Exploring the intricate elements that contribute to the stability and integrity of motorized transport reveals the significance of each component. These structures work in harmony, ensuring optimal performance and safety during operation.

By examining the various segments that comprise the overall assembly, one can appreciate the engineering behind these vital constructs. Each section serves a unique purpose, enhancing durability while facilitating movement and handling.

In this analysis, we will delve into the essential building blocks that support the entire mechanism. Understanding their layout and interaction provides insight into the fundamental principles of automotive design.

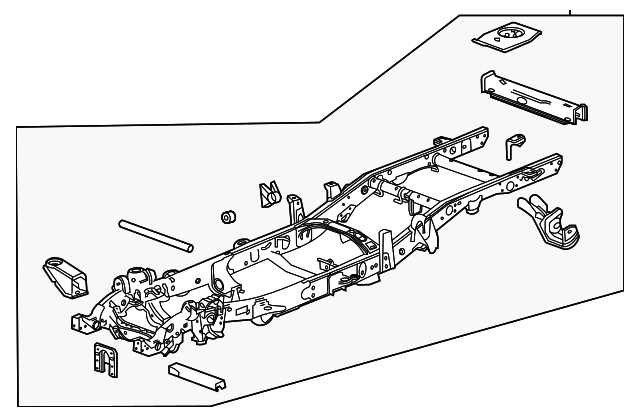

Understanding Car Frame Structures

This section explores the essential components that contribute to the structural integrity and safety of vehicles. A solid foundation is crucial for performance, crash protection, and overall stability, making it imperative to understand the various elements involved.

Key Elements of Structural Integrity

The main components work together to provide support and rigidity. They help absorb impact forces and maintain alignment, ensuring a smooth driving experience. Each element plays a vital role in the vehicle’s overall performance and safety.

Component Overview

| Element | Description |

|---|---|

| Chassis | The core structure that supports all other components. |

| Subframe | A secondary structure that supports specific systems, such as the suspension. |

| Crossmember | Bridges the space between primary structures to enhance rigidity. |

| Reinforcement | Additional materials or structures added to enhance strength. |

Components of a Vehicle Frame

This section explores the essential elements that constitute the structure of a vehicle, providing support and stability. Understanding these components is crucial for grasping how they interact to ensure safety and performance.

- Chassis: The main structure that supports the entire vehicle.

- Crossmembers: Horizontal beams that enhance rigidity and distribute loads.

- Longitudinals: The primary lengthwise supports that run parallel along the vehicle.

- Subframes: Secondary structures that provide additional support for specific components, such as the engine or suspension.

- Mounts: Attachments that secure various systems and components to the main structure.

Each element plays a vital role in maintaining the overall integrity and functionality of the vehicle, ensuring it can withstand various stresses encountered during operation.

Types of Frame Designs Explained

Understanding the various structural designs is crucial for grasping how vehicles are constructed. Each configuration plays a vital role in the overall performance, safety, and aesthetics of the machine. These designs can significantly influence handling characteristics, weight distribution, and even manufacturing costs.

Monocoque structures integrate the outer skin with the supporting framework, providing a lightweight solution that enhances rigidity. This type is commonly used in modern vehicles, allowing for efficient use of materials and better fuel economy.

Body-on-Frame setups feature a separate chassis that supports the body. This traditional design offers advantages in terms of durability and ease of repair, making it popular in larger vehicles and trucks where strength is paramount.

Space Frame systems utilize a network of interconnected beams, creating a lightweight yet strong configuration. This approach allows for greater flexibility in design and can accommodate diverse body shapes and sizes.

Unibody constructions combine the body and frame into a single unit, optimizing weight and enhancing crash safety. This design is prevalent in compact vehicles, providing a balance between performance and structural integrity.

Importance of Frame Materials

The choice of materials in the structure of a vehicle plays a crucial role in determining its performance, safety, and durability. Various substances offer distinct advantages, impacting the overall design and functionality of the vehicle. Understanding these materials helps in making informed decisions during the manufacturing process.

Strength and Safety

Utilizing robust materials enhances the resilience of the structure, providing essential protection for occupants in the event of a collision. Strong substances absorb energy, minimizing the impact and potential injuries. High tensile strength ensures that the vehicle can withstand various stresses while maintaining its integrity.

Weight and Efficiency

Material selection also influences the weight of the vehicle. Lighter substances contribute to improved fuel efficiency and better handling. Reducing weight without compromising strength allows for enhanced performance and lower emissions, aligning with modern sustainability goals.

Frame Assembly Process Overview

The assembly process of structural components is a critical phase in vehicle construction, ensuring durability and integrity. Understanding the sequence of operations is essential for achieving optimal results.

Key stages in the assembly process include:

- Preparation: Gathering necessary tools and materials.

- Alignment: Ensuring all elements are correctly positioned before fastening.

- Joining: Utilizing welding, bolting, or rivets to secure components.

- Inspection: Checking for alignment and structural integrity post-assembly.

Each step is vital to maintaining strength and safety standards throughout the manufacturing process.

Common Frame Repair Techniques

Repairing structural components of vehicles requires specialized methods to restore integrity and ensure safety. Various techniques are employed depending on the type and extent of damage, focusing on alignment, reinforcement, and replacement of affected sections.

| Technique | Description | When to Use |

|---|---|---|

| Straightening | Utilizes hydraulic equipment to realign distorted elements. | When components are bent but not broken. |

| Welding | Joins metal pieces together, often reinforcing weak spots. | When sections are cracked or separated. |

| Replacement | Involves removing damaged sections and installing new components. | When damage is extensive and repairs are not feasible. |

| Reinforcement | Adding material to strengthen vulnerable areas. | When enhancing structural integrity is necessary. |

Impact of Frame on Safety

The structural foundation of a vehicle plays a crucial role in ensuring the well-being of its occupants during collisions and other adverse events. A well-designed assembly enhances crashworthiness, effectively absorbing and dissipating energy upon impact. This characteristic not only protects individuals inside but also contributes to overall vehicle stability.

Robustness in design significantly reduces the likelihood of deformation, maintaining the integrity of vital components. In the event of an accident, a resilient structure can mitigate injury risks by preventing intrusion into the passenger area. Furthermore, properly engineered frameworks facilitate better handling and control, enhancing maneuverability in emergency situations.

Frame Modifications and Upgrades

Enhancing structural components can significantly improve performance, stability, and aesthetic appeal. These modifications often aim to reinforce the vehicle’s architecture, making it better suited for specific driving conditions or personal preferences.

Common Enhancements

Popular upgrades include reinforced sections for increased durability, lowering or lifting kits for adjusted ground clearance, and lightweight materials to improve agility. Each change can contribute to overall handling and response.

Benefits of Modifying

Upgrading structural elements not only boosts functionality but also allows for personalization. Customizations can lead to a unique identity, enhancing both enjoyment and resale value. Additionally, carefully planned enhancements can improve safety by increasing stability during operation.

How Frames Affect Vehicle Performance

The structural components of a vehicle play a crucial role in determining its overall efficiency and handling characteristics. A robust and well-engineered assembly influences stability, agility, and the response to external forces during operation.

Impact on Stability

- A well-designed structure enhances balance, reducing the likelihood of rollovers.

- Improved rigidity minimizes flex during turns, providing better traction.

- Strategically placed reinforcements can absorb shocks and distribute stress effectively.

Influence on Handling

- Lightweight materials contribute to quicker acceleration and braking.

- An optimized design lowers the center of gravity, enhancing cornering capabilities.

- Flexibility in construction allows for better adaptation to diverse terrains.

Diagnosing Frame Alignment Issues

Identifying misalignments in the structural components of a vehicle is crucial for maintaining optimal performance and safety. These issues can lead to uneven tire wear, compromised handling, and potential safety hazards. Understanding the signs and symptoms of misalignment is the first step toward effective resolution.

Common indicators of alignment problems include:

- Uneven tire wear patterns

- Steering wheel off-center while driving straight

- Vehicle pulling to one side

- Increased steering effort

To accurately diagnose these issues, consider the following steps:

- Conduct a visual inspection for any noticeable bends or damages.

- Check tire pressure and condition to rule out simple causes.

- Utilize alignment tools to measure angles and compare them to manufacturer specifications.

- Test drive the vehicle to assess handling characteristics and identify any irregularities.

By carefully evaluating these factors, one can pinpoint alignment discrepancies and take appropriate corrective actions to ensure a safe and efficient driving experience.