In the realm of agricultural machinery, comprehending the intricate elements that contribute to a machine’s functionality is crucial. This section aims to provide insights into the essential components that ensure optimal performance and efficiency in farming equipment.

By exploring the various elements involved, users can gain a clearer understanding of how these mechanisms work together. Whether it’s for maintenance or enhancement, having access to a detailed overview allows operators to make informed decisions regarding their machinery.

Moreover, visual representations can significantly aid in identifying and addressing issues swiftly. A comprehensive breakdown can serve as an invaluable resource for both seasoned professionals and newcomers in the field, ensuring that everyone can navigate the complexities of modern agricultural devices.

Massey Ferguson 1359 Overview

This section provides a comprehensive look at a notable agricultural machine known for its durability and efficiency. Designed to meet the diverse needs of farmers, this vehicle combines innovative engineering with practical functionality, making it a reliable choice for various tasks in the field.

Key Features

The equipment boasts a robust engine, offering exceptional power and performance. Its advanced hydraulic system enhances versatility, allowing users to tackle different operations with ease. The ergonomic design ensures comfort during long hours of work, contributing to improved productivity.

Applications

This model is well-suited for a range of agricultural tasks, from plowing to harvesting. Its adaptability in various terrains makes it an ultimate asset for modern farming, ensuring efficiency and effectiveness in all operations.

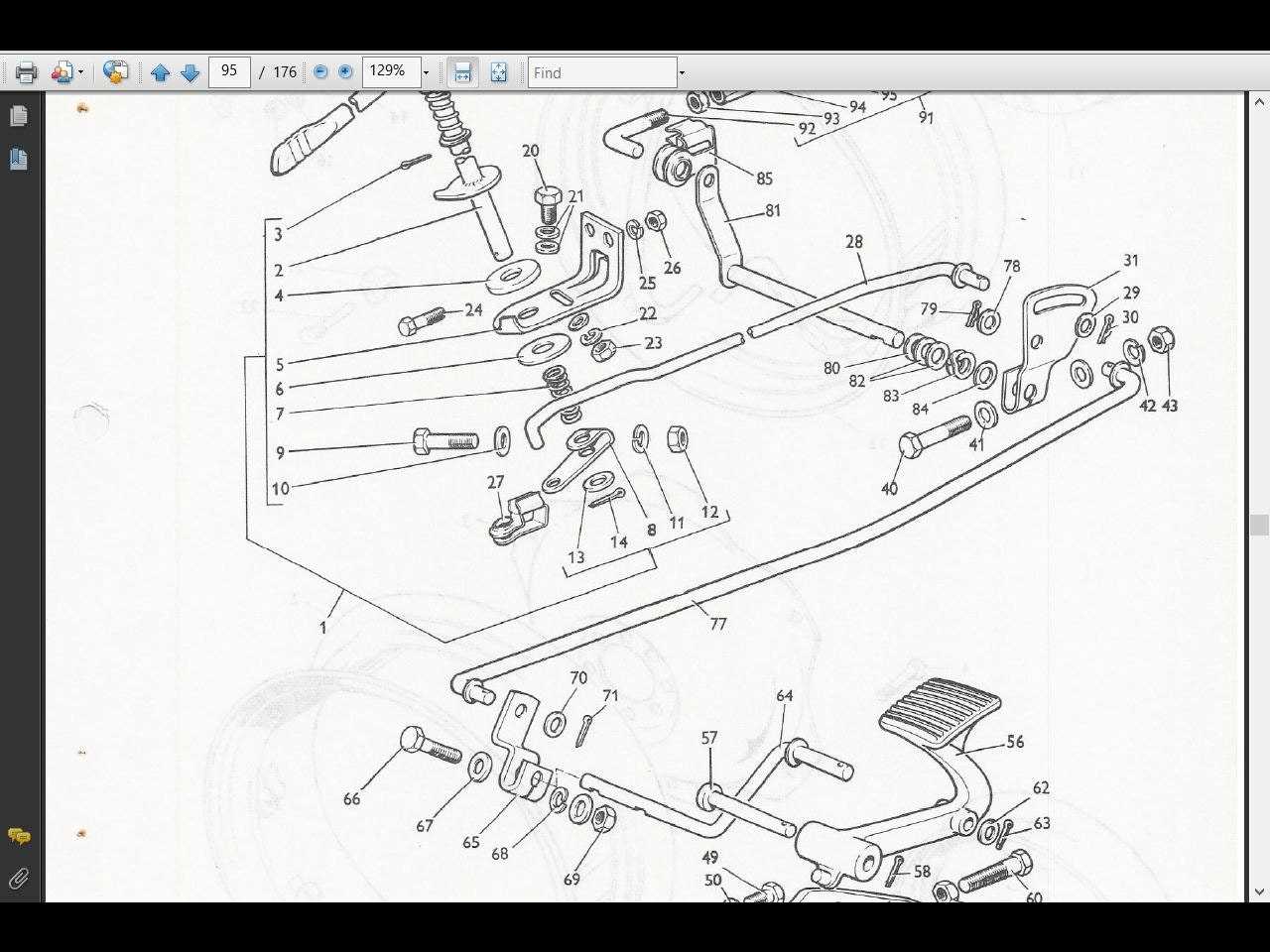

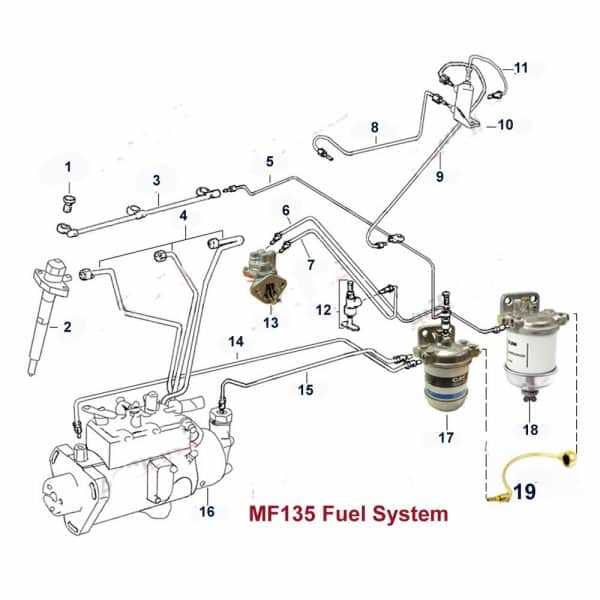

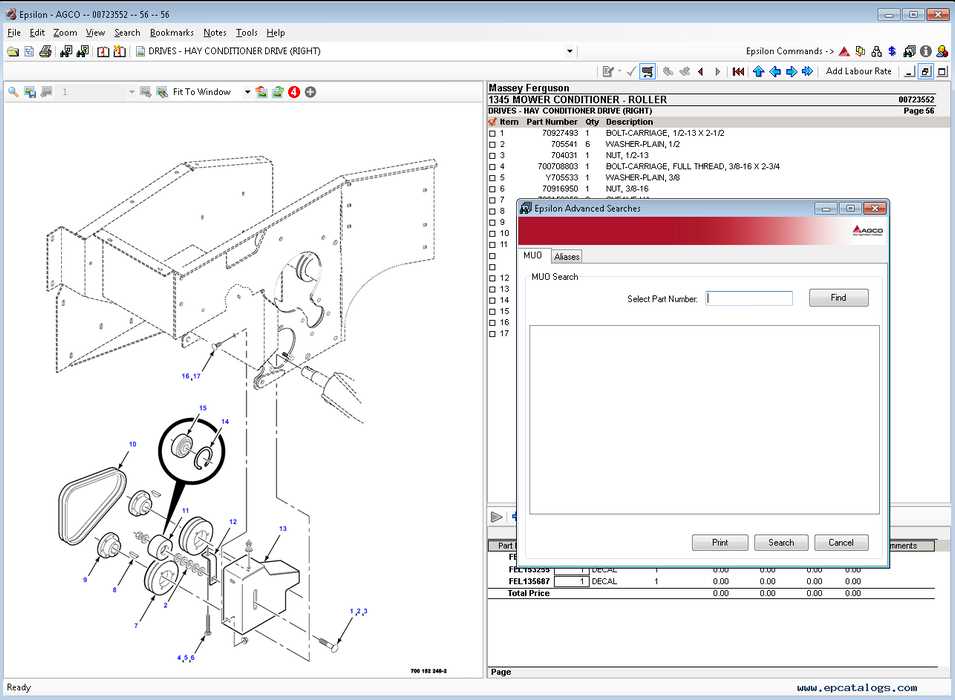

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repair. Visual representations serve as invaluable resources for technicians, offering clarity on the intricate relationships between different elements. They not only aid in identifying specific pieces but also enhance the overall understanding of the equipment’s functionality.

Accurate reference materials allow users to quickly locate and assess each element, facilitating smoother workflows during repairs. This ultimately leads to reduced downtime and increased productivity. Moreover, comprehensive illustrations support training initiatives, enabling new personnel to grasp complex systems more readily.

In summary, utilizing detailed visual guides ensures that every aspect of machinery is thoroughly understood, leading to more informed decisions and efficient operations.

Key Components of the 1359 Model

The intricate design of this agricultural machine relies on several essential elements that ensure its efficient operation. Understanding these key components is vital for maintenance and optimal performance.

Powertrain Elements

The powertrain is crucial for transmitting energy from the engine to the wheels. It comprises the gearbox, axles, and differential, all working in unison to provide the necessary torque and speed for various tasks.

Hydraulic System

A well-functioning hydraulic system is integral for lifting and controlling attachments. This system includes the hydraulic pump, cylinders, and valves, allowing for smooth operation and enhanced versatility in the field.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for anyone involved in maintenance or repair tasks. These illustrations provide a clear overview of individual elements, their placement, and how they interact within a larger system. By becoming familiar with these visuals, you can effectively identify and source the necessary components for your machinery.

Here are some key elements to consider when interpreting these visuals:

| Element | Description |

|---|---|

| Numbers | These often correspond to specific parts in the accompanying list, helping you find the exact component needed. |

| Labels | Written descriptions that provide additional context, such as the function or type of each component. |

| Arrows | Indicators showing the relationships between various parts, including connections and orientations. |

| Color Coding | Used to categorize components based on type, function, or urgency of replacement. |

By focusing on these elements, you can navigate through the visual guide with confidence and ensure you have the right information for your tasks.

Common Issues with Massey Ferguson 1359

When it comes to agricultural machinery, certain challenges frequently arise that can impact performance and efficiency. Understanding these common problems is essential for maintaining optimal operation and longevity. Operators often encounter issues related to mechanical wear, electrical systems, and hydraulic functionality.

Mechanical Wear and Tear

Over time, components such as the engine, transmission, and axles can experience significant wear. Symptoms may include unusual noises, vibrations, or decreased power output. Regular inspections and maintenance are crucial to identify and address these issues early, ensuring that machinery remains in good working condition.

Electrical and Hydraulic Problems

Electrical faults can lead to starting issues or malfunctioning gauges, complicating the operation. Similarly, hydraulic failures often manifest as sluggish movement or loss of pressure, affecting the performance of implements. Diagnosing these problems promptly is vital to minimize downtime and repair costs.

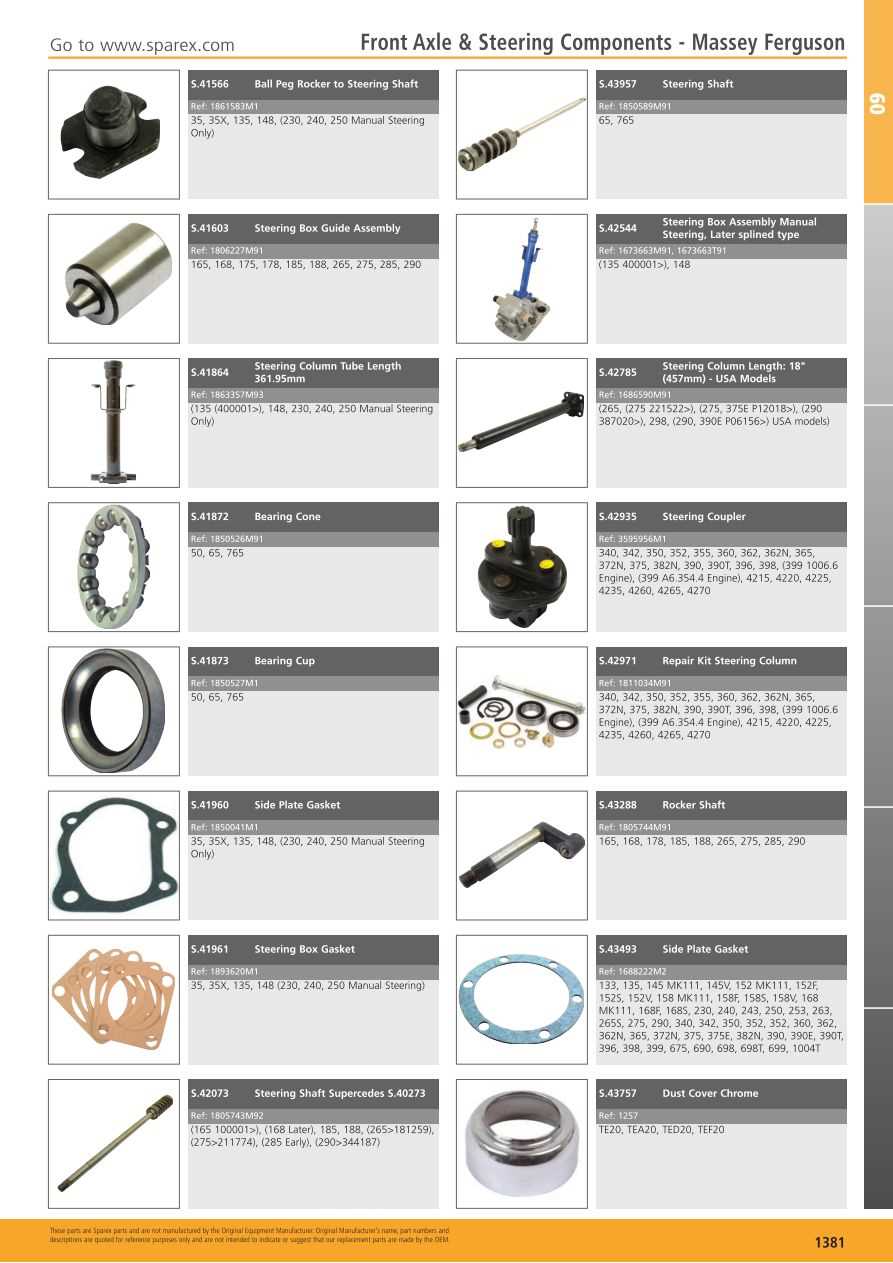

Where to Find Replacement Parts

Locating suitable components for your machinery can be essential for maintaining optimal performance. Various sources provide access to quality alternatives that ensure longevity and efficiency.

Online Marketplaces

- Amazon: A vast selection of components with user reviews.

- eBay: Offers both new and used options at competitive prices.

- Specialty sites: Dedicated retailers often carry hard-to-find items.

Local Dealers and Workshops

- Authorized dealerships: Reliable sources for genuine components.

- Independent mechanics: Often have insights on aftermarket alternatives.

- Farm supply stores: Typically stock common items needed for agricultural equipment.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of agricultural machinery requires consistent attention and care. By following a few essential maintenance practices, operators can significantly enhance the performance and reliability of their equipment, ultimately leading to improved productivity in the field.

Regular Inspections: Conduct routine checks on all critical components. This includes examining fluid levels, belts, and filters. Timely identification of wear or damage can prevent costly repairs and downtime.

Fluid Management: Maintaining proper fluid levels is crucial for optimal operation. Regularly change engine oil and hydraulic fluids as recommended by the manufacturer. Clean filters and check for contaminants to ensure that systems function smoothly.

Calibration: Properly calibrate settings to match specific tasks. This adjustment not only improves efficiency but also conserves fuel and reduces wear on parts.

Cleaning: Keep the machinery clean from dirt and debris. Accumulated grime can lead to overheating and component failure. A regular cleaning schedule will help maintain peak performance.

Storage Practices: When not in use, store equipment in a dry, sheltered location. Protecting machinery from the elements extends its lifespan and maintains its functionality.

Documentation: Maintain detailed records of all maintenance activities, repairs, and inspections. This documentation can provide valuable insights into the machine’s performance over time and help in planning future maintenance needs.

By integrating these practices into routine operations, users can ensure that their machinery remains in optimal condition, thereby enhancing efficiency and productivity on the farm.

Comparing 1359 to Other Models

When exploring various agricultural machinery, it’s essential to analyze the distinctions and similarities between specific models. This comparison not only highlights unique features but also aids in understanding which equipment best suits particular needs. Evaluating performance, design, and functionality can provide valuable insights for potential users.

One significant aspect of this comparison lies in the engine capacity and overall power output. Many machines in the same category offer varying horsepower, which can influence their efficiency in different farming tasks. Additionally, the dimensions and weight of the equipment play a crucial role in maneuverability and suitability for diverse terrains.

Another factor to consider is the availability of accessories and attachments. Some models may offer a broader range of compatible implements, enhancing versatility for various agricultural operations. Furthermore, fuel efficiency is a critical parameter; comparing consumption rates can lead to long-term savings and reduced environmental impact.

Ultimately, understanding how a specific machine stacks up against others can lead to more informed decisions, ensuring optimal performance in agricultural practices.

Understanding the Engine Specifications

When it comes to agricultural machinery, comprehending the engine specifications is crucial for optimal performance and maintenance. The engine serves as the heart of the equipment, driving its capabilities and efficiency. A thorough understanding of its components and characteristics allows operators to make informed decisions regarding upkeep and troubleshooting.

Key specifications often include horsepower, displacement, torque, and fuel type. These factors influence not only the machine’s performance but also its fuel efficiency and operational costs. Below is a summary of important engine specifications that every operator should be familiar with:

| Specification | Description |

|---|---|

| Horsepower | The measure of engine power, indicating the workload it can handle. |

| Displacement | The total volume of all the cylinders in the engine, affecting performance and efficiency. |

| Torque | The rotational force produced by the engine, critical for tasks requiring power. |

| Fuel Type | The type of fuel the engine uses, impacting its efficiency and environmental footprint. |

By familiarizing oneself with these specifications, operators can better appreciate the capabilities of their machinery and ensure it operates at its best, ultimately enhancing productivity and longevity.

Accessories for Enhanced Functionality

Enhancing the capabilities of agricultural machinery is crucial for maximizing productivity and efficiency. Various accessories can significantly improve performance, making tasks easier and more effective. From attachments that increase versatility to components that ensure smoother operation, these enhancements are vital for any operator seeking to optimize their equipment.

Versatile Attachments

Attachments such as plows, harrows, and seeders can transform standard machinery into multifunctional tools. By utilizing these additions, users can tackle diverse tasks ranging from tilling to planting. The ability to switch between attachments seamlessly allows for greater adaptability in different agricultural environments.

Operational Enhancements

Investing in operational enhancements like upgraded hydraulic systems or precision steering aids can lead to improved handling and control. These innovations not only increase safety but also reduce wear and tear on the machinery, ensuring longevity and reliability. Operators can thus achieve their ultimate performance goals with greater ease.

Guidelines for Safe Operation

Ensuring safety during machinery use is crucial for both operators and bystanders. Adhering to specific practices can minimize risks and promote a secure working environment. Understanding these protocols is essential for effective and responsible operation.

| Safety Practice | Description |

|---|---|

| Read the Manual | Familiarize yourself with the equipment’s operation and safety guidelines. |

| Wear Protective Gear | Always use appropriate personal protective equipment to shield against hazards. |

| Inspect Before Use | Check the machinery for any damage or wear before starting operations. |

| Maintain Clear Communication | Ensure all team members understand signals and instructions during operation. |

| Stay Alert | Remain focused on your task and be aware of your surroundings at all times. |