When dealing with complex machinery, understanding the individual elements that make up the system is essential for proper maintenance and efficient operation. Each section of the device plays a crucial role in ensuring optimal performance and longevity. To ensure smooth functionality, it is important to familiarize yourself with how these components interact and contribute to the overall system.

By breaking down the machine into its distinct parts, one can better grasp how each piece fits together to achieve the desired results. This approach allows for quicker identification of any issues and ensures that any repairs or replacements can be done with precision. Having a clear overview of how everything connects is vital for troubleshooting and future upgrades.

Having a comprehensive overview of each element is key to ensuring both reliability and ease of service. Whether you’re a technician or a user seeking to understand the mechanics, a visual guide will help demystify the structure of the machine. Being well-versed in these internal workings will prevent unnecessary downtime and keep the system running smoothly for years to come.

Understanding the YTA18542 Parts Layout

When working with complex machinery, knowing the arrangement of components is crucial for proper assembly and maintenance. A well-organized guide provides clarity on where each element fits, ensuring that no part is overlooked. This layout allows users to visualize the overall system and identify how each part interacts within the structure. By examining the organization of these components, one can improve efficiency during repairs and upgrades.

The following table outlines the general layout of the various elements, providing a clear reference for understanding how everything is structured and connected.

| Component | Description | Location |

|---|---|---|

| Frame | Main structure that holds everything together. | Center |

| Motor | Drives the movement of the system. | Left side |

| Control unit | Responsible for operating the machine. | Right side |

| Power supply | Provides the necessary energy for operation. | Bottom center |

| Cooling system | Maintains optimal temperature during operation. | Upper right |

Each component’s placement plays a significant role in how efficiently the entire system functions. Knowing where each element is situated aids in better understanding of the assembly process and ensures smoother troubleshooting when necessary.

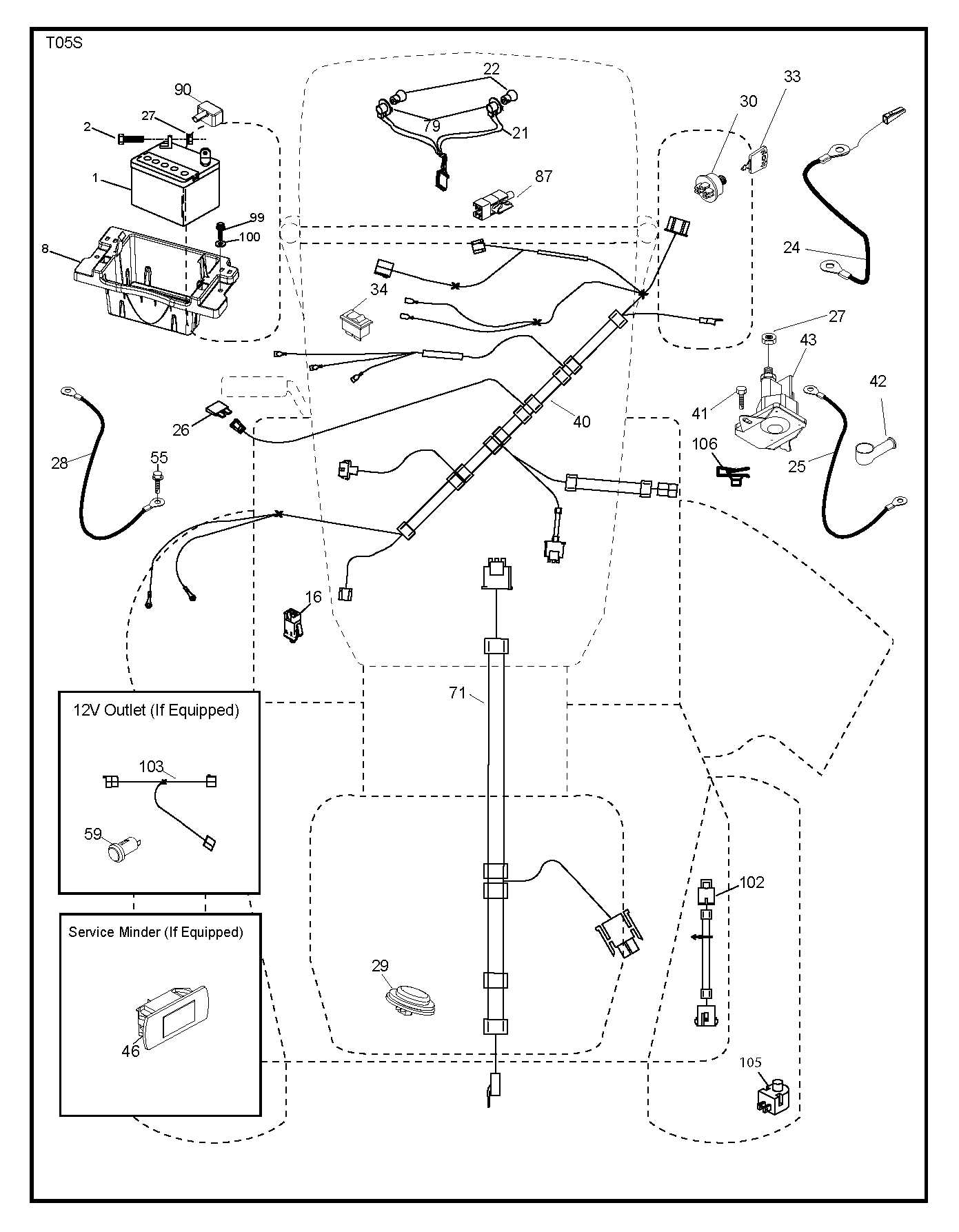

Key Components of the YTA18542 Diagram

The layout for this equipment includes a variety of essential elements that contribute to its optimal functioning. Each component has a unique role, ensuring that the overall system operates smoothly and efficiently. Understanding these key elements allows for better maintenance and troubleshooting, helping users identify any potential issues that may arise during operation.

Among the critical sections, the power unit stands out as it supplies the necessary energy for the machine’s various functions. Another vital piece is the control board, which governs all major processes and ensures synchronization between different subsystems. Additionally, the mechanical linkages serve to connect different parts of the system, transmitting motion and power between them seamlessly.

Finally, the sensor modules are responsible for monitoring the system’s performance and alerting operators to any deviations from the expected standards. This interconnected system of parts forms the foundation of efficient operation and reliable performance, making each element indispensable to the whole structure.

How to Interpret the Parts Diagram

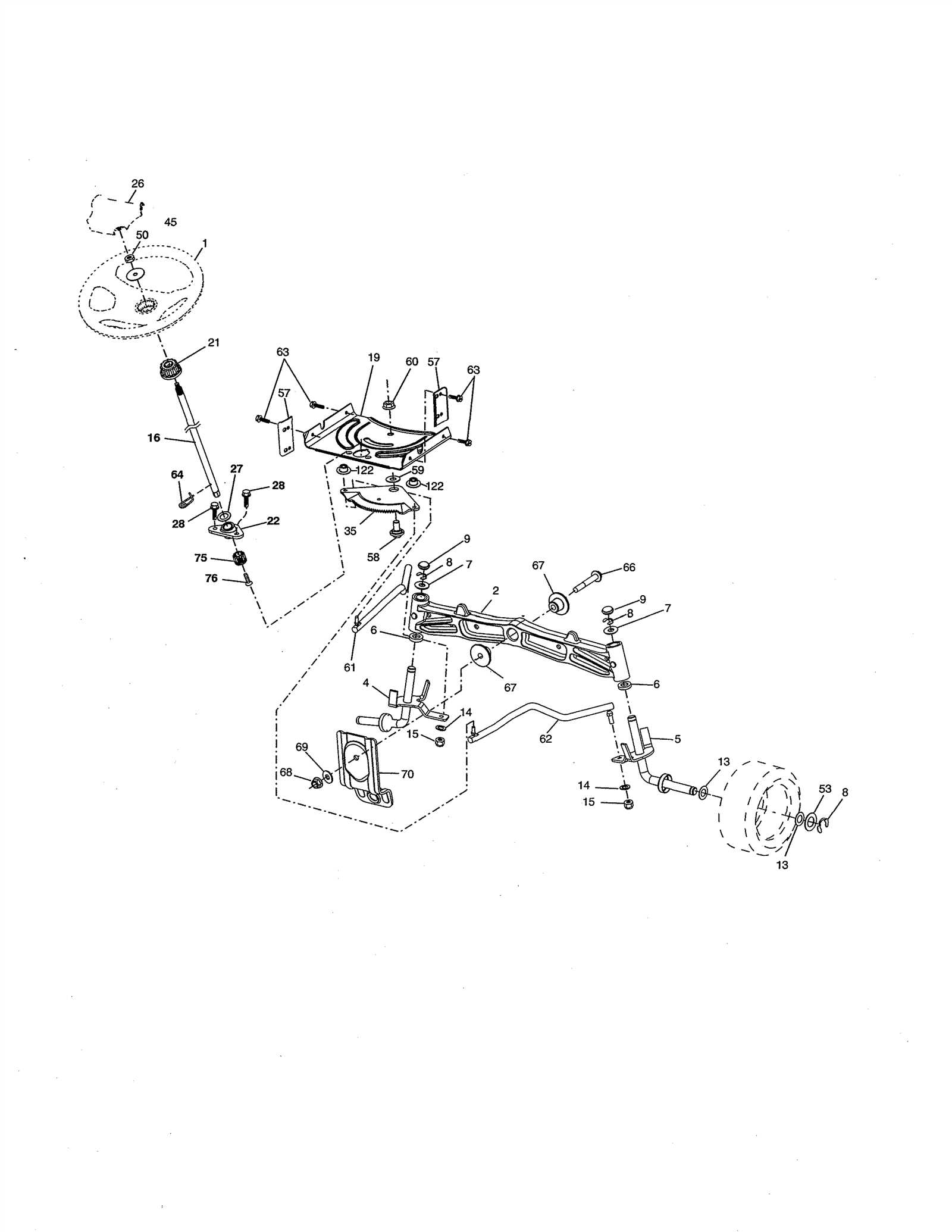

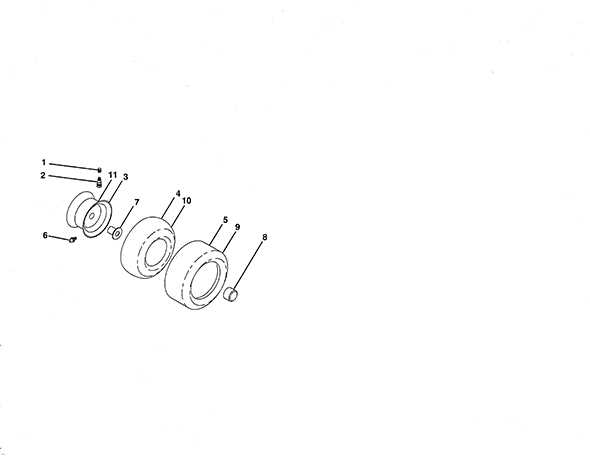

Understanding technical illustrations is essential for successful assembly, maintenance, or repairs. These visuals represent the various components of a system and show how they connect with each other. By carefully analyzing these graphics, one can identify each element’s position and function within the overall structure.

Decoding the Symbols and Labels

The first step in interpreting the visual representation is recognizing the symbols and labels used. Every item is typically numbered or marked, with corresponding descriptions that provide a clear identification of each part. Pay attention to any legends or notes, as these often offer extra details, such as materials or specifications for the individual elements.

Understanding the Layout

The layout is designed to reflect the assembly order or the flow of operations. Start by identifying the central components and work outward, as this often represents how the assembly process progresses. Use the visual cues to match up the labeled parts with their corresponding positions, making sure everything fits together as intended.

Tip: Be mindful of any arrows or connectors, as they typically indicate how parts should be aligned or attached to each other. This visual guidance will assist you in piecing together the overall system correctly.

In conclusion, thorough examination of the technical illustration is critical to understanding how everything functions together. With patience and attention to detail, you can ensure that each component is placed accurately to achieve optimal performance.

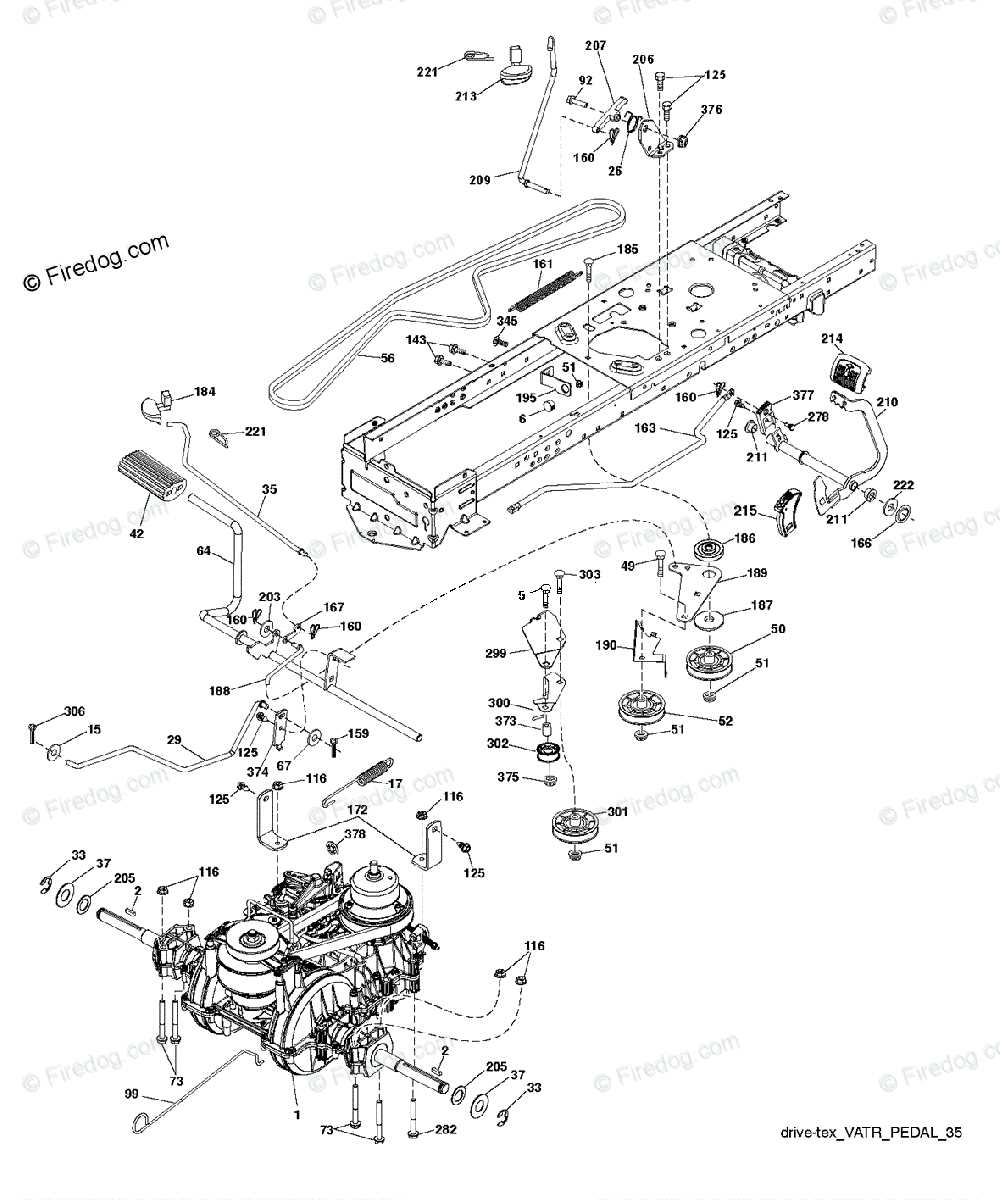

Detailed Breakdown of Engine Parts

Understanding the inner workings of an engine is essential for effective maintenance and repair. This section provides a comprehensive overview of the key components that work together to ensure optimal performance. Each element plays a vital role in the engine’s function, from energy generation to power delivery.

Internal Components

The core of any engine includes several critical pieces that facilitate the conversion of fuel into mechanical energy. These elements include the piston, which moves within the cylinders to convert combustion energy into motion, and the crankshaft, which transfers this motion to other parts of the system. Additionally, the camshaft controls the opening and closing of valves, ensuring proper timing for fuel and air intake.

Cooling and Lubrication Systems

Efficient cooling and lubrication are paramount to engine longevity. The cooling system prevents overheating by circulating coolant through the engine, while the lubrication system minimizes friction between moving parts, ensuring smooth operation. Both systems are interconnected, with components such as the radiator and oil pump playing crucial roles in maintaining proper function.

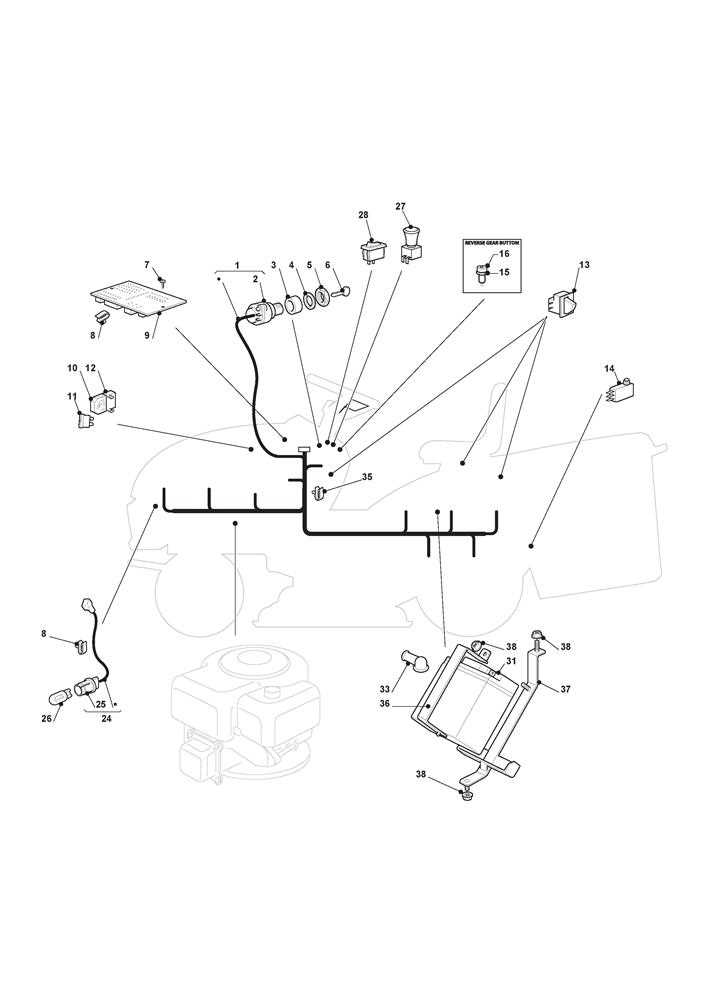

Electrical System Components in Focus

In any mechanical system, the electrical network plays a crucial role in ensuring optimal performance and functionality. This network comprises several interconnected elements that work harmoniously to provide power and control functions. Understanding the main components of the electrical setup is essential for troubleshooting, maintenance, and efficient operation.

The electrical system includes various key elements, each with a specific function that contributes to the overall performance. Among these, certain components are essential for the proper transmission of electrical signals and power distribution. These include:

- Power supply units – responsible for converting and supplying electrical energy to different parts of the system.

- Connectors and wiring – serve as pathways for electrical currents, linking various components together.

- Control modules – facilitate the regulation of electrical signals, ensuring that systems operate according to predefined settings.

- Sensors – monitor the operation and performance of the electrical system, sending feedback to the control units.

- Fuses and circuit breakers – protect the system by preventing overloading and electrical faults.

By carefully understanding each component’s role, one can ensure smoother operations and extend the life of the electrical setup. Regular inspection and maintenance are crucial to avoid potential failures that could disrupt the entire system.

Understanding Transmission and Gear Parts

In any mechanical system, the components responsible for transferring power and motion between different parts are essential for efficient operation. These elements play a crucial role in ensuring smooth transitions between different speeds and torque, ultimately affecting the overall performance of the machine. To gain a deeper understanding, one must look at the individual elements that make up this intricate network and how they work together in harmony.

The Role of Transmission Elements

Transmission components serve as the core mechanism that regulates the flow of power from the engine to the wheels. Each piece is designed to perform a specific function, such as changing the rotational speed or directing power to the appropriate part of the system. Without these components, the system would be unable to function optimally, causing potential wear and inefficiency.

Gears and Their Functionality

Gears are fundamental to altering the rotational speed and direction of motion. They come in various sizes and designs, allowing for flexibility in speed adjustments. The interaction between gears ensures that power is distributed effectively, enabling the machinery to adapt to different operating conditions. Understanding their positioning and how they interconnect is crucial for maintaining smooth operation.

Maintaining a well-functioning system depends on understanding how each of these critical components interacts. Regular inspection and awareness of their roles can prevent issues and extend the life of the equipment.

Identifying the Chassis Components

Understanding the individual elements of the underlying structure is essential for maintaining or repairing machinery. Each section of the framework has a distinct role, contributing to the overall stability and functionality of the equipment. Recognizing these components allows for easier troubleshooting and ensures proper handling during maintenance tasks.

Main Frame

The central framework serves as the foundation of the system. It supports other major assemblies and ensures that all attached parts remain securely in place. Often constructed from durable materials, the frame is designed to withstand heavy loads and provide stability during operation.

Support Brackets and Mountings

Support brackets and mountings play a critical role in securing various elements to the main structure. These components prevent unnecessary movement and vibrations, ensuring smooth operation. Proper identification and alignment of these brackets are crucial for the efficiency of the entire setup.

Hydraulic and Fuel System Insights

Understanding the inner workings of hydraulic and fuel systems is essential for ensuring optimal performance and longevity of machinery. These systems work in tandem to power various components, enabling smooth and efficient operation. Proper maintenance and knowledge of their configuration are key to identifying potential issues and ensuring reliable functionality.

Hydraulic System Functionality

The hydraulic system relies on pressurized fluid to transfer power throughout the machinery. This system typically includes components such as pumps, cylinders, and valves, all of which are designed to work together seamlessly. Fluid flow is critical for the system’s operation, and any disruptions can lead to reduced performance or failures. Regular monitoring and maintenance are necessary to keep this system functioning smoothly and to prevent costly repairs.

Fuel System Efficiency

The fuel system is equally vital, as it ensures the proper delivery of fuel to the engine. Components such as injectors, fuel pumps, and filters play important roles in maintaining efficiency. Ensuring that the fuel system remains free of blockages and contamination is crucial for maintaining engine performance and minimizing downtime. Both systems must be properly maintained for the entire unit to operate efficiently and safely.

Important Attachments and Accessories

When considering the functionality and versatility of a machine, it’s essential to understand the various add-ons and supplementary tools available. These components play a significant role in enhancing performance, ensuring efficiency, and broadening the range of tasks that can be accomplished. Properly selecting and maintaining these accessories can greatly improve the overall usability of the equipment, allowing it to meet specific needs more effectively.

Attachments are designed to augment the capabilities of the primary device. They can include everything from specialized tools for precision work to more general accessories that extend the operational range. Some are built to handle particular environments, while others are versatile enough for multiple functions. Whether you’re looking to increase efficiency in your daily tasks or take on more complex projects, choosing the right add-ons can make a significant difference.

Accessories can range from basic enhancements to advanced modules that further improve functionality. These can include ergonomic supports, storage solutions, or additional safety features. By opting for high-quality accessories, you ensure that your equipment is equipped to handle demanding jobs while maintaining reliability and durability. Understanding the different types of add-ons and how they contribute to performance can help you make an informed decision when upgrading or maintaining your machine.

Comparing the YTA18542 with Other Models

When evaluating different models within the same equipment line, it is essential to understand how each one stands in terms of features, performance, and durability. This comparison provides insight into what each variant offers and helps in making informed decisions about which product suits specific needs better.

In this section, we will examine how this particular model compares with similar alternatives. Key aspects such as build quality, functionality, and efficiency are considered to highlight the differences and similarities among the various versions.

| Feature | Model A | Model B | Model C | Current Model |

|---|---|---|---|---|

| Durability | High | Medium | High | Medium |

| Performance | Advanced | Standard | Advanced | Standard |

| Ease of Maintenance | Simple | Complex | Simple | Moderate |

| Efficiency | High | Low | High | Medium |

Maintenance Tips Using the Parts Diagram

Regular upkeep of your equipment is essential for ensuring optimal performance and extending its lifespan. One effective way to manage maintenance tasks is by consulting a detailed guide that illustrates the individual components. These resources provide a visual breakdown of every section, helping you identify specific elements that need attention. By following these guidelines, you can address potential issues before they escalate, ensuring your machine operates smoothly over time.

Here are some key tips for maintaining your equipment using such a visual guide:

- Familiarize Yourself with the Layout: Begin by reviewing the entire layout to understand how each part interacts with the others. This will help you spot any wear or damage early on.

- Inspect Components Regularly: Periodically check each section shown in the guide. Look for signs of corrosion, cracks, or loose fittings that could lead to further complications.

- Follow Manufacturer’s Recommendations: Many guides include maintenance schedules or steps recommended by the manufacturer. Stick to these suggestions for the best results.

- Use the Right Tools: When performing repairs, ensure you use the appropriate tools to avoid causing further damage to the equipment.

- Keep Spare Parts on Hand: Knowing which components are prone to wear can help you keep essential replacements ready, minimizing downtime.

By consistently using these visual references, you can effectively maintain your equipment, avoid costly repairs, and improve overall functionality.

Where to Find Replacement Parts

Finding the right components for repairs or upgrades is essential to keeping machinery running smoothly. Whether you’re restoring an older model or enhancing a current setup, sourcing high-quality replacements is crucial. There are several reliable options available to help you locate what you need without compromising on quality or performance.

Online retailers often provide a wide range of components, making it easier to compare prices and read reviews. Specialized shops offer detailed information, ensuring you choose the correct parts for your equipment. In addition, manufacturer websites are excellent resources for verifying compatibility and quality standards.

| Source | Advantages | Considerations |

|---|---|---|

| Official Manufacturer Website | Direct access to original items, quality assurance | Potentially higher prices, limited selection |

| Online Marketplaces | Convenient, competitive pricing, various brands | Varied quality, need to check seller ratings |

| Specialized Retailers | Expert advice, tailored recommendations | May offer limited shipping options, can be more expensive |

| Local Repair Shops | Personalized service, hands-on assistance | Higher cost for labor, limited selection |