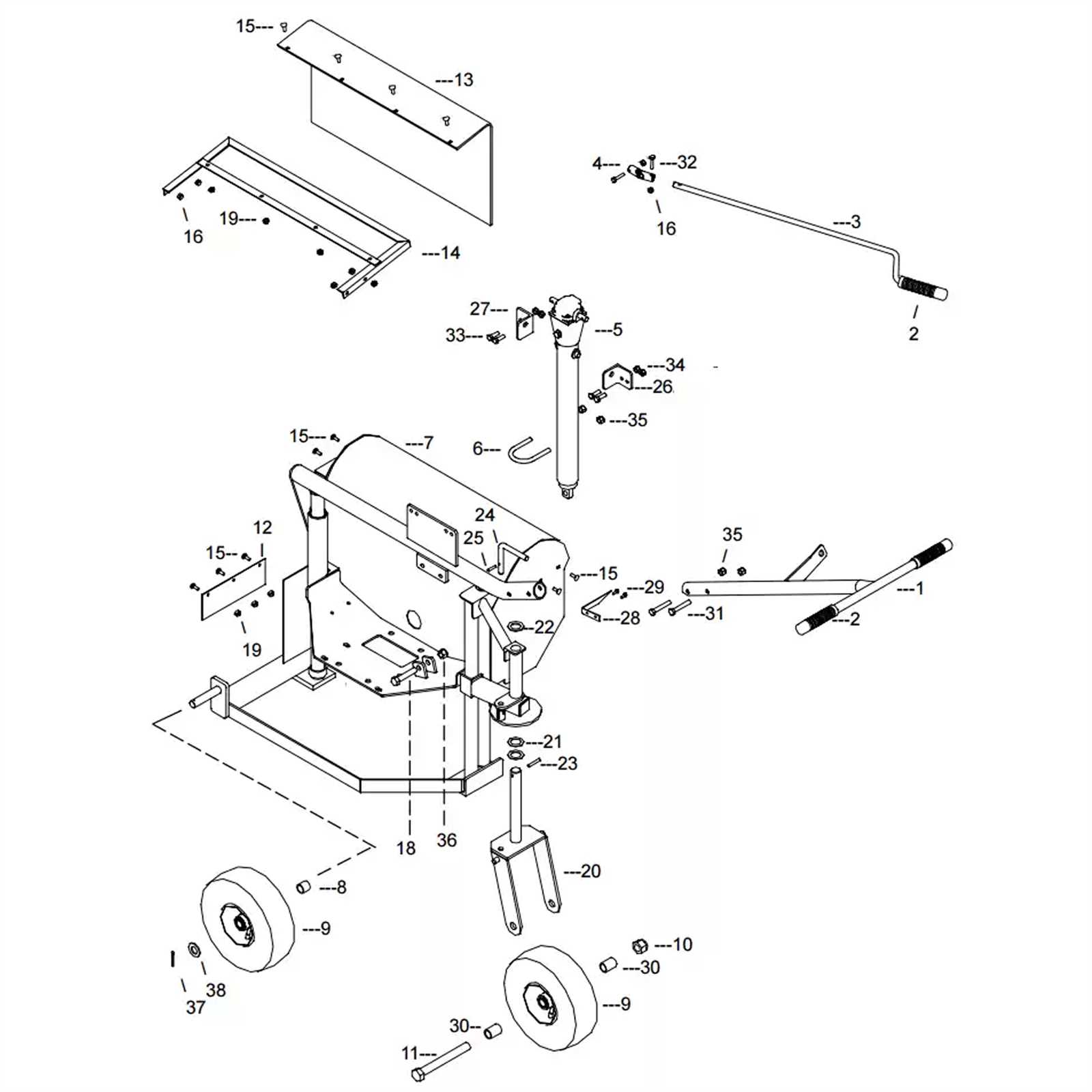

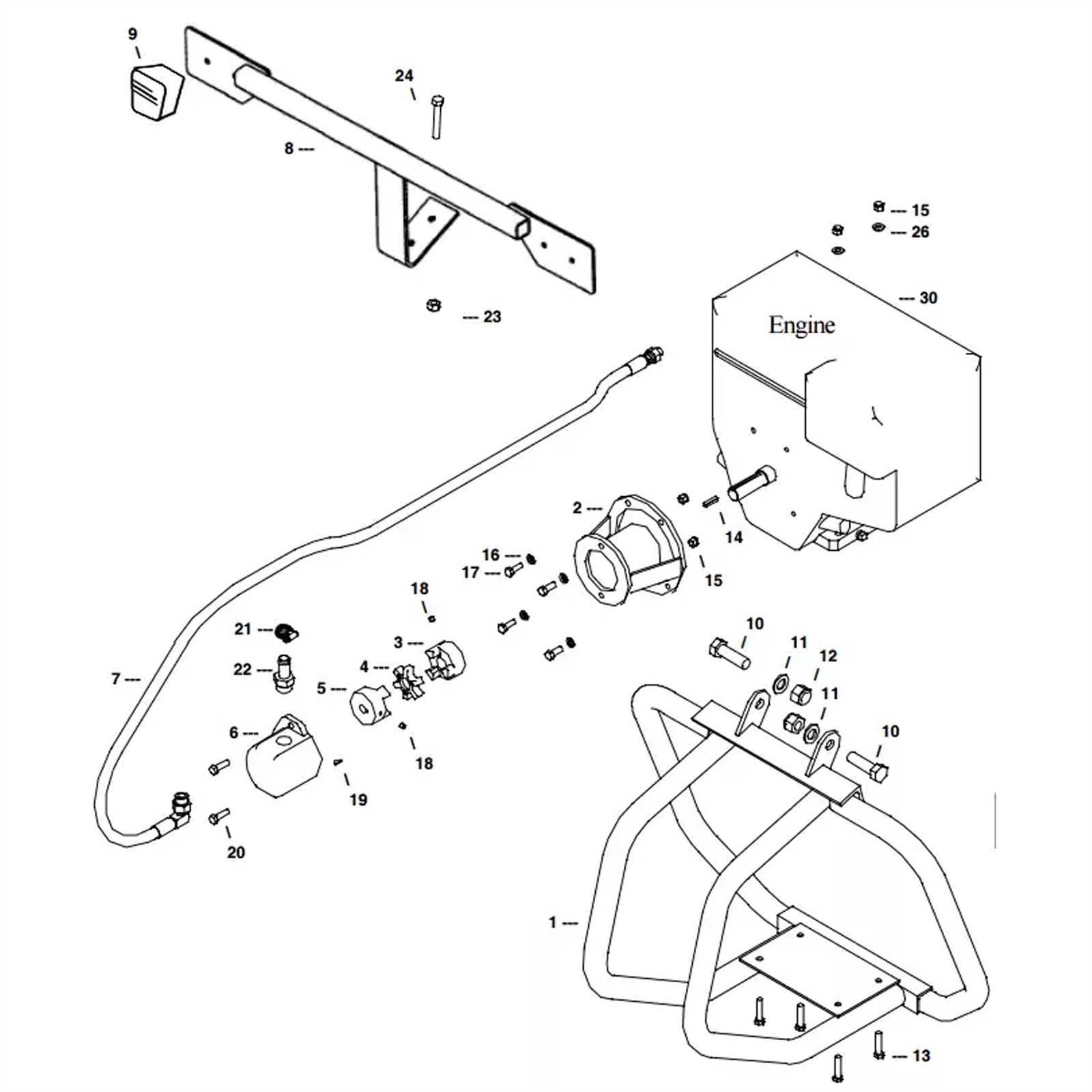

Understanding Little Beaver Components

This section explores the various elements that constitute a specific type of machinery designed for efficient operation. A comprehensive understanding of these components enhances the user’s ability to maintain and optimize performance.

| Component | Description |

|---|---|

| Frame | The main structure that supports all other elements and provides stability. |

| Engine | The power source responsible for driving the machine’s functions. |

| Drill Bit | The cutting tool designed to penetrate various materials effectively. |

| Transmission | Facilitates the transfer of power from the engine to the drill bit. |

| Control Panel | The interface used by operators to manage machine functions and settings. |

Overview of Little Beaver Parts

This section provides a comprehensive look at the essential components of a specific type of equipment, highlighting their functions and interconnections. Understanding these elements is crucial for effective operation and maintenance.

Key Components

- Power Source: The engine or motor that drives the machinery.

- Transmission: Transfers power to various parts.

- Frame: The structure that supports the entire unit.

- Drivetrain: Includes the mechanisms for movement.

- Attachments: Additional tools or accessories that enhance functionality.

Maintenance Considerations

- Regular inspections to identify wear and tear.

- Lubrication of moving parts to ensure smooth operation.

- Replacement of worn components to maintain performance.

Functionality of Each Component

This section explores the roles and contributions of various elements within the system. Understanding how each piece operates is essential for grasping the overall functionality and efficiency of the entire mechanism.

| Component | Function |

|---|---|

| Motor | Provides the necessary power to drive the system, converting electrical energy into mechanical motion. |

| Gear Assembly | Transforms the rotational speed and torque, enabling smooth operation and effective force transmission. |

| Control Unit | Acts as the brain of the system, regulating functions and ensuring optimal performance through programmed instructions. |

| Housing | Protects internal components from external elements while providing structural integrity to the assembly. |

| Sensor | Monitors various parameters and sends data to the control unit for real-time adjustments and feedback. |

Common Issues with Parts

In the realm of mechanical components, various challenges can arise, impacting functionality and efficiency. Understanding these obstacles is essential for effective maintenance and repair strategies.

Wear and Tear

Over time, components may experience deterioration due to friction and environmental factors. Regular inspections can help identify signs of fatigue early, preventing major malfunctions.

Compatibility Problems

Using mismatched elements can lead to performance issues. Ensuring that all parts are designed to work together is crucial for optimal operation.

| Issue | Potential Solution |

|---|---|

| Wear and Tear | Regular inspections and timely replacements |

| Compatibility Problems | Verification of specifications before installation |

| Corrosion | Use of protective coatings and regular cleaning |

Maintenance Tips for Longevity

Ensuring the prolonged functionality of equipment requires a proactive approach to care and upkeep. Regular attention to maintenance not only enhances performance but also extends the lifespan of the machinery. By following a systematic routine, users can mitigate potential issues and enhance overall reliability.

Regular Inspections

Conducting frequent evaluations is essential for identifying wear and tear before it escalates into significant problems. Check all components for signs of damage, corrosion, or misalignment. Timely detection allows for prompt repairs, reducing downtime and preserving efficiency.

Proper Lubrication

Maintaining adequate lubrication is crucial for minimizing friction and preventing overheating. Use high-quality lubricants suited for the specific type of machinery. Regularly inspect and replenish lubricant levels according to the manufacturer’s guidelines to ensure optimal operation.

How to Identify Parts Easily

Understanding various components can significantly enhance your maintenance and repair experience. By employing a systematic approach, you can streamline the identification process and ensure accuracy in your tasks.

Begin by familiarizing yourself with the general structure and function of each element. This foundational knowledge will allow you to quickly recognize the role each piece plays within the overall system.

Utilizing visual aids such as labeled images or reference guides can also be invaluable. These resources provide clear illustrations, helping you associate names with shapes and functions effectively.

Additionally, keeping a checklist of common components and their characteristics will enable you to track essential items effortlessly. This method not only aids in identification but also enhances your confidence when addressing repairs.

Finally, consulting online forums or communities dedicated to this subject can provide insights from experienced individuals. Engaging with others who share your interest can offer tips and tricks that elevate your understanding and skills.

Repairing vs. Replacing Components

When faced with a malfunctioning mechanism, one must consider whether to mend existing elements or to substitute them entirely. Each approach presents unique advantages and potential drawbacks that can significantly impact the longevity and performance of the system.

Repairing components can often be more cost-effective and environmentally friendly. Here are some benefits:

- Preserves original functionality

- Reduces waste

- Can be quicker if parts are readily available

On the other hand, replacing elements might be the ultimate solution in certain scenarios. Consider these points:

- Improved reliability with new components

- May enhance overall performance

- Eliminates recurring issues associated with older parts

Ultimately, the choice between repair and replacement should be based on factors like cost, availability, and the specific context of the malfunction.

Tools Needed for Assembly

Assembling a mechanical structure requires a set of essential implements that ensure precision and efficiency. Having the right tools at hand not only simplifies the process but also enhances the overall quality of the finished product. This section outlines the necessary equipment for a successful assembly experience.

Essential Hand Tools

Basic hand tools form the backbone of any assembly task. Among the most crucial are screwdrivers, which come in various types to accommodate different fasteners. Additionally, a reliable wrench set is vital for tightening and loosening bolts. Pliers, especially those with gripping capabilities, can help in maneuvering small components effectively.

Power Tools and Accessories

Incorporating power tools can significantly expedite the assembly process. A cordless drill is indispensable for driving screws quickly and efficiently. Furthermore, having a saw on hand can assist in cutting materials to the required dimensions. Always remember to equip yourself with the necessary safety gear, such as gloves and goggles, to ensure a secure working environment.

Where to Find Replacement Parts

Locating suitable components for your equipment can be crucial for maintenance and performance. Various sources are available that cater to different needs, from specialized retailers to online platforms. It’s essential to explore all options to ensure you find the best quality and price for your requirements.

Local hardware stores often stock essential items, allowing for immediate purchase and inspection. For more specific needs, specialized shops can offer expert advice and a wider selection. Additionally, online marketplaces provide the ultimate convenience, enabling you to compare prices and find rare components with ease.

Don’t overlook manufacturer websites, as they may offer original items directly, often with warranties. Forums and community groups can also be invaluable, providing recommendations and insights from experienced users who have tackled similar challenges. By leveraging these resources, you can ensure your equipment remains in optimal condition.

Benefits of Proper Part Selection

Choosing the right components is essential for optimizing performance and longevity in any mechanical system. Accurate selection not only enhances efficiency but also minimizes risks associated with failures, ensuring a smooth operation and reliability over time.

Enhanced Performance

When components are meticulously chosen, they work harmoniously together, leading to improved overall functionality. This synergy can result in greater output, reduced energy consumption, and a more satisfying user experience.

Cost Efficiency

Investing in appropriate elements can significantly lower maintenance costs. By preventing premature wear and tear, users can avoid frequent replacements and repairs, ultimately resulting in savings over the lifespan of the equipment.

Exploring Upgrades for Performance

Enhancing the efficiency of your machinery can significantly elevate its overall capabilities. By focusing on various enhancements, you can unlock new potential and improve operational effectiveness.

Key areas to consider for improvements include:

- Engine modifications

- Weight reduction techniques

- Upgraded transmission systems

- Advanced fuel management

Each of these elements can contribute to a more powerful and agile system, ensuring optimal performance under diverse conditions.

To further delve into specifics, consider the following upgrades:

- High-performance air filters

- Tuned exhaust systems

- Enhanced suspension components

- Electronic control unit (ECU) remapping

These upgrades can provide the ultimate edge in performance, allowing for a more responsive and efficient operation.